Aluminum has been used in everyday life and industry for many years.

Thanks to its properties, a variety of products can be made from it. It is possible to melt aluminum at home, since it does not require high temperatures. To carry out such a procedure, you only need to know the properties of the metal.

After reading the article, you will learn how to melt aluminum at home - step-by-step instructions.

- 1 Characteristics

- 2 Details 2.1 Technological process - video instructions

- 2.2 Heat sources used

- 2.3 Making a mold for casting - instructions

Characteristic

The melting point of materials is determined by their purity. Due to its lightness and good ductility, aluminum is suitable for various technological procedures. Under the influence of high temperatures, a reaction with oxygen occurs.

An oxide film appears on the surface of the metal, protecting it from oxidation and corrosion. During melting, aluminum changes its structure, so it needs a protective coating. With sudden cooling, additional internal stress and shrinkage appear.

Melting aluminum at home step by step instructions

Aluminum and its alloys are used in almost all areas of industry, as well as in the manufacturing of household items.

At room temperature, a thin film of oxide (A12O3) forms on aluminum, firmly protecting it from subsequent oxidation. The oxidation time of aluminum increases sharply with increasing temperature.

It is for this reason that in the process of melting aluminum and its alloys in melting furnaces, the surface of the melted material and the mirror of the bath are very quickly covered with an oxide film.

Details

Technological process - video instructions

A refractory container (crucible) is used to heat the metal.

Products are used from materials such as steel, porcelain, corundum, cast iron. At home, a container made of a wide iron pipe or a ready-made crucible is used. To make it, you only need a grinder and a welding machine. The volume of the crucible can be different and is selected individually; it heats up evenly. The metal must be crushed and melted during heat transfer. The melting point must be reduced before heat treatment in order for the state of the metal to change more quickly. To do this, it is crushed into small parts. This is often followed by oxidation or combustion. Aluminum oxide is formed, which changes its state at higher temperatures. This substance is removed after remelting the metal along with the rest of the slag.

REFERENCE! When melting aluminum at home, you must avoid getting liquid into the crucible. This is because the evaporation of water can cause an explosion. Therefore, before lowering the metal into the crucible, you need to make sure it is completely dry.

Mostly aluminum wire is melted. To do this, it is divided into pieces with scissors, and then compressed with pliers. This method prevents the metal from being exposed to oxygen. If you do not plan to obtain high-quality parts, then grinding raw materials is not necessary.

If you need to produce molten aluminum at home, you will have to model the casting technology yourself. The material must first be cleaned of dirt, slag and impurities. Large workpieces must be divided into several small ones. Casting is carried out according to the instructions; the most convenient option is used for melting. Slag must be removed from the surface of the fluid substance. Molten aluminum is poured into a mold, which must be broken after the metal has solidified.

Heat sources used

In order to melt aluminum at home, you can use:

- Melting aluminum in a muffle furnace, which can be done independently. This method is very effective and allows you to quickly convert the metal into liquid form.

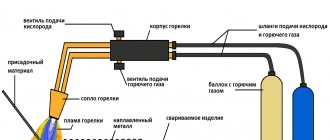

- Blowtorch. It can be used to melt small amounts of aluminum.

- Torch - rarely used.

The hearth is made of bricks, and the frame is made of a metal container. On one side, a drill is used to make a hole for oxygen supply. A hair dryer, vacuum cleaner or other similar device is connected to a metal tube. The crucible is placed in the hearth after the fire has been lit. For better heat treatment, the coals can also be placed on the sides. To avoid losing heat, you can make a lid, leaving a hole for the smoke to escape. It is not worth making a furnace if the metal needs to be melted only once.

Melting aluminum on a gas stove also takes place. An ordinary gas stove can heat metal to the required temperature. Small pieces of aluminum will melt in about half an hour.

A tin can is usually used as a crucible. The jar is placed in another jar so that the gap between the two is about one centimeter. This is necessary for uniform temperature distribution. In the larger jar, you need to make several holes to provide fire access. The diameter of these holes should be 3-4 cm in diameter. In this case, the divider on the burner does not need to be removed. In this way, you can achieve uniform heating of the aluminum can. The larger jar is covered with a lid to prevent heat from escaping.

Making a mold for casting - instructions

If you need to do something simple, then making a special mold is not required; the metal can be poured onto a steel sheet.

If the product is more complex, then you need a mold that can be made from the following materials:

- - clay;

- - plaster;

- - liquid glass;

- - sand;

- - coal ash.

There are two ways to pour the alloy into a mold - open and closed.

Open is the easy way. The metal that has been melted is poured into an ordinary container, cup, tin can, and so on. After the alloy has cooled, the blank is removed from the container. If it doesn't matter what shape the metal object will be, leave the aluminum on a durable surface.

Forming elements are used for complex castings, when the product must meet specified parameters. In open pouring, silica is often used. The item is made from two containers containing compacted earth. The silica pieces are compressed and a casting model is placed between them. This way you get a clear imprint of the desired part. The model is removed, and hot aluminum is poured into the mold. With the closed casting method, river sand is taken and mixed with liquid glass.

For one-time casting, you can use plaster. Models are made from foam plastic or paraffin.

IMPORTANT! The use of these materials is only possible in an open space with good air access.

The foam is not removed from solid plaster, but is filled with molten aluminum. Its combustion products are harmful to human health.

What to make a crucible from

The next point will be the crucible, that is, a metal container with refractoriness parameters significantly exceeding the refractoriness of aluminum. That is, if aluminum melts at 600 degrees Celsius, then the metal from which the crucible will be made must withstand at least 1000 degrees. An old fire extinguisher cut in half is ideal for this purpose. We will fill its lower part with scrap and heat it to the temperature we need, of course, at home.

Possible mistakes and ways to avoid them

Gypsum molds are very convenient and highly sensitive to moisture. Conventional drying does not remove moisture, so the quality of the casting becomes worse. To achieve complete drying of the plaster mold, you will have to wait several days. Aluminum must be heated over a fire until it is poured into the mold, so that you can then distribute it over the mold before it hardens.

Do not use water to cool the product. This is due to the fact that under the influence of water, cracks appear - the internal structure of the substance is disrupted.

Precautionary measures

To work with molten aluminum, you must use personal protective equipment. All exposed areas of the body, hands, and face must be protected.

REFERENCE! It is best to use welding gloves; they can withstand temperatures of more than 600 0 C. This means of protection is the most basic, since the possibility of molten metal getting on your hands is very high.

It is also better to use goggles and a mask to avoid hot elements coming into contact with your face and eyes. To protect the entire body, you can find a metallurgist suit that has high fire resistance. When cleaning aluminum welding flux, a chemical respirator is used.

Source

Useful tips

- The melt must be hot so that the mold is filled evenly. It is poured when it acquires the consistency of mercury.

- Castings with complex configurations are made quickly; they try to fill the molds right away so that the metal does not have time to set and no partitions or voids are formed.

- Metal can be poured into plaster over wax or foam; high temperatures cause the wax and foam to burn out. The surface of the casting will be smooth.

- To cool the casting, do not immerse it in water; the casting will crack.

- When melting pure aluminum, the technology of using protective fluxes is used; they protect the metal from oxidation.

Fire safety must be observed; the casting process involves the use of an open flame. It is important to use personal protective equipment: gloves, goggles.

Source

Before starting work

First you need to decide on the size of the product and the scope of work:

- For smaller ones, a gas stove is suitable.

- For medium-sized ones - a homemade small oven made of refractory bricks

- For larger ones - a muffle furnace.

With any choice, you need to close the container with molten aluminum as much as possible from drafts and seal the walls as much as possible to reduce heat loss. Aluminum gives off heat quickly, so it is difficult to heat it under simple conditions. Let's look at how to achieve this.

Result

Don't rush to take the metal from the barrel! He is now very hot from the contact welding machine. It’s worth going to rest and letting the metal cool. Usually three hours is more than enough for a heated metal barrel to cool down. Half a ton of raw material usually yields a quarter ton of aluminum. The metal obtained from bauxite, of course, is unlikely to be as pure as it is obtained at special ore purification plants. As a result, we will end up with a certain mixture in which the share of aluminum will be from 80% to approximately 90%. Such purity is enough to take what you receive to the nearest point where they accept non-ferrous metals and get money for it. True, of course, no one will pay the full price there, but even under this condition, it’s possible to earn about a hundred thousand rubles in a month.

The technology of chemistry that was literally on the surface is now known. In general, think about it. Are you ready to take the risk or is the usual boring everyday routine of official employment more pleasant for you than the new prospect that has opened up? Decide.

Characteristics of aluminum

It is not necessary to know all the characteristics of aluminum, but in order to know how to melt aluminum at home, you need to keep in mind some features that eliminate technological errors. In addition, during work it is necessary to exercise extreme caution due to the high risk of injury during the casting process.

At home, melting metal on a gas stove is unlikely to be possible, since the melting point of aluminum is 660.3C, and household gas appliances are not able to create the required temperature.

A decrease in the melting point of raw materials can be achieved by grinding it into powder. In addition, you can use ready-made raw materials in powder form. However, one more point must be taken into account here. Aluminum is a fairly active metal and, when interacting with oxygen contained in the air, can oxidize or even ignite. During the melting process, a small amount of oxide is formed, which contributes to the formation of scale. Another unpleasant surprise in the form of an explosion can occur when water gets into the molten metal. Therefore, when adding the necessary components, you need to make sure that they are dry.

Raw materials for smelting

If you plan to melt metal at home, you should not use powdered aluminum for melting. It is better to use aluminum wire, cut into small pieces, pressed using pliers, to reduce the area of interaction with air.

If the requirements for product quality are low , then to obtain raw materials it is permissible to use any items consisting of aluminum.

Is it possible to melt aluminum over a fire?

Aluminum is a very common metal in both industry and households. It is not uncommon that when a part breaks, there is a need to smelt a replacement.

Melting aluminum at home is attractive because it is possible at a relatively low temperature.

To carry out the operation yourself, you need to know the characteristics of the metal when exposed to temperature and its physicochemical properties.

How to cast an aluminum part at home

For many, the term “foundry” is closely associated with back-breaking labor and specialized professional skills.

In fact, casting a part from the required metal is possible for the most ordinary person without professional training at home. The process has its own subtleties, but it can be done at home with your own hands.

Outwardly it resembles the production of lead weights for fishing. Features of the aluminum casting process are related to the technical characteristics of the material.

How to cast aluminum

Characteristics of aluminum.

Aluminum is one of the most common metals.

It is silver-white in color and lends itself quite well to casting and machining. Due to its characteristics, aluminum is equipped with high thermal and electrical conductivity, and also has corrosion resistance.

Technical aluminum has a melting point of 658 degrees, high-purity aluminum has a melting point of 660, and the boiling point of aluminum is 2500 degrees.

For aluminum casting, home heating devices are unlikely to be useful and will provide the required temperature. It is necessary to melt aluminum by heating it to a temperature of over 660 degrees.

What technologies exist for melting metal?

When using a gas stove, you need to remove the existing flat nozzle and install a special device on top of the grate - a cylinder, which can be made from any iron can of a suitable size. A 3-4 cm hole is made at the bottom of the cylinder, and 3 screws are tightened - they are needed so that the mold with aluminum inside the cylinder will stand on them.

A torch will come out of the camphor and enter the cylinder and heat the mold with the metal. The cylinder is needed to save heat and maximize the concentration of the flame around the mold. It is buried on top with a plate so that the heat does not escape, but a small gap is left for traction.

The same principle is used for stoves; large containers can be placed here due to minimal heat loss and large space inside the stove. A small grill is made, on which the molds are placed, after which the oven is closed as much as possible on all sides, leaving only small holes at the bottom and top for drafting.

How to melt aluminum cans at home

Aluminum is a common and useful metal known for its corrosion resistance, malleability and light weight. It is safe enough for use on food and in contact with skin. It is much easier to process this metal than to refine it from its ore.

You can melt old aluminum cans to make aluminum. Pour metal into a suitable mold for making jewelry, tableware, decorations, sculptures or other metalworking project. This is a great introduction to home recycling.

Materials for melting aluminum cans

Melting jars are not difficult, but this is a project for adults because of the high temperatures involved. You will want to work in a clean, well-ventilated area. There is no need to clean the jars before they melt, as organic matter (plastic coating, residual soda, etc.) will burn during the process.

aluminum cans; a small electric stove oven (or other heat source that reaches an appropriate temperature, such as a propane torch); a steel crucible (or other metal with a melting point much higher than aluminum but lower than your oven; could be a durable stainless steel bowl or cast iron skillet); heat-resistant gloves; metal tongs; the shapes you will pour the aluminum into (steel, iron, etc. - be creative);

Processing methods

Losses when recycling aluminum are low; one old can produces almost a whole new one. This type of business brings profit and benefits to the economic and industrial sector. There are several ways to obtain aluminum from cans:

- Pressing. Sorted jars are cleaned of debris and impurities. The containers, freed from drinks and food, are cut into small pieces, and iron is removed from it using a magnet. The resulting raw materials are pressed into slabs and sent to a recycling plant. After this method, additional measures are required to clean the containers from impurities and paints.

- Transformation of aluminum into powder. This method is more effective, because thorough cleaning is done immediately. Unlike pressing, it uses multi-stage grinding and impurity removal schemes. The cost of this method is higher, because the equipment is expensive and requires large premises to accommodate it. Losses during processing using this method are low and the costs are recouped.

- By pyrolysis method. Initial stage: sorting, grinding, cleaning. The resulting elements are placed in a pyrolysis furnace and heated to 750 degrees, the melting point of aluminum is 90 degrees lower. Organic impurities burn out, the resulting pure metal is poured into molds and sent for secondary production.

- The melting point of aluminum allows you to work with it at home. To do this, you need to purchase or build your own small oven for processing. It operates on coal briquettes and will melt a can in 3-4 seconds. To construct it, you will need a heat-resistant vessel in which the coals flare up, and a crucible to accommodate the metal itself. The crucible can be made from a cut-off fire extinguisher body. An ordinary vacuum cleaner or hair dryer will help create high-quality airflow to increase the temperature. You can get a kilogram of aluminum from 90 cans.

To recycle aluminum scrap at home, you must have a fire extinguisher.

A muffle furnace is an ideal home option for frequent work

A muffle furnace is similar to a simple “potbelly stove” only with thick walls. It can be either wood- or electric-powered, depending on your convenience. In the second case, the wire is stretched in a spiral from the inside of the bricks, closer to the mold.

Inside in the middle there is a crucible - a special container for melting metal. In this design, losses are minimized - the free space is occupied by the crucible, with a small gap of 5-10 cm remaining between it and the walls.

Due to the large thickness - 20-30 cm, the walls can be filled with various heat insulators to retain heat. It can be moved or made stationary, and therefore a heat insulator is selected. There is brick inside, iron outside, and how to fill the rest of the space is left to the discretion of each individual.

Required Components

Here's a list of things:

- graphite powder

- metal barrel

- welding machine

- concrete mixer

- bauxite clay

Today, the above, with the exception of bauxite, can easily be found among hardware markets and building materials stores. So let's move on from idle theorizing to the practice of this technology. True, to start you need to find a place where you will get the required raw materials. Drive a car there that can transport loads weighing half a ton. This is exactly the amount of bauxite to be collected. There is no point in taking less than five centners. When stacking bauxite, consider your strength. Now take what you have collected.

Metal smelting

When melting, it is important to use clean dishes (made of iron or non-ferrous metal). If you are melting it for the first time, it makes sense for further preparation. You need to clean the container, remove rust and debris, dust, rinse thoroughly, let it dry, and only then can it be used.

During cooking, remove floating slag - paint residues or dirt; they will significantly reduce the quality of the metal. After the metal has melted well, it needs to cool a little so that there is less splashing and it is more convenient to pour into molds. The latter should not be damp, so that evaporating moisture does not create bubbles in the product.

Extraction process

1. As soon as you bring the bauxite, you will need to dry it. You can spread newspapers and lay out the collected early raw materials. After that, take the most ordinary hair dryer. Use it to dry. Of course, it is much preferable to use some serious drying unit for this purpose. When the weather is sunny, drying can be done outside. However, it is worth remembering that you need to make sure that the dried clay does not dry to anything. To do this, the surface can be sprinkled with flour or sand, depending on what you have at hand.

2. Now is the time to grab a concrete mixer! Using a concrete mixer, grind the dried early. Using a concrete mixer, you need to bring it to the state of sand or even dust, since it is much faster and much less expensive to obtain metal with small crumbs than with large pieces. This principle has been known to chemistry for a long time. For those who do not have a concrete mixer, a simple hammer will be a real salvation. True, it will take a lot of effort to process a whole heap weighing five hundred kilograms. Therefore, it is worth thinking about purchasing a concrete mixer later.

3. It's time to take the graphite powder you bought. Today it will be needed in order to avoid a fire hazard. Next we have to deal with electric current. The resistance of raw materials to electric current passing through it greatly increases the risk of fire. Ordinary graphite powder, on the contrary, reduces resistance and helps control temperature regulation. With its help, it will be much safer to extract from clay. Make a graphite mixture.

4. The main stage comes. Get out your metal barrel. Place the mixture of powders you obtained in the previous step there. Open the tap and fill the mixture in the metal barrel with water. The mixture must be moistened so that the electric current sent through the barrel can freely pass through. Also, with the help of water, we can significantly speed up the process of extracting aluminum from a mixture of powders.

5. The next step is the most important one. Finally, we use electricity using a welding machine. It is imperative to take precautions! Of course, you should wear rubber gloves and boots. This way, avoid possible burns from the electric current of the welding machine. Following normal safety precautions, connect the welding machine to the metal drum. It is worth waiting fifteen to thirty seconds while the electricity passes through the metal barrel. During this time, oxygen from heating by electric current will leave the powder along with water. Remove the welding machine.

Materials for casting molds

With the open pouring method, the simplest material that is always at hand is often used, this is silica. First, the earth is laid with layer-by-layer compaction. A casting model is placed between the layers, which, after careful compaction, leaves an imprint in the silica. This mold is carefully removed and aluminum is poured in its place.

Some craftsmen use river sand with the addition of liquid glass when preparing the base of the mold. A mixture of cement and brake fluid is also sometimes used.

Plaster molds

When making a model of a complex shape, gypsum is often used, which can mainly be used for a one-time casting process. When casting aluminum into a plaster mold, paraffin or foam plastic is used as models.

The wax model of the product is filled with plaster and, after drying it at high temperature, it is melted and drained through a special hole.

Read also: What is metric thread?

If the model is made from foam plastic, it is filled with gypsum mixture and left in it until the mold completely hardens. Hot aluminum melt is poured directly onto the foam. Due to the high temperature of the metal, the foam melts and evaporates, and its place is taken by an aluminum melt, taking the shape specified by the foam.

When using polystyrene foam as a model, work must be carried out in an open space or the room must be well ventilated, since the combustion products of polystyrene foam are harmful to humans.

Typical mistakes and tips for proper casting

- When working with plaster, you should avoid common mistakes. Despite the fact that plaster molds are a convenient way to cast the desired configurations of parts, this material is very sensitive to moisture. During normal air drying, it remains part of the gypsum. This is detrimental to the quality of the aluminum casting, as it can cause the formation of small shells and bubbles. Therefore, plaster molds need to dry for several days.

- The metal must be hot enough before pouring to fill the entire mold before it begins to harden. Therefore, after reaching the melting temperature, taking into account the rapid cooling of aluminum, there is no need to delay pouring it into the mold.

- It is not recommended to immerse the resulting casting in cold water to speed up the hardening process. This can disrupt the internal structure of the metal and lead to cracks.

Aluminum is one of the most common metals on earth. It is present even in the human body, so what can we say about the surrounding reality. Every home or personal car has aluminum functional elements, parts or assemblies that, alas, break quite often. These are furniture and window fittings, guides for doors and shutters, lock latches and other necessary little things.

They can be replaced with purchased new products, repaired, or made independently. In the last two cases, you may need to melt aluminum at home.

Source

Quality indicators of aluminum melt

Aluminum melt is the starting material for the manufacture of any aluminum products. Different types of aluminum products require different levels of purity of the aluminum melt. The quality of the aluminum melt is one of the most important conditions for ensuring a given level of quality of the final aluminum product. The melt quality level is determined by three types of contaminants [1, 2]:

- dissolved hydrogen;

- solid inclusions;

- dissolved impurity metals.

Figure 2 – Types of contaminants in aluminum melts [3]