After installing pipelines and technical tanks, it is important to check the tightness of the connection so that there is no leakage of transported media and the structure does not collapse under pressure. Structural welding defects and microcracks in the heat-affected zone are detected by capillary inspection of welds. To conduct research, contrast liquids that easily penetrate microdefects are used. Lack of penetration, fistulas, burns on the surface of the seam are immediately visible. Internal discontinuities of metals and non-metals (nylon, PVC, polyethylene) are determined using equipment for non-destructive diagnostics of welded joints. Inspection using dyes helps to detect defects and accurately determine the size of structural defects. Thanks to non-destructive color testing, it is possible to detect critical structural changes in and around the welded joint, in the heat-affected zone. If the welding technology is violated or overheated, residual stresses are formed at the seam, leading to the formation of cracks.

Content

- The essence and scope of application of the capillary flaw detection method

- Classification of capillary flaw detection methods

- Basic control methods

- Combined methods of penetrant control

- Penetrant flaw detection technology

- Stages of penetrant control

- Penetrant testing materials

- Preparation and preliminary cleaning of the surface to be tested

- Application of indicator liquid

- Intermediate surface cleaning

- The process of manifestation of surface defects in a weld

- When using fluorescent indicator liquids

- When using colored indicator liquids

Flaw detection materials

The degree of reliability of the visual assessment of the results of penetrant testing depends on the quality of the target sets of flaw detection materials that meet the conditions that apply to the test object. The target kit contains the following chemicals:

- penetrant;

- cleaner;

- developer.

Chemicals from sets or combinations must be mutually compatible and must not reduce the technical quality of controlled environments, semi-finished products or products.

One of the leaders in the domestic flaw detection market, from Kazan, offers sets and combinations of chemicals necessary when using the capillary method:

- Magnaflux SPOTCHECK SCD-S2 developer is used at temperatures from -5°C to +50°C, compatible with Magnaflux SPOTCHECK SKL-SP2 dark red penetrant and SKC-S cleaner;

- Sherwin D-106 developer suitable for use at temperatures down to -30°C in conjunction with Sherwin N-120 cleaner and Sherwin LTP-82 low-temperature penetrant;

- developer for color flaw detection Helling NORD TEST U-89 providing indication of defects up to 0.00025 mm in size, applicable at temperatures from -10°C to +100°C, compatible with dark red penetrant Helling NORD TEST U-88;

- Sherwin D-100 developer, compatible with Sherwin DP-55 universal dark red penetrant, Sherwin DR-60 cleaner in the operating temperature range from +10°C to +50°C.

| Developer Sherwin D-100 | Developer U-89 | Cleaner Magnaflux SKC-S |

These sets and combinations of chemicals make it possible to detect surface defects of any size and configuration; they cover the entire range of controlled environments, products and semi-finished products in all sensitivity classes.

The quality of flaw detection chemicals, as well as the correctness of the penetrant testing technique, is checked with a standard sample - a standard. The sample is a standard; it is a plate made of St20 steel with a dead-end crack made on its surface, the opening width of which corresponds to the I, II or III sensitivity class of capillary testing.

The essence and scope of application of the capillary flaw detection method

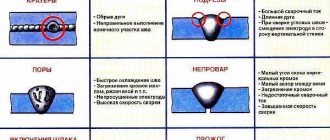

Penetrant testing of welded joints is used to detect external (surface and through) defects in welds and adjacent heat-affected zones. This testing method allows you to identify defects such as hot and cold cracks in welds, lack of penetration, pores, cavities and some others.

Using penetrant flaw detection, it is possible to determine the location and size of the defect, as well as its orientation along the metal surface. This method is used both when welding ferrous metals and when welding non-ferrous metals and alloys. It is also used in welding plastics, glass, ceramics and other materials.

The essence of the capillary testing method is the ability of special indicator liquids to penetrate into the cavities of seam defects. By filling defects, indicator liquids form indicator traces, which are recorded during visual inspection or using a transducer. The procedure for penetrant control is determined by standards such as GOST 18442 and EN 1289.

How to apply liquid

We have already said that liquid application during capillary control can occur using a spray can or brush. These methods are the simplest. When working with a spray can and a brush, the substance itself penetrates into the seams.

You can also use one familiar method: immersing the part in a tank with a substance. The temperature regime of penetrates is from five to fifty degrees. Therefore, application can be done outdoors.

Another method of applying penetrant is called vacuum. It is much more expensive, but at the same time more effective. The workpiece is placed in a vacuum chamber, and then the air is pumped out. In areas with defects, the pressure level decreases.

Then a substance is launched that selects the places you need. This method is used when high-quality testing for defects is necessary, but another method cannot be used.

The latter method involves the use of sound and ultrasonic waves. They act on the liquid and drive it into the joints. However, when using this method, the defect may become deformed.

Classification of capillary flaw detection methods

Penetrant testing methods are divided into basic and combined. The main ones involve only capillary control with penetrating substances. Combined methods are based on the combined use of two or more methods of non-destructive testing of welded joints, one of which is penetrant testing.

Basic control methods

The main control methods are divided into:

- Depending on the type of penetrant:

- penetrant testing

- testing using filter suspensions

- Depending on the method of reading information:

- brightness (achromatic)

- color (chromatic)

- luminescent

- luminescent-colored.

Combined methods of penetrant control

Combined methods are divided depending on the nature and method of exposure to the surface being tested. And they happen:

- Capillary-electrostatic

- Capillary-electroinduction

- Capillary-magnetic

- Capillary-radiation absorption method

- Capillary radiation method.

Penetrant flaw detection technology

Before performing penetrant testing, the surface to be tested must be cleaned and dried. After this, an indicator liquid, panetrant, is applied to the surface. This liquid penetrates into the surface defects of the seams and after some time, intermediate cleaning is carried out, during which excess indicator liquid is removed. Next, a developer is applied to the surface, which begins to draw the indicator liquid from the weld defects. Thus, defect patterns appear on the controlled surface, visible to the naked eye, or with the help of special developers.

Stages of penetrant control

The control process using the capillary method can be divided into the following stages:

- Preparation and pre-cleaning

- Application of indicator liquid

- Intermediate cleaning

- Manifestation Process

- Detection of welding defects

- Drawing up a protocol in accordance with the results of the inspection

- Final surface cleaning

Penetrant testing materials

The list of necessary materials for carrying out penetrant flaw detection is given in the table:

Indicator liquid

| Intermediate cleaner | Developer | |

| Fluorescent liquids Colored liquids Fluorescent colored liquids | Water | Dry developer |

| Oil based emulsifier | Water-based liquid developer | |

| Soluble Liquid Cleaner | Aqueous developer in the form of a suspension | |

| Water sensitive emulsifier | Solvent based liquid developer | |

| Water or solvent | Liquid developer based on water or solvent for special applications |

Preparation and preliminary cleaning of the surface to be tested

If necessary, contaminants such as scale, rust, oil stains, paint, etc. are removed from the controlled surface of the weld. These contaminants are removed using mechanical or chemical cleaning, or a combination of these methods.

Mechanical cleaning is recommended only in exceptional cases, if there is a loose film of oxides on the controlled surface or there are sharp differences between the weld beads or deep undercuts. Mechanical cleaning has received limited use due to the fact that when it is carried out, surface defects are often closed as a result of rubbing, and they are not detected during inspection.

Chemical cleaning involves the use of various chemical cleaning agents that remove contaminants such as paint, oil stains, etc. from the surface being tested. Residues of chemical reagents can react with indicator liquids and affect the accuracy of control. Therefore, after preliminary cleaning, chemicals must be washed off the surface with water or other means.

After preliminary cleaning of the surface, it must be dried. Drying is necessary to ensure that no water, solvent, or any other substances remain on the outer surface of the seam being tested.

Application of indicator liquid

The application of indicator liquids to the controlled surface can be carried out in the following ways:

- By capillary method. In this case, filling of weld defects occurs spontaneously. The liquid is applied by wetting, immersion, jet or spraying with compressed air or inert gas.

- Vacuum method. With this method, a rarefied atmosphere is created in the defect cavities and the pressure in them becomes less than atmospheric, i.e. a kind of vacuum is obtained in the cavities, which absorbs the indicator liquid.

- Compression method. This method is the opposite of the vacuum method. Filling of defects occurs under the influence of pressure on the indicator liquid exceeding atmospheric pressure. Under high pressure, the liquid fills the defects, displacing air from them.

- Ultrasonic method. Filling of defect cavities occurs in an ultrasonic field and using the ultrasonic capillary effect.

- Deformation method. Defect cavities are filled under the influence of elastic vibrations of a sound wave on the indicator liquid or under static loading, which increases the minimum size of defects.

For better penetration of the indicator liquid into the cavities of defects, the surface temperature should be in the range of 10-50°C.

Intermediate surface cleaning

Substances for intermediate surface cleaning should be applied in such a way that the indicator liquid is not removed from surface defects.

Cleaning with water

Excess indicator liquid can be removed by spraying or wiping with a damp cloth. At the same time, mechanical impact on the controlled surface should be avoided. The water temperature should not exceed 50°C.

Solvent cleaning

First, remove excess liquid using a clean, lint-free cloth. After this, the surface is cleaned with a cloth moistened with a solvent.

Cleaning with emulsifiers

Water-sensitive emulsifiers or oil-based emulsifiers are used to remove indicator liquids. Before applying the emulsifier, it is necessary to wash off excess indicator liquid with water and immediately apply the emulsifier. After emulsification, it is necessary to rinse the metal surface with water.

Combined cleaning with water and solvent

With this cleaning method, excess indicator liquid is first washed off from the monitored surface with water, and then the surface is cleaned with a lint-free cloth moistened with a solvent.

Drying after intermediate cleaning

To dry the surface after intermediate cleaning, you can use several methods:

- by wiping with a clean, dry, lint-free cloth

- evaporation at ambient temperature

- drying at elevated temperatures

- air drying

- a combination of the above drying methods.

The drying process must be carried out in such a way that the indicator liquid does not dry out in the cavities of the defects. To do this, drying is performed at a temperature not exceeding 50°C.

The process of manifestation of surface defects in a weld

The developer is applied to the controlled surface in an even thin layer. The development process should begin as soon as possible after intermediate cleaning.

Dry developer

The use of dry developer is only possible with fluorescent indicator liquids. The dry developer is applied by spraying or electrostatic spraying. The controlled areas should be covered uniformly and evenly. Local accumulations of developer are unacceptable.

Liquid developer based on aqueous suspension

The developer is applied uniformly by immersing the controlled compound in it or by spraying it using a device. When using the immersion method, to obtain the best results, the duration of the immersion should be as short as possible. The compound to be tested must then be evaporated or blast dried in an oven.

Solvent based liquid developer

The developer is sprayed onto the controlled surface so that the surface is evenly wetted and a thin and uniform film is formed on it.

Liquid developer in the form of an aqueous solution

Uniform application of such a developer is achieved by immersing the controlled surfaces in it, or by spraying with special devices. The immersion should be short-term; in this case, the best test results are achieved. After this, the controlled surfaces are dried by evaporation or blowing in an oven.

Duration of the development process

The duration of the development process lasts, as a rule, for 10-30 minutes. In some cases, an increase in the duration of manifestation is allowed. The development time countdown begins: for dry developer immediately after its application, and for liquid developer - immediately after drying the surface.

Detection of welding defects as a result of penetrant flaw detection

If possible, inspection of the controlled surface begins immediately after applying the developer or after drying it. But the final control occurs after the development process is completed. Magnifying glasses or glasses with magnifying lenses are used as auxiliary devices for optical inspection.

When using fluorescent indicator liquids

The use of photochromatic glasses is not permitted. It is necessary for the inspector's eyes to adapt to the darkness in the test booth for a minimum of 5 minutes.

Ultraviolet radiation should not reach the inspector's eyes. All monitored surfaces must not fluoresce (reflect light). Also, objects that reflect light under the influence of ultraviolet rays should not fall into the controller’s field of view. General ultraviolet lighting may be used to allow the inspector to move around the test chamber without obstruction.

When using colored indicator liquids

All controlled surfaces are inspected in daylight or artificial light. The illumination on the surface being tested must be at least 500 lux. At the same time, there should be no glare on the surface due to light reflection.

Repeated capillary control

If there is a need for re-inspection, then the entire penetrant flaw detection process is repeated, starting with the pre-cleaning process. To achieve this, it is necessary, if possible, to provide more favorable control conditions.

For repeated control, it is allowed to use only the same indicator liquids, from the same manufacturer, as during the first control. The use of other liquids, or the same liquids from different manufacturers, is not permitted. In this case, it is necessary to thoroughly clean the surface so that no traces of the previous inspection remain on it.

How to clean

After applying the penetrant substance, you need to clean it from excess particles. To do this you will need a rag or sponge. You can take the ones you use when you wash dishes.

Dampen the rag and wipe all areas of the connection. This cleaning method is the simplest and least expensive, but it is not very effective.

You can also use a solvent, it will be more effective than ordinary water. In order to apply the solvent, you must first dry the part thoroughly. Although using solvent is more effective than water, there are even better ways.

The first thing that comes to mind is to combine the two previous methods. Use water first and then apply solvent. But if you want maximum effectiveness, you can buy a cleaner in a can.