Hi all! This creative post was born after an incident that Master Sergei spoke about. True, it was not a board, but a connector, and not after soldering, but after debris got into the connector %-). Damn, how does my brain work?! But this does not change our topic. Here are my Top 3 best ways to clean the board after soldering. The same methods are, in principle, applicable for cleaning all kinds of connectors from micro-debris and dust. The above division is quite arbitrary and is a personal opinion, which you can challenge in the comments at the end of the text.

How and with what to clean your computer motherboard from dust

To clean this important component, you do not need to use special products.

Various solutions, special brushes or branded wipes are necessary only if the contamination is serious. In most cases, you can do it yourself without any special expenses. Our Computer advises you to purchase:

- A small but fluffy brush.

- A can of compressed air (optional).

If you have a cylinder, then simply blow out all the microcircuits - this will complete the cleaning. But, in the absence of such luxury, you can take a brush. Gently walk it over the dusty contacts and use a sweeping motion to clean them of dirt. After this, remove all dirt on the surface with a regular vacuum cleaner.

How to make liquid rosin

Rosin is a natural material that is obtained from the resin of coniferous trees by evaporating turpentine. After processing, a solid translucent resin is obtained, which is used as a soldering flux. Rosin is used not only in its pure form, but also in combination with various chemical additives. Rosin is mainly used in amateur radio as a cheap and high-quality flux. For soldering radio components and tinning printed circuit boards, it is very convenient to use an alcohol solution of rosin. Liquid rosin easily penetrates into all hard-to-reach places, both when soldering SMD components and conventional radio components, does not leave dirty marks on the board and, if necessary, is easily washed off with acetone or alcohol. Rosin easily dissolves the film of oxides formed on the surface of radio elements during the soldering process, and also reduces the surface tension of the solder melted by the soldering iron tip, allowing it to spread evenly over the entire surface of the soldering area.

In radio stores, the shelves are simply full of various expensive and cheap, chemical, acidic and natural fluxes based on pine rosin. There's a lot of choice, I don't want to take it. But as a real radio amateur, for the sake of experiment, I wanted to prepare an alcohol solution of rosin with my own hands. As my grandfather, an avid radio amateur, did.

Enough words, now I’ll start my experiment, I just can’t wait to see what happens in the end...

As always, I prepared very carefully for the experiment: I took two 20 grams. jars of pine rosin, 100 ml. pure 96° alcohol and an empty plastic bottle for preparing liquid rosin.

You definitely need to take new and clean rosin; dirty rosin, burnt by a soldering iron tip, will not work, because it will contain a lot of dirt and all sorts of impurities. Rosin can be dissolved in anything, in acetone, in all sorts of strange solvents, even kerosene. But the safest and non-toxic solvent for rosin, as you may have guessed, is 70° medical alcohol; you can also use 96°, it will dissolve even faster.

The rosin must be thoroughly crushed, I do this with such powerful pliers, right in the jar. The compression of the rosin crumbles into small pieces, which is very convenient; there is no need to do anything shamanic with glasses, mortars, crushers and other crap.

Now I pour it into a plastic bottle. There are exactly two jars of rosin here.

I fill this whole thing with alcohol, one to one. I have two jars, which is 40 grams of rosin, which means you need to pour in at least 40 milliliters of alcohol, maybe a little more. As they say, by eye. If all the rosin is not dissolved, I will add more. For such an interesting experiment, I donated a bottle of pure alcohol. What won't you do for the sake of science? Now I’ll mix this whole thing thoroughly. After about an hour, all the rosin should dissolve.

After an hour, the rosin had completely dissolved, resulting in a homogeneous, transparent honey-colored rosin-alcohol solution with a pleasant smell of pine rosin.

And now, as always the most interesting thing, I’ll see how liquid rosin will solder.

It turned out not bad, even better than store-bought flux (LTI-120, KE, FKEt, FKSp and so on), one might say it’s a little thicker.

Liquid rosin works, the experiment was a success! It solders perfectly and has such a pleasant light rosin smell. I'm just delighted!

Friends, I wish you good luck and good mood! See you in new articles!

I recommend watching a video on how to make liquid rosin with your own hands

How and with what to clean a laptop motherboard

When the motherboard of a laptop gets dirty, the task becomes a little more complicated. Unfortunately, you can’t take your mother to the dry cleaner, so usually people have to make do on their own. Motherboards on a laptop are usually more fragile, delicate, and moreover, they are very difficult to get. Were you able to disassemble the device? Well, then about 70% of the work has already been done.

Try to use only compressed air. In the absence of this, simply fill a little oxygen into a special bulb located in the car of any car enthusiast. Don't release it too quickly.

How and with what to clean the motherboard after flooding

The most difficult part is cleaning after a spill. In this case, the PC owner must not only eliminate the liquid and dry the motherboard, but also avoid corrosion. Many even believe that it is impossible to do this on their own and that it is better to turn to a professional.

But in fact, there is a way out - it is not as difficult as it seems. Using a small cloth and alcohol, simply wipe off the oxidized contacts once the motherboard itself is dry.

How to make liquid rosin with your own hands

Rosin contains from 60 to 90% resin acid (abietic acid), from 1 to 12% fatty acids and up to 20% neutral substances.

Rosin does not dissolve in plain water, but it dissolves well in alcohol, benzene or acetone; dissolution is slightly worse in kerosene. At temperatures from 40 to 75° Celsius it softens well, and at 100-140° the melting process begins, boiling occurs at 250°. When organic and mineral substances are added to the composition, a special rosin soap is obtained, and when dissolved with polyhydric alcohol, a rosin ester is obtained. Rosin found its main use in amateur radio when soldering radio components. Pine rosin is an excellent and cheap soldering flux. Despite the modern abundance of chemical fluxes, it still continues to be actively used in electronics. Rosin melted by a soldering iron tip easily removes the oxide layer from the surface of radio elements undergoing the soldering process. In addition, rosin reduces the surface tension of the solder and helps it spread evenly over the entire plane.

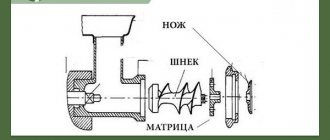

Before the soldering process, the tip of the soldering iron is dipped in rosin, then it is used to touch the solder, after which it is touched to the place where the parts are soldered. The main advantage of rosin, which has retained its popularity as a soldering flux, is its acid neutrality, since raw materials of natural origin are used in its production. Unlike other acid-based fluxes, the soldering area does not corrode and there is no current leakage through it. As a soldering flux, rosin is used both in pure form and in combination with various substances. The simplest flux made from it is a solution in pure medical alcohol in a ratio of 4 to 6.

The technology for soldering metal parts using rosin is very simple and accessible to beginner radio amateurs. The heated tip of the soldering iron is dipped into frozen rosin, after which it takes a small piece of solder and applies it to the surface of the part to be soldered. The same algorithm is repeated with another part, which is connected to the first. Then both metal surfaces are superimposed on each other and a heated soldering iron is brought to them, whose tip is again covered with rosin and solder. As a result, the molten solder forms a special monolithic mass, which, when hardened, will well connect the surfaces into one whole.

And so we take an ordinary crystal of frozen amateur radio rosin.

Then we grind a piece of rosin into dust, for this we take some non-porous fabric or paper, place a crystal in it, and beat it with a hammer until a homogeneous mass is obtained. This is necessary for good dissolution of rosin in ethyl alcohol.

Next, pour this rosin dust into a bottle and fill it with pure ethyl alcohol in a ratio of 1 to 1.5 (rosin: alcohol).

We close the bottle with a lid and place the glass bottle in a bowl of warm water. When the solution heats up, you need to shake the mixture well so that it turns into a homogeneous mass. That's all, now the flux is ready, pump it into medical syringes and use it comfortably.

Is there alcohol for cleaning motherboards?

The motherboard is considered a rather fragile, complex mechanism, so many people are reasonably afraid for its safety. The consequence of this was an increased need for special means. According to the manufacturer, they clean much more effectively and do not harm in any way, so it is worth using them. Some even claim to have invented a special alcohol for this purpose.

There really is such a remedy. It's called "isopropyl alcohol." The old time-tested medicine is safer than its ethyl analogue. But it’s not easy to buy, and the price is simply amazing!

Alcohol-rosin soldering flux

For soldering, not only pure rosin, but also its solutions are used as a flux. In particular, many people know alcohol-rosin flux. It is neutral, so residues do not corrode metals and do not need to be washed off.

The ingredients for the alcohol-rosin solution have been known for tens and even hundreds of years. Raw materials for their production are always in abundance, so this flux is inexpensive.

Positive properties

Rosin was obtained from cuts of coniferous trees.

Volatile components were evaporated. The remainder was three-quarters of the original mass of resin. Rosin for soldering was used only after such preliminary preparation. Everything would be great, but when working, you need to dip a hot soldering iron into the resin flux. The main tool is then covered with chemical mud, so that the working area is not very visible.

Over time, it became clear that liquid rosin as a flux is much more convenient to use. Due to the presence of natural resin substances of a soft acidic nature, it:

- perfectly removes the oxide layer on parts;

- spreads well;

- occupies the entire adhesion site.

Cleaning products for printed circuit boards

Those interested can also buy special products marked “clean” on the packaging. These contain special technical alcohol, which belongs to the class of the most powerful cleaning agents. In addition, they also contain additional components that protect the motherboard from rust formation.

Buying these is a rather controversial and ambiguous step. Everyone must decide on their own purchase.

Why do Ballerinas need rosin?

To dance in both soft and hard shoes, dancers use rosin (which, by the way, musicians use to play the bow). ... The rosin is knocked out of such a package by turning it upside down, it crumbles and falls out.

Interesting materials:

What are the similarities between proverbs and sayings? What is the meaning of the White Guard? What is the point of the book 1984? What's the point of wearing a bodysuit? What does glucose contain? What does chlorophyll contain? What are the consequences of unemployment at the societal level? What is the main idea of Descartes' method of radical doubt? How to create a GIF? What is the essence of the philosophy of existentialism?

Is it possible to wash the motherboard?

Some people believe that the motherboard in a computer is immortal. It is not possible to explain to others that they wash it in ordinary water. Of course, after this, nothing will work anymore - the contacts will simply oxidize, which will lead to the possibility of a short circuit.

But, no matter what, you can wash the motherboard. But this must be done using distilled purified water. Moreover, you need to really understand the structure of the motherboard and know what you are doing.

Preparing for work

Before cleaning microcircuits, it is worth understanding whether it is worth doing at all. Many people have encountered oxidation of an electronic board. This process can be called inevitable. There may be several reasons for the appearance of contamination: the fan pulled debris and dust inside, water penetrated, or excess was not removed after soldering.

Any contamination to a certain extent affects the boards:

- The layer of debris or dust on the device is an additional thermal insulation layer. The heat that an electric current produces is not dissipated, but remains at a specific point. Because of this, some parts of the board may fail.

- Moisture or dirt stuck to the top can cause current to pass through. This can lead to a short circuit and damage to the board.

Preparation for cleaning begins by turning off the device and de-energizing it. Then you need to disassemble the device, but only if you can later put it back together. Otherwise, it is better to contact specialists. It is better to work in dry clothes away from moisture.

What is ultrasonic cleaning of a motherboard and is it worth doing?

One of the fairly popular ways to save your computer after being flooded with water is to place it in an ultrasonic bath. This method allows you to both clean the motherboard from dust and dry it after liquid, but only specialists can carry it out. Trying something like this at home is dangerous.

A dirty motherboard will never fully cope with all its responsibilities. One of the main components of the computer serves as a link between all components of the system, so its incorrect operation can easily lead to serious damage, including failure of RAM, processor and video card.

Guys, please tell me how to remove oxide from the contacts of the dist. The remote control sat for a long time with batteries, from which oxide formed. Thank you.

Comments 47

hydrogen peroxide - from battery drips

ammonia - just oxides from time

put in water for 3-4 minutes and wipe with a cloth, it will remove perfectly, you can also remove oxide from the battery terminals

why the hell should I suffer? I need to buy a new remote control. what model? If I can help you with anything.

Carbcleaner will help you))) perfectly removes oxides and dirt, and leaves no traces when dry. I have cleaned more than one circuit with this rubbish))))

Maybe good advice for metal, but plastic, rubber... It will probably get inside the case and can corrode the buttons or something else.

Well, first of all, the oxide needs to be removed. acetone or other liquids. and tin the contacts

You can use vinegar or dissolve citric acid. this is the most gentle way.

you remove acid with acid, obviously not a gentle way

Alkaline batteries :))) these are in acc. acid.

I'm for oxide. I wrote below that the best remedy is peroxide.

and I tell the author, his alkaline battery leaked. To avoid damaging the remote control, you can use vinegar; it will not burn the elements.

hot water from a kettle

Hydrochloric acid solution. Back in school, I remember experiments where you immerse a rusty nail in hydrochloric acid and the rust dissolves. Don't you remember chemistry?

Cleaning process

Depending on the type of contamination, boards can be cleaned in different ways. If the contamination is too strong or the device requires certain skills, it should be taken to specialists. But usually you can cope on your own.

Source gesrepair.com

Dry cleaning

Before you clean the chip, you should choose a method. Dust and dirt can be removed using a brush, brush or compressed air. The amount of dust depends on the cleanliness and humidity of the room.

Depending on the location of the contamination, you can use:

- Paint brush. It is well suited for large areas, such as CRT TV boards;

- Thin brushes for painting with synthetic or fine bristles. They are best used for open spaces and recesses with a large gap (for example, when cleaning inside the system unit).

- Toothbrush. It copes well with dirt along small circuit boards with small recesses. For example, it is good for cleaning smartphone circuit boards.

- Compressed air, such as rubber enemas or bulbs. They are good at blowing dust out of secluded places where it is impossible to reach with a brush.

- Thin needles. They are used in places where a brush cannot reach and air cannot remove dirt.

- A clean cotton cloth is suitable for cleaning flux after soldering or greasy marks. You can also use paper napkins.

- Cotton swabs are good for cleaning exposed areas of the board or optics.

Source neoteo.com

It is not difficult to understand how to clean the board from oxidation and dust. It is necessary to carefully brush the area of contamination several times or blow off the dust with a blower. If the dirt has dried and cannot be removed, it must be dissolved and carefully scraped off.

Wet cleaning

Although contact with water is harmful for electronic circuit boards, water can be used to easily clean the area. It is necessary to use distilled water - it has no effect on the appearance of oxides, since it does not conduct electricity.

The parts are washed under water, blotted with a cloth and dried. It is convenient to rinse some boards or parts under running water; for others, carefully remove dirt with a damp cloth or cotton swab.

Usually special ultrasonic baths are used: a cleaning solution is poured into them, the board is placed and left for the specified time (up to 15 minutes). then the part is rinsed with distilled water or alcohol, blotted with a soft cloth and left to dry. When working, it is important to strictly follow the instructions and pour only the appropriate solution inside.

Source siriust.ru

Chemical methods

When choosing how to clean a microcircuit from oxidation, do not forget about chemical compositions. These are the best options for cleaning electronic circuit boards. You can use both simple alcohol and professional products.

Each option is suitable for certain conditions:

- Alcohol does a good job of removing small amounts of flux. You need to apply alcohol to a napkin and gently rub the area. The second option is to soak the board in alcohol, then blow with compressed air to remove any remaining alcohol. Soaking will allow the alcohol to penetrate into the tiniest crevices and remove all dirt and remaining water.

- A universal cleaner based on alcohol, solvent and surfactants (surfactants). It is sold in a bottle and is convenient to use.

- The solvent does an excellent job of removing flux and soldering. However, some solvents can be bad for the plastic.

- Ethyl or ammonia. This is not a very effective product, since it is more designed for degreasing, but if the stain is small and only these alcohols are nearby, you can try it. Important! Do not use perfumes, colognes or any mixtures with essential oils.

Source severdv.ru

- When deciding how to wipe the boards, do not forget about acids: aspirin, lemon juice or citric acid. They must be diluted in water and applied to the site. Aspirin has caustic fumes and should be handled with caution.

- You can use flux or rosin. They clean the area well and prepare it, but they should only be used if soldering is planned, otherwise you will have to clean the board of them.

Some experts advise removing oxides mechanically: using sandpaper, a sharp knife or an eraser. Using these products requires certain skills and may damage the surface.

In the video you can see a comparison of the effects of the most popular board cleaning products