A common tool is an impact driver. It is important to understand what the advantage of the product is and the difference from a conventional design, why professionals choose an impact-rotary device and how to choose the right high-quality model in order to use it for many years.

What is an impact screwdriver?

This is a tool adapted for a specific type of work. A power screwdriver is a general technical mechanical device that is correctly called an impact screwdriver. It is used both in production and at home for carrying out household repair work. The range and functionality of such tools is regularly expanded.

Impact screwdriver device

The unit is simple in design and consists of a few parts. Describing what an impact screwdriver looks like when assembled and disassembled, we note that the main part is made of high-strength steel. The handle may have a rubber pad to prevent the device from slipping in your hand. The internal part consists of a washer, a cotter pin that controls the mechanism, an axis for replacing the lever, a spring and two steel balls. The end of the handle has a flat shape; a sting is installed on a removable section of the tool. Modern types of screwdrivers are equipped with reverse. The kits contain long or simple 25 mm bits from 2 to 6 pcs.

Working principle of an impact screwdriver

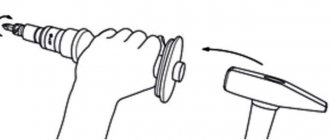

A simple mechanical tool is easy to use. You need to find out how an impact screwdriver works, what the mechanism of action is. The use of the unit does not require special knowledge and skills. Anyone can use the device. The tool is installed at a right angle with a tip into the thread of a screw or bolt. Using a neat, precise movement, strike the outer base of the screwdriver with a hammer. Upon impact, the thread on the nut rotates 1-2 mm towards its axis. Apply several shock-turning movements to unscrew the stuck fastener.

Advantages and disadvantages

Having analyzed a tool such as an impact screwdriver, you should note all its advantages and disadvantages. Based on these criteria, appropriate conclusions can be drawn about the benefits and necessity of such a device.

An impact screwdriver is the best assistant for a car mechanic.

The advantages of impact devices include:

- Instead of applying physical force in the form of turning the handle of a screwdriver, impact energy is used, which is tens of times more effective than a conventional product

- High speed of unscrewing fasteners

- No need to drill out hardware that cannot be unscrewed

This is interesting! It is impossible to unscrew a rusty screw using a screwdriver or drill, since the torque reserve of these tools is not enough to set a strong connection in motion.

Among the disadvantages of an impact screwdriver, the following factors can be noted:

- Although the tool is designed to be impacted, this will shorten its service life. The harder the hammer hits, the higher the likelihood of breaking the reciprocating mechanism.

- Wear. Depending on the quality of steel used for the production of the device in question, the service life will differ

If you are planning to purchase an impact screwdriver that will definitely not lie idle, then you need to know that the cost of an average quality set starts from 3,000 rubles. The tool in question is also sold separately without bits, and its cost in this case starts from 1000 rubles. In the video below you can familiarize yourself with the design of a Chinese impact screwdriver, as well as the operating features of the tool.

What is an impact screwdriver used for?

Each technical tool has its own functional purpose. An impact rotary screwdriver is used to unscrew fasteners. Improved models with installed reverse not only remove screws, but also tighten self-tapping screws. The manual mechanism is used in metalwork and the automotive industry. The impact-rotary design is successfully used at home when repairing sanitary equipment. A steel impact screwdriver is effective for disassembling motor engines.

Flexible screwdrivers

This unusual tool, instead of a classic rod, has a flexible shaft that allows unwinding and twisting at almost any angle. This model is produced in two versions:

- a screwdriver with a flexible rod made of elastic materials;

- an analogue of two rigid rods connected by a hinge.

How to choose an impact screwdriver?

Construction markets and hypermarkets offer a huge selection of tools of various profiles. If you don’t know which impact screwdriver to choose for daily professional use, then before purchasing you need to familiarize yourself with the options and brands offered by the manufacturers. Recommendations for selection:

- Decide what purpose you need the screwdriver for. For daily use, purchase a tool with a powerful handle in a rubber casing.

- Models with reverse perform two functions: mounting and dismantling the mount.

- A set with a large number of different attachments is suitable for professional activities.

Impact screwdriver bits

Included with the tool, depending on the model and brand of the manufacturer, from 2 to 20 bits of different formats are offered. The impact rotary screwdriver is equipped with two types of attachments: Phillips and flat. The composition from which the nozzle is made is of great importance during operation. Nickel and chromium bits have increased strength and a long service life. Nozzles made from low-quality raw materials become deformed and break when used. The cost of hand tools depends on the material, number of bits, and manufacturer.

Tools

0 votes

+

Vote for!

—

Vote against!

Very often we have to unscrew rusted bolts or screws. An ordinary screwdriver is practically useless in such cases. Even if you try to unscrew it with a simple screwdriver, you are guaranteed to knock off the tip and render it unusable. In this case, an “unusual” screwdriver comes to our aid, namely an impact screwdriver . Let's talk about it...

In appearance, you can immediately distinguish an impact screwdriver from a regular one. The drum has a reinforced steel body and is several times larger than its “brother” in size. The kit usually includes 2 or 4 bits (cross and flat). The bits are inserted in the same way as into a regular screwdriver.

The impact screwdriver has a torsion switch (reversible), usually you still use it to unscrew it, but if you need to tightly tighten any part, the reverse will come in handy.

Table of contents:

- Operating principle

- Impact screwdriver FORCE

- Stayer Impact Screwdriver

- Topex impact screwdriver

- Screwdriver Jonnesway SL 9.11mm

- Conclusion

Operating principle

The principle of operation of an impact screwdriver is very simple - during an impact, the bit rotates in the required direction, and not at all by much (1-3mm), but these millimeters are quite enough to knock off a stuck bolt. Next, you can use a regular screwdriver. The main purpose is the initial phase of unscrewing, when it is impossible to do it manually.

How to use an impact screwdriver? Having previously set the reverse on the screwdriver, carefully place the bit on the stuck bolt and start hitting with a hammer until the bolt moves from its dead point. If you have a screwdriver on your household, it can easily replace an impact screwdriver. As you can see, the impact screwdriver works simply and effectively.

Each tool usually comes with instructions, and an impact screwdriver is no exception. But often such instructions are written in a foreign language. In this case, you can download the instructions for the impact screwdriver on the Internet, there are plenty of them here.

Impact screwdriver FORCE

FORCE impact screwdrivers are widely used not only by ordinary users, but also by professionals who need an effective impact screwdriver for every day. One of the well-known models on the Russian market is FORCE 5064. Let’s take a look at it.

FORCE 5064

High quality impact screwdriver, renowned for its ability to withstand very heavy loads. Such loads include working with a tool at heavy industrial enterprises, service stations, car service stations, etc. But it is also irreplaceable in daily use.

If you want to purchase a tool that will last for years and at the same time be simple and effective, FORCE 5064 is exactly what you need.

By looking at the photo of an impact screwdriver you can visually assess its power.

Stayer Impact Screwdriver

German goods have long been known among our citizens as high quality and safe, with all the attendant consequences. Despite the slightly increased price, they are in great demand among all segments of the population. The German company KRAFTOOL was no exception. This company occupies a leading position in the world of building materials.

Stayer 2565-H6

An impact screwdriver for installing and dismantling threaded connections copes well with the tasks and is superior to many analogues. Hardened impact bits made of chrome vanadium steel are capable of unscrewing stuck bolts very well for a long time.

The screwdriver kit includes 4 36mm bits and 2 75mm bits. The price is higher compared to the Chinese counterpart, but the quality is worth it.

Topex impact screwdriver

TOPEX is a Polish company producing tools for construction. This is one of the few companies that produces more than one and a half thousand products in the “hand tools” category. The majority of tools (a screwdriver is no exception) are intended for amateur use, and it is highly not recommended to use tools of this brand at a professional level.

The availability of products of this TM makes the products even more popular. TOPEX brand tools can be purchased both in small construction tool stores and in large supermarkets.

Impact screwdrivers TOPEX x6

A set of TM TOPEX impact screwdrivers consisting of six different screwdrivers will help you unscrew any necessary bolt. High quality CrV steel protects your screwdriver from damage, thereby preserving and extending its service life. The hardened magnetic tip greatly simplifies the operation of the tool. This type of screwdriver is intended for household use, but they have also performed well in heavy industry.

Screwdriver Jonnesway SL 9.11mm

The Jonnesway SL 9.11mm impact screwdriver is a universal tool that is designed to work in both domestic and heavy-duty industrial environments. The tool has a good price/quality ratio. The screwdriver has a long service life and excellent performance. Professionals often resort to the Jonnesway model because it meets all their expectations.

Conclusion

The choice of impact screwdrivers on the market is limitless, so everyone will choose a tool for themselves. Here is a list of the most popular and in-demand screwdrivers, but in reality it is much more. When choosing an impact screwdriver, pay attention to brands, they may be a little more expensive, but they will exceed all your expectations. And among the cheap options there are decent ones, but there are very few of them. Therefore, do not spare money on construction tools, because the stingy pays twice.

Finally, watch the video about impact screwdrivers

Impact screwdriver rating

A professional needs to have a high-quality, durable tool in his arsenal. Before purchasing, in order to choose a model suitable for the job, you need to familiarize yourself with the characteristics of the proposed product. Review of popular manufacturers of reversible impact screwdrivers:

- NORGAU - made of chrome-molybdenum steel, strong, has a long service life and two types of bits: slot and hex.

- FIT

- reversible screwdriver with straight and Phillips slots, made of high carbon steel with a rubber handle, has 6 types of bits. - Stayer

- a screwdriver from a German manufacturer has two types of hardened impact bits. - VIRA

is a product made of chrome vanadium steel with a strong rubber layer on the handle, and comes with 6 attachments. - TOREX

- country of manufacture Poland, the screwdriver is equipped with a magnetic tip, used in everyday life. - Jonnesway impact screwdriver

- made of high-strength steel, equipped with a faceted attachment for turning with an open-end wrench, has a comfortable rubber handle, the manufacturer guarantees a long service life.

Indicator screwdrivers

They are an indispensable tool for measuring electrical network parameters, but are not suitable for power work. The product has a special indicator built into the cavity of the handle, which allows you to determine whether the object is energized. Electrical screwdrivers can be contact or non-contact (highly sensitive), when, for example, you need to find current-carrying wires under a layer of plaster.

Types of indicator screwdrivers:

- with neon light;

- with LED (for working with electrical networks, voltage up to 60V);

- with LCD display (digital indicator screwdriver);

- universal, equipped with a display, as well as sound and light indicators;

- on batteries.

How to use an impact screwdriver?

When performing any repair or technical work, safety precautions must be observed. There are recommendations on how to properly use an impact screwdriver when loosening a screw. In order for the purchased tool to serve for a long time, you need to read the operating instructions and follow all the advice.

- Prepare your tools: impact screwdriver, set of bits, hammer.

- Wear gloves when working to prevent injury and contamination.

- Check the new screwdriver for grease; if the mechanism is dry, lubricate it with MC1000 grease.

- Insert the required bit size into the connecting part.

- Clean the screw cap from dust and dirt.

- Place the blade of the screwdriver into the screw thread perpendicularly, at a right angle.

- Using a not very strong blow of the hammer, apply a pointed blow to the heel of the screwdriver.

- Repeat several times so that the clip moves along its axis.

- When the screw moves freely, unscrew the screw with a screwdriver.

Some tips for choosing

When choosing a tool, it is important to pay attention to the design of the screwdriver. The quality of the rod can be checked by the presence of factory markings. The tip tends to be darker than the shaft, indicating the presence of chrome vanadium or molybdenum alloys. A long rod will help you deal with fasteners that are impossible to get to. The tip can be made of a magnetized alloy, which helps to hold the loosened bolt or screw without using your hand. When it comes to the handle, ergonomics are very important when working with any plumbing tool, as it affects efficiency and comfort.

When choosing the handle of a regular screwdriver, you need to consider several factors:

- the handle should not be slippery so that a sweaty hand does not slip at the most crucial moment;

- a short handle will allow you to cope with fasteners that are difficult to unscrew;

- The handle material can be different (metal, plastic, wood or rubber);

- if the handle is made of rubber, then it is important to make sure there are no microcracks or unnecessary sagging;

- For hanging storage, the handle may have a hole.

In addition, the handle can be one-component or two-component (with an overlay). The anti-friction coating can occupy only part of the handle or cover it completely.

DIY impact screwdriver

Many craftsmen use household appliances that have expired to make necessary items and products. Do-it-yourself impact screwdriver from a starter - step-by-step manufacturing algorithm:

- Equipment required for the work: angle grinder (angle grinder), bench vice, lathe, cutter, welding, drilling device with a drill with a diameter of 5 mm, tap with M6 thread, core, M6 screw, boring cutter, old machine starter, wrench with tetrahedron, a metal tube equal in diameter to the bendix, 2 springs, iron balls, a metal washer, a hammer, tape, a bottle of hammer paint, gloves, glasses.

- Clamp the anchor in a vice.

- Press out the stem.

- Wear safety glasses.

- Saw off the part with the splines from the bendix using an angle grinder with a cutting disc.

- Cut the angle grinder's tetrahedron from the driver.

- On a lathe with a boring cutter, make a step on a round metal blank for installing the Bendix spline.

- To secure the rod, clamp the main part in a vice.

- Using a drilling machine, make a hole with a diameter of 5 mm for the screw.

- Clamp the part in a vice.

- Check that the screw is screwed in.

- Tighten the rod in a vice.

- Use an angle grinder to make a middle groove.

- Install the splined part into the base.

- Clamp in a vice.

- Weld the parts together.

- Tap the seam with a hammer to remove slag.

- Clamp the part into the three-jaw chuck of the lathe.

- Remove weld marks using a through cutter.

- Clamp the rod with the tetrahedron on in a vice.

- Weld the parts.

- Remove uneven seams.

- Weld a thick washer flush against the slots.

- Grind it on the machine.

- Collect all the parts.

- Cover the tetrahedron and spline part with masking tape.

- Paint with hammer paint.

- After drying, install a ball with a spring to fix the nozzles.

Clock screwdrivers

Such tools are also called precision screwdrivers. Miniature hardened tips allow you to work with electronics (laptops, mobile phones, joysticks and game consoles, as well as a variety of photographic equipment), watches, compact household appliances and other products. To avoid making a mistake with the slot size, it is recommended to purchase a set of such tools.

How to disassemble an impact screwdriver?

The simple device is not difficult to assemble and disassemble. The flat impact screwdriver is easily folded into parts and stored disassembled in a special case with a set of attachments. Algorithm for disassembling an impact screwdriver:

- pull the bat out of the handle with a turning motion;

- pry up the ring with a screwdriver or knife and carefully remove;

- a movable device in the form of a V-shaped groove remains on the handle;

- Inside the movable device there is a spring and balls that can be easily removed.

Dielectric screwdrivers

To protect an electrician from electric shock, screwdrivers are used that have a plastic or rubber handle (a thick layer of carbonate coated with polyformaldehyde), as well as a special dielectric coating of the rod up to the tip. Screwdrivers with a dielectric handle allow you to work with hardware under voltage up to 1000V (as a rule, the marking contains information about the voltage limits).

How to replace an impact screwdriver?

Is there an analogue that allows you to replace the tool? An impact Phillips screwdriver is considered a universal device for unscrewing and tightening old fasteners. The design of the device is convenient for use, does not require much effort, is compact, lightweight, and affordable. You can replace the screwdriver with an electric impact wrench, but this tool is not affordable for everyone and is only needed for a professional. An impact flat-head screwdriver cannot be replaced with a screwdriver, since the functional properties and principles of operation of the tools are different.

Simple screwdrivers

This group is represented by classic specimens that have a tip with a cross-shaped or flat (straight) slot. The only drawback of a flat-head screwdriver is that it works in one plane, which is why the tip can jump out and damage the surface of the device or object. The Phillips head screwdriver provides a tighter torque and is self-centering. It is noteworthy that the vast majority of structures are fastened with hardware with exactly this type of slot.

There is a popular variation of the simple Phillips head screwdriver that features a redesigned tip (Pozidrive). This slot is distinguished by additional four edges and a deeper fit. There are other forms of slots, intended mainly for repairing expensive branded devices or installing items with anti-vandal protection.

Tool characteristics

If you want to buy an impact screwdriver, then you need to understand some of the nuances and key technical characteristics of the tool, as well as the configuration of specific models.

Reference. First of all, pay attention to the metal from which it is made. Trusted companies never use poor quality steel. But products from China can sometimes be made from low-grade metal. Therefore, avoid fakes, since at the first blow the instrument may either become deformed or simply crumble in your hands.

The next thing you should pay attention to when purchasing this instrument is the presence of reverse. It greatly expands the basic capabilities of a screwdriver, allowing you to both twist and tighten fasteners.

The next important aspect is the design of the handle. It is designed to hold the tool and strike it. If it has a special pad (it can be made of rubber, polyurethane or polyethylene), then it will be much easier to hold the screwdriver during impacts. If the lining has a “tide”, this will increase safety during operation.

Most often, the dimensions of the handle may differ from each other, and there are several important nuances here:

- if the handle is of a standard size, then it has high strength, but it cannot be used in cramped conditions;

- if the handle is slightly smaller than the standard size, then it can work in extreme conditions and in limited space - however, in this case the reliability of the tool suffers.

When choosing an impact driver, weigh the pros and cons, and only then make a purchase.

Modern impact screwdrivers are equipped with a set of different attachments, without which this tool becomes simply ineffective. Included are:

- cartridge holder;

- universal nozzles.

The set is replete with attachments for different splines and hexagons. When purchasing these elements, always pay attention to their quality, since this is an important nuance that determines the reliability of the tool and its service life.