Welding inverters, which are easy to use and lightweight, have replaced transformer welding units. By visiting the store, you can make a choice by looking at a wide range of welding equipment represented by dozens of models. They differ in technical characteristics and cost.

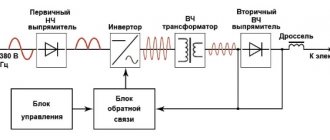

Welding inverters appeared not so long ago, in the 70s. last century. The main difference between such a device and a transformer is the method of current conversion. In an inverter, alternating current is supplied to a rectifier and converted into direct current. In the next step, the constant is converted into a high-frequency variable. At the next stage, the alternating voltage is reduced. Such conditions are necessary for welding.

High-frequency transformers are compact in size, but welding machines can have a weight that is sometimes significant. When choosing a welding inverter, several factors must be taken into account, including:

- model class;

- thickness of materials being welded;

- intensity and volume of work;

- terms of Use;

- power network.

The design may have a display that displays performance indicators. The market today offers a huge variety of models, among them the “Resanta SAI 190” should be highlighted, reviews of which you can read below. Consumer opinions will allow you to understand whether you should incline your choice towards this device.

Description of the model "SAI 190"

The above-mentioned version of inverter welding equipment costs 4,800 rubles. The unit is used in manual arc welding using coated stick electrodes. The equipment is small in size and light in weight, but the device is highly productive, does not require maintenance and is easy to use.

After reading the reviews about Resant SAI 190, you can understand that the device is protected from overheating and belongs to the IP21 protection class. The welding current is adjustable from 10 to 190 A. Operation is simplified thanks to the anti-stick and hot start functions.

Instructions: Welding machine Resanta SAI 190T LUX [65/70]

Product return process

To begin the procedure for returning a product purchased from us, you must write an email in free form, in which you must indicate the date of purchase and describe the reason for the return (requests regarding warranty issues are not accepted by phone).

Specifying the subject of the email is mandatory, otherwise the message may be subject to a spam filter. Keep the complete set of goods.

Return/exchange of goods of good quality

in case of purchasing goods remotely in an online store

In addition to the right to exchange goods of good quality, provided for by the Law of the Russian Federation of 02/07/1992 N 2300-1 On the Protection of Consumer Rights, you have the right to refuse goods purchased remotely at any time before its transfer, as well as within seven days after the transfer of the goods.

If information on the procedure and terms for returning goods of proper quality was not provided to you in writing at the time of delivery of the goods, the specified period is extended in accordance with the Rules for the sale of goods remotely.

When returning/exchanging goods of proper quality, the presentation, integrity of the packaging, and complete set must be preserved. The presence of traces of use may be grounds for refusal to satisfy your requirements.

Return/exchange of goods of inadequate quality

If a defect is identified in the purchased product, the buyer has the right, at his choice, to declare one of the requirements specified in Article 18 of the Law of the Russian Federation of 02/07/1992 N 2300-1 On the protection of consumer rights.

Moreover, if the specified product is technically complex, approved. By Resolution No. 924 of November 10, 2011, the requirements specified in Article 18 can only be submitted within 15 calendar days from the date of purchase.

· After 15 days, presentation of these requirements is possible in the following cases:

· a significant deficiency was discovered;

· deadlines for eliminating deficiencies were violated;

The product cannot be used in total for more than thirty days during each year of the warranty period due to the need to eliminate manufacturing defects.

Product quality check

When you make a claim, the seller has the right to check the quality of the goods. In this regard, we remind you of the need to provide the purchased goods along with the claim to the goods return point or provide the seller with the opportunity to pick up the goods for delivery to an authorized service center to confirm the defect.

The delivery service employee records the fact that the goods have been accepted for diagnostics with a corresponding report filled out in two copies, one of which remains in the buyer’s hands.

Based on the results of such a quality check, the Seller will provide you with a response to your complaint.

If you do not agree with the results of the quality check, you have the right to make a written request for an independent examination of the product. The examination is carried out at the expense of the seller. You have the right to be present during the examination. If the examination reveals the presence of deficiencies that did not arise through the fault of the store or manufacturer, you are obliged to reimburse the store for the costs of conducting the examination, as well as the costs associated with its conduct.

Specifications

Before purchasing a welding inverter, you should familiarize yourself with its technical characteristics. The described unit is no exception. Among the main ones, the class of the product should be highlighted. The device is a household appliance. Its maximum power is 5.5 kW. The minimum input voltage is 140 V.

The duty cycle at maximum current is 70%. There is no TIG welding option in the equipment. The no-load voltage is equivalent to 80 V. Before purchasing the Resanta SAI 190 welding machine, you should inquire about its overall dimensions, they are 180x300x280 mm. The model weighs 4.7 kg. The minimum current is 10 A.

The diameter of the electrode or wire can vary from 2 to 5 mm. No case included. We use DX25 welding wire. The design includes a power plug. The maximum current reaches 190 A. The device operates from a 220 V network.

Review of the device Resanta SAI 190 PROF

This model is more popular among professional welders. The principle of operation is similar to the model we have already considered, but there are also some additions in the form of the ARC FORCE function. It allows you to regulate the change in current strength during the welding process. Before work, the types of metals to be welded and their thickness are taken into account, then the required value is selected from 0 to 100% based on the previously determined welding current. In this case, the arc will have durability, and the metal will gain fluidity.

See also: Resanta SAIPA 165

Technical indicators:

- Housing protection - lP21;

- Adjustable welding current from 10 to 190 A;

- Arc voltage - 26 V;

- Electrodes d - 5 mm;

- Mon — 70%

- Operating voltage - 100-260 V;

- Maximum current consumption - 33 A;

- Idle speed - 65 V;

Advantages of the model

First of all, the modern appearance of the device catches your eye. The control panel has a protective transparent cover made of durable plastic. The digital display will show all values and set indicators for ease of operation. The number of ventilation holes has increased. There is a special handle on top for easy movement; the unit weighs about 4.8 kg. All measures taken made it possible to save consumed electricity by 30%. A power factor corrector was installed; it will ensure stability when operating with voltages from 100 V. The device also maintains its functionality when connected to many autonomous power sources.

Interesting! If the Resanta SAI-190 apparatus requires a generator with a power of at least 5.5 kW, then for the PROF model, 4.6 kW will be sufficient. In this case, the stability of operation will not be affected.

Instructions for use of the Resanta SAI 190 inverter

Connecting a device to the network occurs without special rules and requirements. The device is grounded through the plug-in cord, so the outlet must be grounded. The instructions state that for successful connection it is appropriate to install circuit breakers with a value of at least 16 A.

No work should be carried out with tools that create a dusty atmosphere at a close distance from the unit. These include grinders, electric saws or grinders. If Resanta is operating in normal mode or even idling, you should not cover it, creating restrictions on heat conduction; to ensure stable operation, the cooling system should not be irritated.

Welding is strictly prohibited in the rain or in areas with high humidity. Work with the device does not begin immediately, if it was brought in from the street, where the temperature is currently below freezing, the inverter must stand indoors without operation for at least 2 hours.

Recommendations

Do not turn off the equipment too often; if the indicator lights up, it is appropriate to simply wait a little over 15 minutes until it cools down. When work occurs in intermittent mode for 7-9 minutes, welding does not turn off, you need to wait about 3 minutes of idle operation. A harmless shutdown is only possible if no work is carried out for one hour.

To care for equipment, it is recommended to clean the internal surfaces from possible dust and dirt. The frequency depends on the degree of pollution or the time spent working in dusty areas.

What are the most common causes of device failure?

The first and simple rule that should be followed in order for the welding machine for welding Resanta SAI 190 to serve for a long time and without problems is periodic cleaning and compliance with operating rules, but there are other factors that can lead to repair of the model:

- Fast heating if the fan fails;

- An open circuit or cable malfunction will not allow the device to turn on;

- Due to a cable break, there is no arc, this leads to the burning of the printed circuit board or loss of ground.

Consumer Reviews

If you are also interested in the Resanta SAI 190 welding machine, then you should familiarize yourself with consumer opinions about it. Among other positive features, buyers highlight:

- convenient control;

- ease of transportation;

- reliability.

As for control, it is provided by the ability to adjust the current, which indicates precise work and smooth seams. Easy transport is guaranteed by a practical strap that makes it easy to move the inverter around the job site. If you like the Resanta inverter, you should pay attention to its reliability. The device will be ready to serve for a long time, which was achieved thanks to the durable metal case. It protects internal components from mechanical damage.

The unit is built on IGBT transistors. Overheating protection is provided by forced tunnel cooling. The inverter is highly efficient and, according to consumers, does not require special maintenance. Buyers also like the light weight of the device.

Low voltage welding machine SAI-190PN

Description

Main advantages

- The Resanta SAI-190 PN low-voltage welding machine

is endowed with all the capabilities that allow high-quality, smooth and precise welding work of almost any complexity. - The welding current generated by the product does not change the qualitative composition of the metal in the elements being connected.

- The control panel of the unit is protected by a transparent cover and contains light indicators and a digital display, and the handles allow you to easily and smoothly adjust the parameters for operation.

- The device is reliably protected from overheating and is able to smooth out significant differences in the supply voltage.

- The device is equipped with useful functions “Anti Stick”, “Hot Start” and “Arc force”, which facilitate the work of the welder and ensure uninterrupted arc performance.

- IGBT technology was introduced into the system, which made it possible to reduce its external dimensions, weight and freely operate even in relatively inconvenient places.

- The unit is easy to set up, does not require special professional skills, and can be easily carried manually or using a convenient shoulder strap.

general description

The design of the Resanta SAI-190 PN product is based on advanced inverter technologies based on a rectifier with pulse-modular regulation and a current stabilizer. The device is powered by a conventional single-phase 220 V power supply. This inverter welding machine has become a fairly common tool for creating the strongest possible connection of metal parts in private households, workshops and other professional or domestic situations. Using this fairly compact device, you can ensure high quality and accuracy of the weld formed by an electrode using direct current. The delivery set includes a meter cable with a special convenient electrode holder, as well as a cable with a fastening device that ensures the circuit is closed.

The inverter operating principle of the welding machine, together with the use of IGBT transistors, made it possible to make the device lightweight (about 6.9 kg) and fit it into small dimensions. This significantly increased the convenience and versatility of the device. The operator can easily carry it manually or using a shoulder strap, and can also be positioned to work in inconvenient and hard-to-reach places. This quality will definitely be appreciated by experienced welders who have had to work with heavy and bulky welding machines based on a conventional transformer.

With the use of modern technologies in the production of the Resanta SAI-190 PN device, it was possible to ensure that this small and lightweight product contains serious practical qualities. The welding current is quite significant (10-190 A), and the welding current voltage of 80 V makes it easy to maintain the arc and use electrodes up to 5 mm in diameter. The load duration (LOD) of the system reaches 70%. That is, out of a time period of 10 minutes, the device can continuously cook for as long as 7 minutes, and only 3 minutes are required for rest.

The viability of a working device is maintained by an effective forced heat removal system that prevents the device from overheating. In addition, the temperature control sensors of the device will promptly, through a light indicator, notify you of the need to take a break and give the device additional rest to recover.

The design of the welding unit Resanta SAI-190 PN is such that even a beginner in this matter can now perform high-quality welding, since the unit has become the bearer of a number of useful functions:

— “Anti Stick” – automatic reduction of the operating current, facilitating easy tearing of the electrode if it gets stuck on the surface to be welded. After the electrode is torn off, the operating parameters of the system are immediately restored.

- “hot start” (Hot Start) – a pulsed short-term increase in the operating current at the moment of contact of the electrode with the surfaces being welded, easily igniting the electric arc and facilitating the start of the welding process.

- “Arc force” – allows you to adjust the depth of penetration (arc rigidity) and control the parameters of the metal at the welding point. This function is controlled manually.

In addition, the equipment of the unit allows you to smooth out unstable supply voltage within fairly significant limits (from -30% to +10%). Thus, the device ensures stable operation and uniform penetration in the range of supply voltage fluctuations from 140 to 240 V.

Design and functionality

The Resanta SAI-190 PN inverter welding machine is a rectangular body (300x170x300 mm), assembled from a steel sheet coated with a dielectric compound that protects it from corrosion. There are special slots in the housing designed for free access of cooling air. A durable handle is attached to the top for manual transportation, and there is also a shoulder strap that frees the operator’s hands. The bottom of the case is flat and therefore holds the device firmly on the surface. The electrical safety of the housing is IP21. This means that the device is not recommended for use in high humidity (more than 90%) or during rain.

On the rear panel of the case there is a network switch and a power cord with a plug for a regular outlet.

The front panel became the location of the unit's control panel. Here, under a folding transparent cap made of durable polymer, there is a handle for continuously adjusting the welding current (10-190 A), an arc adjustment handle (0-100%), light indicators for network and emergency overheating, as well as a digital display showing the current setting . Below the control panel there are receiving ports for attaching work cables (ground cable and cable with electrode holder).

The main working element of the device is located inside the housing and is protected by it. This is a special transformer with an inverter conversion system based on pulse frequency modulation. The purpose of this component is to create a welding current with optimal operating parameters. First, the network current with a frequency of 50 Hz and a voltage of 220 V is rectified to constant, but with an increased voltage (400 V). Then this current turns into an alternating current of high frequency and is rectified again, having an output voltage of 80 V. This voltage simplifies the start of the welding process.

The workload on the welding machine leads to increased heat generation in its main operating components. Removing excess heat and preventing the temperature from rising to emergency levels is a primary task for such systems. In this case, to increase cooling efficiency, the heating surfaces of the components are equipped with finned aluminum plates, and their forced air flow is provided by a built-in electric fan.

The welding process occurs due to the fact that a closed loop of working current is created with the help of working cables. At the point in the circuit where the electrode touches the surfaces being welded, an electric arc occurs, melting the electrode and the edges being welded. When burning, the flux that coats the electrode creates a protective gas environment that prevents accelerated oxidation and the formation of slag in the melt.

Preparing for work

The welding inverter Resanta SAI-190 PN is simple in design and is almost always ready for work. You just need to connect the working cables, make the appropriate settings, turn on the power and the machine is ready to perform welding work. Necessary preparatory operations should include a detailed study of the technical instructions on safety precautions, setup and methods of working with the welding machine. Such instructions, as a rule, are an integral part of the delivery kit.

A working welding machine creates conditions under which sparks and sometimes drops of molten metal can fly in different directions from a local point of increased heating. Thus, the device may be a source of increased fire hazard. This should be taken into account when assessing the location of the upcoming work. In addition, the gases released during the welding process are harmful to the operator’s body, so the work area must be well ventilated. The welder himself must use his own protective equipment (special clothing, a special welding shield for the eyes and face, gauntlet gloves, a hat and thick leather shoes).

The manufacturer of the inverter welding machine Resanta SAI-190 PN has established a warranty period of 24 months for its product. However, by observing the basic standards for the intended operation of such a unit, it is possible to make its operation practically indefinite.

User manual

Before you start using Resanta SAI 190, you should definitely study the operating instructions. Among other sections, it covers safety rules. The manufacturer emphasizes that the operator must protect himself from burns. They can be caused by hot metal, slag and sparks, as well as arc radiation. All of these exposures can cause serious harm to the skin and eyes. Therefore, the welder and other people who will be in the work area should use personal protective equipment. This should include:

- gloves;

- boots;

- headdress;

- mask or welding shield.

Before starting to operate the device, it is recommended to wear a fire-resistant suit and pants that will cover all parts of the body. Before you start using the Resanta inverter, you should familiarize yourself with the rules of its operation. It is important to note that during operation, ultraviolet radiation will be emitted, which can be harmful to the skin and eyes. To prevent irreversible effects, it is necessary to use a welding helmet and protective clothing. The shield must be equipped with a light filter with a darkening degree of DIN 10.

Before turning on the unit, it is important to ensure that fire extinguishing means are available in the immediate welding area. Flammable and explosive materials should be removed to a distance of 10 m or more. It is prohibited to weld closed containers containing explosives or toxic compounds. If such a need arises, the container should be cleaned. You should not carry out welding work in an atmosphere where there is a high concentration of flammable gas, dust and flammable liquids.

Feedback on operating features

In order to extend the life of the welding inverter, according to consumers, it is necessary to follow the rules for its use. For example, it is prohibited to turn on the device during rain or in a damp room.

After reading the reviews about the Resant SAI 190, you will be able to understand that you should not use cutting tools such as electric saws and grinders next to the device being turned on. This can cause metal dust to get inside and damage the equipment.

It is prohibited to carry out welding work if the insulation of wires or cables is damaged. When the device was stored at sub-zero temperatures, consumers are advised to keep it at room temperature for 2 hours to prevent the appearance of condensation.

Instructions: Welding machine Resanta SAI 190PN [65/19]

Product return process

To begin the procedure for returning a product purchased from us, you must write an email in free form, in which you must indicate the date of purchase and describe the reason for the return (requests regarding warranty issues are not accepted by phone).

Specifying the subject of the email is mandatory, otherwise the message may be subject to a spam filter. Keep the complete set of goods.

Return/exchange of goods of good quality

in case of purchasing goods remotely in an online store

In addition to the right to exchange goods of good quality, provided for by the Law of the Russian Federation of 02/07/1992 N 2300-1 On the Protection of Consumer Rights, you have the right to refuse goods purchased remotely at any time before its transfer, as well as within seven days after the transfer of the goods.

If information on the procedure and terms for returning goods of proper quality was not provided to you in writing at the time of delivery of the goods, the specified period is extended in accordance with the Rules for the sale of goods remotely.

When returning/exchanging goods of proper quality, the presentation, integrity of the packaging, and complete set must be preserved. The presence of traces of use may be grounds for refusal to satisfy your requirements.

Return/exchange of goods of inadequate quality

If a defect is identified in the purchased product, the buyer has the right, at his choice, to declare one of the requirements specified in Article 18 of the Law of the Russian Federation of 02/07/1992 N 2300-1 On the protection of consumer rights.

Moreover, if the specified product is technically complex, approved. By Resolution No. 924 of November 10, 2011, the requirements specified in Article 18 can only be submitted within 15 calendar days from the date of purchase.

· After 15 days, presentation of these requirements is possible in the following cases:

· a significant deficiency was discovered;

· deadlines for eliminating deficiencies were violated;

The product cannot be used in total for more than thirty days during each year of the warranty period due to the need to eliminate manufacturing defects.

Product quality check

When you make a claim, the seller has the right to check the quality of the goods. In this regard, we remind you of the need to provide the purchased goods along with the claim to the goods return point or provide the seller with the opportunity to pick up the goods for delivery to an authorized service center to confirm the defect.

The delivery service employee records the fact that the goods have been accepted for diagnostics with a corresponding report filled out in two copies, one of which remains in the buyer’s hands.

Based on the results of such a quality check, the Seller will provide you with a response to your complaint.

If you do not agree with the results of the quality check, you have the right to make a written request for an independent examination of the product. The examination is carried out at the expense of the seller. You have the right to be present during the examination. If the examination reveals the presence of deficiencies that did not arise through the fault of the store or manufacturer, you are obliged to reimburse the store for the costs of conducting the examination, as well as the costs associated with its conduct.

Possible malfunctions and ways to eliminate them

During operation of the Resanta SAI 190, malfunctions may occur. When the “Network” indicator does not light, you need to check the position of the switch and make sure that the device is connected to the network. If the equipment does not develop full power, then this may be indicated by low mains voltage or a wet welding electrode.

If you notice that the “Overheat” indicator lights up, then the PN value may have been exceeded. The temperature inside the device is quite high. In order to continue operation, the device must be allowed to cool down. The indicator mentioned above may also work if a lot of dust has accumulated inside the case. To clean it, you need to contact a service center.

Instructions: Welding machine Resanta SAI 190 PROF [65/30]

Product return process

To begin the procedure for returning a product purchased from us, you must write an email in free form, in which you must indicate the date of purchase and describe the reason for the return (requests regarding warranty issues are not accepted by phone).

Specifying the subject of the email is mandatory, otherwise the message may be subject to a spam filter. Keep the complete set of goods.

Return/exchange of goods of good quality

in case of purchasing goods remotely in an online store

In addition to the right to exchange goods of good quality, provided for by the Law of the Russian Federation of 02/07/1992 N 2300-1 On the Protection of Consumer Rights, you have the right to refuse goods purchased remotely at any time before its transfer, as well as within seven days after the transfer of the goods.

If information on the procedure and terms for returning goods of proper quality was not provided to you in writing at the time of delivery of the goods, the specified period is extended in accordance with the Rules for the sale of goods remotely.

When returning/exchanging goods of proper quality, the presentation, integrity of the packaging, and complete set must be preserved. The presence of traces of use may be grounds for refusal to satisfy your requirements.

Return/exchange of goods of inadequate quality

If a defect is identified in the purchased product, the buyer has the right, at his choice, to declare one of the requirements specified in Article 18 of the Law of the Russian Federation of 02/07/1992 N 2300-1 On the protection of consumer rights.

Moreover, if the specified product is technically complex, approved. By Resolution No. 924 of November 10, 2011, the requirements specified in Article 18 can only be submitted within 15 calendar days from the date of purchase.

· After 15 days, presentation of these requirements is possible in the following cases:

· a significant deficiency was discovered;

· deadlines for eliminating deficiencies were violated;

The product cannot be used in total for more than thirty days during each year of the warranty period due to the need to eliminate manufacturing defects.

Product quality check

When you make a claim, the seller has the right to check the quality of the goods. In this regard, we remind you of the need to provide the purchased goods along with the claim to the goods return point or provide the seller with the opportunity to pick up the goods for delivery to an authorized service center to confirm the defect.

The delivery service employee records the fact that the goods have been accepted for diagnostics with a corresponding report filled out in two copies, one of which remains in the buyer’s hands.

Based on the results of such a quality check, the Seller will provide you with a response to your complaint.

If you do not agree with the results of the quality check, you have the right to make a written request for an independent examination of the product. The examination is carried out at the expense of the seller. You have the right to be present during the examination. If the examination reveals the presence of deficiencies that did not arise through the fault of the store or manufacturer, you are obliged to reimburse the store for the costs of conducting the examination, as well as the costs associated with its conduct.

Fan problems

The characteristics of the “Resanta SAI 190” are not all that you should know before starting to operate the inverter. It is also important to familiarize yourself with possible problems. For example, if the cooling fan stopped rotating, it could be blocked. Sometimes this is caused by foreign objects caught in the rotating part. In order to continue operation, the fan must be cleaned. However, its refusal to work may also indicate that this piece of equipment has burned out. To replace the unit, you must contact a service center.