Dimensions of dowel-nails

The first number when marking a product is its diameter, and the second is its length. The parameters of such a product can vary from five by twenty-three millimeters to ten by one hundred and sixty millimeters.

The load that the dowel-nails can bear must be indicated. The most common size is six by forty millimeters. It is ideal for thin parts.

- The dimensions for the slats are six by sixty and six by eighty millimeters.

- The longer the dowel, the thicker the part can be or the further into the wall the expansion zone will be.

- Dowels begin their size range with five, six, eight and ten millimeters in diameter.

- For installation, you need to drill a hole slightly larger than the length of the nail itself.

It is advised to make the hole twenty millimeters larger. There are times when it is not known what kind of wall is hidden under the plaster. In such cases, you can try drilling a hole in non-impact mode.

It is possible that this is a weakened wall and this nail will not fit. Some manufacturers save money and make the diameter of these nails five and a half millimeters, but indicate all six.

This can be a serious problem during installation. Or you will have to look for a five and a half millimeter drill or try to expand the diameter with a five millimeter drill, which results in a loss of time and quality of work.

Specifications

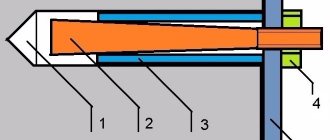

Enterprises in the metallurgical industry produce hardware of the type in question with standardized technical characteristics indicated in the table below. The designation of the parameters corresponds to the letters shown on the design drawings. Dimensions are presented in millimeters.

| Rod diameter (parameter d) | Weight of 1000 pieces of washers, 1.5 mm thick (kg) | Weight 1000 pcs. dowels, (kg) | Dowel size: diameter×length (d×L) | h | D1 | L | D |

| 4,5 | 1,15 | 9,15 | 4,5×60,0 | 1,0-1,5 | 12,0 | 60,0 | 10,0 |

| 7,95 | 4,5×50,0 | 50,0 | |||||

| 6,75 | 4,5×40,0 | 40,0 | |||||

| 5,55 | 4,5×30,0 | 30,0 | |||||

| 3,7 | 1,2 | 5,2 | 3,7×40,0 | 40,0 | 8,0 | ||

| 4,3 | 3,7×30 | 30,0 |

Common mistakes at work

The most common installation mistake is twisting the nail. Although it has a thread, its structure allows us only to unscrew it. Tightening a nail can only waste time.

Even the dowel itself does not have any hooks, so as not to rotate in the wall, based on the fact that the nail will be driven into it.

- If screwing a nail is not a critical mistake, then not driving a nail into a dowel so that you can hang a kitchen cabinet on it is a fatal ignorance of the basics of fastening. A nail will come out of the wall a hundred times out of a hundred.

- Let's see how this fastener works. There is a half-finished nail, the dowel did not open, which means that no friction force was created, the result is a fallen cabinet. Another mistake when working with dowels is wrapping electrical tape around it.

- This happens if the diameter of the hole is larger than expected and the dowel, when wedging, does not reach the walls of the hole. Duct tape is a slippery option.

- The exterior is glossy and smooth, which means it will slide out perfectly. And although the inner side is adhesive, the glue stretches and does not dry out. The most reliable option in such a situation is to fill the hole with gypsum mortar and carefully re-drill.

By the way, a regular wooden scale will do. If all this is not available, then you can take a noodle type wire or another copper cable. This is an old method from the times of the USSR and it works. Currently, the prevailing method is enveloping the dowel with silicone or liquid nails.

\

Using dowel nails on the ceiling is another mistake you shouldn't make. The nail itself is not fire resistant and does not work in voids. The location of the dowel nail in the hole plays a special role.

The nail should rest on the plastic dowel when loaded. That is, if the hole is in the wall, then the spacer parts of the dowel should be located below and above the nail. If the wall is concrete, then you can safely hammer in a dowel and a nail.

Technical requirements

The quality of dowel-nails installed using a construction gun is standardized by the provisions of TU 14-4-1141-82. This document puts forward a number of requirements that the final product must meet. Let's name just a few of them.

- To produce these fasteners, an alloy that is resistant to mechanical loads is used. Its hardness, determined by the Rockwell method, should be in the range 54≤HRC≤56.

- Curvature (φ) of the dowel-nail rod is allowed. With length: L<5 cm, φ=0.1 mm; L>5 cm, φ=0.15 mm.

- The bluntness of the point of the rod (ω) should be ω<0.8 mm.

- The point should transition into the cylindrical part of the rod evenly, without disturbing the continuity of the steel (as sunsets are scientifically called), nicks or signs of cracking.

- It is acceptable to have traces on the surface of the metal rod left during processing with clamping devices. The point can be formed by several edges.

- The distance between the corrugations (S) of the dowel-nail made according to the second design should be as follows: S≤0.8 mm. The following requirement is imposed on the size of the recesses (H) between these notches: H≤0.15 mm.

- A zinc layer of anti-corrosion coating with a thickness of at least 6 microns-7 microns is applied to the surface of the fastener using cathodic reduction.

Cost of fasteners

The price is more than affordable. It varies from eight to thirty-five rubles per piece, depending on the size and load.

There are universal models, but they are more expensive, from thirty-one to thirty-eight rubles.

Control methods

The regulatory document TU 14-4-1141-82 also establishes methods for monitoring the parameters of manufactured dowel-nails for a construction gun.

- Checking the conformity of the geometric dimensions of these products is carried out using templates, calipers, and a micrometer.

- The appearance of dowels is checked visually; magnifying devices cannot be used. The roughness of the working surface cannot be controlled. This characteristic is ensured by the technological tool used.

- Inspection of the cross-section of fasteners manufactured:

- according to design drawing No. 1, it is carried out on a part of the rod located at a distance of 5 mm from the flat washer towards the dowel head;

- according to design drawing No. 2 - along the largest cross-section of the corrugation.

- the place where the defect is located is cleaned with a file or emery cloth;

- then a comparative measurement is made with a caliper in the cleaned area and where this operation was not carried out.

The guarantee period for maintaining mechanical characteristics for dowel-nails of ordinary quality is 12 months, and for products of higher quality, 18 months, starting from the date the consumer received the purchased fasteners.