The “Cold Welding” glue stick is used to connect metal parts, build up chips, and fill cracks. A distinctive feature of the method is that there is no need for heating or increased temperature exposure.

The connection occurs as a gluing process, called welding because of the strength of the resulting seam. The mass of glue does not penetrate at the intra-atomic level into the surface of the parts that need to be connected. The permanent connection occurs due to other characteristics.

Question 38 Repair of threaded connections

There are the following types of threaded connections:

- bolted; It is advisable to use in connections of small thickness and frequently subjected to assembly and disassembly;

— screw; used when a bolted connection is not applicable due to the fact that there is no room for a nut;

- using a hairpin; used in conditions of frequent disassembly.

Threaded connections are made both using threaded fasteners and through threads cut into housings, shafts and other parts.

In threaded connections, especially those that absorb large or alternating loads during operation, increased wear and damage occur due to insufficient tightening of screws and nuts. The thread is also destroyed by over-tightening the nut or screw. Under the combined influence of various loads, wear of threaded connections is observed,

appearing as follows:

- bolts and screws stretch; the bolt rod elongates as a result of axial operating loads and tightening forces;

— the thread pitch and its profile are violated; the thread profile along the average diameter changes - the gap increases (observed in screws and frequently unscrewed fastening bolts);

— the nuts “stick” (the thread pitch changes under the influence of axial work loads);

— wear of the faces of the heads of bolts and nuts.

— the working surfaces of the thread profile are crushed under the action of work loads;

Worn or damaged mounting bolts and screws are not repaired, but replaced with new ones.

To make it easier to disconnect the connections, tap the nut, inject kerosene into the threaded connection, and cut off the nuts.

Defects in threaded connection parts and their repair;

1) Wear, breakdown, collapse of threads on bolts, shafts:

- cut off the worn thread and (if this is allowed by strength conditions) cut a new one, processing it to the nearest diameter according to the standard; (parts of significant diameter).

— a bushing or threaded bandage is placed on the part (parts of significant diameter).

2) Wear, breakdown, collapse of threads in housings:

Worn or torn threads in the holes of a part are usually not restored, making repairs as follows:

a) the hole is drilled to a greater depth (if possible) and the thread is cut into it again; a new screw with an elongated threaded part is screwed into the recessed hole;

b) the hole is drilled out, a new thread of a larger diameter is cut and new screws with threads of the given diameter are installed; The hole for the screw in the second part to be connected is drilled out.

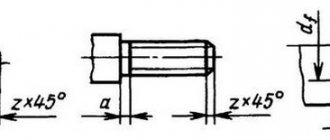

c) instead of the old stud, they make a new one with a shoulder and thread of two diameters (Figure 4.63, a): the larger one is for screwing the stud into one of the parts to be connected and the smaller one is for connecting to the second and tightening them with a nut;

d) restore the nominal (original) thread: the existing hole is drilled out, a new thread is cut, then an adapter sleeve is made (with external and internal threads designed for a normal screw), installing it flush with the plane of the part and locking it with a pin (Figure 4.63, b) However, the adapter sleeve must be thick-walled, so it is preferable to install it with epoxy glue (Figure 4.63, c)

e) a worn threaded hole in a part is “plugged” by drilling another hole next to it and cutting a thread of the required diameter in it. A new hole is also drilled in the second part to be connected.

Figure 4.63 - Schemes for repairing threaded connections using the installation:

A -

a new stud with a shoulder of two diameters,

b

- bushings with external and internal threads, in -

bushings for glue

3 Nicks and dents on the thread are eliminated by “pushing” with taps, dies or a mating part.

4 Compression of the faces of nuts and bolt heads is eliminated by sawing or surfacing, followed by processing of the faces.

5 Non-straightness of the axis of a rod, bolt, screw, or stud is eliminated by straightening in a vice or using a screw press.

Thread restoration method

Damaged threads can be completely restored using the following technology:

1. Drill the threaded hole to the diameter indicated in the table below 2. Cut a special profile thread in it with a special tap 3. Screw a spiral repair insert (a durable stainless steel sleeve) into the resulting thread using a special tool.

Threaded insert

After such an operation, the thread becomes stronger than the original one in good condition. This effect is especially noticeable when the carving is made in a soft material such as aluminum. When a bolt (stud) breaks off in a threaded insert, there is no “biting” effect. A broken bolt (stud) can be easily removed.

Watch a video of how the threaded insert is used

What capabilities do threaded inserts have?

This method is especially relevant for restoring threaded holes in body parts of automobile engines, for example, a spark plug hole. The candle thread becomes very durable and reliable.

Threaded insert screwed in

Threaded insert screwed in

If the thread for a stud is broken, sometimes they drill it out and cut the thread to the next size. In this case, you have to use a stepped stud of unknown origin and dubious quality. And not every stepped hairpin can be found at the right time. If you repair the hole using a threaded insert, you still have the option of using a standard, branded pin.

Another use for repair threaded inserts is in brass exhaust manifold nuts. The result is a nut that combines a very strong thread and the property of not “sticking” to the studs.

Owners of some foreign cars should pay attention to the possibility of replacing the M12 x 1.5 thread with an M12 x 1.25 thread. It often happens that a bolt with such a thread is damaged, and it is almost impossible to find it in a retail chain in your city (we have such bolts in our store)

A turner will not turn out a decent bolt, because... The threads on factory bolts are formed by pressure (knurling), which provides the necessary strength. And on a lathe, the thread is made with a cutter, while the fibers of the steel bar are cut and the threads cannot bear the required load.

If you replace the thread in the body part with the more common in Russia M12 x 1.25, it becomes possible to select a bolt of the required size and strength from the assortment of Russian and European manufacturers of automotive fasteners presented in our catalog.

Video - how a threaded insert works, demonstration

What tools are used to restore threads?

1.

Drill

The drill diameter is selected from the table.

Table for selecting drill diameters for the most common threaded holes

| No. | Repairable thread sizes | Drill diameter |

| 1 | M5 x 0.8 | 5,2 |

| 2 | M6 x 1 | 6,3 |

| 3 | M8 x 1 | 8,3 |

| 4 | M8 x 1.25 | 8,4 |

| 5 | M10 x 1 | 10,25 |

| 6 | M10 x 1.25 | 10,4 |

| 7 | M10 x 1.5 | 10,5 |

| 8 | M12 x 1.25 | 12,25 |

| 9 | M12 x 1.5 | 12,5 |

| 10 | M12 x 1.75 | 12,5 |

| 11 | M14 x 2 | 14,5 |

| 12 | M14 x 1.5 | 14,5 |

| 13 | M14 x 1.25 (for a candle) | 14,25 |

2.Tap

To repair the spark plug hole, a stepped tap is recommended. It is centered in the old hole with its lead-in part, and immediately cuts a new thread, bypassing the drilling operation.

A stepped tap significantly reduces the risk of damage to the spark plug hole, but it is noticeably more expensive than a regular tap.

To lengthen the tap when repairing a deeply recessed spark plug hole, you can use a regular 10-point twelve-sided socket with the appropriate tool.

3.Spindle (tool for screwing the insert)

The working part of the spindle is similar to the threaded part of a bolt, with a hook at the end.

4.Repair insert

The insert is a diamond-shaped spiral.

At one end there is a leash, behind which the insert is rotated by a spindle. The inserts have different lengths.

Disadvantages and advantages

Each method has its own advantages and disadvantages. Let's take the following as an example:

- Cold welding and polymers can be used when the hole diameter cannot be changed. However, the resulting coils are characterized by low strength.

- The tap is used only when the hole can be slightly enlarged. This produces high-quality and durable coils.

- Inserts allow you to expand the range of application of the cutting tool, but the restored thread is also not designed for heavy loads.

In general, we can say that there are simply a huge number of ways to restore fasteners. The choice is made depending on where it is used and what the load is.

If you find an error, please select a piece of text and press Ctrl+Enter.

They write that: since many people use equipment with a gasoline two-stroke engine, due to design features, they often have to unscrew the spark plug from the block head, which leads to damage to the threads in the spark plug channel. The spark plug has a strictly defined thread diameter (M14) and therefore it will not be possible to drill a mounting hole or use a screwdriver for restoration. In most cases, the block head material is aluminum; the metal is quite soft and thread repair by passing it with a tap does not bring the desired result.

In such cases, the so-called liquid thread will help you - a polymer composition that is intended for repairing spark plug channels. You can use the reconditioned threaded connection after 24 hours of polymerization. Also, the connection remains completely removable, and the composition has less adhesion to steel than to aluminum. This means that with some initial effort you should be able to remove a spark plug or bolt from a remanufactured aluminum housing.

Who used it? How was it ? Your opinion?

| Reply to this message |

| Re: Liquid thread - restoration of broken threads. |

| Author: STORM (—.95-54-233-131.dynamic.murmansk.avangarddsl.ru) Date: 09-03-13 10:34 |

All my adult life I have been scratching the threads on a candle with a soft pencil, applying graphite, the candle always unscrews normally without damaging the thread. This is advice on how to prevent it, not how to eliminate it.

| Reply to this message |

| Re: Liquid thread - restoration of broken threads. |

| Author: Tomato (—.qwerty.ru) Date: 09-03-13 11:00 |

I usually use graphite lubricant.

| Reply to this message |

| Re: Liquid thread - restoration of broken threads. |

| Author (—.pppoe.avangarddsl.ru) Date: 09-03-13 11:36 |

Me too, but it needs fixing.

| Reply to this message |

| Re: Liquid thread - restoration of broken threads. |

| Author: Tomat (—.qwerty.ru) Date: 09-03-13 12:14 |

Then a pinwheel or spiral insert.

| Reply to this message |

| Re: Liquid thread - restoration of broken threads. |

| Author (—.pppoe.avangarddsl.ru) Date: 09-03-13 12:19 |

I understand that ETA does not inspire?

| Reply to this message |

| Re: Liquid thread - restoration of broken threads. |

| Author: Tomat (—.qwerty.ru) Date: 09-03-13 12:23 |

Maybe, of course, something has already been invented, but I haven’t heard it yet.

| Reply to this message |

| Re: Liquid thread - restoration of broken threads. |

| Author: Bubble67 (Cheerful Village) (—.broadband.corbina.ru) Date: 09-03-13 12:23 |

This is all nonsense. I tried to use similar crap on the trimmer, and in the end the spark plug shot past my friend’s ear immediately when starting it up. Well, not in the eye. There are special kits with a tap and screws (futures), as in the photo. It costs a little, but it really helps.

| Reply to this message |

| Re: Liquid thread - restoration of broken threads. |

| Author: HUNTER-1 (—.opera-mini.net) Date: 09-03-13 13:15 |

Not impressive at all.

| Reply to this message |

| Re: Liquid thread - restoration of broken threads. |

| Author: STORM (—.178-65-207-246.dynamic.avangarddsl.ru) Date: 09-03-13 14:15 |

I think that such gadgets exist as an emergency/temporary measure, such as getting to the service.

| Reply to this message |

| Re: Liquid thread - restoration of broken threads. |

| Author: Garlic (92.240.136.—) Date: 09-03-13 14:29 |

I make screws for people from bronze, outer diameter m18 pitch 1.5, never had any complaints. For some reason, mostly on Gazelles. But there is no faith in this chemistry, since the engine has a very large temperature difference. Metal does not hold up, but polymer is doubtful.

| Reply to this message |

| Re: Liquid thread - restoration of broken threads. |

Read also: Hot air guns for soldering radio components

| Author: Gorynych (195.135.239.—) Date: 09-03-13 19:14 |

In general, some magical properties are often attributed to epoxy compounds, although almost any of them loses strength at 70-90 degrees.

| Reply to this message |

| Re: Liquid thread - restoration of broken threads. |

| Author: Alexander 13 (—.kirov.comstar-r.ru) Date: 09-03-13 19:27 |

“since many people use equipment with a two-stroke gasoline engine, due to design features, they often have to unscrew the spark plug from the block head, which leads to damage to the threads in the spark plug channel.” - Did the bathhouse fall out of the blue? With the right hands, unscrew it at least a million times, screw it to the light bulb absolutely, but with crooked hands you’ll ruin the girl’s mono the first time