Select the appropriate adhesive according to the markings on the material. Liquid, contact, epoxy and hot-melt adhesives can be used to bond plastics. It is important to clean the plastic surface, prepare the material and tools and wait for the setting time indicated on the pipe. Cosmofen Plus-S, Permatex Super Glue, Henkel Super Moment Maxi, Mastix Poxy Termo, Titan were recognized as the best compositions of plastic adhesives.

Breaking plastic products at home is not uncommon. If this happens to you, take the time to throw it away, it's an easy fix. To stick plastic permanently, you need to understand its type, choosing an adhesive material based on it.

Determining the type of plastic

In order to reliably glue plastic, you first need to find out what kind of plastic the object is made of. Knowing the plastic, you can choose the most suitable adhesive for it.

All manufacturers put recycling symbols on their plastic products - this is the well-known Recycling Triangle - a triangle with arrows on the sides, symbolizing the reuse of materials.

The triangle contains numbers from one to seven. Often the numbers are supplemented by an abbreviation. These designations are used to determine the type of plastic.

What does the marking on plastic mean?

- PET low density polyethylene or polyethylene terephthalate. It is mainly used for packaging or packaging food products. Available in the form of film, bags or transparent containers for liquid and bulk goods, as well as drinks.

- HDPE compacted low pressure polyethylene. Used for the production of shrink film and packaging bags.

- V (PVC) polyvinyl chloride is a non-food plastic used for the manufacture of strong and durable items, such as household buckets, metal-plastic window frames, and linoleum.

- LDPE Low density polyethylene of high pressure. Used in the production of bottles for drinks and dairy products, packaging bags, toys, cold water pipes.

- PP polypropylene. Plastic is not chemically active, heat-resistant (up to 150 °C), and is most widely used in the production of medical goods, heat-resistant dishes and household utensils, toys, pipes and fittings for hot water, and much more.

- PS polystyrene. Also food grade plastic, it is used to make disposable tableware, household utensils, and kitchen appliance housings. If it is foamed, it forms an excellent porous heat insulator - polystyrene foam, used in everyday life and in construction work.

- O Other (others) - materials that are not intended for recycling, for example, with inclusions of metal, paper or other substances). This also includes plastics that do not belong to one of the six groups.

PS - polystyrene

To reliably glue plastic, you need to carefully examine the markings on the product and select an adhesive intended for polymers of this group. There is another way to determine the type of plastic - a small piece of it must be set on fire. Each type burns with a characteristic smell and type of flame. To reliably use this method at home, you need to gain considerable experience.

Product examples

What can be found on the shelves of construction and hardware stores:

- “ Moment plastic” is a type of glue that connects many types of plastics. It has a transparent base, sets quickly and forms a strong connection. This is a waterproof and heat-resistant composition. However, it contains toxic substances and is not used to repair products that come into contact with food or skin.

- “Super Moment ” - second glue.

- 3M Scotch-Weld PR100 is an epoxy adhesive that hardens in 20 seconds. Simple and easy to use composition.

- Cosmofen is a brand that offers several types of glue for plastic. Among them are adhesive-sealant for transparent plastic, Plus composition for PVC, PMMA - adhesive for polystyrene and acrylic surfaces.

- " Second " - superglue for hard plastics. One of the fastest acting compounds.

- For minor car repairs, special automotive plastic sealants are sold.

- Rexant is a hot melt adhesive, available in the form of rods. It can be transparent or colored (to disguise joints if colored parts are connected).

- Akfix HT300 is a heat- and water-resistant composition. Withstands temperatures up to +300 degrees. This adhesive sealant contains silicone. It reacts to humid air.

This is not the entire range that the adhesive industry offers. It cannot be said that any glue is better or worse. Each composition is designed for specific types of work. Read the instructions carefully and follow all recommendations.

Rexant and Akfix HT300

Glue marking

Tubes with glue are also marked, it’s just a pity that the designation system does not always coincide with the designations in the triangle on the plastic product. Most often you can see the following symbols on the tube:

- PC-polycarbonate (used for covering greenhouses and canopies).

- ABS is an acrylonitrile copolymer.

- PP polypropylene.

- PPMA organic glass for general purpose.

- PE is a well-known polyethylene.

- PVC is another familiar one - vinyl, or polyvinyl chloride.

- PS – polystyrene.

- PA 66 - polyamide.

- PUR polyurethane.

Adhesive for acrylic (plexiglass)

If you are not an expert in organic chemistry, then most likely, further study of labeling at home will not be successful. It is better to read in the user manual, which must be included with the tube, which plastics can be glued with it.

Features of choice

When choosing an adhesive, you need to consider the type of plastic. To do this, each product is marked in the shape of a triangle with arrows:

- PETE is the most common polyethylene, a thermoplastic used to make food containers and packaging materials. Often used in the production of electrical and radio components, containers for cosmetics.

- PVC is plasticized polyvinyl chloride, a universal material used in the production of the vast majority of items: furniture, building materials, various parts, containers for food products.

- LDPE is a thermoplastic considered a good thermal insulator. It is used to make pipes, packaging, and toys.

- PP is durable, rigid, the cheapest polypropylene, considered a cheap and popular plastic. It is used in the production of sewer pipes, automobile parts, and various tools. Excellent resistance to aggressive substances and temperature changes.

- PS polystyrene is a thermoplastic polymer that is resistant to chemicals and moisture. One of the common types of plastic from which furniture, dishes, and heat-insulating coatings are created.

- Other and other types of plastic, to which various polymer elements are added. Not reused. It is characterized by high strength.

The tube must be sealed, undamaged, and contain information and detailed instructions. To repair toys, you should purchase a solution based on BF glue.

Valera

The voice of the construction guru

Ask a Question

It is advisable to choose packaging of a volume that is sufficient for repairs, so that there is no surplus left. Despite the tight closure of the lid, the fixing compounds are prone to drying out and losing their adhesive (adhesive) properties.

When choosing an adhesive, you should consider the material to which the plastic is glued.

When purchasing an adhesive, it is important to consider the material to which the plastic is attached : paper, leather, metal, wood, etc. If the product is planned to be used outside or in places with high humidity (kitchen, bathroom, shower), moisture-resistant types are used. When working with contact adhesive compositions, ensure ventilation and ventilation.

One-component and two-component adhesives for plastic have their own markings in the form of letter abbreviations. For example, PPMA (plexiglass), PP (polypropylene), PA 66 (polyamide), etc. For ordinary consumers, these designations do not have much meaning, since any adhesive for plastic has instructions that indicate the types of plastic suitable for gluing.

Types of adhesives

The variety of plastics used in everyday life corresponds to an equally wide variety of manufactured compositions and methods of their use.

How to glue plastic

To dissolve the surface layer of a material, it is necessary to destroy the chemical bonds between the molecules. For this purpose, special substances are used - strong solvents. Each solvent is suitable for its own group of plastics, and may not even leave a trace on a material from another group. The basis of each adhesive composition is such a solvent. In addition, the composition may include:

- a hardener that promotes drying;

- filler - dissolved molecules of the substance for which the glue is intended.

One of the strongest solvents is dichloroethane. It is used to glue polystyrene and plexiglass.

Dichloroethane

Depending on the method of use, the products are divided into several groups:

- liquid;

- contact;

- reactionary;

- hot melt adhesives.

Liquid

Liquid ones are widely used in everyday life; they are easily and simply used at home for gluing plastic that has a porous structure. They are produced both on the basis of an organic solvent and on a water basis. They are applied to surfaces that are pressed against each other for a time sufficient for the base to evaporate. After this, the adhesive layer hardens, forming a connecting seam. A typical example is PVA glue; it can be used to glue not only linoleum, but also wood at home.

Contact

Bonding takes place in two stages:

- the surfaces to be glued are lubricated with a thin layer, which dissolves the surface layer of plastic, softening it and facilitating contact with another surface;

- After a few minutes, the parts are pressed against each other with force, the softened layers are mixed, the solvent evaporates and a seam is formed.

Moment for plastic

This is how Moment, BF-2 and others work. They can be used to glue polystyrene and other plastics together at home. They contain toxic substances, so you need to work in a well-ventilated area and prevent drops from coming into contact with the skin or mucous membranes.

Reactionary

One-component reactive agents dissolve the bonded material very quickly and harden just as quickly. These are such well-known brands as Secunda, Superglue and their analogues. The seam is strong and rigid.

Two-component ones consist, respectively, of two components stored separately from each other:

- hardener;

- fixative

Two-component adhesive

The components are mixed immediately before use and applied to the surface, where the mixture hardens to form a compound. The basis is epoxy or polyester resins. The seam at home turns out to be very durable. A characteristic feature is that complete hardening takes quite a long time, and the seam gradually increases both strength and fragility.

Hot melt adhesives

This group includes substances that exhibit their properties when heated to 110-120 °C. To use, you need a special glue gun with a heating element. Differs in precision of application. In addition to plastic, it can be used to glue wood, fabric, and paper together at home.

TOP 5 adhesives for plastic

To decide which adhesive to use for plastic, check out our ranking of the best adhesives for plastic.

Table 1. Rating of the best adhesive mixtures

| Name | Manufacturer | Volume, g | Cost, rub. |

| Cosmofen Plus-S | Weiss (Germany) | 200 | 250 |

| Permatex Super Glue | Permatex (USA) | 2 | 130 |

| Henkel Super Moment Maxi | Henkel (Germany) | 20 | 295 |

| Mastix Poxy Termo | Mastix (Russia) | 50 | 70 |

| "Titanium" | Titan (Russia) | 250 | 60 |

Cosmofen Plus-S

Waterproof “liquid plastic” adhesive made in Germany has proven itself to be an excellent choice for plumbing work.

The compound adheres firmly to bathtub chips, sinks and tanks. Due to its water resistance and indifference to alcohol, Cosmofen Plus-S is used for the manufacture of doors, plastic windows and billboards. It is resistant to precipitation, UV radiation and temperature changes.

Permatex Super Glue

Super Glue is a gel-like consistency with high adhesive strength and cost-effective properties.

In addition to plastics, it glues rubber, metal, and ceramic products.

The adhesive, transparent seam breaks under a pressure of 245 N, which distinguishes the product from its competitors.

Henkel "Super Moment Maxi"

The choice of professionals. It sets quickly and reliably glues a variety of materials. The elongated thin spout makes it easier to work with small and vertical parts.

Mastix Poxy Termo

Two-component heat-resistant adhesive for gluing plastics, ceramics, metal, wood and glass. Valid at room and elevated temperatures. Glue and hardener are mixed in equal proportions, which is convenient to use. Process both surfaces to be glued, dry for 5-6 hours.

How to glue plastic tightly at home

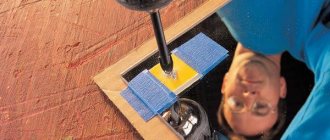

After the type of plastic has been determined and the appropriate substance has been selected, you should:

- Thoroughly degrease the surfaces to be bonded. To do this, use alcohol, a degreaser or a soap solution (only laundry soap);

- To glue objects more reliably, you need to increase wettability. To do this, treat the surface with a velvet file or fine sandpaper;

- Mix two-component reactive substances only after completing the preparation of parts;

- do not use brushes with natural bristles;

- Apply enough adhesive so that when pressing the workpieces, the excess is not squeezed out beyond the gluing zone.

The parts should be pressed so as to prevent their displacement in the gluing plane relative to each other.

How to glue plastic together

The most common question is how to glue plastic together. If you want to solve the problem once and for all, a little preparation is required. First, try to tentatively answer the following questions.

- What type of plastic is this?

- What is the surface condition? (raw, painted, etc.)

- What is the geometry of the adhesive surface? Are these sheet metal or injection molded parts?

- What can be said about the type and degree of load on the area being glued?

- Where are glued plastic parts supposed to be used?

Of course, not all questions and not always have answers. But the information obtained in this way is very important for choosing a suitable adhesive. Having determined the type of plastic, we study its characteristics and only after that we look for a suitable adhesive.

Main types of plastic:

- A.S.A.

- ABS,

- PA,

- PBT

- PC,

- PE,

- PAT,

- POM,

- PP,

- PS,

- PS,

- PTFE,

- LDPE,

- PVC.

How to achieve maximum effect when gluing plastic parts

To ensure maximum effect when gluing plastic at home, you should:

- accurately determine the material and select the appropriate adhesive for it;

- carefully follow the instructions for use;

- wait for the required time for the seam to gain strength and do not try to use the product ahead of time;

- for outdoor use or for items used in high humidity conditions, you need to choose a waterproof brand;

- despite the declared heat resistance of the adhesive, the parts themselves may not survive this temperature;

- If there is no marking on the product, then you can try dropping a drop of adhesive in an inconspicuous place and see if the material dissolves.

Epoxy resin

Epoxy glue produces one of the strongest bonds and is compatible with many types of plastics.

Results

Foam glue can be used for exterior finishing of house facades. For example, for waterproofing the base, fastening roofing felt, blocking the opening of a sewer pipe in the country. Also, the glue works well in contact with tiles and asbestos-cement slate. If there are cracks, they are treated with an adhesive composition on both sides, and a fabric-based patch is applied on top. This patch can last at least 1.5 years.

Share the post “How to make foam glue with your own hands from acetone and gasoline? + Photo and Video" by copying the link: https://kaksdelatsvoimirukami.ru/kak-sdelat-klej-iz-penoplasta-svoimi-rukami-iz-acetona-i-benzina-foto-i-video/

What affects the reliability of gluing

The reliability of the seam is influenced by a number of conditions. All of them are important, and failure to comply with any one can lead to the fact that what is glued at home will fall off, despite compliance with all the others. So:

- Compliance of the product material and adhesive composition.

- Correspondence of the type of adhesive composition to the magnitude of the forces that the connection will experience. The direction of these efforts is equally important. Thus, compounds that produce rigid seams are not suitable for repairing, for example, shoes - after all, the sole will bend and twist during use, despite the fact that the tensile force will be small. At the same time, this composition can successfully glue, say, a hook to glass, and hang tens of kilograms on it.

- Compliance with application technology. Everything is important here - how many seconds or minutes the surfaces need to be compressed, and how to degrease them, and how long to keep the parts pressed against each other. All this depends on the properties of a particular “plastic-glue” pair, is described in detail in the instructions and must be followed verbatim. A deviation of one second in the exposure time or premature start of use of the product can lead to secondary failure.

- Mechanical part of the process. It is important to thoroughly clean the surface from dust and roughen it. In addition, the direction of pressing the parts against each other must be perpendicular to the surfaces being glued. You should not allow the parts to move mutually after pressing - this will also lead to failure.

Gluing plastic tightly is not so easy. Carefully following simple rules by the home craftsman will allow you to obtain strong and durable connections. The main thing is not to forget about safety precautions: do not inhale vapors of the adhesive and do not allow it to get into food, skin or mucous membranes. If accidentally swallowed, consult a doctor immediately, making sure to take the tube with you.

How to choose a soldering iron for soldering plastic?

In case of an accident, bumpers take the main load. The part is damaged and therefore needs to be repaired. To do this, use a special soldering iron for plastic. With its help, you can level the surface, eliminate cracks and connect broken elements.

Requirements for soldering irons for plastic

Requirements for soldering irons for plastic

The main characteristic of such devices is power. For efficient and comfortable work, it is recommended to use a device with at least 100 W. If you use a soldering iron of lower power, the plastic will not melt. When choosing thermal hair dryers, you need to pay attention to devices from 1600 W.

Another requirement is the heating speed of the soldering tip. For processing plastic elements, it is recommended to select options that heat up in 7-10 seconds. For domestic use, you can take equipment with prolonged heating, but for professional activities this will be associated with some inconveniences.

Tool types

Tool types

The modern market offers several types of tools for working with plastic parts. Among them:

- Devices with standard configuration . This tool can have a curved or straight soldering rod. Most often it is used to connect broken plastic elements. Standard models create strong seams due to high temperature exposure and can work at different angles.

- Thermal gun . The equipment is designed to correct the deformation of parts and solder them. The soldering gun is equipped with temperature control, which expands its scope of application. This bumper repair kit may include additional attachments that simplify and speed up the work.

- Hot air station for soldering . This tool is universal. It combines a hot air gun and a standard soldering iron. Additional attachments may be sold with it.

What to look for when choosing

What to look for when choosing

When choosing a soldering iron, you must take into account that it is designed to heat plastic. In this case, you should pay attention to several characteristics. First, the equipment must have optimal power, otherwise the plastic will not melt. The optimal indicator is at least 100 W.

Secondly, a soldering iron for car bumpers should have a convenient design. The user should not experience any discomfort when working with it. In addition, you need to choose a reliable unit from a trusted manufacturer.

Experts recommend giving preference to models equipped with wooden handles. This material does not heat up and does not lose its performance properties for a long time under the influence of high temperatures.

Best models

Best models

A soldering iron for repairing plastic parts is an expensive device, which is explained by its technical characteristics and operating features. There are several of the most reliable and effective devices on the domestic market:

- Steinel . This brand produces a whole repair kit, which includes a heat gun. The device has a power of 2.3 kW. With its help, plastic can be heated to a temperature of 650°C. Sold in a durable polymer case with additional accessories (electrodes, extension cord, etc.) and attachments.

- RT-2003 from Intertool . This device is great for processing thin plastic materials.

- Teroson . A convenient kit for repairing plastic parts, which contains a heat gun. Additionally, the device comes with attachments and accessories, including mixers, replaceable cartridges and reinforcement materials.

- Neiko . This tool is professional and made in China. Its power is 1600 W. Additionally, a special roller and attachments are supplied with it. Precisely selected components can ensure fast and simple operation. The advantage of Neico is that you do not need to purchase auxiliary materials for it.

- Stapler . Budget class model with a power of 100 W. The seams are created using special staples, which is why the tool got its name.

- Lukey . This is a cheap Chinese model. It is perfect for beginners and home use.

It is necessary to choose a tool taking into account your goals and financial budget.

Application area

Application area

In most cases, a soldering iron is used in car repair shops for processing plastic elements. They are used to repair bumpers, mirror structures, interiors, torpedoes, body kits, etc.

In addition, this device makes it possible to quickly and easily repair broken plastic parts on motorcycles, ATVs and bicycles, boats and yachts.

In a private home, a soldering tip for plastic is useful for repairing pipes, polymer frames of greenhouses and greenhouses.

How the tool works

How the tool works

The surface to be treated must first be lubricated with a degreasing compound and sanded. This will make it possible to achieve the highest quality docking.

Using a standard soldering iron model, you simply melt the edges of the element, then fix them to each other and expose them to temperature.

If the operation was performed correctly, a strong seam will appear at the junction of the plastic parts.

Treatment with a hot air gun is carried out using a similar principle. A targeted flow of hot air ensures the transition of the polymer into a liquid state.

If you are leveling defects, you need to wait until the car bumper softens and becomes plastic. Only after this can you manipulate it.

If the ends of the parts melt, they must immediately be tightly connected to each other and held until completely solidified.

When working with a soldering iron, you must follow the following rules:

- To make the tool heat up faster, it is recommended to clean its tip with fine-grained sandpaper. After prolonged use of the equipment, more thorough cleaning is necessary.

- A broken soldering tip can be replaced with a nail or steel wire.

- To extend the life of the tool, you need to let the transformer cool down when using it.

- When processing highly deformed plastic elements, it is better to use a special electrode. When heated, the material will fill all existing defects.

- Processing must begin with the internal surfaces. This will allow you to set the optimal heating level. If the temperature is not suitable, the defect on the wrong side will be invisible.

- When reinforcing plastic with mesh or staples, metal inclusions must be lubricated with anti-corrosion agents.

By following these recommendations, you can achieve the highest quality fastening of plastic bumper parts.