What the article is about:

How to choose a welding inverter based on the welding cycle

Most people, when choosing a welding inverter for their home, are guided by the manufacturer's company, reviews from friends and approximate characteristics, such as current strength and power of the device. Very few people pay attention to such an important parameter as the welding cycle.

What is an inverter welding cycle? The welding cycle means a certain time period after which the welding inverter will begin to overheat and wear out. After this time, the temperature sensor will work and turn off the inverter so that it begins to cool.

So, this time period is intended for working with an inverter. It is different for each inverter model: some models allow you to cook for 5-6 minutes without interruption, while others allow you to cook for 10 or more minutes. Then it needs time to cool down, otherwise the inverter may burn out.

How to choose an inverter for welding according to the operating cycle (DC)

Such a parameter as the welding cycle is designated in the characteristics of the inverter apparatus as PV. Literally, the PV of the inverter stands for “On Duration”, in simple words saying how long the inverter can operate without shutting down.

Most average models of welding machines have a duty cycle of 60%. This means that you can cook without stopping with the inverter for 6 minutes (60%), the remaining 40% (4 minutes) is needed for the inverter to cool down sufficiently.

Why should you consider the PV parameter when choosing a welding inverter? Everything is very simple, and if you have any specific requirements for a welding inverter, then this is a very important parameter. For example, you need a welding machine that requires welding almost all day long. Then the PV of the inverter should be as large as possible, but not less than 80%.

It is also important to consider the conditions under which the inverter will operate. If it overheats greatly as a result of elevated temperatures in the summer, then it would be advisable to choose a PV device with some reserve. In this case, the temperature sensor will not turn off the inverter due to overheating, and it will be possible to cook for a noticeably longer time.

In the photo you can see the operating cycle of the inverter, taking into account its on-time. The figure clearly demonstrates that PT is calculated based on a time interval of 10 minutes. In addition, as you can see, the duration of switching on the inverter entirely depends on the parameters of the welding current.

And if at the maximum welding current parameter, the inverter can weld without interruption for 6-7 minutes, then when the current values decrease, this time almost doubles. What does it mean? In simple words, if we choose an inverter with a certain reserve of current power, and even with a good duty cycle, at least 70-80%, then such an inverter will be more than enough for us to perform most welding work.

What is the duty cycle of a welding inverter

Official Representative

Made in Germany

Articles about welding

- Welding processes

- Manual arc welding

- Argon arc TIG welding

- Semi-automatic MIG/MAG welding

- 10 welding process mistakes and simple ways to solve them

- Welding equipment and materials

- Selection of the optimal welding machine

- How to choose a welding inverter

- How to choose a welding inverter (continued)

- Welding cycle, duty cycle

- Welding torch for semi-automatic machine

- Welding contact tips and welding nozzles

- Selection of welding shielding gas

- Choosing the right welding wire

- An important means of protection is a welding helmet.

- Metal welding

- Electric arc welding of steel

- Stainless steel welding

- Aluminum welding

- Welding cast iron

- Welding titanium and its alloys - technology and features

- Welding of copper and copper alloys

- Automation and robotization

- Welding automation: flexible or fixed system?

- Beam welding

- 5 Guidelines for Selecting, Operating and Maintaining a Welding Positioner

- Setting realistic goals for robotic welding projects

- Robotic TIG welding

- Tandem welding technology

- Industrial robots. Welding robots in process automation

- Welding robots and lean manufacturing

- Miscellaneous about welding

- Main types of welded joints and seams

- Types of weld defects and methods for their elimination

- Electric arc welding of pipes

- Plasma cutting of metal

- Welder personal protective equipment

- Welding arc and its characteristics

- Purpose of the feeding mechanism for semi-automatic electric welding

- contact welding

- Types of resistance welding

- Devices for manual spot welding

Why is it so important to consider the PV of the welding inverter?

Many people do not clearly understand why a work cycle is needed. If you purchase equipment with insufficient turn-on time, serious problems may arise in the future.

If the PV of the inverter is low, then the welder will have to adjust the capabilities of the welding machine during the work. All this threatens to waste time and further difficulties in using welding equipment to the maximum of its capabilities.

Load duration (LOD) of the welding inverter. What is it and why should you know it?

Why do you need to know and observe PN - the load duration of the welding machine? How to prevent overloading of the inverter and its breakdown? How to operate an inverter taking into account the PN?

As a rule, in the descriptions of the welding inverter (passports, instructions, advertising brochures) the rated welding current in amperes is indicated with the corresponding value of the load duration (load duration) in percent. The rated welding current is the current at which the inverter will operate without overload and will not overheat, taking into account compliance with the PN (%), i.e. in intermittent mode.

■ Load duration - PN (%) of the welding inverter or switching duration - PV: Most welding sources - rectifiers and inverters in particular, operate in intermittent mode . This means that the period of operation under load (welding) alternates with a period of operation without load (idling, pause mode). These periods are repeated and form a welding cycle. The intermittent mode is characterized by Load Duration PN (%). The PN value is determined by dividing the operating time of the inverter under load (welding time - Tw.) by the total welding cycle time (welding time Tw. + pause time Tpause), as a percentage.

The welding cycle time is usually 5 minutes, for industrial rectifiers or inverters - 10 minutes.

The PN of the inverter can be 20, 30, 40, 60 or 100%, taking into account this value the rated welding current .

The manufacturer may indicate several values of the rated current with corresponding values of PN%, for example for the Forsazh-200 inverter: 200A – 40% 160A – 80% 140A – 100%

Example : For the popular inverter BARS Profi ARC-207D, the rated current at PN=60% will be 200A, at PN=100% the current will be 160A. (with a welding cycle of 5 minutes). You can work at a rated welding current of 200A for 3 minutes with 5mm electrodes, and the pause time should be at least 2 minutes (PN=60%). At a welding current of 160A, the inverter can operate in long-term (continuous) mode (PN=100%) with 4mm electrodes. As a rule, for Russian-made equipment, PN is calculated at an ambient temperature of 25°C, for Asian and European equipment - at a temperature of 40°C. It is believed that in practice it is impossible to work in the PN=100% mode, because technological time is always required to change the electrode, inspect the seam, remove slag, position parts, physiological breaks, rest, etc. Scientifically based PN, at which the welder is physically able to work during the shift - no more than 60%. Therefore, for professional devices, PN = 60% at rated current is more than sufficient,

For most European-made models, PN = 30% is the norm, because equipment is rarely used at full power for long periods of time. The PN value = 30-40% at maximum current should not confuse anyone.

For example , for the BARS MiniARC-200D inverter, PN=35% at a current of 200A. At the same time, with a decrease in air temperature, the PN of the source increases, as its cooling improves. At a temperature of 15º C, the load duration of this inverter will be approximately 50%, and at a current of 160A - about 60%. The inverter can operate with a 4mm electrode in the following mode: 3 minutes – welding, 2 minutes – pause, provided that the length of the welding cables does not exceed 3-5m. This is quite enough for work in domestic conditions. Therefore, when choosing an inexpensive household inverter, you can focus on the PN = 30% indicator, if the model, manufacturer and brand are trustworthy.

A number of unscrupulous manufacturers overestimate the rating data for current and PN%, as a result of which the inverter either does not provide the required current or operates with overload, overheats and fails. This is typical for cheap household appliances. Be careful! In addition to advertising materials, we recommend that you read passports, nameplates on the device body , and also study reviews about the operation of inverters.

Main characteristics of the welding inverter

Essentially the same characteristic of the operating current range. Sometimes, due to illiteracy or malicious intent, the diameter of the electrode is indicated, which will not be able to cook with the stated maximum current. Sometimes it’s the other way around: the maximum diameter of the electrode is indicated, which clearly does not reach the value of the declared welding current.

The latter option is occasionally a glimpse into the conscience of deceptive suppliers. They indicate the short-circuit current as the maximum current. But the maximum working diameter of the electrode is still indicated honestly.

Welding current type: direct (DC) or alternating (AC)

Cooking with constant (or direct, in English - DC) current is simpler: it is easier to hold the arc. Therefore, 99.9% of modern MMA inverter machines produce constant welding current.

But among transformers, previously the majority were AC devices.

Alternating current (in English - AC) is used for welding non-ferrous metals. But not with MMA devices, but with TIG devices. Therefore, an MMA welding inverter that produces alternating current is a rarity.

No load voltage

After turning on the device, until the arc is ignited, the voltage at the tip of the electrode is significantly higher than during operation. And the higher it is, the easier it is to ignite the arc. But standards prohibit open-circuit voltage levels on devices delivering direct current above 100V.

To further reduce risks, the so-called VRD blocks. A device equipped with a VRD has only a few volts at the tip of the electrode before the arc starts. And only when you touch the metal, the no-load voltage is restored to the level necessary to ignite the arc.

All electrodes always indicate the polarity of the connection, the type of welding current (direct or alternating) and the minimum level of open circuit voltage required for ignition. For the vast majority of widely used electrodes, it does not exceed 60V.

The open circuit voltage, as well as the welding current, depends on the input voltage level. The lower the voltage in the power supply, the lower the open circuit voltage. Therefore, as the supply voltage decreases, ignition of the electrode becomes more and more difficult.

Duty cycle, also known as PV (on period), also known as PN (payload)

PV is indicated by two numbers. The first is current strength. The second is the percentage of time. For example, “130A-50%” means that this device with a current of 130A can cook half the time. And the same amount of time will remain idle, waiting for cooling to operating temperature.

If measurements are carried out at the maximum current of the device, the first digit is omitted, leaving only the percentage indicator.

For example, if a device with a rating of 160A has the entry “30%” opposite “PV”, this means that with a current of 160 amperes it can operate 30% of the time, and 70% will cool down.

That's right. It only remains to add that the domestic GOST R IEC 60974-1-2004 does not establish a single mandatory method for measuring the PN indicator for MMA devices. “The standard does not apply to limited-duty manual arc welding power supplies that are designed primarily for non-professional use.”

The European methodology, set out in the EN60974-1 standard, suggests measuring on a load stand at an ambient temperature of 40C only until the first shutdown due to overheating. The result obtained is referred to a 10-minute period. It turns out that the thermal protection worked after 3 minutes, the cycle of the device at this current is 30%.

Methodology of the TELWIN concern. To date, it is used by most Chinese manufacturers (those that generally conduct such tests on their cars). The Italian concern itself, when measuring the PV of its devices using its own method, modestly indicates “TELWIN” after the indicator. The vast majority of Chinese manufacturers do not do this.

Finally, there is a Russian, also known as Soviet, methodology. In essence, it is closer to the TELWIN method: all intervals during the control period when the device was working are summed up. But the segment is taken not 10, but 5 minutes. And - most importantly - the device is first put into overheating protection mode, after which measurements begin.

As a result, the same device produces completely different percentages using all 3 methods! Naturally, the most modest “numbers” are obtained using the European method, and the most impressive ones – up to 2 times or more – using the Telwin method.

Version: IP protection class

The IP protection class indicates the performance of electrical devices in relation to solid objects (first digit) and liquids (second digit).

You can determine the degree of protection of the device visually. If a device with IP21 has all the ventilation slots completely open, then with IP22 they are already covered on top with protruding visors. And on a device with IP23, these visors almost completely cover the cracks.

The degree of protection IP24 and higher is technically difficult and makes no sense.

Version: insulation class (heat resistance)

Many materials lose their working properties when heated above a certain temperature. To standardize materials according to this criterion, a classification of insulation based on heat resistance has been introduced.

Almost all welding inverters using IGBT transistors have insulation class H, which corresponds to a maximum heating temperature of 180C. The previous “step” - class F - means a heating limit of 155C.

Above class F is only class C, indicating a possible heating temperature of over 180C.

Operating temperature

Like internal heating, external heating and especially cooling impose certain operating limitations. Most inverter welding machines are suitable for operation in the range from 0C to +40C. If the device is suitable for use in cold weather, its limit value must be indicated: minus 20C or minus 40C.

Author of the text: Yu. Shklyarevsky.

Mid-budget inverters

DEKO DKA-200 – an attractive offer on Ali

The model is included in the rating of the best devices in the mid-price category. The body is compact. Suitable for household needs. The seam quality is professional. The product comes with a shoulder strap, making it easy to carry the device. Processing materials: thin steel and other metal alloys.

View on Aliexpress

Technical description:

- current adjustment range – 20-200 A;

- power – 5800 W;

- protection class – IP21S;

- electrodes – 1.6-4 mm;

- duty cycle – 60% – 200 A, 100% – 115 A;

- dimensions – 28x23x12.5 cm;

- weight – 2.9 kg.

Advantages: built-in fan for cooling working units, digital display, accuracy of settings.

Disadvantages: none significant.

ANDELI MIG-250E – semi-automatic

The semi-automatic model has a good power reserve. The welding type and metal thickness are manually set, and the amperes are selected independently. The device is supplied with a MIG torch, grounding cable, and electrode clamp. Additional equipment: 1 kg of welding wire, 5 welding rods.

View on Aliexpress

Technical description:

- current adjustment range – 20-200 A;

- power – 3300 W;

- protection class – IP21S;

- electrodes – 0.8-5 mm;

- duty cycle – 60% – 100 A, 100% – 77 A;

- dimensions – 31x15x25 cm;

- weight – 5.2 kg.

Advantages: display, compact size, simple operation, fast delivery.

Disadvantages: there are complaints about the strength of the packaging.

Keygree Flux-135 – gasless device

The model is equipped with a reliable cooling system. The current settings are reflected on the digital display. Refill – 1 kg of welded wire. The device copes with low-carbon steel up to 4 mm thick. The device performs a simple connection of metal parts and point connections. Security option available. The body is made of metal and ABC plastic. For ease of transportation, an aluminum handle is provided.

View on Aliexpress

Technical description:

- power – 5500 W;

- frequency – 50-60 Hz;

- wire diameter – 0.8-1 mm;

- duty cycle – 40%;

- dimensions – 39x29.5x16.5 cm;

- weight – 6.2 kg.

Advantages: reliability, high power, carrying handle.

Disadvantages: short wires.

DGM DUOMIG-253E – convenient access to internal elements

Semiautomatic belongs to the class of professional tools. It is widely used in repair and construction work, when welding automotive steel and metal structures. The case is durable and equipped with a transport handle.

View on Aliexpress

Technical description:

- current adjustment range – 15-250 A;

- power – 4300 W;

- insulation class – N;

- wire diameter – 0.4-1 mm;

- welding type – TIG, MMA;

- dimensions – 42x20x30.5 cm;

- weight – 13 kg.

Advantages: mobility, compactness, 4 operating modes, informative display.

Disadvantages: flimsy clamp.

REBOOT MIG 1300 machine – best price on Aliexpress

The manufacturer refuted the statement that a good welding machine cannot be cheap. The MIG 1300 model is proof of this. This is a full-fledged station operating in a carbon dioxide environment.

View on Aliexpress

Technical description:

- current adjustment range – 30-130 A;

- power – 4500 W;

- insulation class – F;

- wire diameter – 0.8-1 mm;

- welding type – Gas/Gasless, TIG, MMA;

- dimensions – 41.5x27.3x31 cm;

- weight – 9.2 kg.

Advantages: light weight, compact, no problems during transportation.

Disadvantages: short cables, packaging is not always reliable (corners get wrinkled).

HITBOX Tig TIG200P – digital control

The device operates from a 110, 220V network. Despite its compactness, the device is capable of creating a neat seam with a thickness of 1.5-12 mm. Contents: electrode holder, clamp, consumables, gas tube. Packaging – cardboard box.

View on Aliexpress

Technical description:

- current adjustment range – 10-200 A;

- duty cycle – 60%;

- insulation class – F;

- welding type – DC TIG/ARC;

- housing protection – IP21;

- dimensions – 40x15x18 cm;

- weight – 8 kg.

Advantages: high quality, quick access to internal parts, delivery within 2-5 weeks.

Disadvantages: short cables.

START MigLine 190 – for precise and complex work

Semi-professional model. Air cooling system. Efficiency indicator – 85%. Scope of application: small production, construction, installation and repair at home, body work. Cables (3 pcs.) in good braiding, length 3 m.

View on Aliexpress

Technical description:

- current adjustment range – 30-180 A;

- power – 6000 W;

- insulation class – F;

- welding type – DC TIG/ARC;

- wire – 0.6-1 mm;

- dimensions – 50x30x25 cm;

- weight – 9 kg.

Advantages: minimal amount of splashes during cooking, smooth adjustment of wire feed.

Disadvantages: the gas supply valve is electric.

IGBT MIG 200D3 – with overheating protection

The body is made of metal and durable plastic. The upper part is equipped with a rigid handle, which makes it easy to transport the device. The current settings are shown on the digital display. Cable length is 2 m. There is a gas connector. Equipment: device, cables, flashlight, mask and brush.

View on Aliexpress

Technical description:

- current adjustment range – 20-200 A;

- duty cycle – 60% – 200 A;

- speed – 2.2-12 m/min;

- welding type – MIG/MMA/TIG;

- housing protection – IP21S;

- dimensions – 50x30x25 cm;

- weight – 9 kg.

Advantages: protection against overheating, light weight, neat weld.

Disadvantages: none significant.

Apparatuses used for welding metals

Classification scheme of transformers depending on the methods of their power supply.

Electric or arc welding is the primary method for creating permanent connections. Welding machines are also used for cutting metals. All these devices can be called sources of current, adjustable in magnitude, which is the main element of the product.

- Welding transformers. The simplest current source is a step-down transformer, with the help of which the network voltage (220 or 380 V) is reduced to the value required for welding. The transformer itself is heavy, but to improve welding conditions and for welding non-ferrous metals, other rather heavy elements are used, and the whole structure turns out to be bulky. During the welding process, there is always a strong voltage drop in the network, a “sag”. It is inconvenient to work with such massive structures. However, transformers have a significant positive quality: they are relatively inexpensive and, most importantly, durable and reliable in operation.

- Welding rectifiers. This is the same step-down transformer, at the output of which there is an AC-to-DC voltage converter (rectifier unit), and it has a device for regulating the amount of welding current. With direct current, better characteristics of the electric arc are obtained and, as a result, a better quality seam, which is their advantage over a transformer. In this design, like the transformer, there is practically nothing to break. In terms of weight and cost, welding rectifiers are not very different from transformers and have the same positive qualities and the same disadvantages.

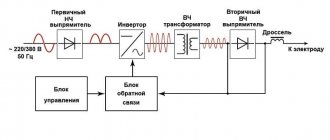

- Inverters. A very complex modification of the welding power source that has recently appeared on the market.

Mini welding machines

WERT MMA 180N – a great option for a beginner

The device is easy to use. It is easy for beginners to understand the device and operating principle. Purpose – connection of metal parts and structural elements. The assembly is high quality. The seam turns out smooth. Useful options include: hot start, arc force, anti-sticking. The seller offers a detailed review of the model on the website.

View on Aliexpress

Characteristics:

- type of welding – manual arc;

- power indicator – 3700 W;

- protection class – IP 21S;

- min. and max. carbon diameters – 1.6-4 mm;

- PV – 60%.

Pros: light weight, neat assembly, compact size.

Cons: wires are a bit short.

ZX7-250 – high power output

The device is equipped with functions: anti-stick protection, built-in traction, thermal arc start, etc. There is a European quality certificate. The device is equipped with a hex key, welding wire, grounding wire, and a 1.5 m long cable. The plug is Euro.

View on Aliexpress

Characteristics:

- current setting – 20-250 A;

- welding thickness – 2-6 mm;

- dimensions – 20x8.5x12 cm;

- min. and max. carbon diameters – 1.6-2.5 mm;

- weight – 1.85 kg.

Pros: digital control, neat welding seam, VRD option, fast delivery.

Disadvantages: the electrode takes the three well, a thicker one does not cook well.

PRACMANU ARC-225 – the best mini device

The miniature device is endowed with good technical parameters. Current range – 20-225 A. Pulse frequency – 50-60 Hz. The size is compact, the device fits on your hand. The housing is protected from dust and splashes. Supplied in a cardboard box with foam inserts to prevent damage to the package during transportation.

View on Aliexpress

Characteristics:

- voltage – 220 V;

- protection class – IP21;

- duty cycle – 40%;

- electrodes – 1.6-2.5 mm;

- dimensions – 25x15x10 cm;

- weight – 2.5 kg.

Pros: compact, light weight, simple controls, fast delivery.

Cons: suitable for small amounts of welding work.

KeyGree – attractive price

The seller offers several modifications of the tool - ARC-200/220/240 MINI. The device has a powerful cooling system. The current settings are reflected on the digital display. Useful options include: micro-adjustment of voltage, automatic adjustment of wire feed speed, etc. Number of modes – 3. The wires are thick and well-braided.

View on Aliexpress

Characteristics:

- voltage – 220 V;

- electrodes – up to 4 mm;

- dimensions – 29.5x16.5x3.9 cm;

- weight – 6.2 kg.

Pros: suitable for simple work and spot welding, safety, equipped with a belt, which allows you to carry the device over your shoulder.

Cons: not always fast delivery.

ARC-225 – portable device

The model is small in size, but combines good technical qualities with functionality. Even a beginner can handle the controls. The case is durable, made of metal. The assembly is neat. The engine is from the ZX7-250. Wires in a reliable braid (diameter - 1 cm).

View on Aliexpress

Characteristics:

- voltage – 150-270 V;

- frequency – 50-60 Hz;

- current adjustment range – 10-225 A;

- dimensions – 33.5x14.5x28.5 cm;

- weight – 3 kg.

Pros: portability, functionality, durable thick wires.

Cons: Reviews mention problems with packaging and delivery.

RESANTA SAI-190K 65/36 – high performance

In the budget category, the device has a high current rating (190 A). At the same time, the lightweight design is maintained. The device will cope with most tasks in private households and in the country. The model is also suitable for mini-workshops.

View on Aliexpress

Characteristics:

- voltage – 140-240 V;

- protection class – IP21;

- electrodes – 1.6-5 mm;

- power – 5500 W;

- dimensions – 31x13.5x25 cm;

- weight – 4 kg.

Pros: hot start option, anti-sticking, low energy consumption, tunnel-type overheating protection.

Cons: lacks a case, short wires.

Drillpro MMA-400 – Advanced IGBT Inverter Technology

The body is made of metal and ABC plastic. The cables are durable and well braided. The model is equipped with a grounding clamp with a cable, an electrode holder with a wire, and a brush. Packaging – cardboard box. Delivery from China - within 2-5 weeks.

View on Aliexpress

Characteristics:

- current adjustment range – 20-115 A;

- protection class – IP21S;

- electrodes – up to 2.5 mm;

- duty cycle – 60%;

- dimensions – 9.5x23.5x15 cm;

- weight – 4 kg.

Pros: digital display, hot start, arc strength, high welding efficiency.

Cons: the box is sometimes damaged during transportation (the product remains intact).

Professional reliable welding machines

ANDELI TIG-250MPL – intelligent device

The model is equipped with a high-speed upgraded ARM processor. The device performs continuous draw and spot welding. There is a cold welding option. A reliable handle is built into the upper part of the case. With its help, the tool is easier to transport.

View on Aliexpress

Technical information:

- frequency – 50-60 Hz;

- electrode parameters – 1.5-4 mm;

- Max. current – 180 A;

- ignition – non-contact;

- cooling system – air;

- size – 27x38x14 cm;

- weight – 7 kg.

Pros: durable housing, digital display, user-friendly control panel.

Cons: requires mastering the settings, delivery is not always fast.

START WEGA 200 miniMIG – overvoltage protection

The device has a 2-stroke and 4-stroke control mode. Welding is performed with stick electrodes (MMA). You can manually adjust the voltage. Thanks to a reliable cooling system, the operating time is not limited to a certain time.

View on Aliexpress

Technical information:

- welding current – 50-200 A;

- electrode parameters – 0.6-4 mm;

- insulation class – N;

- modes – MIG; MMA; TIG;

- Efficiency – 85%;

- power – 7800 W;

- size – 46x31x17 cm;

- weight – 10 kg.

Pros: manufacturer's warranty (2 years), synergetic control panel.

Cons: rather weak clamp.

Aurora PRO OVERMAN 180 – high quality seam

A neat and durable seam is obtained by adjusting the current, inductance and welding voltage. The model is among the top most reliable devices on Ali. The popularity is due to the high productivity and efficiency of the tool.

View on Aliexpress

Technical information:

- welding current – 40-175 A;

- electrode parameters – 0.6-1 mm;

- PV – 60%;

- cooling – air;

- mode – with gas, without gas;

- power – 4700 W;

- size – 46.5x20x47.5 cm;

- weight – 15 kg.

Pros: adjustable wire feed speed, arc stability.

Cons: none significant.

KEYUE TIG200P AC DC – with remote control

The device is multifunctional. Copes with any thickness of metal. The settings are precise, which allows you to achieve high results. You can create the effect of a wide and thin drop. Options include saving parameters.

View on Aliexpress

Technical information:

- welding current – 40-200 A;

- electrode parameters – 0.6-1 mm;

- Efficiency – 70%;

- cooling – air;

- power – 5000 W;

- size – 49.6x21.2x38 cm;

- weight – 14.75 kg.

Pros: performance, neat seam, instant response to changing settings, fast delivery.

Cons: flickering display.

ANDELI TIG-250PL – simple control

The model is designed for welding on alternating and direct current. Qualitatively connects parts made of aluminum, non-ferrous metals and other alloys. The control panel is clear, you can figure it out without instructions. Supplied with grounding cables, clamp. The packaging is reliable.

View on Aliexpress

Technical information:

- welding current – 10-200 A;

- electrode parameters – 0.1-1 mm;

- frequency – 50-60 Hz;

- housing protection – IP21S;

- power – 5700 W;

- size – 50x23.8x39 cm;

- weight – 12.6 kg.

Pros: durable body, neat seam, fast delivery from China.

Cons: none significant.

TywelMaster MIG218XPulse - the most reliable

When developing the model, new generation inverter technology was used. The result is an energy-efficient device with high performance. Work in modes – TIG, MMA, MIG.

View on Aliexpress

Technical information:

- welding current – 20-200 A;

- electrode parameters – 0.1-6 mm;

- frequency – 50-60 Hz;

- housing protection – IP21S;

- wire feed speed – 2-15 m/min;

- size – 55x19.5x37.5 cm;

- weight – 13 kg.

Pros: large graphical interface, portability, many settings, argon-arc welding function.

Cons: not always fast delivery.

Distinctive features of inverters

Types of welding power sources.

Having made sure that an inverter is suitable for performing a small amount of welding work at home, you should understand how the individual models of these current sources differ from each other.

There are two technologies for their production: MOSFET and IGBT. In the middle of the last century, MOSFET technology was developed. However, modern models made using IGBT technology turned out to be much more economical. In Europe, where they take energy saving seriously, only models made using this technology are available for sale.

In our retail network you can still find both types of these products. Therefore, there is a need to talk about their differences. Perhaps someone will consider it an appropriate option to purchase a less economical, but cheaper product made using MOSFET technology. They are more suitable for welding simple welds at home and are still more reliable than devices made using IGBT technology. With a small amount of work, the advantages associated with lower energy costs are not of practical importance.

IGBT inverter.

IGBT inverters operate at a frequency of 60-85 kHz, higher than that of a MOSFET inverter, which makes it possible to further reduce the weight of the entire structure. IGBT technology is more reliable in temperature characteristics. The emergency shutdown temperature for overheating is 90°C, which is approximately 30˚ higher than that of MOSFET technology devices.

But there is something to think about here too. If the duration of the actual welding is short, then this advantage may not be significant.

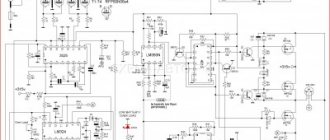

Regarding such an important issue for inverters as repairs, the opinions of those who perform it differ. MOSFET technology devices have more parts, but they have easier access, which is an advantage for repairs. Some people think so. Others believe that an IGBT technology inverter that is compact and has fewer elements fails less often and is easier to repair.

More significant is the fact that the IGBT inverter is better suited for welding not only ferrous, but also non-ferrous metals and cast iron.

What should you pay attention to when purchasing a device?

Structures of single-phase PWM inverters.

The purchase of such a welding machine in itself is quite expensive, but its repair can also be expensive. For example, replacing the main element, called the motherboard, will cost about half the cost of the entire inverter. Therefore, when purchasing an expensive item, do not hesitate to bother the seller, try to get as much information as possible from him and carefully study the documentation of the inverter welding machine.

- All inverters, in accordance with the standards, have three modes: Anti-Sticking and Arc-Force eliminate sticking of the electrode during the welding process and reduce the current after switching on; the Hot‑Start mode automatically increases the current at the moment the electrode touches the seam and ensures reliable ignition of the arc.

- For inverters assembled on elements sensitive to accumulating dust, their ventilation is of great importance. It should be organized so that as little dust as possible accumulates on the boards. It is better if the product has two fans.

- The range of operating temperatures is also important. Even if you plan to use the inverter only in a heated room, it is possible that there will be a need to use it in winter conditions, in frost.

- For work in rural areas, the voltage range in which the manufacturer guarantees reliable operation of the inverter is essential. The usually regulated voltage deviation of ±10% is almost never maintained in rural areas. There are models that have a significantly larger operating range.

- It would be a good idea to ask whether parts are available for the model you are purchasing and what the delivery time is. The presence of parts may indicate either that such a model is often repaired, or that the manufacturer cares about the consumers of its products.

- In everyday life, 3 mm electrodes are usually sufficient for welding, but it is better to use the table No. 1 below (Ratio of the thickness of the parts to be welded, the diameter of the electrode and the current required).

| Thickness of parts, mm | 0,5 | 1-2 | 3 | 4-5 |

| Electrode diameter, mm | 1 | 1,5-2 | 3 | 3-4 |

| Welding current, A | 10-20 | 30-45 | 65-100 | 100-160 |