If you want to know how much oxygen cylinders weigh, what types they come in, their volumes and sizes. You will find all this in our article, and also learn how to find out the amount of oxygen in a cylinder and the features of cylinder inspection.

Oxygen is used in various fields of activity: construction, industry and medicine. Stored and transported in special oxygen vessels, the weight of which is a key parameter.

All characteristics of oxygen containers are usually written on the body of the product, where there is information about the weight of the tank in kilograms, a special trademark of the manufacturer, its own unique number, the number of further maintenance, maximum pressure and displacement.

Characteristics of an oxygen cylinder.

Oxygen-containing containers are needed for containing and transporting gas. The tank is painted with blue indelible paint with the signature “OXYGEN”. The vessel has a volume of 40 liters and is made of steel. The normal pressure of a gas cylinder is from 9.8 to 9.6 MPascal. The container has a total diameter of 219 mm and a length of 1350 mm.

The weight of a 40 liter oxygen cylinder can reach up to 51 kilograms without valves, caps and other devices. The neck thread complies with the standards, and the valve is installed using a special seal.

Containers must undergo timely inspection. The main condition is that it must be manufactured with a strength of 65 kilograms per millimeter squared and the surface of the cylinder must be smooth without foreign defects.

Useful article - How to check your NAKS certificate using the register of welders - find yourself by last name on the official website

Maximum oxygen cylinder pressure.

Container pressure is a parameter that is responsible for the volume of gas that the container can withstand. In a tank with a volume of 40 liters, the highest pressure indicator is 150 kilograms per centimeter cubed. Such a tank holds 6 thousand liters or 6 cubic meters. The pressure of a 50 liter oxygen cylinder puts 200 kilograms per centimeter cubed, which is 10 cubic meters of gas.

The oxygen tank pressure may deviate due to increased or decreased temperature. The standard indicator for a gas container is +20 degrees, and at +40 degrees the pressure can rise by 10 Pascal. In turn, at 0 temperature it will decrease by 10, and at -40 it will decrease by 30 Pascal.

When refilling the container, it is important to pay attention to this parameter. It is necessary to use a special formula that allows you to correctly determine the required pressure, and when calculating, take into account all the characteristics of the container model.

Weight of a full and empty oxygen cylinder.

Oxygen-containing containers are manufactured in different volumes, on which, first of all, the weight of oxygen in the cylinder depends.

Empty cylinder weight.

To determine the mass of the remaining gas, you need to know the weight of the container without and with contents. It is impossible to say exactly what the weight of the container is because it can come in different sizes. The weight of an empty 40 liter oxygen cylinder varies depending on the size and substance from which the product is made. The weight of the container, which is made from forty-five d steel, is 58.5 kilograms with parameters of 1370 millimeters and 76.5 kilograms with dimensions of 1430 millimeters. The gas container is made of 30KhGSA steel, has a length of 1350 millimeters, and weighs fifty kg.

Elements that come with a gas cylinder. The weight of an empty oxygen-containing vessel consists of the following elements:

- The gas vessel itself;

- Fan made of brass (0.5 kilograms);

- A cap made of aluminum or plastic (1.8 kilograms);

- Ring for putting on a cap, (0.3 kilograms);

- The shoe is made from steel tape (5.2 kilograms).

The latest equipment gives the structure greater stability.

When producing containers, solid drawn metal tubes are used. The wall size reaches 7 millimeters. A tube of the required length is pressed into a rounded shape and a neck is created, which is needed to install the valve.

A ring is put on the other neck, which is necessary to secure the gearbox. The cap is necessary to protect against technical damage. The components may have a lot of weight, which must be calculated during use.

Useful article - How to properly prepare welding documentation and submit work on time

Weight of a full oxygen cylinder.

To calculate the weight of a full oxygen cylinder, use various special calculations for gas or look at table values. The weight of a full oxygen cylinder is the sum of the capacity and gas pressure. The weight of an empty container from a filled one usually differs by ten kg, and the pressure does not exceed 14.7 MPascal.

An ordinary oxygen-containing container, which is made in accordance with GOST, can hold 40 liters of oxygen. It weighs about 70 kg, and the pressure reaches 19.6 MPascal or 193 atmospheres.

This vessel can hold about 11.5 kg of gas. When adding up all the indicators, the total weight of the cylinder filled with oxygen is from 76 to 86 kg.

Useful article - Certification of welders and specialists: what is it for, how does it happen, types of certification

Oxygen cylinder volumes.

The volume of oxygen in the cylinder varies depending on the purpose and the amount of content that was filled into it. It may depend on the type of gas transportation. Each volatile substance has its own standards for filling containers.

Oxygen cylinder, the volume of which may vary. This depends on the material from which the container is made. Metal containers made of steel can reach a volume of 5 to 50 liters. There are small disposable containers that cannot be refilled.

They are also called cartridges. They are made in the form of steel containers and can hold up to 450 grams of gas.

Dimensions of oxygen cylinders.

The dimensions of steel containers are determined by:

- Gas cylinder volume;

- The thickness of the walls of the vessel;

- Container diameter;

- Container lengths.

All characteristics are measured in millimeters or liters.

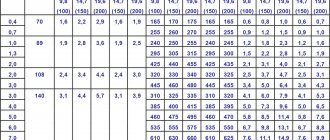

The weight of a standard oxygen-containing cylinder ranges from 9.8 to 93 kg, and may contain dimensions: 70x165, 89x240, 108x310, 140x460, 140x495, 140x610, 219x770, 219x1775 millimeters, where the first number is the diameter and the second is the length.

Safety precautions

The oxygen cylinder design is very simple, but reliable. The main thing is to accurately observe the parameters of the gas pumped inside so that the container does not rupture. During operation and storage, some very strict requirements must be observed.

- If an oxygen cylinder is used in a stationary welding station, then it is installed vertically and secured with a rigid clamp.

- Before installation, the gearbox must be inspected for the absence of grease and oil stains.

- The fitting must be purged, after which the gearbox itself is screwed on.

- After complete extraction of gas, it is necessary to leave some oxygen inside under a minimum pressure of 0.5 kg/cm². The reason is so that filling stations can analyze previously filled gas and compare it with what is available.

- Oxygen must not be transported with other flammable gases.

- At sites, oxygen cylinders must be transported in special trolleys on soft rubber wheels.

- The distance from the installed oxygen container to an open flame source or welding machine is at least 5 meters.

- There must be protection from precipitation and sunlight during prolonged use outdoors.

- If the valve of an oxygen cylinder is frozen, then it should only be thawed with a clean rag soaked in hot water.

- Cylinders should be stored in metal boxes with holes; a lock must be attached.

- A small cylinder must be carried in a special metal box, which is equipped with a handle and a strap for carrying on the shoulder.

Refilling with oxygen is a complex process, because it is the gas that is pumped into the welding cylinders. And it reaches the distribution station in a liquid state. Such oxygen is much safer than gaseous oxygen, but it evaporates quickly and in large quantities, which is not profitable financially. But manufacturers take such losses because safety comes first. Moreover, liquid oxygen is transported in large quantities (road and rail tanks). If such a volume catches fire and explodes, the losses will be several times greater.

Gas is pumped into cylinders using pumping and pumpless methods. In this case, filling does not occur with supercooled oxygen. When performing any actions with a cylinder, it is very important to comply with accuracy and safety requirements. The most vulnerable point is the valve; most often it is the valve that fails because it is subjected to repeated opening and closing.

It cannot be repaired, you can only replace it with a new one. Doing this with your own hands is prohibited; such an operation can only be carried out in a factory setting. Here it is important to follow the installation rules, which are based on pressing, that is, screwing in under a certain pressure. Then the cylinder itself with the valve is checked with test pressure. By the way, testing is hydraulic. Water is pumped inside the cylinder under a pressure of 225 or 300 kg/cm², which remains there for 5 minutes. After which the pressure is reduced to working pressure - 150 or 200 kg/cm².

It should be noted that the same technology is used to check the cylinders themselves to detect leaks. If nothing is found: all joints and walls have not become wet, then the test was successful and the device itself can be used further.

Inspection of gas containers.

Inspection is a process that allows you to determine how long it is possible to use a gas container and under what circumstances use should occur. When a container is accepted for diagnostics, an internal inspection is carried out, the weight is measured, valves and adapters are made, after which cleaning and degassing occurs.

All walls inside and out are checked for unevenness, rust, cracks and other mechanical damage. After which the gas cylinder is again washed, disinfected, painted, and the weight and capacity of the cylinder are checked.

This is necessary in order to see damage to the walls and decide on the further use of the gas cylinder. If the capacity increases by 1.5 percent or more, and the weight decreases by 5 percent, then the container can be used, but with little pressure. If the indicators have changed in the opposite direction, it is prohibited to use such a cylinder.

Next, during the inspection, hydraulic tests are carried out. The vessel is connected to a pressure many times greater than the operating limits. This allows you to check the walls for wear. After which the vessel is dried. At the end, the gas cylinder must be branded.

Useful article - Metal welding: methods, types, types, classification and scope of application

Scope of use

Compressed oxygen is a popular gas, the scope of which depends on the type of raw material. The medical substance is used during the resuscitation of patients. The element has a beneficial effect on the heart and lungs, so therapeutic procedures are often prescribed for health problems. The component is taken to saturate cocktails during oxygen starvation.

Technical gas heats up quickly and maintains high temperatures for a long time. The resulting continuous jet burns through metal of any density, which allows you to cut or solder parts. The characteristic is useful both in construction and in domestic use. In metallurgy, the substance increases the efficiency of furnaces, thereby improving the quality of the finished product.

In the chemical industry they are used in the production of complex acids and explosives. In the pulp industry, paper is cleaned and bleached with oxygen; in the fish industry, ponds are enriched. In aviation, gas is involved in the oxidation of motor fuel.

How to find out the volume of a gas cylinder and how much oxygen is in cubic meters

Often, all the characteristics and material about the company that manufactured the product are indicated on a steel label attached to the top of the container, which contains data on the volume. It is written in a standard unit - liter, but the mass of gas per meter cubed can vary depending on the type of gas.

Oxygen-containing containers can be of medium or small capacity.

In order to find out the remaining mass of gas in cubic meters, it is necessary to find out the initial pressure of the gas cylinder, the readings of which are on the pressure gauge. It is necessary to calculate an indicator for measuring volume based on the data from the pressure gauge and tables.

By multiplying the value of the standard volume, which is measured in cubic decimeters. The weight of the full cylinder volume is indicated on the label.

Welding device

Oxygen cylinders are made from seamless steel pipes and have a cylindrical shape.

- A gas cylinder is a cylindrical vessel with a narrow neck and a convex bottom.

- A conical hole with a thread is made in the neck, into which a locking mechanism - a valve - is screwed. The gas supply is regulated using the valve.

- The valve includes a spindle that is moved by a handwheel when the gas supply valve opens.

- A ring with an external thread is tightly fitted onto the neck of the container, onto which a safety cap is screwed.

- From below, the container is placed on a special shoe with a square platform. Thanks to this device, he can stand stably in an upright position.

How to find out the amount of oxygen in a cylinder and how many kilograms are in an oxygen cylinder

This gas is mainly needed for welding work. Gas welding allows you to create neat and high-quality seams.

For a full container of oxygen, there is no need to calculate when the contents will run out. And if the container has been used, it will be problematic to determine the amount of oxygen in the remaining gas cylinder. Often the definition is based on the fact that one liter of oxygen weighs 1.13 kg. Therefore, to calculate the mass of a gas, you need to multiply the volume by a factor of 1.13. However, there are special tables for welding.

Types of welding mixtures

Argon . Argon is used for argon arc welding. This gas is used for welding workpieces made of high-alloy steels, copper, aluminum, cast iron, titanium, and silver.

Carbon dioxide . To weld stainless steel workpieces, a balloon welding mixture based on carbon dioxide is used. For example, when hydrogen is added to the gas mixture, the welding process is significantly accelerated. Oxygen and hydrogen in a carbon dioxide cylinder range from 10 percent. When performing plasma cutting, 25-45 percent hydrogen is added to the mixture to increase power.

Nitrogen . This chemical element is used in gas mixtures to join workpieces made of copper, silver, and their alloys, increases corrosion resistance, and reduces the presence of iron in carbon deposits. But when using nitrogen mixtures, TIG electrodes wear out faster.

To perform MIG and MAG welding, two-component gas mixtures (5% oxygen), three-component mixtures (oxygen-2.5%, CO2 -20%, argon-75%) are used. This composition makes it possible to avoid burnout and splashing of alloying components.

For welding work, two cylinders are used simultaneously: with argon and carbon dioxide or oxygen and carbon dioxide.

Advantages of using balloon welding mixtures

- Improved working conditions

- High stability

- Minimizing post-processing of welded products

- Saving consumables

- Improved welding quality

- The total cost of welding work is significantly lower

Coloring

For safety purposes, strictly defined coloring of containers and inscriptions on it have been introduced. The gases most commonly used in cooking are color coded as follows:

- The highly purified argon cylinder is gray in color and has a green inscription on it. The black cylinder with technical argon has a blue inscription. There is also so-called raw argon with its own markings. This gas is not used in welding;

- carbon dioxide cylinders are painted black, the inscription on them is in yellow;

- oxygen cylinders for welding are always blue, and the inscriptions on them are black. Both medical and technical grades of gas are colored this way. In medicine, oxygen is used very often. It is transported on trolleys, then, if necessary, the cylinder is installed in a special case;

- containers containing acetylene, which is very popular in welding, are black in color. Acetylene explodes very easily. Therefore, it is not pumped into empty volumes, but containing special fillers with a large number of pores. This filling method significantly reduces the likelihood of explosions.

Gearbox

To work with any gas you need a reducer. There are models that simply show the pressure in the cylinder and with the function of regulating the gas flow.

The latter types are called regulators. They are adapted to a specific gas, painted in accordance with the color of the cylinder. There are regulators with dial scales and rotameters on sale.

If you plan to carry out argon arc welding, you need to take a regulator with two rotameters. When working with stainless steel, you need air blowing from the reverse side, which only this regulator model can control.

In other situations, a dial regulator is quite suitable, which also costs less. Practitioners consider the switch model to be more economical. If used correctly, it allows you to avoid pressure release at the beginning of work. On regulators with rotators, pressure release at first is almost inevitable. This is accompanied by some gas losses.

All regulators have gaskets made of inert polymers. Gas contamination from contact with them is absolutely excluded. When welding you have to use different gases. For such production applications, it is advisable to have regulators suitable for several types of threads.