home

About company

Directory

Armature

A1 fittings

AI reinforcement is a type of hot-rolled metal profile with a round cross-section with a smooth surface, made from carbon steel in accordance with GOST 5781-82. Mechanical static characteristics and performance qualities of AI allow the use of this reinforcing bars in various fields of construction (manufacture of reinforced concrete and metal structures for various purposes), in the coal industry, in the long-distance transportation of oil, gas, etc.

AI marking, range, weight and technical characteristics

According to the international classification, AI fittings are designated by the abbreviation A240 and are produced with a diameter of 6 to 40 mm. For standard marking, the following algorithm is used: in the first place is the number - the diameter in mm, then the class designation and GOST. For example, the marking of AI reinforcement with a diameter of 25 mm is written as follows: 25-AI (A240) GOST 5781-82.

| Diameter | Weight, kg/1 m.p. | Number of meters in 1 ton | Diameter | Weight, kg/1 m.p. | Number of meters in 1 ton | Diameter | Weight, kg/1 m.p. | Number of meters in 1 ton |

| 6 | 0,222 | 4504,50 | 14 | 1,210 | 826,45 | 22 | 2,980 | 335,57 |

| 8 | 0,395 | 2531,65 | 16 | 1,580 | 632,91 | 25 | 3,850 | 259,74 |

| 10 | 0,617 | 1620,75 | 18 | 2,000 | 500,00 | 28 | 4,830 | 207,04 |

| 12 | 0,888 | 1126,13 | 20 | 2,470 | 404,86 | 32 | 6,310 | 158,48 |

Class AI reinforcement with a diameter of 6, 8, 10, 12 mm is manufactured both in coils and in the form of rods (measured and unmeasured lengths from 6 to 12 meters); AI reinforcement, the diameter of which is more than 12 mm, is manufactured only in the form of rods.

Reinforcement length standard regulated by GOST

The length of the reinforcement depends on several factors:

- Norms established by state standards.

- According to the wishes of customers.

- Technical specifications of the manufacturer.

- Generally accepted standard sizes of other materials and products used in construction.

The main document regulating the length of steel or composite reinforcement is GOST for the corresponding material. The standards define the lengths of products, as well as errors and tolerances when compiling individual batches.

Length of rods according to GOST5781-82

In accordance with this document, products are manufactured with a diameter from 6 to 80 mm. The size of the cross-section of the reinforcement determines how it will be supplied in coils or rods. This applies to the most popular fittings of class A1 (A240) and A300 with a diameter of 6-12 mm. Products of the same classes of large sizes are supplied only in rods.

Reinforcement transportation options

Products of class A400 can be supplied in rods and coils with a transverse size of up to 10 mm. Products with a larger cross-section are made only with rods.

Reinforcing bars of other classes (A600, A800 and A1000), as a rule, are produced in rods. But, by agreement with the customer, production in skeins is allowed.

The standard length of reinforcement according to GOST 5781-82 varies from 6 to 12 m.

Deliveries are carried out in three versions.

- In batches of rods of exclusively measured length. When supplied, the rods have one standard length in the range from 6 to 12 m. The required size is specified in advance in the contract between the plant and the customer.

- With the presence of unmeasured rods in the measured supply. Their length should be taken from 2 m. And the content of rods of non-standard length should not exceed 15% of the total weight of the delivery.

- In batches with unmeasured segments. The presence of rods from 3 to 6 m is allowed. However, the percentage of such rolled products is limited to 7% of the total weight of the supply.

According to GOST 5781-82, the maximum length of supply of fittings is allowed to be 25 m, but subject to prior agreement on product dimensions between the supplier and the buyer.

Another parameter on which the actual length of the reinforcement depends is the maximum deviation in the length of the bars. The standard establishes the following cutting tolerances.

- With a rod length of up to 6 m, and normal cutting accuracy, deviation is allowed up to 50 mm in a larger direction, with an increased one - up to +25 mm.

- For rods longer than 6 m, deviation is allowed - with normal accuracy up to 70 mm, with increased accuracy no more than +35 mm.

High-precision cutting is assigned only at the request of the customer.

The most popular length of construction reinforcement supplied from the factory is 11 m 70 cm, as this is the most transportable size.

When transported in skeins, the length of the products may vary. This is explained by the fact that the standard imposes requirements not on the length of the rods, but on the mass and content of the coil. The reinforcement must be of continuous length, the mass of the coil must not exceed 3 tons. For example, the length of a coil of A240 reinforcement with a diameter of 10 mm will be about 4860 m, and 12 mm rods will be approximately 3380 m.

GOST 10884-94: length of thermomechanically strengthened rods

The standard regulates the production of rods with a diameter of 6-40 mm. Their length ranges from 5.3 to 13.5 m, but by agreement with the customer, it is possible to produce rods with a maximum length of 26 m. Welded rods (indicated by the index “C” in the class marking) can be produced in batches:

- Measured, with the inclusion of unmeasured rods from 2 m. The number of unmeasured segments is allowed no more than 15% of the delivery weight.

- Unmeasured, from 6 to 12 m. The content of rods 3-6 m is set in a volume not exceeding 7% of the total weight of the shipment.

The standards and tolerances for cutting, as well as the conditions for supplying reinforcing bars in coils in accordance with GOST 10884-94 completely coincide with the values defined by GOST 5781-82.

Length of reinforcement А500С and В500С: GOST 52544-2006

The standard regulates the production of rods with a cross section from 4 to 40 mm. Products with a diameter of up to 6 mm are shipped to consumers only in continuous coils weighing 0.3-1.5 tons, 6-12 mm - in coils or rods, from 14 mm or more - in rods.

It is also possible to supply reinforcement in coils consisting of two sections, but with the condition: their share should not exceed 10% of the total weight of the shipment.

Steel rods are available in lengths:

- Measured in the range from 6 to 12 m. The exact length is established by agreement with the customer.

- Unmeasured in the range of 6-12 m. The permissible content of short rods with a length of 3-6 m is established in an amount not exceeding 7% of the total mass of the batch.

The permissible deviation in the length of reinforcing bars is set to +10 cm.

GOST 31938-2012: size of composite reinforcement

Composite reinforcement is produced with a diameter of 4-32 mm. According to GOST 31938-2012, they are manufactured from the factory with a length from 0.5 to 12 m in increments of 0.5 m - this is the standard length of products. It is also possible to produce longer rods.

Options for packaging and transportation of ASP.

The standard defines permissible deviations in the length of measuring rods, depending on their length:

- from 0.5 to 6 m – no more than 25 mm in the larger direction;

- from 6 to 12 m – up to +35 mm;

- from 12 m – no higher than +50 mm.

Due to the fact that composite reinforcing bars are used, including for the construction of large facilities, manufacturing plants offer the supply of reinforcement with a diameter of 4 to 8 mm in coils.

The use of reinforcing bars improves the strength characteristics of reinforced concrete structures and products when reinforcing columns, foundations, floor slabs, arches and many others. The choice of products is quite wide, so you can easily select a material suitable in length and diameter for any object.

The difference between class AI and AIII fittings

Of the extensive list of fittings, classes AI and AIII are the most popular; but, despite the fact that both types of fittings are equally often used, they differ in appearance, they have different compositions, they have different areas of application and perform different tasks. There are four main categories of differences:

- geometric dimensions

- AI class reinforcement has a round cross-section and a smooth surface. Class AIII reinforcement has a corrugated surface of the rod: two longitudinal protrusions-ribs (along the entire length of the rod), between which there are inclined transverse corrugations; - material of manufacture

- for the manufacture of AI, carbon, unalloyed steels are used: St3 calm, semi-quiet and boiling (St3Sp, St3Ps, St3Kp). For the production of AIII, low-alloyed manganese and boron grades are used: 32G2Rps, 35GS, 25G2S; - mechanical properties

- Due to alloying additives, the strength of AIII reinforcement is higher than that of AI: - AIII, Brinell hardness: HB 10 −1=202 MPa

AI, Brinell hardness: HB 10 −1=131 MPa

For the same reasons, specific viscosity and elongation at break differ in favor of AIII, but AI has better weldability, ductility and cold resistance.

The geometric shape also affects the mechanical characteristics: due to the corrugation, the AIII profile section for the same linear meter weight is less efficient than that of the AI, which puts the AI in a more advantageous position.

- since the area of the corrugated surface of AIII is larger than the smooth surface of AI (with equal diameters), the adhesion to concrete for AIII is significantly higher and the reinforcement effect is enhanced. An absolute plus seems to be such only at first glance. For example, rigid reinforcement of a roadway can lead to destruction due to short-term but large loads. And even minimal play (if you use smooth AI reinforcement) allows reinforced concrete to “give in” to fractions of a micron and maintain integrity under the influence of serious loads;

Technical characteristics of A1 fittings

Main physical characteristics:

- yield strength – 235 N/mm2;

- temporary tensile strength – 373 N/mm2;

- relative elongation – no less than 25%.

Performance properties of steel reinforcement A1 (A240):

- Good weldability due to low carbon steel construction.

- Environmental friendliness. These products have safety certificates indicating their compliance with regulatory requirements.

- Possibility of bending at the angle necessary to create a structure.

- Low resistance to corrosion. Increased by painting, galvanizing, aluminum zinc plating.

- Lower cost compared to periodic profile reinforcement.

Area of application AI

Relatively low weight, strength, ductility, and optimal price make class AI reinforcement universal and explain its demand in various fields:

- monolithic, low-rise and road construction, reinforcement of reinforced concrete products and structures (mainly for the manufacture of loop and connecting elements, when pouring concrete into corners and transitions, for the manufacture of reinforcing meshes and frames);

- mining and extractive industries;

- construction of main pipelines.

You can also:

- “Hot-rolled steel for reinforcement of reinforced concrete structures”;

- “Rolling of periodic profiles from reinforcing steel”;

- find out prices and buy A1 fittings

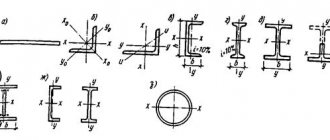

Types of bar reinforcement

Reinforcing bars are divided into types and classes. All types of rod products are produced in accordance with GOSTs, which determine standard lengths. It should be noted that the length of the products is determined not only by the type, but also by the class of reinforcement and its diameter.

Based on the material of manufacture, the range of reinforcement is divided into steel and polymer.

Steel reinforcement

Based on the characteristics of the production technology, the alloys used, and the purposes of use, reinforcing bars are classified according to GOST standards:

- hot-rolled steel in accordance with GOST 5781-82 - used to strengthen conventional structures, and prestressed ones;

- thermomechanically strengthened steel in accordance with GOST 10884-94 - due to its strength characteristics, it is installed for reinforcing critical structures made of reinforced concrete;

- weldable reinforcement of classes A500C and B500C according to GOST 52544-2006 - used to strengthen reinforced concrete products and structures.

Smooth and periodic profile reinforcement.

Steel reinforcement has a high level of strength and resistance to vibration, and works well under conditions of bending and tensile loads.

The main disadvantage is susceptibility to corrosion, which reduces the service life; storage in open areas is undesirable. Also, due to their significant weight, some construction organizations refuse to use steel rods in favor of polymer rods, which are lighter when calculated values allow.

Composite reinforcement

Composite reinforcement is manufactured in accordance with GOST 31938-2012 and, depending on the continuous reinforcing filler used, is divided into 4 types:

- fiberglass;

- basalt plastic;

- carbon fiber;

- aramidocomposite.

In the production of the first type of reinforcement, glass roving is used, obtained through the polymerization of epoxy resin. This material consists of glass threads of continuous length collected in a bundle. These bundles serve as the basis for creating internal fiberglass reinforcement rods.

For the manufacture of basalt-plastic reinforcement, polymers based on basalt are used. Basalt-plastic reinforcing material is gradually losing its position in the market. Consumers prefer glass roving products that are cheaper and more convenient to use.

In terms of cost, composite rods are not much more expensive than steel rods. Due to their low weight, they are convenient to transport and can be left for long-term storage in open areas. The rods are not subject to corrosion processes, are chemically inert: they do not react with salts, acids and alkalis. The disadvantage of fiberglass is insufficient bending work, the impossibility of welding when reinforcing structures and products.