A do-it-yourself roller knife for sheet metal is a homemade tool, the demand for which is growing every day, which is explained by the productive speed of operation of such a device and its simple design. The mechanical basis is extremely simple, and is based on two metal knives rotating in opposite directions, pressing into the steel plane of the workpiece, which leads to its cutting.

The classic design involves the installation of rotating disks at the top and bottom, classified according to the material of manufacture:

- Parallel roller knives are used for cutting steel sheets into strips, while maintaining good quality of the workpiece.

- Roller knives with one inclined edge - this design, in addition to slicing, allows you to cut workpieces with rounded shapes.

- Roller knives with multiple inclined edges - maintaining a small radius, helps to produce parts with curved lines and rounded shapes.

Design

Roller metal shears, assembled at home with your own hands, have a common essence that remains unchanged - the presence of a cutting knife. It is made from steel alloys with a maximum strength threshold and other characteristics that should be higher compared to similar parameters for steel that will be processed on a cutting machine.

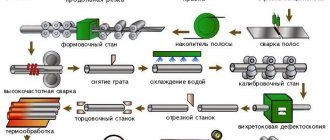

Roller knife device

In practice, it is known that roller knives produced at the factory for cutting metal have a service life of about 30 km of steel sheets, with a caveat to the maximum sheet thickness, which will not exceed 0.5 mm.

Accordingly, if the thickness of the material is higher, then the durability of the tool is reduced. However, nothing prevents you from sharpening the tool and thereby extending its service life.

Necessary materials

A machine for cutting sheet metal, constructed with your own hands at home, requires knives, the range of materials for which is very wide, and the choice of one of them mainly depends on the type and thickness of the material that will need to be cut. If you have to work with not the most durable, thin sheet steel, such as aluminum, then the simplest bearings will be the ideal option. But for the required functionality of a roller knife, they lack sharpening, which should be carried out independently along the entire end of the future tool.

The main roller knife is installed on a movable part of the structure with a pressure handle, which, when pressed, clamps the workpiece between two cutting surfaces. The diameter of the bearings directly affects the speed of work performed. That is, the larger the bearing diameter, the higher the production speed on the machine.

Making a roller knife for metal with your own hands

To simplify the work with the tool and make it more convenient, it would be nice to equip the sheet cutter with a guide plane.

The manufacture and installation of this part is not very difficult, and in return it will greatly simplify the entire process. The result is a universal machine with roller knives, which can interact with other metalworking equipment, which can also be easily constructed at home.

The best gas cutters for metal

A gas cutter consists of several modules: a holder, a valve system, tubes and a nozzle. Each model has its own characteristics. For example, the nozzle should be equipped with kickback protection, and the handle should fit comfortably in the hand and not slip out. When choosing, special attention is paid to the valve system, which bears the main load during operation. The location of the valves also matters in terms of convenience, and in some models the purge valve is replaced with a lever. Such tools are also presented in our rating.

Manufacturing instructions

Factory models of cutters sold in stores, even in standard configuration, will cost a large amount. The price of models offered on the market starts from 20,000 rubles. Such conditions are not beneficial for purchasing a tool for home use or a small workshop, and it will be used extremely rarely.

To begin with, the main body of the instrument is designed, which everyone chooses for themselves. The main attribute of the machine is manufactured - a roller knife for sheet metal. The material from which the part is made directly affects the durability and performance of the unit. As mentioned above, the strength characteristics should be significantly higher than the similar characteristics of the material being cut. Otherwise, the minimum problem will be a low-quality cut, forcing the craftsman to clean and process the edges of each cut piece.

Scheme for assembling a roller knife

Do-it-yourself roller metal shears are mostly made from bearings. Sharpening the ends of the part forms the cutting surfaces. The main roller, connected to the drive, is attached directly to the handle. The lower one is installed on the fixed lower part of the machine. If you have skills in processing iron alloys, manufacturing such a device will take a maximum of a little more than a week, including setting up the unit.

Description, principle of operation

A roller cutter for metal is a device designed to separate sheet metal into two parts. The principle of operation is based on the destruction of the strength bonds of the processed material in a local area.

The force on the metal is carried out along two parallel planes. The force vectors are directed towards each other. Example: household scissors or industrial guillotine.

In roller shears, the power parts are made in the form of two disks. The internal (facing each other) cutting surfaces are in the same plane. The edges of the rollers extend (displaced) a small distance in a perpendicular plane. When moving (rotating), the device slides onto the metal sheet.

A sheet sandwiched between two disks experiences two forces at the point of contact. Shear deformation and separation of the material occurs. The discs, performing a translational-rotational movement, shift the point of contact in the direction of the cut. In this way, the process of continuous processing of sheet iron is carried out.

Features of metal cutting at home

Circular knives are an excellent replacement for metal shears, having a number of advantages:

- Small dimensions and dimensions.

- Simplicity of design.

- Easy adjustment.

- Convenience and ability to work with a wide range of materials.

Cutting metal with a roller knife

Do-it-yourself sheet metal cutting at home is usually done with cutters or drills. Of course, this approach helps to give the part the desired shape, and at the same time polish the surface. However, it would be much more practical to construct a machine with roller knives with your own hands once (unless, of course, we are talking about cutting scrap metal, since accuracy is not so important there), thereby reducing both the time allotted for processing and minimizing the amount of debris and defects that may occur when using hand tools. To put it simply, circular knives are an excellent replacement for metal shears and even an industrial guillotine.

Read also: Designation of surface cleanliness class in drawings

If you find an error, please select a piece of text and press Ctrl+Enter.

Various cutting tools, both manual and electric, are used to cut sheet steel. To cut a straight sheet of galvanized or stainless steel, you can take hand-held metal scissors, a grinder or a jigsaw. But all these devices are not always convenient to use for cutting sheet steel. For such purposes, roller shears for cutting metal are also produced. To avoid having to buy such a tool, you can make it yourself.

Advantages

A disc knife is an alternative to manual metal shears or an industrial guillotine. Compared to them and other devices, it has a number of significant consumer properties:

- small overall dimensions and weight;

- simple design;

- easy setup and adjustment;

- ease of use;

- ability to work with a wide range of sheet materials: steel, roofing iron, aluminum, copper.

The edges of the processed semi-finished product, after exiting the machine, have a clean cut, without deformation or burrs.

Roller shears and sheet metal cutting features

In the metalworking industry, roller shears or knives are used to process sheet material. This tool is called knives because its operation is based on the use of two cutting discs. The cutting process is based on the fact that rollers are pressed into the sheet material from two sides - top and bottom. In this case, it is cut without the use of any sharp knives. The role of cutting and sharp knives is played by rollers, which touch the walls to each other on both sides.

Rollers not only cut sheet material, but also facilitate the process of moving the tool along the surface of the sheet. This means that cutting with a roller knife is not only convenient, but also effective. If we compare the operation of the device with hand scissors, the following advantages should be noted:

- Speed - cutting a sheet of steel with roller shears can be done in a matter of seconds, but using scissors requires a lot of time, which depends on the length of the material being cut

- Cut quality - the roller knife cuts not only quickly, but also with high quality. There are no chips, bends, bends, etc. at the site of the cut

- Physical fatigue - cutting with hand scissors requires physical effort, while using a roller tool eliminates this need. To cut, you only need to move the roller shears along the guides, thereby cutting the steel sheet

Roller shears are classified according to the types of knives into three types:

- They are located in parallel. The most popular type of cutting tool, which is intended exclusively for cutting material into strips, that is, cutting is performed in a straight direction

- They have one slope. They are intended for cutting not only even strips of sheet material, but also for cutting round and ring-type workpieces

- With several slopes. Such roller devices are intended directly for cutting workpieces of various shapes - ring, round, curved, etc.

After cutting, the edge of the material does not need additional processing, as it turns out smooth, without chips or burrs.

Do-it-yourself roller sheet cutter - Metals, equipment, instructions

When working with tin, two main tools are used. Metal shears and sheet bending machine.

Of course, when making a gutter for the roof of a barn, you can use the old-fashioned method - tap a galvanized sheet with a mallet on the edge of a workbench, or using a metal corner.

Examples of such work can be seen on roofing in the private sector. However, the quality of the product leaves much to be desired, and the metal is damaged at the point of impact.

In addition, artisanal bending of metal is suitable only for simple structures. If the bending profile has several multidirectional edges, you cannot do without a professional tool.

For example, the correct ridge for a roof “on the knee” cannot be bent, and its appearance will always remind you of the owner’s negligence.

Buying an industrial sheet bending machine is an unforgivable luxury. The craftsman is afraid of the work - we will tell you how to make such a useful device in a private household with your own hands.

Roller

The second name is three-roll. The machine is used to create smooth bent surfaces - large-diameter pipes, semicircular drains and other structures without sharp corners. It works on the principle of a rolling machine. The sheet is profiled between two support rollers and one thrust roller, the movement of which sets the bending radius of the workpiece.

Press brake

The workpiece is placed between two punches (templates), under great pressure they close, giving the required shape to the sheet of metal. Typically used for working with thick workpieces. Useless for household use.

Traverse mechanism

The principle of operation of the design is that the workpiece is clamped with a clamping ruler, and a movable traverse bends the edge to the desired angle. Perhaps the most popular type of sheet bending machine.

There are both industrial stationary machines and manual tabletop devices. In fact, it has no restrictions on the bend angle - from 0 to 180 degrees. The width of the processed sheet is determined by the length of the traverse.

This is the only design flaw. It will be problematic to bend a single rolled strip several meters long at home. But you can quickly make a composite structure of any length with bends for merging the ends.

With traverse structures, a bending knife is often used, which is included in the delivery package.

Roller-type end knives are designed for high-quality alignment of the edge of the workpiece.

Roller bending machine

It would be more correct to call it a manual end bender. Although, using a roller mechanism, you can bend workpieces far from the edge. The process is simply too inconvenient. Mainly used as an auxiliary device.

How to make a homemade sheet bender

The simplest design is to clamp the edge of the sheet between a steel corner and a rule (or two corners) using a clamp, and bend the workpiece by hand. This is how the simplest roofing elements are usually created.

However, it is quite possible to make a traverse sheet bending machine yourself. Precision markings and patience are required.

The design and operating principle are visible in the drawings.

Let's look at the assembly step by step.

To make a traverse sheet bender we will need:

- 4 meters of steel angle, side – 50 mm;

- Ball joint for car, with mounting bracket;

- The stabilizer rod is from the same, with a diameter of 10 mm;

- Grinder, drill, electric welding.

We cut the corner with a grinder into 1 meter pieces.

If there is a need to work with metal of a larger width, the length of the corners increases. At least 100 mm must be added to the width of the working surface. Using an angle grinder, we cut out two eyes from the ball joint bracket. These will be the working loops of the movable traverse.

From the stabilizer strut we make an axis on which the hinges will rest.

We carefully measure and mark a sample on the corner for attaching the axle.

We grind the flats strictly to size to install the axle shafts. This must be done as accurately as possible so as not to waste time and material on subsequent adjustments.

Popular: Do-it-yourself workbench - drawings, principles of construction

We apply the markings exactly in the center of the axis, and combine it with the top of the corner - the traverse. This point is important. because if the alignment is incorrect, the quality of the workpiece bending on the machine will deteriorate, or the sheet bender will be unsuitable for work.

We weld the axle shafts to the samples, maintaining parallelism to the top of the angle. To increase accuracy, you should use a jig when welding. For example, a vice and a clamp. The length of the protruding part of the axis does not exceed 1 cm.

The result should be a structure with perfect alignment at the ends.

Place the corners next to each other.

We mark the sample on the second corner strictly opposite the axes of the first corner.

The angles relative to each other should be located as follows:

We fold both traverses, keeping them flat, and fix them for welding. We weld the loops onto the second corner on both sides.

The corners should rotate freely relative to each other on their hinges. When turning 180 degrees there should be no snags or wedging. In this case, the gap between the traverses should be minimal.

The clamping angle will be positioned as follows:

Having previously marked, we use a grinder to cut out a sample around the axis on the clamping angle.

The lower side of the clamping angle is ground at an angle of 45 degrees.

Opposite the axes, mark and drill holes for 10 mm bolts. We weld the bolts with the threads up to the lower fixed cross-beam.

We also make a hole in the center of the traverse, but do not weld the bolt. This will be a removable element, so we weld the short axle to it in a T-shape.

Bolts are needed to press the workpiece to the crossbeam when bending. The central bolt is used when the workpiece has a width that is half that of the traverse. When working with wide workpieces, the bolt is removed.

From a 15-20 mm circle we cut two handles 30 cm long. A thinner rod will not work, since the force on the handles can be significant, and you can simply bend them.

Popular: Die for cutting threads on pipes: how is it different from a die?

We weld the handles from the bottom of the turning angle (traverse).

Next, we make a bed for the sheet bending machine. We weld the fourth corner to the lower fixed cross-beam on both sides for strength. We drill holes in the frame. The entire structure must be fixed on a stable surface, for example, on a steel workbench.

We screw the sheet bender to the workbench and check the free movement of the movable traverse.

The design allows you to work with iron sheets up to 2 mm thick and 92 cm wide. Bend angles can be selected to any size; the workpiece can be bent either in one direction or in steps. When working with a thick workpiece, the handle is extended with a metal pipe; the strength of the angle is always sufficient.

Working with standard galvanized sheeting is not difficult; the device bends it with the ease of cardboard.

Additional accessories

For ease of operation, the clamping angle can be spring-loaded, and wing nuts can be used instead of conventional nuts. It is convenient to work with such a device with a roller knife, using the upper clamp as a guide.

Temporary structure according to a simplified scheme

The considered version of the sheet bender is made for regular work, and is actually a stationary device. If you urgently need to do one-time work on making tin products, you can create a simpler device.

For production you will need:

- Three corners 40-50 mm, width according to your needs;

- A pair of door hinges;

- Two powerful clamps;

- Two rods (circles) as handles.

The two corners are fastened together with loops as tightly as possible.

The third, shorter corner, using clamps, presses the workpiece and the lower crossbeam to the workbench. This machine is not very convenient, but this is compensated by its ease of manufacture. The manufacturing option is up to you to choose.

instructions for making a homemade sheet bender

An interesting article on the topic of how to assemble a pipe bender with your own hands. Available diagrams and drawings, as well as a video and a detailed description of the assembly.

Making roller shears for cutting metal at home

Cutting sheet material into pieces is carried out using various tools. Roller shears for sheet metal cutting are popular, a trend due to their simple design and high productivity. The device is used in industrial and small workshop environments.

- Characteristics of scissors

- Description of scissors

- How to make a roller knife

The intended purpose of roller knives is to cut steel sheets up to 1 mm thick. They are necessary at the site for the production of ventilation ducts, when working with roofing metal, when building a fence and arranging the roof.

The mechanism is used to produce semi-finished products for subsequent bending of profiles for various purposes. The equipment is installed in car body repair shops. In auxiliary production, blanks are prepared for the assembly of racks and cabinets.

Roller scissors can successfully replace the manual version or guillotine due to a number of advantages:

- Compact dimensions and light weight.

- Simple device.

- Convenient to use.

- Just getting set up.

- Suitable for working with sheets of different materials: aluminum, copper, tin, steel, roofing iron.

The processed product is obtained with a clean cut and no burrs or bends. It is easy to cut sheet metal with such a device.

Scissors can be purchased at a specialized store or made independently. It all depends on the volumes performed and the economic component. With a daily cutting rate of 30–50 meters or more, an industrial design will be required.

Description of scissors

The task of dividing a sheet of metal into parts is solved by destroying the strength bonds on a local segment.

The power part consists of two cutting roller discs with multidirectional rotation. Their cutting edges lie in the same plane. When rotating, the rollers are pressed into the surface and cutting occurs due to shear deformation. The sheet metal is fed to the tool by friction of the knives against the metal.

How to cut sheet metal at home

In industry, roller shears are used to cut factory-produced sheet metal. Their distinctive features are high accuracy, long service life, and the absence of the need to make them yourself. Often in the household there is a need to obtain even strips of sheet steel, which are used for various purposes. If you need one strip, then there is no need to buy or make such a device, since you can use ordinary metal scissors. If you need to cut the entire sheet or carry out cutting work regularly, then it is imperative to acquire a roller knife.

There is no justifiable sense in buying such a factory-made device, since the price ranges from 15 thousand rubles or more, which depends on the design, size and quality of the device. Roller shears for cutting sheet metal can be made with your own hands at home, using available consumables for manufacturing. Although this method requires time, it allows you to save money, resulting in a universal cutting tool for cutting sheets of stainless steel, galvanized steel, etc.

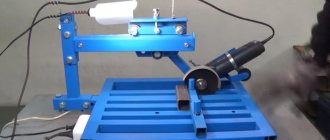

Features of making a tool yourself

If you are tired of cutting sheet metal with scissors or a grinder, then a roller cutter is an excellent alternative to replace these tools. The advantages of this device include quiet operation and lack of energy consumption. In addition, having such a device in your home arsenal, you can even make money when your neighbors need to cut sheet metal material.

The purchase of a tool is justified only in one case, when it is necessary to perform work in large quantities. And even in this case, you can make the device yourself to use it for professional purposes. There are many designs for the devices in question, so making a device yourself is not at all difficult if you understand the principle of operation of the device.

When making a homemade tool, the following properties must be taken into account:

- Cutting knives - there should be two of them, one located on top and the other on the bottom. Knives must be made of high-quality alloy, which has a strength higher than the materials being cut. Bearings that fully meet the described requirements are used as knives.

- Base - simultaneously acts as a surface on which the steel sheet is located, as well as a guide for moving the roller shears when cutting the sheet or cutting strips

- Body of the device - for manufacturing, a steel angle with a thickness of 3 mm and a wall size of 40-60 mm is usually used

- Auxiliary tools - they are designed to secure the sheet material to the table surface while cutting it

Read also: Selection of slings based on load weight

The service life of a homemade device is influenced by such an indicator as the quality of its manufacture. Moreover, this even applies to the quality of bearings, so if you get down to business, you will need an appropriate approach.

Application

The main purpose of the device is to process sheet metal material with a thickness of no more than 10 mm. For example:

- working with roofing iron when constructing a roof or fence;

- production of semi-finished products - strips for the production of ventilation from galvanized steel;

- cutting stainless steel to create countertops or kitchen cabinets.

The equipment has found application in auto repair shops for the manufacture of body or cabin elements. Factory cabinets and shelving are assembled from cut metal.

What to make a roller knife from

There are no difficulties with purchasing roller shears, since such a machine can be found in an online store and ordered. The only difficulty is that you will have to shell out a considerable amount of money to purchase it, which will not pay off soon if you do not use such equipment often. Making your own will not require any costs, but the biggest difficulty is choosing the necessary materials and assembling full-fledged roller shears from them.

Using a homemade machine allows you to cut the following types of materials:

- Cink Steel

- Stainless steel

- Aluminum

- Steel sheets up to 0.5 mm thick, for example, window slopes of metal-plastic windows

Bearings are used to make cutting knives. The diameter of these bearings depends on the size of the roller blade housing, but 20-30mm ball bearings are commonly used. In order for the bearings to ensure cutting of material, it is necessary to grind off their end faces, making them strictly at an angle of 90 degrees. The effectiveness of the tool depends on this.

Before you make a roller-type cutting tool, you need to understand its principle of use. The application is based on the fact that a homemade knife moves along guides. The corner part of a workbench or table is used as such guides. The sheet to be cut is placed on the surface of the table, and in order for the cut to be smooth and neat, it should be fixed in a stationary position. This can be done using two clamps and a wooden block of appropriate length. A block is placed on the sheet, and then it is fixed on both sides with clamps, thereby ensuring immobility during processing.