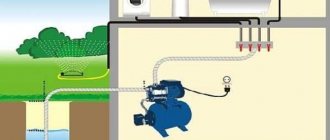

Individual water supply for a private house or cottage can be from two sources - a well or a borehole. To automate the supply of water to the house, as well as to create stable pressure, it is necessary to install a pumping station. It consists of a pump, a hydraulic accumulator, a pressure switch and a safety group (pressure gauge and drain valve). The advantage of this idea is that any household appliance can work with such a water supply scheme; another good news is that connecting is not too difficult a task; if you wish, you can install and connect the pumping station with your own hands.

Purpose of pumping stations

Such a station is intended for the functioning of the water supply system of a household, dacha, cottage and maintaining the required pressure in it. Thanks to its operation, it is possible to equip an extensive water supply network, creating conditions for connecting household appliances to it - a washing machine, dishwasher, shower stall, boiler, etc.

According to the installation diagram of the pumping station, it contains a pump, a hydraulic tank, filters, automation and a pipeline structure. The source of life-giving moisture is a well or borehole. In some cases, water intake may be carried out from open reservoirs or other reservoirs.

When installing a pumping station at a dacha is needed to supply water from a pond, lake or river, it can be used exclusively for watering the site or other household needs. Samples of liquid supplied from wells and wells must be taken to a laboratory for analysis - their results will show whether it can be used as drinking water.

Typically, the depth of a well in a personal plot is approximately 20 meters - this is the optimal parameter for placing automatic equipment. This distance allows liquid to be supplied to water collection points without the use of additional devices.

Water supply pumping units operate in cycles consisting of two stages. When the unit is turned on, water rises from the source, fills the system and the hydraulic accumulator. This happens until the pressure reaches the upper limit, after which a special relay turns off the pump and the liquid supply stops.

When you open the taps or operate household appliances that consume water, it flows from the storage tank. The liquid from it is consumed until it reaches the bottom mark. Next, the pump comes back into operation and begins to pump water into the hydraulic tank.

The number of cycles per hour must not be allowed to exceed the permissible number of starts of the pumping equipment being used.

The advantages of installing a water pump in a private home are undeniable:

- Autonomous water supply is provided;

- the efficiency of the water supply system is increased;

- equipment and pipelines are operated in safer conditions;

- it is possible to create a supply of water and, in the event of a lack of power supply, supply it;

- the system maintains a constant pressure and stable liquid pressure;

- the service life of various household appliances connected to the water supply structure increases;

- energy consumption costs are reduced.

In addition, such a station has compact parameters, relatively light weight, and is easy to install.

How to do a test run

The main condition for this is that the pumping station is filled with water, including all lines, as well as the hydraulic accumulator. Water enters the device through the filler hole. Turning on the power and starting the engine is carried out after the shut-off valves have been opened. After this, water gradually fills the pressure pipe. This is necessary in order to displace all the air from it. As a result, pressure increases. As a rule, this parameter can take values from the range from 1.5 to 3 atmospheres; when the limit is reached, the equipment turns off.

Thus, the effective operation of such equipment is ensured not only by the correct choice of model suitable for use in certain conditions, but also by proper connection. And for this, it is first decided where the equipment will be installed, after which a hermetically sealed connection of the equipment with the internal and external pipelines is organized.

Criterias of choice

When it is planned to install a pumping station in a private house, it is selected so that it fully performs its function, and therefore meets the needs of people who live there permanently or who often come to visit.

Before installing a pumping station in a private house, certain criteria are taken into account:

- Technical features of the equipment.

- Features of the operation of water sources.

The best furniture for a large hall

Many people wonder what furniture to choose for a large hall so that the room does not look empty and can be divided into zones. For a large room, a good option would be to create a dining room together with a living room.

The dining area should have display cases, a table, and comfortable chairs or armchairs. This area needs to be arranged in such a way that the whole family can gather during lunch or dinner.

In the recreation area you need to create the most comfortable environment so that you can relax after a difficult day at work or receive guests. This zone should emphasize the overall style as much as possible and show the refined taste of the owner.

Technical indicators

If you plan to install a pumping station for a dacha or household, when choosing it, pay special attention to performance. The best solution would be a design that will provide the required pressure from the well, capable of satisfying the need for water for domestic needs and for a personal plot.

For a comfortable stay outside the city for a family of 4 people, installing a water station of medium or low power is suitable. Typically, such designs are equipped with a hydraulic tank designed for 20 liters. They lift liquid from the well in a volume of 2 - 4 cubic meters per hour and create a pressure of 45 meters or more.

In addition, before installing a pumping station, when purchasing, take into account its dimensions, the water level when the pump is off and running, the type of filter and the cross-section of the pipes.

Installation diagrams

Before installing a pumping station, you need to choose the optimal location for it.

This takes into account:

- distance from the station to the source;

- humidity and temperature conditions at the pump location;

- availability of space for repairs and maintenance;

- the ability to soundproof the room.

After choosing a location, the water pumping station is installed step by step:

- Work begins with preparation. A solid base with a flat surface made of wood, concrete or brick is created for the transfer pump. You can use a special metal bracket.

- Since the unit begins to vibrate strongly during operation, leaks may appear at the joints of the pipes. Therefore, before connecting the pumping station, a rubber mat or special pads are placed under its supports. Anchor bolts can be used to securely fasten the legs.

- In order to ensure uninterrupted water supply, it is necessary to ensure a constant supply of liquid from the source. It is necessary to follow the instructions on how to properly connect the pumping station to the well, protecting it from freezing. To do this, dig a straight trench in the direction from the source to the foundation of the house to lay pipes in it, preferably with a cross-section of 32 millimeters.

- Pipes are laid below the freezing mark of the ground. When forming a trench, take into account the slope in the direction of water intake. When groundwater lies close to the surface, the pipes are placed above the critical level, but at the same time they are insulated or a heating cable is used.

- When the pipeline is located above the ground, high-quality thermal insulation and heating are required; for this, basalt-based mineral wool can be used.

- Before connecting the pumping station to the water supply, they complete the water intake unit with a surface device and a built-in ejector, connecting polypropylene pipes to the end along with a check valve and a metal mesh, which performs the work of a coarse filter. The check valve ensures stable filling of the pipes with water. To fix it, use a coupling with an external thread. When operating a submersible pump, you only need a pipe and a check valve - it already has a filter of this type.

- The pump weighs a lot, so a strong cable is required to hang it. When lowering the water intake unit of a structure with a surface pump, take into account that the gap between it and the bottom of the well or borehole must be at least 1 meter. For a submersible unit it is 0.5 meters.

- Next, in accordance with the connection diagram of the pumping station, a hydraulic accumulator and a control unit are placed using a five-pin fitting; it is placed in a convenient location in the pressure pipeline. Then a pressure switch and pressure gauge are mounted to it. The storage tank is connected to the side entrance of the fitting.

- All piping elements of the pumping station are complex units, and the breakdown of one of them leads to a malfunction of the water supply system. For this reason, shut-off valves are installed at each site so that it is possible to carry out local repairs by disconnecting a certain part of the structure. This is best done using an American type tap (for more details: “American tap - rules for using fittings for connections”).

- It is advisable to provide in advance the possibility of draining water from the system. Therefore, a branch is made in the pipeline from a tee with a drain valve. A coarse filter is installed on the water supply branch, and a fine filter is installed on the pressure branch.

- Then consumers are connected to the station, the first of them will be the distributing collector.

- The electric motor of the pump is characterized by high power, so a separate power line must be allocated for it. The electrical connection diagram for the pumping station provides for grounding and connection of a voltage stabilizer.

- During the installation process, you need to check the pressure in the air chamber of the accumulator. Its value compared to the switch-on pressure of the unit should be 10% lower. The setting is performed in operating mode. Preliminary values for a tank with a capacity of 20 - 30 liters are 1.4 - 1.7 bar, and for a tank with a volume of 50 - 100 liters 1.7 - 1.9 bar.

- When you install a pumping station with a surface-type product yourself, you need to fill the working part of the system before starting. Unscrew the plugs from the filler hole located at the top of the pump. When the pipeline is equipped with a filler funnel, use it. Water is poured in until it begins to flow out, and then the valve is tightly closed.

- The pump is connected to the power supply during startup. To remove any remaining air that has entered the funnel, open the valve on the pipeline.

- You need to not only know how to properly connect the pumping station, but also how to start it. After turning it on, water should appear from the outlet of the pressure pipeline or a slightly open water tap. When this does not happen, the pump is stopped, water is added and it is started again. After a successful start of the equipment, it is run in and the pressure switch and valve body are adjusted. Most often, adjustment of the pressure switch at the pumping station is performed by a specialist.

Using recycling

The recirculation line serves to maintain water pressure in the supply and protect the pump from idling. It is necessary to understand that this wastes part of the pump power.

To organize recirculation, a tee must be installed on the pressure pipe of the water supply system. It is advisable to install a shut-off valve on the recirculation line. It will provide regulation of water flow. The second tee must be installed on the suction pipe in a convenient place and connected to the recirculation pipe.

1 - tee; 2 - shut-off valve; 3 - recirculation pipe

When repairing or servicing the water supply system, in order not to relieve the pump pressure and refill it with water, install a tap on the accumulator, then you will leave water under pressure in the accumulator. After the repair, simply unscrew the valve and the pump with the pressure pipe will fill with water. In most cases, the hydraulic accumulator reserve is sufficient to fill the pump and start it.

Such simple actions will increase the reliability of the uninterrupted operation of the system.

Station assembly

To assemble a pumping station, you need to understand what it is and how it functions.

The station has the following main components:

- a centrifugal pump that pumps out and transports water into the house;

- pressure switch;

- hydraulic tank preventing hydraulic shock;

- an electric motor connected to a relay and a pump;

- pressure gauge for pressure control;

- intake system with check valve;

- line connecting the pump and water intake device.

The installation of these units is carried out in accordance with the water supply diagram of the pumping station of a private house.

The pressure switch regulates its value in the system. When it is below the required parameter, the pump starts, and if it is higher, then it turns off. Using a pressure gauge, the pressure is adjusted. A mandatory element of any water supply station scheme for a home is a hydraulic accumulator. It is sometimes replaced with a storage tank, but this design is considered obsolete.

Some valuable recommendations

Threaded connections must be tightened with a wrench and not by hand to ensure the required tightness. To connect fittings, protective devices and the pumping station itself, it is better to use pipes whose diameter is slightly larger than the calculated one in order to compensate for the load increased due to bends in the line.

The recirculation line will protect the pump and increase the water pressure in the system. To install the return line you will need a tee

To protect the pump from idling, you can install a recirculation line. To do this, tees are placed on the supply and suction pipes and the free pipes are connected with a return line.

A valve should be placed on it to control the intensity of the reverse flow. This addition will improve the pressure, but will slightly reduce the performance of the device.

A bracket can be used as a base for the pumping station, but it must stand level on shock-absorbing pads so that vibration is minimal

The pumping station is placed on a perfectly level base equipped with shock-absorbing pads. This will reduce the vibration impact and also reduce the amount of noise.

About once every three months you need to check:

- condition of joints for leaks.

- condition of filters for timely cleaning.

- relay settings for their correction;

- the condition of the hydraulic tank to determine the location of leaks.

If the pressure level in the HA does not meet the required level, it is easy to pump it up using a compressor or pump. On larger containers a nipple connection is provided for this purpose. If fluid leaks from the hole, the inner membrane is torn and needs to be replaced.

Installation location

Usually the pumping station is assembled in a heated room. The ideal place would be a boiler room with well-equipped sound insulation. There are other options for installing a water supply station. Often it is placed in the basement or basement, but subject to their heat, sound and waterproofing. You can also use a special box - it is placed in the underground with a hatch providing access to the equipment.

A platform is used to place the station in the well. It is installed below the freezing level of the ground. In this case, the structure of the well should be insulated from above. But this method of placing a water station is characterized by problematic access to it.

You can also provide space in the caisson for the pumping station. To do this, a structure is built around the well, buried below the freezing level of the soil. The caisson is closed and thermally insulated at the surface of the earth. For maintenance, a small hatch will be sufficient.

You can also build a house for a pumping station or place equipment in an extension. If this is a separate building, it must not only be insulated, but also heated in cold weather.

Self-installation allows you to significantly reduce the cost of installing a pumping unit. Depending on the type of source, different connection schemes for the water station are used. Correct installation depends, among other things, on small elements such as an oil seal, check valve, filters, etc. They can improve and make the operation of pumping equipment longer.

Expert advice

When, thanks to the operation of the station, an uninterrupted water supply has been established in the household, it must be periodically serviced. First of all, you need to monitor the condition in which the coarse filter is located. If necessary, it must be cleaned.

If this is not done, the performance of the equipment will decrease and water will flow in fits and starts. When the filter is completely clogged, the pump will run idle and then turn off. The frequency of cleaning depends on the amount of impurities present in the water.

It is advisable to check the pressure in the air compartment of the hydraulic tank once a month after installing the water station. The same should be done in case of preservation for the winter, repairs, or downtime. Its value should be 1.2-1.5 atmospheres. If necessary, air is pumped up with a car pump or compressor.

When the station is used exclusively in the warm season, the water must be drained from it before frost sets in.

If all the recommendations on how to correctly install the pumping station specified in the instructions have been followed and the equipment is connected for debugging and determining the pressure at which it will turn off, two liters of water are poured into the receiving device and the unit is started.

When the station turns off, you need to record the fluid pressure. You should also know this parameter when starting the unit automatically. The station may not turn off at a certain liquid pressure. You can deal with this problem using the screws on the pressure switch. They adjust the compression ratio of the springs. To do this, first remove the cover on the device, then tighten the screw with the letters “DR” towards the “plus” or “minus”. To regulate the pressure at which the start will occur automatically, you need to engage the screw marked with the letter “P”.

Common mistakes

When installing all components of plumbing equipment, a number of common mistakes are possible, knowledge of which will help you avoid them:

- Small stock of pipe lengths used. Often overlooked are the presence of corners and the thickness of the foundation, which increase the distance to be laid. Be careful. It’s better to overpay for an extra length that can be reduced than to worry about increasing the product and losing large sums on sealed adapters.

- Tightening threaded fasteners with bare hands. At the moment of tightening, it may seem that the part is seated tightly, but during operation it may leak. Be sure to use a key to ensure complete sealing.

- Negligence in relation to the hydraulic accumulator. Be sure to check the internal pressure in it. If it falls below 1.2 atmospheres, then it must be increased using a compressor or pump for cars.

Filtration system at the station

Any water carries many impurities in the form of sand, clay and other heavy elements. They are harmful enough to the internal structure of the equipment that, if accumulated in large quantities, they can damage it. Therefore, if you want to extend the life of the station, its installation is required.

But at the same time, it is necessary to remember about the negative effect: a decrease in the force of water influx. To prevent this problem, it will be enough to regularly clean the dirty filter elements. The main thing is to prevent the system from becoming completely clogged, which will certainly lead to a breakdown of the device.