A sandblaster is one of the most important devices in the repair of almost any car. The main task is to effectively prepare the surface of the vehicle for further processing, including painting. The high level of functionality contributed to the fact that many people were able to note the maximum benefits of the sandblasting machine.

The main tasks of a sandblasting machine

Before you understand what the operating principle of a sandblasting machine is, you need to carefully study all the possibilities for using the equipment:

- removing existing rust;

- removal of scale, as well as molding primer from the car body;

- getting rid of previous layers of paint;

- preparatory activities before matting;

- increasing the strength of the car body;

- removal of burrs and polishing coatings that have aged;

- preparation before further painting or applying anti-corrosion agents.

Carrying out all of the above activities requires minimal financial investments. At the same time, high quality cleaning of the car body is guaranteed.

Description of the sandblasting machine

Any model has a certain device that is classic. So, modern sandblasting machines consist of the following parts:

- compressor to create an air flow of optimal pressure;

- storage receiver;

- a gun that allows you to successfully treat the surface of a vehicle with a jet of sand;

- container with abrasive material;

- systems used to automatically perform assigned tasks and monitor the quality of events;

- connecting hoses to create a reliable, sealed structure.

One of the main elements of any sandblasting machine is an automation system that allows you to control the pressure for supplying abrasive material to the gun. If necessary, you can use the system for emergency shutdown in the event of failures during the operation of the equipment.

The existing control system guarantees full control of the sandblasting compressor to prevent potentially dangerous situations. As a result, the equipment can be easily switched to idle or working mode. Sometimes the control system is located in the work area and in areas of additional equipment maintenance.

Another important element is the connecting hoses. They determine the power and other technical parameters of the device. When choosing hoses for equipment, you should consider the pressure they can withstand. It is imperative to take into account the diameter and internal resistance, length, since these are the parameters that determine the productivity and power of sandblasting equipment.

Types of abrasive materials

The very first abrasive for surface treatment was sand: the devices got their name from it. Nowadays, metal is cleaned using sand and other, more modern and effective materials. They differ in the following physical characteristics:

- hardness – determines the intensity of processing and its speed,

- particle size – coarse materials have a higher impact force,

- uniformity – uniform surface treatment is ensured only by particles of approximately the same size,

- shape - round elements remove dirt through direct contact with the surface, elongated ones act by friction, grain-shaped ones give a polishing effect.

Abrasive materials are also classified by origin:

- Natural. The group includes different types of sand - river, quartz, desert, sea. Now their use is limited, since there are many more effective analogues.

- Vegetable. These are different seeds, husks, and other products of plant processing. They are very gentle and are most often used to clean delicate surfaces.

- Industrial. They can be based on metal, products of its processing, or non-metallic. The most famous abrasive in this group is steel shot, which can be used repeatedly. The most commonly used non-metallic abrasives are glass grain and crushed plastic, and waste abrasives are slag and corundum.

Main settings

Power and performance are the main parameters that determine how effective a sandblaster can be. The first characteristic directly depends on the pressure created by sandblasting equipment. The optimal indicator is considered to be up to eight atmospheres, and this figure largely depends on the size of the nozzle.

Capacity determines the amount of compressed air flow that is delivered over a certain period of time. In most cases, the parameter is measured in liters of air per minute, and it determines the volume of sand that is supplied to the work area over a certain period of time.

Other characteristics are secondary. In this regard, when trying to understand how sandblasting works, it is not necessary to pay attention to them.

Specifics of the operation of sandblasting machines

So how does a sandblaster work? In fact, the car coating processing scheme is extremely simple. A compressed air flow is supplied through the hose, and abrasive particles are picked up at this time and accelerated to thirty to forty meters per second to further knock down contaminants and corrosion elements from the vehicle’s coating. According to this scheme, the device used can successfully prepare the car for further painting or other activities, but before performing further actions, a thorough cleaning is carried out using a metal brush. If you don't clean your car using a wire brush, the abrasive particles won't stick.

When choosing sandblasting, you should remember the principles of its operation and technical parameters. The effectiveness of the tasks performed depends on this.

Reading time: 8 minutes No time?

A sandblasting machine is useful to almost everyone. This device will help you quickly and efficiently clean surfaces from traces of old paint, rust and scale. It is not difficult to find sand cleaning devices on sale, but they are not cheap. The most “budget” of them will cost at least 9,000 rubles. Today, the HouseChief editors offer you detailed instructions on how to make sandblasting yourself. Videos, tips from experts and important recommendations for operating the device are in this article.

A sandblasting machine will help you quickly and efficiently clean any surface for further processing.

Read in the article

How does a sandblasting machine work and its diagram

It will not be possible to make a sandblasting machine entirely from homemade parts; you will have to purchase some parts of the device before starting work. In principle, sandblasting is similar to a spray gun. It consists of a compressor that provides air flow, a line into which sand flows and a nozzle that ejects the filler towards the surfaces being treated. The device itself can have impressive dimensions if, for example, you need to clean a brick wall from traces of paint, or compact if we are talking about delicate work of engraving on glass.

In addition to the three main elements that have already been mentioned, the device circuit includes a receiver, a tap system, electrical relays and hoses. To fill the sand you will need a main tank.

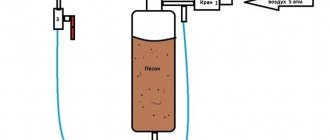

General diagram of the sandblasting machine

This is what the device diagram looks like.

Sandblasting machine diagram

As you can see, all the components of the device can be purchased or manufactured separately, which means that the task at hand - making a sandblasting installation with your own hands - is feasible.

Pros and cons of homemade units

If we talk about the positive aspects of sandblasting machines assembled by hand, then they are on the surface - this is an opportunity to clean surfaces for a very modest amount that a master will spend on taps, fittings and pipes. And that’s if it’s not in his garage. This is where the advantages end. What about the minuses? There's a more serious question here. Dust during work is understandable, but what about the risk of injury? Any mistake when welding parts will lead to a rupture in this place. In this case, death is also possible. Therefore, the editors of HomeMyHome.ru warn: weigh everything 1000 times and think about whether you can do this job with perfect quality. If not, then it’s better to abandon the idea.

Operating principles of a sandblasting machine and its scope of application

The simple principle of the action of sand as a powerful abrasive is known to everyone. The smallest particles falling on the work surface under pressure tear off all layers of paint, plaque, and rust. The task of sandblasting is precisely to direct the abrasive in the desired direction and provide the necessary pressure to complete the job. The pressure is provided by an air compressor.

It is too difficult to make a compressor yourself, so you will have to purchase one

For your information! A sandblasting machine will require a compressor with a power of at least 3 kW and a capacity of 500 l/m.

You can use a sandblaster with water - it will replace air, and instead of a compressor you can use a high-pressure washer. In order for sand to flow into the main line, the container of the apparatus must have the correct angle of inclination of the walls, like in an hourglass.

The operating principle of the sandblasting machine in the training video

How surfaces are cleaned with a pressure-type sandblaster in practice is demonstrated in the following video:

Using such a device, you can clean not only metal from traces of corrosion. By adjusting the pressure of the incoming abrasive, you can easily remove old paint or whitewash from walls and floors, tidy up a wooden fence, and matte the surface.

Types of machines

Guided by the chosen goals, you need to decide which devices are best to purchase. Three types of sandblasting units have been created:

- Suction based sandblasting units . In such machines, air is needed both for the jet and to move the material from the container (without pressure) to the tip.

- Vacuum type sandblasting units . In this device, the abrasive grains hit the material being cleaned, then immediately, thanks to the vacuum, they are captured and used again a second time.

- Pneumatic types of units . A pneumatic powered sandblasting device is an installation necessary for high power use.

Sandblasters also come in injection and pressure types. Specialists also use stationary and mobile equipment.

Stationary devices

These sandblasting units are placed in factories. They are equipped with their own filter system and powerful ventilation is attached to them, so that they cannot be moved. Often with their participation, small surfaces, individual objects and parts are cleaned.

Mobile equipment

These installations are used for domestic purposes. They are small in size and can be made independently. They are also in demand for processing building facades, large equipment, tanks, and are required for body repairs. They are mobile and easy to move wherever needed, depending on the need.

Injection devices

Injection supply of abrasive particles is considered the most popular. In these units, air and sand are supplied through separate hoses, then the device creates a vacuum in the flow, and the abrasive elements enter the air stream. Due to the fact that the speed and power of the sand supplied by air is low, an injection-type sandblasting device has a lower cost.

Pressure devices

In these devices, abrasive particles and air are supplied through one hose. The sand cylinder is made of durable metal and is completely sealed, because it constantly experiences high pressure. The intensity of supply and ejection of abrasive is high, so with the help of a pressure device it is possible to carry out complex work of enormous volumes.

How to choose the right sand for sandblasting

Initially, sandblasters used quartz sand. This is the cheapest consumable material for such installations. Modern manufacturers offer to load other bulk abrasives into the device, the effect of which is significantly different from ordinary sand. It got to the point that some European countries banned the use of simple sand in work, citing the fact that it causes serious health problems for people who are within the radius of work.

The worker himself must wear protective clothing, a respirator and goggles

Proponents of the use of sand, in addition to its main advantage - price, also mention the possibility of reusing the abrasive, including for construction purposes. The average hardness of the particles allows the device to be used by a person with insufficient experience without the risk of damaging the surface being treated. In addition, sand has fractions of different sizes, which allows you to select the optimal mode for cleaning different types of coatings.

What other types of abrasive materials can be used in sandblasting:

- Cooper slag or nickel - waste from nickel and copper production, characterized by high strength and hardness;

- garnet sand – used for cutting metal in powerful sandblasting machines;

- aluminum oxide - electrocorundum - is the hardest abrasive, capable of coping with any task and at the same time retaining its particle shape;

- cast iron and steel shot - not cheap, but has the ability to harden the surface, like forging.

Abrasives for sandblasting machines are sold in packages starting from 20 kg

By what principle is this or that consumable material selected? First of all, you should decide on the purpose of the work: if you need to clean the wall of a house from facade paint, you should not buy an expensive abrasive. If your device is unable to collect and reuse the material, then give preference to quartz sand. It can at least be used in bulk in a sandbox.

To clean a durable hard coating, solid fractions will be required; for quick rough processing, large particles will be required.

Personal protection for sandblaster

When working with sandblasting machines, special attention is paid to the individual protection of the sandblaster. This type of material processing poses several dangers to human health.

The first of them is grains of sand flying out at very high speeds, which can reach 700 kilometers per hour. Many particles ricochet off the surface being treated, which can cause serious injury to the skin. To protect yourself from their effects, you must use the following personal protective equipment:

- special shoes;

- overalls made of durable material;

- leather gloves;

- protective helmet.

Sand dust and other particles knocked off the surface being treated have a negative effect on the respiratory system. To protect against this harm, the sandblasting helmet is equipped with an independent air source. Air usually comes from outside the work shop and is forced into the helmet for breathing. Sometimes self-contained air supply systems are used, similar to those used by scuba divers.

Well, the last, no less dangerous source of harm to health is noise. Its creation involves a rather loud compressor, a whistling stream of compressed air and the noise of sand hitting the surface being treated. If you remain under the influence of all these noises for a long time, you can very quickly get injured in your hearing aid. To protect against excess noise, special sound-absorbing headphones are used, mounted in the sandblaster’s helmet.

How to choose a sandblasting machine from those presented in stores

If you choose a device in a store, a reasonable question arises: which sandblasting machine is better to choose?

To choose the right device, you need to consider it from the point of view of convenience and practicality of use. Here are some basic selection criteria:

- criterion No. 1 : size of the abrasive container. The larger the tank, the less often you will have to fill the material, but at the same time, the heavier the entire structure will be. For manual work, a hundred-liter barrel is enough;

Sandblasting can get rid of graffiti

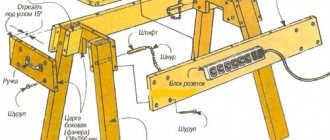

What tools and materials are needed to make a sandblasting machine with your own hands?

Returning to the issue of making sandblasting with your own hands, let’s consider what is required for the work:

- A compressor that provides pressure for the sandblaster. As we have already said, it is very difficult to make a compressor for sandblasting with your own hands, and the resulting result is unlikely to please you with its power. So you just need to buy this part. You will need a device with a power of at least 3 kW with a forced cooling system and a pair of piston groups.

- Container for abrasive. The main requirement for the tank is the correct slope of the walls, ensuring natural pouring of sand. The walls should be at an angle of 30 to 60°. The container must be made of thick-walled metal. A gas cylinder or fire extinguisher is excellent for this purpose.

Main processing rules

You can get a truly high-quality processing result only by selecting good equipment, consumables and components. The abrasive material must be ideally suited for the specific type of work, otherwise the surface will not be cleaned sufficiently or will be scratched.

The higher the performance of the sandblasting compressor, the faster the cleaning will occur, and the greater the efficiency. It is necessary to select installations with hoses of significant diameter to reduce pressure losses. Couplings and connectors must exactly match the diameters of the hoses. You should also pay attention to the quality of the nozzle - the most durable ones are made from boron carbide, however, they cost much higher than others.

How to make sandblasting with your own hands from scrap materials: master classes and videos

Think before you start sandblasting. How large is the work you are planning? Buying an air compressor is also an expense for the family budget. If your only task is to clean the porch of your house, maybe it would be easier to rent such a device at one of the rental stores?

It’s another matter if the unit is needed regularly. Its purchase will affect your wallet. Factory models often fail, and manufacturers give them a very modest warranty due to specific operating conditions. So it turns out that doing sandblasting yourself is cheaper, and given the use of replaceable parts, it will serve you indefinitely. Let's look at the most popular models made from scrap materials.