Kitchen knives, like any tool with a cutting surface, need sharpening from time to time. This can be done with a special bar or against the bottom of a mug or plate. But it's not as easy as it seems at first glance. If you don't have the skills, you can easily ruin the instrument instead of making it sharper. To prevent this from happening, there are special devices - knife sharpeners.

Sharpening a knife is a delicate process.

Type of machine depending on the tool

There are two types of sharpening machines. We will consider their features below.

Mechanical

Grinding tanks without electric drive. They are a body with slots, inside of which sharpening stones are fixed at different angles, for different types of sharpened objects.

One of the advantages is that such devices are usually compact and do not require electricity, and the disadvantage is that these are so-called “home” sharpeners and they are well suited for kitchen knives, but are not suitable for other tools.

Mechanical sharpening machine.

Electrical

They have a motor that turns the grinding disc. Of course, they are not as compact as mechanical sharpeners and they require electricity to operate. However, most of these units are universal, that is, suitable for sharpening all types of sharp objects. They are like this:

- knives;

- chisels;

- drill;

- axes;

- cutters for cutting leather.

Electric sharpening machine.

These machines are relatively inexpensive (from 1500 rubles to 5000 rubles). However, if there is a need to sharpen some specialized tool, for example, professional haircutting scissors (hairdressing scissors), then this is a different classification of machines and the price for such equipment will be several times higher (about fifty thousand rubles).

The difference between professional tools is that it is necessary to maintain different sharpening angles on the surface of the cutting element.

This cannot be done on inexpensive, universal devices. Specialized machines provide for setting different angles of contact with the grinding wheel.

The more features, the higher the price.

Mounts for sharpening certain tools

In principle, the simplest machine is a motor with an abrasive wheel attached to it, and in order to work with such equipment, a certain skill is required. If such dexterity is absent, it is better to purchase a device with ready-made mounts for each tool being sharpened.

Separately for knives, drills, chisels and so on. Essentially this is an attachment to the machine.

Depending on what tool you plan to work with, the appropriate attachment is selected.

It is also important to note that it is not possible to change the sharpening angle on the mounts.

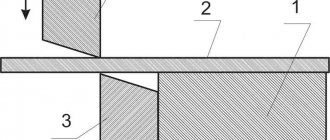

Machine with adjustable sharpening angle.

What size sharpening disc should I buy?

As a rule, it is not possible to change the size of the grinding wheel on universal machines. Its size is important for what you plan to sharpen on it. For example, a disc for standard knives used in the kitchen is not suitable for sharpening professional, large chef's knives. For this it is better to have a larger disk.

Questions and answers

Besides sharpening tools, what can you do on sharpening and grinding machines?

In addition to sharpening cutting surfaces, such machines can: process forged parts, clean the surface of various types of materials, polish glass products, etc.

Is it possible to avoid overheating of the blade of a cutting tool when sharpening it?

Avoid heating the blades of cutting tools when sharpening them on machines equipped with water tanks. Grinding discs are immersed in it during operation.

What models of sharpening machines can be used for professional use?

For professional work, you can use TSh-1.10, ZVS-20 machines.

How can you clean the aluminum oxide wheels of a sharpening machine quickly and efficiently?

The wheel is cleaned with a carborundum block.

Why are transparent protective screens installed on the body of grinding machines?

Protective screens prevent the spraying of metal dust when sharpening tools.

Flexible shaft

This device is needed to use engraving attachments to work on metal and wood surfaces. However, it is worth saying that this is a weak replacement for professional engraver equipment and is only suitable for small-scale work in this area.

Adjusting the disk rotation speed

When working with sharpening various objects, at some point you need high speeds, and at other times low speed. Some machines have a function for controlling the speed of rotation of the disk, while others do not.

Backlight

Machine with flexible shaft.

Used to improve visibility in the workplace when needed. For example, with ultra-precise sharpening, additional lighting is needed.

As a rule, it looks like a tripod that bends in all directions and has a lamp at the end.

Some machine models are sold with built-in lighting, but in practice it is just “for show” and does not actually provide any functionality.

It is advisable to check this point before making a purchase.

Exploitation

When using devices for sharpening various scissors, you must follow a number of rules:

- installation of equipment is carried out only on a flat, reliable surface;

- scissors should be firmly secured to prevent them from moving during processing;

- if problems are detected in the operation of one of the nodes, it is necessary to eliminate them;

- sharpening of nail scissors should be carried out continuously for no more than 5 minutes;

- it is important to keep the machine clean, carry out lubrication and maintenance in a timely manner;

- when switching from dry to wet sharpening or vice versa, you need to let the abrasive disc run at idle speed;

- To change the grinding wheel, you must stop the machine;

- working without a protective screen is strictly prohibited;

- the abrasive disk must be attached securely and motionlessly, even minimal imbalances must be eliminated;

- It is unacceptable to manually carry out manipulations with adjusting the sharpening angle or others while the machine is running, which could result in injury due to touching moving parts;

- You cannot install drives that are not recommended by the equipment manufacturer.

Operating conditions must meet the manufacturer's requirements. Failure to comply with them increases the risk of breakdowns, reduces processing accuracy, and reduces the service life of parts.

Sharpening technology and sharpening angle

Each sharpened tool requires a specific sharpening method.

There are 3 main ways:

- The standard sharpening angle is 40-50 degrees. The smaller the angle, the more brittle the cutting edge, so the steel must be of high quality.

- Convex is the sharpest type of sharpening of scissors. Has no sharpening limit. The metal cut goes from start to finish

- Semi-convex is a cross between the two previous types of sharpening. The cutting edge angle is from 42 to 45 degrees.

How to keep scissors sharp?

The first rule is to use tools for their intended purpose. This applies to a greater extent to sharp tailor's scissors, which are often used for other purposes.

Conventional fixtures are made from carbon steel protected by a very thin chrome plating. Incorrect handling of them causes scratches and nicks, the consequences of the formation of these defects are oxidation and rust. Unfortunately, such tools are unlikely to guarantee the sharpness of the blades. After contact with water, scissors must be wiped dry. It is better to store them in a dry place, inaccessible to moisture.

Any sharpening method requires preliminary cleaning of the blades. For this step, you can use either alcohol or solvent. It is better not to try to fix a professional tool yourself. The result can only be guaranteed by a specialist and his equipment.

To prevent problems from occurring, every six months the mechanical part of household tools is lubricated with oil, but only with oil that is used to service sewing machines. This treatment is necessary to protect the metal from corrosion.

As you can see, there are quite a lot of answers to the question of how to sharpen scissors, but many (if not most) are only able to provide “first aid” and guarantee a temporary effect. After some time, the instrument will become dull again.

For example, they say that two operations are not very useful - sandpaper and foil. These materials cause the cutting edge to change: it becomes uneven. Such “corrected” tools are already less amenable to sharpening.

A master from a popular video will tell you how to sharpen scissors:

Was this article helpful? We want to improve. Thanks for your opinion!

The Best Inexpensive All-In-One Tool Sharpeners for Home Tools

Each person can find a machine according to their needs and capabilities. There are a great variety of models. They come in both household and semi-professional and professional types. Let's look at the best options.

Caliber EZS-65MF

3 removable attachments for sharpening scissors, knives, chisels and drills.

- Motor: 65 W.

- Working surface thickness: 7.5 mm.

- Size: 49.3 mm in diameter. Caliber EZS-65MF.

Has holes for mounting on the surface of a table or workbench. After finishing sharpening, manual finishing of the tools is necessary, since the grinding wheel installed on this machine is standard and coarse-grained.

Whirlwind TS-200

The asynchronous motor has a low noise level and a power of 200 W.

- Working surface size: 150 mm in diameter.

- Thickness: 16 mm.

Designed for rapid sharpening of various piercing and cutting tools such as knives, axes, scissors, shovels. Aluminum housing. At the bottom of the machine there are rubber heels. This gives it stability during operation even without the use of additional fasteners.

There are special holes for attaching the device to a table or workbench. This model has a work area illumination lamp that turns on when the machine is running. Two removable grinding wheels are located on the sides of the body.

Whirlwind TS-200.

Diold MZS-03 M

Diold MZS-03 M.

Specifically, this is a modification of the machine - marked “M” it has a flexible shaft that can be used for engraving. Attachments for working with scissors, knives, chisels and drills, as well as screwdrivers and chisels. The sharpening angle can be changed depending on the purpose.

Manual finishing after sharpening is not required, but there is no control over the speed of the disk. The metal circle is 48 mm in diameter and 8 mm thick and has diamond coating.

Makita GB602

Equipped with two replaceable grinding wheels - coarse-grained and fine-grained, located on both sides of the body. Above each of them there is a casing made of transparent plastic, which on the one hand protects from flying sparks and chips, and on the other hand provides an overview for monitoring the workpiece.

- Power: 250 W.

- Working surface: 150 mm.

- Circle width: 16mm

The machine is also equipped with two lamps for illumination. The engine has low noise and vibration levels.

Makita GB602.

Varieties

Machines for sharpening hairdressing scissors according to the installation method are:

- manual (compact);

- tabletop household;

- professional.

By purpose:

- machine for sharpening manicure scissors;

- for professional tools;

- for medical instruments and equipment.

According to the location of the sharpening disk relative to the table surface:

- horizontal;

- vertical.

Bottom line

When choosing an electrical device, you first need to decide on its purpose, since cheap options are not suitable for working with professional tools. On the other hand, machines that allow you to sharpen profile tools cost about 10 times more and are more complex devices, so it is not advisable to use them only for sharpening kitchen knives.

Cutting and piercing tools must be properly maintained after sharpening to ensure they last longer and stay sharp longer.

What should you consider when choosing a sharpening machine?

When purchasing equipment, its performance, purpose and power are taken into account. Its ability to carry out the volume of planned work depends on these indicators.

It is important what kind of grinding wheels the machines are equipped with. If they are not available for sale, the equipment will be useless.

Other factors determining the choice of machine include:

- type of instalation;

- availability of additional functions;

- manufacturer;

- sharpening angles;

- method of fastening the tool being processed;

- price.