ABICOR BINZEL offers proprietary, reliable plasma cutters with liquid and air cooling systems that contribute to consistent high quality work and excellent results. By design, they are extremely durable, provide excellent cooling, which guarantees a long service life of the products themselves and their replacement parts, which wear out over time and require replacement. For high-amperage loads, the company offers optional plasmatrons that can be operated with non-contact ignition of the arc using a high-frequency discharge.

Design and principle of operation of a plasma cutter

Plasma cutting equipment consists of:

- power supply;

- burners;

- ground cable;

- compressor or compressed air cylinder.

The power source is an inverter that produces direct current, which has previously been converted several times with an increase in frequency. To connect, you need 220 or 380 V, depending on the characteristics of the device. At the output, the device produces a voltage of up to 400 V and a current of 25 to 125 A. The burner in such equipment is called a plasma torch. It has a nozzle and a button to start the power supply. The plasma torch can be manual or automatic on a bracket with rails.

Components of a plasma cutter.

Plasmatron device.

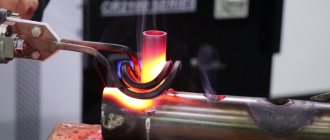

The principle of operation of a plasma cutter is to excite an electric arc into which compressed air is supplied. When heated, it turns into plasma, which is used to cut all types of metals and even ceramics. The plasma temperature is about 20,000 degrees, which is 6 times higher than oxygen cutting.

Plasma also has a high cutting speed of 1500 m/s, which a gas-oxygen flame, which cuts due to a pressure of 10 atm, does not have. from a cylinder. These arc characteristics provide a clean cut, a narrow edge and a minimum of slag on the back of the part.

For cutting with a plasma torch, the following processes are carried out in the equipment:

1. The current source supplies voltage to the cathode and anode located in the plasma torch nozzle. An electric arc occurs between them. At the same time, compressed air is supplied from the compressor and passed through a filter drier. The air passing through the arc is ionized and turns into plasma. This arc is called the duty arc and burns only on the plasma torch.

Operation of a plasma torch.

2. The welder then brings the torch to the workpiece. Thanks to the ground cable, which carries a positive charge and is connected to the product, the arc closes on the material. The pilot arc becomes cutting. The welder controls the torch and cuts along the intended contour. The plasma length and width can be adjusted by the current strength and the diameters of the installed nozzles.

3. When the cutting is completed, the welder removes the torch from the workpiece and the pilot arc lights again. By releasing the button, it is extinguished and air is supplied for some time to cool the nozzle.

Scheme of operation of a plasma cutter.

Benefits and Features

The plasma cutter is easy to use; it is easy to replace parts that have already served their useful life, including the insulator. There is a huge range of wear parts available on the market for these products. The use of products from inexpensive manufacturers is not recommended. Because of them, an unclean plasma arc can result, which can lead to a slanted cut edge. It is better to use products from ABICOR BINZEL. Thanks to a wide selection of consumables and accessories, these cutters are very popular.

Reliable design and optimal cooling system for cutters and their consumables are the key to their long service life. The cutter handle has a long switch, thereby providing a reliable and safe distance of the hand from the cutting area and creating increased comfort for work. Parts that tend to wear out quickly are easily replaced with new ones. The wide variety and volume of consumables and other accessories for this device allow you to solve many important problems.

Plasma cutting torches from ABICOR BINZEL are very popular all over the world and have earned the love and trust of professional welders.

Buy a plasmatron:

8

Scope of application, pros and cons of plasma cutting

Equipment for plasma cutting of metals is used in factories and private workshops. It is used to cut sheet iron with a thickness from 1 to 100 mm (depending on the power of the machine). Plasma can be used to cut out complex patterns, burn holes, and cut edges. Subsequent blanks are used for welding to other structures or are subjected to turning or stamping. Unlike oxygen flame, plasma cuts all types of metals and ceramics, so its functionality and application area are wider.

To decide whether you need a plasma cutter, consider the advantages and disadvantages of such equipment.

The main advantages of this cutting method include:

High cutting speed

Thanks to a temperature of 20,000 degrees, a plasma cutter can cut workpieces much faster than other methods. For example, a sheet with a cross section of 25 mm can be cut at a speed of 1000 mm/min.

Fast through-burn

If you want to start cutting not from the edge of the sheet, but in the center, then the plasma will burn through a thickness of 15 mm in 2 s, and a gas-flame cutter will take about 30 s.

Minimal heating of neighboring areas

Plasma acts precisely on the metal without heating the surrounding surface. This reduces the amount of deformation and allows you to hold large workpieces with gloved hands, turning them as necessary.

High cutting quality

After the plasma, there are almost no leaking drops of slag left on the back side of the workpiece. The edges contain a minimum of relief, so they do not require processing - subsequent welding of the structures can be performed immediately. If you need to cut thin sheets of 1-2 mm, then they can be grouped on top of each other and done all at once - the workpieces will not stick to each other at the edges.

An example of metal cut with a plasma cutter.

Safety

This equipment does not use flammable gases. The use of compressed air or inert gases makes the process safer - there will definitely not be an explosion, as in the case of a backlash of flame in an oxygen cutter.

Ease of use

Unlike flame cutting, there is no need to adjust the supply of flammable gas and oxygen separately, and then also adjust the flow of cutting oxygen. Everything is turned on with one button and can be quickly mastered even by a beginner.

Possibility of automation

The plasma cutter can be easily equipped with a bracket (portal or console type) so that it automatically moves over the product. Control is carried out with CNC. In it, the operator sets the configuration and cutting speed, while one person can simultaneously monitor the processes on five installations.

Minimum preparation before the process

Plasma can cut any metal without first cleaning it from dirt or rust. There is no metal splashing or air popping during operation.

But this cutting method also has disadvantages that you need to know in order to choose a plasma cutter wisely and not be disappointed.

Here are the most basic disadvantages of the devices and the method itself:

- The best cut quality is achieved by holding the torch at an angle of 90 degrees to the surface. Only expensive models can cut a chamfer at an oblique angle.

- It is difficult to heat metal with this equipment to perform bending or forging.

- The maximum cutting thickness is 100 mm, while flame cutting can cut 200-300 mm.

- The equipment itself is more expensive. You will also need a compressor. The price of argon is higher than propane or oxygen.

- The devices depend on the electrical network. To work in the field, a gas generator is required. Its power must be high enough to cover the needs of the plasma cutter and compressor.

Look what a plasma cutter can do:

Types of plasma cutters

Understanding the principle of operation of a plasma cutter and its design, let’s consider the types of equipment. This will help determine the details of the choice for specific production tasks.

Plasma cutters by cutting type

Plasma cutters can be manual or automatic. It is important to take this into account when choosing so that the equipment is suitable for the upcoming processes.

Plasma cutters for manual cutting

Used to work with small sections 1-10 mm. This is relevant for garages and small workshops where doors, gates, gates, and barbecues are made. They are convenient for cutting holes, cutouts for locks and hinges, and cutting blanks for canvases and bent boxes. More expensive equipment can cut through 10-30 mm.

This expands the scope of use and is suitable for cutting workpieces for subsequent mechanical processing in production (manufacturing flanges, shafts, cutting pipes, etc.). Such installations are mobile and convenient.

Plasma cutter for manual cutting.

Plasma cutter for automatic cutting

Used with cutting heads moved on portal or console type brackets. CNC controlled. They can simultaneously cut with 2-4 heads at once. Suitable for cutting parts with dimensions from 1x1 to 3x30 m. They require sufficient space and are difficult to transport.

Plasma cutting machine.

Plasma cutters by type of gas used

To operate a plasma cutter, air is needed to ionize in the electric arc. There are two types of equipment here:

Compressed air plasma cutters

Household and semi-professional class. They are cheaper, easy to control (only the current strength is adjusted), and universal. Very small devices are designed for cutting sections up to 10 mm. More powerful ones can handle 12-25 mm. The main advantage is inexpensive maintenance (price of nozzles, one-time purchase of a compressor). Subsequently, you won’t have to buy anything expensive.

Plasma cutters using argon, oxygen, nitrogen or mixtures thereof

Used on large plasma cutting machines. They require lengthy adjustments, but are able to perform cuts faster, more accurately and more complexly. It is necessary to regularly spend money on purchasing gas cylinders. This type is suitable for large enterprises with a large volume of products.

Argon plasma cutting machine.

Plasma cutters based on arc ignition type

Plasma cutters are also divided according to the method of exciting the electric arc:

- Contact. This type of ignition is found in household inverters. The plasma torch nozzle must touch the product to which the mass is connected. The simple design of the burner is less likely to break, but the nozzle becomes covered with scale faster.

- Pneumatic. They form an arc independently when gas is supplied (without touching the product). This is convenient for frequent moving and making small cuts. Saves nozzle life and increases productivity.

- High frequency (HF). The most comfortable type of ignition, achieved using an oscillator. The arc is excited by a high-frequency pulse between the cathode and anode in the nozzle. When brought to the product, it automatically switches to cutting. The ignition type is suitable for precisely starting the cut so that no electrical traces are left on the workpiece.

Plasma cutters by cooling type

Air

Used in household and semi-professional models. Heat from the burner is removed naturally into the surrounding air. Inside, the channels are cooled due to the supply of oxygen or inert gas. In the case itself there is a fan that blows air over the transformer and the rectifying unit. Periodic breaks will be required during operation to avoid melting the nozzle.

Air-cooled plasma cutter.

Liquid

Used on industrial versions of equipment. The plasma torch has channels through which, using a water pump, distilled water and ethyl alcohol circulate. This quickly absorbs heat and allows the device to work without interruptions. Suitable for large-volume tasks or operation of a plant in two shifts.

Kinds

ABIPLAS CUT plasma cutters are available in manual and mechanized versions and are used for plasma cutting using compressed air. The latter plays a plasma-forming and cooling role. The product is intended for individual use in continuous operation, even under difficult conditions. Can be used in any cutting position that is commonly practiced and most common in this area.

ABICUT are plasmatrons that are cooled by air flow. They are used for plasma air cutting. The applied current can range from 20 to 75 A. The product allows you to obtain high quality cutting, it is highly durable and maximum ease of use. The system works optimally in any cutting position without losing its positive properties.

This plasmatron fits comfortably in the palm of your hand, which contributes to high quality work, allowing the master to perform all actions accurately and efficiently. The structure of its handle allows you to work for a long time without getting tired. Innovative protection against self-starting ensures maximum safety of the device, and the reliable design of the product and cooling capabilities are the key to its long service life.

How to choose a plasma cutter

When choosing a plasma cutter, there are several key characteristics to consider.

Thickness of cut metal

This parameter directly depends on the current strength (number of amperes) generated by the inverter. If you need to cut ferrous metal, then for every 1 mm of thickness you will need 4 A of power. For example, to cut 7 mm sheet iron, look for a machine with a current of at least 30 A. For non-ferrous alloys, the calculated value is 1 mm = 1.5 A.

There is also the concept of finishing cut and maximum cut. For example, the first value in the characteristics may be 12 mm, and the second - 18 mm. This means that for thicknesses up to 12 mm no subsequent machining is required at all. It is better to take a plasma cutter with a power reserve so that it does not work at full capacity all the time. This will extend its life.

| Type of metal | Current required to cut a workpiece 1 mm thick |

| Copper, brass, aluminum, copper alloys | 6 A |

| Stainless steel, ferrous metals | 4 A |

Duration of activation

This indicates how long the device can operate without interruption. Depends on the power and type of cooling. For a garage and a small workshop, installations with a duty cycle of 40% are suitable. For production where plasma cutting of workpieces is often required, choose a duty cycle of 60-80%.

Required compressor power

In order for plasma cutting to be of high quality, a stable air supply from the compressor is necessary. Its performance should be 20-30% higher than required according to the inverter's passport. Buy a compressor with a filter drier and an oil separator so that impurities do not affect the quality of the plasma.

Hosepack length

For a plasma torch, the cable length can be 1.5-8 m. When choosing, consider the size of the structures you will have to work with. The shorter the hose package, the more often the device will have to be rearranged. But if it is required for cutting out small parts above the table, then you can save money and buy a plasma torch with a short cable.

Video. How to choose a plasma cutter

The best plasma cutters

Having studied the characteristics of the equipment and tips for choosing, let’s move on to the rating of the best plasma cutters, based on reviews of welders. Perhaps here you will find a device suitable for yourself and go to the store for a specific product.

Aurora PRO AIRHOLD 42 Mosfet

The rating was topped by a plasma cutting machine with an affordable price. Its dimensions are 40x16x30 cm. It operates on a single-phase 220 V network and consumes 6.6 kW. The maximum current strength of 40 A allows you to cut thicknesses up to 12 mm without subsequent stripping. PV at maximum up to 60%. The inverter is suitable for cutting cast iron, alloy and carbon steel, copper. To ignite, you need to touch the nozzle to the surface of the part. The equipment weighs 9 kg, so it is not difficult to transport.

Watch the product video

Pros of Aurora PRO AIRHOLD 42 Mosfet 16337

- A convenient device with good build quality.

- Affordable price.

- The nozzle does not wear out for a long time (it just turns black).

- Clear control panel.

- It's easy to buy consumables.

- Rigid handle on the lid.

- The iron corners are covered with plastic.

Cons of Aurora PRO AIRHOLD 42 Mosfet 16337

- Contact type of ignition.

- If you buy a burner with an oscillator separately, there is no standard connector for connection.

- Sensitive when the mains voltage drops to 190-200 V.

- Above a thickness of 10 mm, the cutting speed drops significantly.

- You need a compressor with a capacity of at least 350 l/min (otherwise it will be enough for a 5 cm cut and the air will run out).

Conclusion. This plasma cutter is distinguished by a long standard torch with a cable channel of 5 m. Great for working with large workpieces in production and in the garage. Judging by the reviews of welders, the device easily lights an arc in cold temperatures down to -20 degrees. If you often have to cut metal on the street, then this is the best choice.

BRIMA CUT-40

Another professional plasma cutter in the rating at an affordable price. It has a maximum current of 40 A, which is enough for a clean cut of 12 mm. Belongs to the semi-professional class. Powered by 220 V with a power consumption of 5 kW. According to the passport, a compressor capacity of 170 liters of air per minute is required. PV at maximum reaches 60%. To initiate an arc, you will need to touch the product. It is not difficult to store and transport the inverter due to its dimensions of 44x16x31 cm. The device uses air cooling. The case has numerous holes and a built-in fan.

Watch the product video

Pros of BRIMA CUT-40

- Light weight 10 kg and rigid handle.

- Durable steel body.

- Clear control panel.

- Consumables available.

- The kit already includes three nozzles and three electrodes.

- It punches holes through paint well.

- Cuts thickness up to 3 mm very quickly.

- There are almost no slag leaks on the “ten”.

Cons of BRIMA CUT-40

- There is no Euro connector for replacing the burner with a higher class model.

- Contact ignition of an electric arc.

- The nozzle deteriorates quickly.

- The drain from the built-in dryer is located next to the cooling fan (it receives splashes).

Conclusion. This plasma cutter has a very compact plasma torch. If you need to dismantle metal structures and crawl into narrow places to cut racks, shelves or other elements, then this torch is suitable. The head is equipped with a short ceramic nozzle with an angle of 100 degrees. The cutter is comfortable to hold.

Resanta IPR 40

Next in the ranking is a product from a Latvian brand assembled in China. The inverter-type plasma cutter is made in a steel case and is air-cooled. There is a pressure gauge on the front side, so the welder does not need to look at the indicators on the compressor. The plasma torch has a soft clamp that makes it easier to hold the start button pressed during long cuts. The device is powered from a single-phase network and produces up to 40 A. PV is allowed at 35%. A pressure of 5000 bar is required for a quality cut. The thickness of the clean cut is 12 mm.

Watch the product video

Pros of Resanta IPR 40

- Loops for winding the hose package. Reliefs on the plasma torch handle, making it easier to hold and manipulate. Smooth current adjustment from 15 to 40 A. Built-in pressure gauge to control the pressure in the system - no need to look at the compressor. With steel thickness up to 5 mm, it cuts very confidently. Any service center has spare parts for it.

Cons of Resanta IPR 40

- Relatively high cost. Euro connector missing. The quality of the cut is worse when the network voltage drops. A powerful compressor is needed. Sometimes the mass clamp on the product does not fit well.

Conclusion. This plasma cutter features an arc on/off function at 5 second intervals. This mode is useful for quickly cutting mesh. The welder does not need to press the button often, which saves its resource. The speed of cutting such materials with an intermittent arc is much higher than if you had to set it on fire every time, hitting thin wires of the mesh.

BlueWeld Prestige Plasma 54 Kompressor

The rating continues with products from the Italian brand. The plasma cutter has a current range of 7-40 A and is capable of cleanly cutting metal sections up to 10 mm. It consumes 4.5 kW, but welders share in reviews that the device can operate even from a generator with a capacity of 3 kW. The power supply weighs 16 kg. The length of the plasma torch cable is 4 m. The unit operates not very noisily and is easy to transport. The dashboard has an indication of mass, network and overheating.

Watch the product video

Pros of BlueWeld Prestige Plasma 54 Kompressor 815725

- Ergonomic burner handle.

- There are slots for attaching a shoulder strap - you can cut at height.

- The controls are protected from accidental changes to settings.

- Start button lock in clamped position.

- You can lower the current to 7 A to accurately cut 0.6-0.8 mm thick sheet metal.

- The length of the cable package is 4 m.

- The brushless compressor motor will last a long time.

Cons BlueWeld Prestige Plasma 54 Kompressor 815725

- The burner nozzle is longer than other models.

- There is no rigid handle.

- High price.

- No EURO connector.

- PV 30% - after cutting 1.5 m, you have to let it cool for up to 20 minutes.

- Larger sizes 51x17x34 cm.

Conclusion. The peculiarity of this plasma cutter is already clear from the name. It has a built-in compressor designed specifically for the arc. By purchasing it, you get everything you need in one package for plasma cutting. This simplifies transportation and is useful for mobile work (field teams for on-site installation/dismantling, construction of metal structures). With it you can even cut something at a height, because you don’t need to drag a separate compressor or a long hose behind you.

Plasma torch device

The design of a plasma torch for cutting metal is represented by the following structural elements:

- Electrode/cathode with an insert made of zirconium or hafnium - metals with high thermionic emission

- Plasmatron nozzle, usually isolated from the cathode

- Mechanism for swirling plasma-forming gas

Nozzles and cathodes are the main consumables of plasma torches. When the thickness of the metal being processed is up to 10 mm, one set of consumables is enough for one work shift – eight hours of work. The nozzles and cathodes of plasma torches, as a rule, wear out at the same rate, so their replacement can be organized at the same time.

Untimely replacement of consumables can have a great impact on the quality of the cut: for example, if the geometry of the nozzle is violated, the effect of an oblique cut may occur, or waves will appear on the cut surface. The wear of the cathode is expressed in the gradual burnout of the hafnium insert, the production of which in a volume of more than 2 mm contributes to the burning of the cathode and overheating of the plasma torch. Thus, untimely replacement of worn-out consumables entails faster wear of the remaining components of the plasmatrons.

To protect the plasma torch from splashes of molten metal and metal dust during operation, a special casing is put on it, which must be removed from time to time and cleaned of contaminants. Failure to use a protective casing leads to the risk of a negative impact of the above contaminants on the quality of operation of the plasma torch and even to its breakdown. In addition to cleaning the casing, it is worth cleaning the plasma torch itself from time to time.

You can learn more about plasma cutting technology by watching the following video: