An individual hydraulic extraction point provides many advantages for residents, including an independent supply of liquid, good pressure, and high quality of the resource. But all this can be achieved only if the well or borehole is created taking into account all the nuances, features of housing and terrain. In the article we will talk about how a home water supply pumping station is designed, its design principle and pump operation diagram, the composition of a water installation for a summer house or private home. This should help you choose the equipment that is right for you based on the required power, pressure, number of consumers and other aspects.

Purpose and advantages of equipment

If there is a need for hydraulic extraction for a small summer cottage with a house for seasonal living, then usually residents do not focus on high water pressure and constant pressure; they prefer a conventional, inexpensive pump. And even if it is not very reliable, it copes with its task quite well - providing watering for the garden for several months a year and satisfying the small needs for household water for 1-2 people.

But if an individual water intake point is required for a large private house, then the structure in question is installed. It has more power and has a number of advantages. But first, let’s look at what a water supply pumping station is needed for and how it is used – application and purpose:

- Autonomous water supply for housing. There is no need to connect to the main water supply. Residents are not dependent on the water utility, which means that they receive a constant amount of a resource of good quality. No outages associated with scheduled line repairs or emergency situations.

- Industrial use. Large wells with appropriate pump power are used in factories and production workshops. Water is supplied not only from the bowels of the earth, but also from open reservoirs and liquid storage tanks. Often large volumes are required for cooling, for example, in the field of metallurgy and energy.

- Watering greenhouses, gardens, vegetable gardens. Irrigation systems can be designed for industrial agriculture or for individual purposes. In addition to irrigation, the supply of moisture for livestock is no less important in the agricultural field; it can also be automated.

So let's summarize. The purpose of pumping equipment is known to everyone - it is lifting liquid from a reservoir (well, well, reservoir, storage tank) and supplying it to a house, production workshop or irrigation system. This creates a certain pressure and, accordingly, pressure. But, unlike a standard submersible pump, the operation of a water pumping station also depends on its design and components. Thus, additional elements ensure its autonomy and automatic operation; the relay allows you to determine the number of pascals and some other indicators. But in order to consider the purpose of each part separately, it is first worth talking about the system as a whole.

Device types

- Superficial.

- Submersible.

In most cases, surface devices are used.

They are mounted on a frame. It has a hydraulic accumulator and automation. The pump has two outlets for pumping/supplying into a private home. Surface type units have the following advantages and disadvantages:

Pros:

- Ideal for sources with small diameter.

- The optimal solution for wells whose depth is no more than ten meters.

Minuses:

- If the water level drops, problems will arise.

Submersible well units are ideal for deep wells.

Automation and other equipment, except the pump, remain on the surface. This system allows you to lift water from a depth of about 50 m. Pros:

- If it is not possible to dig a well, then a submersible installation will allow you to lift liquid from deep wells.

Minus:

- Air in the line makes it difficult to start the pump. Therefore, it is necessary to install a check valve on the supply pipe.

What does the water supply apparatus consist of?

Depending on your preferences and skills, you can install two system options:

- In factory configuration. Then all the components will be assembled compactly and will not take up much space. They will correspond to each other in terms of technical characteristics, and the entire set will have a warranty from the manufacturer, instructions for use, installation and repair work. In our opinion, this is the most preferable option. As a result, it will also save you money.

- Assembled with your own hands. First you need to know exactly what the pumping station consists of and its operating principle. Then you need to find all the components, check their operation separately, and then assemble them correctly. This is relevant, for example, if you already have some elements of the system, and you only need to purchase part of it. With the right approach, this option can be more economical.

There are people who make their own devices, excluding one of the elements. For example, they remove the hydraulic accumulator. Indeed, without a storage tank it is possible to maintain a certain pressure directly in the pipes, automation will be achieved and costs will be minimized, however, the savings will only be temporary. In fact, the absence of this necessary element will lead to an increased impact of water hammer. The fact is that when the tap is turned on and off, a pressure surge occurs. And without a water tank, shocks will fall directly on the pump, which will lead to its rapid wear.

Based on the reasons presented above, we will consider the structure of a purchased pumping station. It consists of the following components:

- Electric pump. It can be submersible or surface, it depends on which reservoir is chosen as the source (well or surface of the reservoir). It can be centrifugal or vortex type.

- A membrane hydraulic tank, also known as a storage tank or hydraulic accumulator with a “pear”. Due to the expansion of the membrane, switching on and off occurs.

- A device for measuring pressure - a pressure gauge.

- Relay. It turns the pump on and off automatically when the sensor requires it.

- Connecting fittings.

We mainly consider the composition of a compact installation, that is, equipped not with a submersible, but with a surface pump. On the water intake side, a coarse filter must be installed (you can order it at), and on the outlet side, a pipeline is connected that supplies liquid directly to the building.

Here is a view of one of the common models:

Belamos XK 08ALL

The pumping station is made in Belarus and has the same characteristics as the model described above: pump motor power – 800 W, maximum productivity – 6 l/min. Approximate cost – 4.9 thousand rubles.

If you are interested in Marina pumping stations, check out our article How to choose and at what price you can purchase a Marina pumping station, technical characteristics and reviews from owners.

The Russian company AquaRobot also produces good pumps; read reviews of these devices, prices and selection tips here, buy exactly what you need!

Pump design and design diagram of a water pumping station for water supply at home

1.5 m3/h For process water

1.5 m3/h For process water

MBFT-75 Membrane for 75GPD

The presented system is on average designed for a pressure of 1.5 atmospheres (maximum - up to 4.5), which is usually sufficient for a two-story cottage with permanent residence of 4-5 people and the use of all household appliances that consume resources.

During installation, it is important to note that the device is compact and does not require concreting or any other foundation. The heaviest element is the hydraulic accumulator; its weight directly depends on the maximum volume of accumulated fluid. When installing, it is necessary to prepare a separate room or use a room for domestic purposes, remote from residential ones, for example, a basement or storage room on the ground floor. This is necessary because the station makes a hum.

Sometimes a reasonable solution is to install a caisson, that is, a separate chamber. This allows you to create sound insulation, protect equipment from precipitation and other environmental influences, and also make access for maintenance and repair easy.

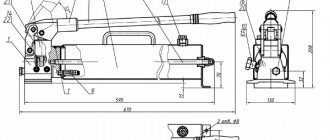

Let's give a diagram of the pump for installation:

Control unit - what it is and how it works

The main advantage of the pumping station is automation. That is, you don’t need a special person to monitor the pressure in the network and turn the device on and off. All this is done automatically. And it consists of two main semi-automatic components:

- pressure gauge - a device that measures the pressure in pipes; when it is low, a signal is sent to start the pump;

- relay - consists of two springs that open and close the circuit to apply pressure and remove it. It works based on the liquid level in the tank.

It is important to pay attention to the factory settings, as they usually correspond to the values of the shut-off valves, but in some cases it is necessary to change the extreme values on the relay.

An additional element is the flow controller. When there is no water in the system or the flow becomes smaller for some reason, the device signals this. Its actions lead to minimizing the risk of engine overheating.

Below is a diagram of the electric pump control unit:

Principle of operation

The device in question works as follows. A pumping station from a well supplies water to the membrane under a certain pressure. When the pressure reaches a threshold value, the pumping station is switched off.

During liquid consumption, the pressure drops, which causes it to turn on again. The efficiency of the device depends on the volume of the tank. As the tank size increases, the load on the pump decreases. The pressure switch can be set to a certain water supply by rotating special nuts.

During prolonged operation of the accumulator, the air present in the liquid accumulates in the membrane, filling the useful space that could be used for water. In this regard, it is recommended to carry out preventive actions, which include releasing accumulated gases. Such operations must be carried out at intervals of 1-3 months.

Operating principle of a pumping station with a hydraulic accumulator

When you choose a connection with a hydraulic tank, it is important to decide on the volume of the tank. It directly depends on the expected daily amount of water consumed (this should be calculated in advance, taking into account how many people live in the house and what equipment they use). For a large family you need a tank of 100 liters or more. The smaller the tank, the faster the membrane wears out, since pumping is done more often. But if little fluid is used and the accumulator is too large, then the unused resource can stagnate and deteriorate, so the axiom “the more the better” is not relevant here.

The operating principle is shown in the diagram:

The meaning is this: inside, like into a car tire, air is pumped through the nipple, creating an internal pressure of 1.5 atmospheres. When the pump operates, water enters the cavity on the back side of the membrane. Thus, the more liquid, the more the bulb compresses - the pressure value increases. When the moisture supply does not work, water flows into the tap due to the influence of oxygen.

SF-mix Clack up to 0.8 m3/h

SF-mix Runxin up to 0.8 m3/h

SF-mix manual up to 0.8 m3/h

In standard models, the space for water takes up about ⅓ of the total volume of the tank, the rest is compressed air. Its main purpose is to maintain constant pressure in water pipes. The second task of the hydraulic tank is to reduce the impact of water hammer on equipment. A modest-sized tank is also suitable for these purposes. However, the smaller it is, the more on/off cycles occur, and this negatively affects the equipment.

First start

Having completed the installation of a water station, you should take a responsible approach to its first start-up. To do this, follow the instructions:

- Unscrew the plug in the pump body and fill it with liquid.

- The suction pipe is filling. Make sure the liquid has filled the entire space.

- Check the pressure in the accumulator; it should not drop. If it falls, it means the check valve is not holding. You can increase it with a car pump. If the pressure is too high, it releases through the nipple.

- After filling the system, close the cap tightly.

- Connect the pump to the mains.

- Remove air from the equipment by opening the valve slightly.

- To do this, the unit must operate for about three minutes. Water will begin to flow through the outlet.

- If the liquid does not flow out, add water to the pump and repeat the procedure.

To start correctly, it is important to know how the device works.

Selecting a location

The closer the water intake point to the house, the better. This is explained by the fact that every 10 meters of the pipeline reduces the suction characteristic by 1 m. This must be taken into account when choosing a pump and its maximum depth.

Suitable location:

- Outside the building in a special chamber in the ground near the well.

- The outside of the premises is in a pavilion with insulation.

- In the basement of the house.

If all-season operation is planned, then it is necessary to bury the pipes to the depth of soil freezing and, accordingly, insulate them. Installation diagram:

What are the advantages of an installation with a hydraulic tank?

Let us list the advantages of pumping stations and their components:

- Automation of all processes. A person is not obliged to regulate the operation of the device, monitor the water level, pressure in the system - the control panel is responsible for all this. This not only frees you from unnecessary actions and minimizes labor costs, but also reduces the risk of breakdown, since there is no human factor. And the device is responsible for preventing overload.

- Cost savings up to 50%. The presence of a hydraulic accumulator (a reservoir for temporary storage of water) allows you to reduce the number of pump starts and stops. Moisture accumulates in the tank and is gradually consumed. And only when it reaches the minimum level, the sensor is triggered, indicating that the system needs to be turned on. This device involves reducing energy consumption.

- Maximum reliability. Depending on the model and the components of the pumping station, it will have different service life, however, it will significantly exceed the period of use of a conventional pump with the same volumes of pumped resource.

- Relative autonomy from the electrical network. The presence of a hydraulic accumulator allows you to use the water supply for some time after a power outage. The amount of water in reserve depends on the volume of the storage tank.

- Uninterrupted pressure. A conventional pump can produce different pressures in the pipeline. This will depend on many parameters, including the groundwater level. And with a hydraulic accumulator, the pressure remains constant.

Dry running protection block

The practice of operating pumping stations shows that there is a real risk of pump operation without water (“dry running”), which is prohibited by all manufacturers. This situation arises in the following cases:

- the flow rate of the well/well is less than the pump capacity (incorrect pump selection);

- drying up of sources (decrease in flow rate) during the dry period of the year;

- unmonitored emptying of the source container;

- loss of water in the water source when the pumping station is used as a booster station.

Imagine the situation: the pressure inside the system is less than the lower threshold plus the water supply disappears. The pump continues to grind dry, trying unsuccessfully to increase the pressure. The breakdown of the unit will be completely guaranteed. Therefore, a station equipped with a dry-running protection unit is much more reliably protected.

As such protection, a special pressure switch can be used, set to a low value (less than 0.4 bar), called a “dry running” relay. It turns on next to the main pressure switch.

Connecting the dry running relay.

A number of manufacturers offer flow sensors, as well as flow switches, sometimes called press controls. The latter combines the functions of a conventional pressure switch and additionally detects the absence of water flow through its internal channel, generating a command to turn off the pump motor with a short delay relative to the moment the flow disappears.

Press control can always be purchased separately and installed in the pressure pipeline to record water flow/pressure. The station's standard pressure switch can be removed. The electrical connection of the unit is made using a cord with a plug and socket; it is intuitive and feasible even for non-specialists.

What to consider during installation

An important point: even before installation, care should be taken to ensure the availability of rough water treatment. Otherwise, soil particles and other contaminants will enter the pump, which will quickly lead to equipment failure. It is best to order filtration systems from - there is a large selection and excellent quality.

AMETHYST - 02 M up to 2 cubic meters/day.

Aeration unit AS-1054 VO-90

Main table dispenser AquaPro 919H/RO (hot and cold water)

You should also not forget about the check valve. It should be installed to prevent water from flowing back into the well when the system is not working.

Special attention should be paid to electrical safety, since the combination of moisture and electricity is not the best tandem. Be sure to install an RCD to avoid short circuits.

Otherwise, the station is very easy to connect.

User reviews

Catherine.

More than two years ago, a Marina CAM 60/25 station was purchased to supply water to the house and property. All this time, the equipment worked without a single failure; the only serious problem arose with the hydraulic accumulator tank, in which the membrane quickly ruptured. Finding a spare for this model proved impossible. In addition, the tank body quickly rusted, so in the end it had to be replaced with a tank from a different model, for which the station had to be slightly redesigned.

The equipment should be installed outside the home, otherwise the noise and vibration when the pump is turned on will be too uncomfortable. Performance allows you to connect a shower, sink, washing machine, irrigation system and faucet in the barn.

Alexander.

I bought the Grundfos MQ 3-45 model. A very low noise level made it possible to install the equipment in the underground of the house. The disadvantages include high cost and increased requirements for water quality (it easily becomes clogged with sand and other impurities). Overall, I am very pleased with the performance of the model.

Ivan.

Installed Gilex Jumbo 60/35 P-24. I like both the price and build quality. The performance allows you to take a shower while the washing machine is running. The absence of a check valve in the kit is annoying, which, however, is typical for all models of pumping stations.

Pumps and ejectors

Pumping equipment can be:

- Centrifugal. Inside the chamber there are two parallel wheels that rotate and, with the help of blades on them, set the liquid in motion. This type is the most popular.

- Vortex. It implies the presence of a working area in the form of a ring. While moisture flows through it, it swirls in vortices.

An ejector is a mechanism inside a pump that operates using differential pressure. Due to the narrowing of the shape, a change in atmosphere occurs and, as a result, the working medium is forced to be sucked into the pipe. It is connected according to this scheme: