The Ural 2T Electron chainsaw is designed for use in difficult conditions and for operations with large-sized trees and workpieces made from them. The most applicable areas are felling and bucking trees. The device can be used in aggressive conditions at critical low and high temperatures. The saw is mobile and does not depend on a power source. For long-term storage it is preserved using fuels and lubricants.

Chainsaw Ural 2T Electron

Description

Chainsaws "Ural" are products of a Russian machine-building plant located in the city of Perm. Currently, production has been moved to the city of Biysk. The Ural chainsaw is a kind of improved version of the Druzhba chainsaw, which was very popular several decades ago. Now Druzhba chainsaws are used more for domestic purposes, while Ural saws are produced for professional purposes.

Photo of the Friendship chainsaw

The first Ural chainsaw was released in 1935, since then the manufacturer’s product range has expanded significantly, the range of chainsaws is represented by both household and professional models with two-stroke gasoline engines. The advantages of Ural chainsaws over domestic analogues are the following technical characteristics:

- the ability to work for a long time on fuel of any quality (even medium-purified gasoline is suitable);

- omnivorous oils (any oil is suitable for 2T gasoline engines);

- large selection of spare parts and their reasonable cost;

- easy setup of the chainsaw;

- availability of models for specific tasks (household, professional, semi-professional);

- powerful motors, the ability to withstand intense loads, operation at any time of the year at any temperature.

Chainsaw Ural 2T Electron

The purpose of Ural chainsaws is very wide: tools of this category are successfully used in sawmills, sawmills, logging industries, in everyday life, and for municipal needs. Suitable for remodeling, can be used as a technique for harvesting firewood, cutting boards and beams. Another area of exploitation: construction of wooden houses, baths, saunas, cottages.

Chainsaw Ural 2T Electron is a saw for professional use. Equipped with a gasoline engine with a power of 5.5 horsepower. This power is equivalent to 4045 W. The saw is used for working with large-diameter trees, for harvesting wood, and for felling trees. Owners of the Ural 2T Electron chainsaw often talk about the possibility of converting this tool into a more universal one, for example, the Ural 2T Electron is often converted into a boat motor.

Chainsaw Ural 2T

This “second life” for the device is made possible thanks to the sustainability of the materials, high power and functionality of the device. Some owners even install a 2T Electron motor on a moped or snowmobile, or a household snow blower. The technical characteristics of the engine are such that it operates successfully in both cold and wet weather. Such homemade units, according to reviews from owners, are in no way inferior to the original equipment.

Chainsaw Ural BP 3800 – parameters of the popular model

This Ural brand gas powered tool is equipped with all the necessary options to ensure stable operation of the model under high loads. The factory equipment of the popular branded saw includes a reliable gas engine, a high-precision lubrication system for cutting parts, an effective modified anti-vibration damping system for continuous vibration damping and a pre-reinforced mechanical inertial mechanized brake.

Options:

- power – 5.16 l. With.;

- branded tire length – 45 cm;

- factory chain pitch – 0.325″;

- weight including headset – 6.45 kg.

The saw is equipped with an intelligent forced fuel injection system, which ensures continuous fuel supply for stable operation of the tool in any operating conditions.

Basic configuration, equipment, assembly

Basic equipment of the Ural 2T Electron chainsaw:

- engine power 5.5 horsepower;

- starter (ignition system);

- stop/start button;

- gas line;

- saw blade, chain;

- handles for holding a chainsaw;

- muffler;

- package;

- operating instructions, engine manual.

Production and assembly of the Ural 2T Electron chainsaw: Perm Machine-Building Plant named after. F. E. Dzerzhinsky. Assembly and production are not carried out in China; equipment from a Chinese manufacturer is a fake.

Purpose

In the USSR, 2 models of chainsaws were mass-produced - the Ural and Druzhba, and there was also the Parma electric saw. The Druzhba model was planned for small farms and was a “folk” product, and the Ural model was positioned as a professional-level tool intended for logging on an industrial scale.

Although in general these two saws are very similar, the Ural, as a more professional tool, has the ability to rotate the blade to a horizontal position in order to cut down a tree trunk while standing and not put so much strain on the operator’s back.

The use of the Urals in everyday life or at work greatly facilitates the already physically difficult work of loggers. This chainsaw can not only cut down trees, but also use it as an assistant in construction and household work, dismantling, bucking, and sawing firewood.

Instructions for use and maintenance

A detailed assembly diagram and operating diagram of the chainsaw are described in the instructions. We provide only the basic rules for operating and maintaining the tool. Immediately after assembly, we recommend that you break in the chainsaw and let the tool operate for several hours in normal mode while maintaining the factory carburetor settings. Later, you can adjust the carburetor as needed by the owner.

Rules for safe operation of the Ural 2T Electron chainsaw

- protect all parts of the body from damage when working with a chainsaw (it is recommended to use special protective shields for the right hand, as well as anti-vibration gloves, glasses or a plastic one-piece mask for the whole face, headphones to suppress noise);

- do not smoke when operating a chainsaw, smoking may cause a fire;

- Keep animals or children away from the area where the chainsaw is used;

- always turn off the tool if visual contact with the surface being cut is not possible;

- use the correct ratio for mixing oil and gasoline (for Ural chainsaws this ratio is 1:25);

- Perform tool maintenance in a timely manner and ensure that there is oil available to lubricate the chain.

Chainsaw maintenance

- regular maintenance - after completion of work and before starting sawing;

- monitor the condition of the chain, the degree of lubrication of the chain and blade, the presence of burrs on the chain sprockets;

- change the fuel mixture on time, use high-quality oil, good gasoline - this will extend the life of the chainsaw;

- It is recommended to adjust the carburetor after running in the tool (after the first 5 hours of operation) and then perform it as necessary.

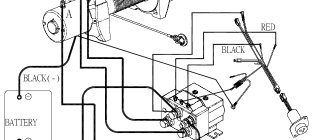

Carburetor KMP-100U of the Ural-2T Electron chainsaw

Main malfunctions of the model and their elimination

Let's look at the main reasons why a chainsaw refuses to work, as well as possible ways to eliminate such problems.

- The Ural 2T Electron chainsaw does not want to start or starts stalling right during operation.

The reason for this malfunction may be the following: clogged filters, low-quality fuel, low oil, insufficient lubrication on the saw blade.

Solving the problem: cleaning the filters, monitoring the level of fuel and lubricants.

- Sawing occurs with difficulty; as a result of the operation of the chainsaw, only small chips are formed.

Reason: Chain needs to be sharpened.

Sharpen with a special file or replace the chain.

Setting algorithm

Calibrating the carburetor of the Ural 2 Electron saw involves changing the amount of the fuel mixture and its quality characteristics. There are two types of adjustment.

Setting idle speed

Before proceeding with the adjustment, you should make sure that:

- The engine runs smoothly and the chain does not move.

- There is no strong smoke.

The adjustment algorithm looks like this:

- The Ural saw engine starts and warms up a little. Screw No. 3 sets the minimum speed so that the chain remains in place. If the mixture is too rich (strong smoke comes from the exhaust pipe), then screw No. 1 should be tightened a little. This will reduce smoke and increase speed.

- Then you need to return all settings to the level of minimum and stable speed. This is done by partially unscrewing screw No. 3.

- The next step is to test the engine for throttle response. If, after pressing the throttle lever firmly, the revolutions quickly go up, then everything is done correctly, and screw No. 3 must be securely fixed in this position.

If the engine stops working or the speed increases slowly, screw No. 1 should be turned out a little. In order to increase the speed, screw No. 3 is tightened slightly. Afterwards, the Ural saw engine is re-checked for throttle response.

Setting the maximum power

Power adjustment on the Ural 2 Electron chainsaw is carried out only after the break-in period has expired (it is 25 hours of operation) and after adjusting the idle speed.

Not fully tightening the propeller means introducing more air and less fuel. When the screw is unscrewed, the opposite happens, that is, the combustible mixture becomes richer. The most preferred position of the screws can only be determined experimentally.

When setting up the Ural carburetor, you must remember the following principles for the proper operation of the chainsaw:

- The engine should always have good cutting performance and smoke should be moderate.

- The engine should always have excellent throttle response. At the same time, during the process of cutting wood, the chain should not stop, the saw should not overheat, and the engine should not slow down on its own.

If a complete misadjustment of the carburetor occurs and the engine stops starting, it is recommended to perform the following actions:

- Screw No. 1 is screwed in completely until it stops, and then turned out one turn, no more.

- Screw No. 2 is tightened to the limit, and then turned out half a turn.

This will allow you to return the adjusting screws to their original position, and then carry out proper adjustment of the carburetor of the Ural chainsaw according to the standards described above.

Owner reviews

Roman, Krasnodar:

“I used an Electron 2T chainsaw while I had the opportunity, then I made a small modification and made myself a snow blower. This homemade product was very useful to me in everyday life. I had to tinker, and I needed to set up a lot of things and buy additional parts, but I managed. Now I use a snow blower with a 2T engine, it helps a lot in winter. Instead of the Urals, I bought another model of chainsaw, a German one. I was satisfied with the quality of the domestic chainsaw, but it was time to change something. I don't regret the new purchase. The Urals also have their pros and cons.

Among the disadvantages, I can highlight the heavy weight, the saw is more for professionals than for beginners, as well as high fuel consumption.

Advantages: power, functionality, technical parameters.”

Technical characteristics of the saw Ural 2T Electron

- Engine - gasoline, single-cylinder, two-stroke;

- Power, kW - 3.68;

- Fuel consumption, g/kW h - 632;

- Working length of the sawing apparatus, cm - 46;

- Vibration velocity level on the control handles, m/s - 7.9x10-2;

- Weight, kg - 11.7;

- Overall dimensions, mm - 460x880x460;

- Cylinder diameter, mm - 55;

- Engine power after 25 hours of running-in, kW, (hp) - not less than 3.68 (5);

- Engine crankshaft rotation speed at maximum power, min - 1 6200±200;

- Fuel consumption at maximum power mode, g/kW*h (g/l s.h.) - no more than 632 (465);

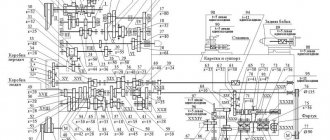

Fig.2

Use two MZx10 screws to tighten it to the console so that the screw heads are on the inside of the console. Using two standard M4 screws, the console is secured to the carburetor body. An M4 screw (stud) 62 mm long with a pre-screwed lock nut is screwed into the M4 threaded hole of the uterus ( photo 2 ).

At the end of the pin facing downwards, select a slot for a screwdriver. Drive the screw all the way into the bent flag on the throttle valve axis. Tighten the screw enough so that the damper opens slightly. Do not tighten the locknut yet. The final adjustment of the idle speed on the assembled, warm engine is carried out according to the instructions. But now, instead of adjusting the speed with the standard control lever, the speed is adjusted with a new adjusting screw. The throttle cable and shifter for setting constant speeds are used from motorcycles. In some cases, the shifter is replaced with a throttle handle (also from a motorcycle) if it is necessary to automatically reset the speed when releasing the handle in emergency situations. A new cable tip is made from brass or steel wire rod in the form of a cylinder d4.5 mm for the throttle valve lever (flag). Using a 2 mm drill, make a hole in the cylinder on the side in the middle. The cylinder is put on the end of the cable and soldered. The throttle valve control unit assembly is shown in Fig. 3 .

Fig.6

The modified control coil is put in place, and a bracket with a carrier is installed under it and both parts are tightened with standard screws and nuts. After this, the magneto is put in place ( photo 8 ).

Springs are installed on M4x35 screws, placing washers under them on both sides. The landing spots of the washers on the magneto are lubricated with thick lubricant. The screws are screwed in instead of the magneto mounting studs and the magneto is pressed to the crankcase through springs.

A rod is made from a steel bar d4 mm. Ears made of 2 mm thick sheet steel are soldered to the rod ( Fig. 7 ).

How to set the ignition on a Ural chainsaw?

Signs that the ignition system needs to be adjusted include loud chainsaw sounds hitting the carburetor or muffler. In this case, the fuel does not have time to completely burn in the internal combustion engine cylinder, which gradually makes starting more difficult and increases the consumption of fuel consumed.

The adjustment procedure looks like this:

- First you need to remove the plastic cover of the saw's protective housing and inspect the space underneath it. If necessary, the parts of the instrument should be carefully cleaned with a hard brush;

- Next you need to find the flywheel position adjustment screws. By turning them counterclockwise one by one, the operator will be able to move the element away from the standard magneto;

- Then you need to attach the template used to the ignition coil;

- After this, you need to turn the screws one by one in a clockwise direction. Once the engine's built-in flywheel is closely aligned with the previously set template, the operator can release the adjustment screws.

At the end, you will need to install the housing cover and monitor the operation of the tuned saw.

Basic malfunctions and ways to eliminate them

The main malfunctions of the 2T model saw or modern analogues are related to the operation of the power unit or circuit. Difficulty starting the engine occurs when there is no fuel in the tank or carburetor chamber. The service instructions recommend checking the fuel level in the tank and pumping liquid into the chamber. A problem with engine operation occurs when the flexible fuel line is clogged or an excessively rich mixture floods the spark plug.

Ignition system failures occur when fuel or oil gets on the electrodes or the gap is broken. The repair consists of cleaning the spark plug and adjusting the gap; the worn part is replaced with a product recommended by the manufacturer. Sparking failures occur when the additional resistance or metal conductors of the power cable are damaged. Damaged insulation of the ignition wires or malfunction of magneto structural elements also has a negative impact on the operation of the spark plug.

If the engine starts and stalls, check that there is no water in the fuel tank. Additionally, the gaskets installed at the junction line of the engine body parts, cylinder and carburetor are inspected. The check is carried out by applying a soap solution; if bubbles appear when turning the crankshaft, then you will need to replace the gaskets and grind the metal mating surfaces. Engine malfunctions occur when the carburetor is clogged or incorrectly configured.

Engine overheating is possible when excessive load is applied to a new or overhauled power unit. Before using the Ural saw, it is necessary to grind the unit parts in a gentle mode; the running-in time is 5-6 hours (indicated in the technical documentation). Overheating of a run-in engine indicates a lean mixture or clogging of the ventilation ducts with a mixture of sawdust and oil. To restore functionality, you will need to adjust the carburetor and clean the chainsaw body from foreign objects and debris.

Overheating of the gearbox housing indicates slipping of the clutch mechanism; it is necessary to adjust the tightening of the springs. Dull chain teeth increase the load on the gear train and engine. To increase work productivity, it is necessary to sharpen the tool and check the condition and geometry of the tire. Bent or broken elements must be replaced. Increased noise and increased gas formation indicate a breakdown of the muffler and incorrect carburetor adjustment (excessively rich mixture).

Fig.11

In this case, part of the tides is removed, forming a channel for supplying hot gases from the cylinder to heat the carburetor in cold weather. In the short part of the channel in the newly formed hole, an MB thread is cut and a plug 6-7 mm long is installed. This prevents gas leakage from the cylinder. When using the engine in winter, a plug is also placed in the cut of the long channel. The standard plugs are removed and both parts of the channel are connected using a metal tube with fittings.

CLUTCH UPDATE

When using a chainsaw engine on units and devices that have a rigid coupling between the load and the engine, a centrifugal (standard) clutch is not suitable. Therefore, in such cases it is blocked, and the smoothness of the ride when starting off is ensured by a friction device. The gearbox is removed from the engine, as well as the drive coupling half.

The friction shoes are removed from the drive half of the coupling. Four pieces (two in pairs) are cut out of a steel strip or sheet steel 4 mm thick using a hacksaw and blocks are made from them according to the drawings ( Fig. 12 ).

Safety precautions

The most important thing is not to forget that you need to work with a chainsaw only in special clothing. That is, you must have special gloves, specialized shoes and, of course, clothing and durable material that would fully cover your body. The second important nuance is your position during operation.

Remember that your body should move away directly from the saw. Also, under no circumstances should you manipulate the saw if you have consumed alcohol, taken any medications, or simply feel unwell.