Design and principle of operation of a water pump and pump

In a private home, it is important to properly organize the water supply system so that it serves for a long time and with high quality. Pumping equipment is used to pump liquid. When choosing a model, they rely on the operating principle and design of water pumps and pumps. Knowing the nuances of the operation of the equipment, it is easy to decide on the choice of unit.

How the mechanism works. The device is based on a core of brass tubes that have a flat oval shape. They are arranged vertically and form 4 plates.

There are racks around it to secure the tanks from below and above. To soften vibrations at the joints between structural elements and the radiator, shock absorbers are used. There is a ventilation hood on the engine side. There is a lining on the front side of the radiator for protection. In addition to the casing, brackets are attached to the radiator stand, onto which the expansion tank is attached.

General information

To understand the principle of operation of the pump and why it is designed this way and not otherwise, you first need to define what an autonomous water supply is. This is a complex system with different effects depending on the type of product. It consists of many elements and provides water under pressure. The key element of this system is the pump, of which there are countless varieties. There is submersible and surface. The predominant manufacturers are:

- China;

- Russia;

- European countries.

But effective operation is ensured only if the equipment is complete with a battery and automation.

The pump sucks water from a source, for example, a well, collects it in a special container, and then delivers it under pressure to the consumer. The main difference between the pumps is in the characteristics and dimensional data. It is important to choose this equipment correctly so that the water supply is ensured at the proper level.

Water pump

The shape of the blades can be either straight or angled, which affects the rotation speed. In high-speed pumps, the vanes come from bushings. Wheels with such blades are fastened with keys. Simple household low-power water pumps use riveted impellers.

The rotor is mounted on a shaft, which transmits torque to it. The shaft is mounted on bearings to eliminate vibration and distortion during operation.

The material for the manufacture of shafts of simple pumps is steel; for pumps with increased loads they are made of alloy steel with an alloy of chromium, nickel or vanadium; shafts for pumps pumping various acids are made of stainless steel. If the shaft is not balanced correctly, vibration may occur, which will cause serious damage to the pump.

There are shafts:

- Flexible: used in pumps with exceeding critical speed;

- Hard: used for quiet operation pumps without high speeds;

- Solid (the pump working shaft also serves as a motor shaft): installed in household pumps in which pump impellers are installed on the electric motor rotor.

Water pump bearings are made with cast iron liners, which are filled with babbitt. They are lubricated with liquid or thick lubricant. Bearings can be roller, ball, rubber, textile, etc. The casing also belongs to the body and is part of it. The rubber gasket between the casing and the body serves for sealing.

The oil seal serves to protect the engine from water and is located at the junction of the working chamber and the rear wall. The seals have soft padding made of cotton, paper or asbestos cord. On the liquid suction side, a water seal is installed on the oil seal. The oil seal device contains a coupling and a sealing ring, to which liquid flows from the discharge pipeline, preventing air from entering the working chamber.

About water supply and its pressure

When planning to choose a liquid pump, you need to look at its parameters. All characteristics are important, but one of the key ones is the water flow rate. It is necessary to calculate how many cubic meters of water the home owner spends per hour to find out which option is suitable.

The next, no less important characteristic is pressure. It indicates with what force the unit will supply water. This parameter is calculated according to how far the water source is from the house. The pressure is lost under the influence of height and forks in the pipeline, so it is better to provide a small margin when calculating.

When looking for a model to use at home, the scope of choice narrows. There are deep and surface pumps. The first are used for wells less than 10 meters deep. They are fixed on a special platform.

The latter are suitable for use in wells and wells whose depth exceeds 10 meters. How the pump is controlled is important. It will be easiest for those whose choice falls on automatic control.

What is an ejector

We have already written that self-priming pumps cannot raise a column of water above 9 meters. As you know, if you need to organize water intake from a well, such a depth will not be enough, since the water at this level will not be of high quality, it contains many impurities and may contain organic inclusions. What to do in a situation when you need to get water from great depths?

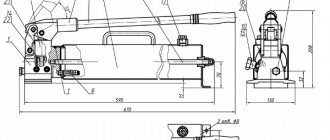

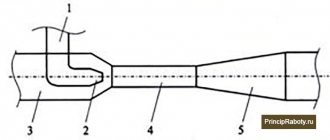

For these purposes, a special device is used - an ejector. This is a specially shaped tube with two inlets and one outlet - you can see its structure in the diagram above. The lower, wide inlet is intended for drawing water from the well, and the second, tapering inside, is used to recirculate water supplied from the pump; through the outlet, both flows, mixed, rush back to the pump. What does such a scheme provide, and why is it possible to overcome the pressure drop limit in this way?

A pump with an ejector can lift water from a depth of up to 40 meters

This is where Bernoulli's law comes into force. When water flows through a tapering pipe, a certain turbine effect is created - the water receives additional acceleration, which is why a low-pressure area is created in the ejector. Since our world does not tolerate emptiness, these areas are immediately filled with water entering through the main nozzle from the well. As a result, the pressure of the well increases, the difference between its drop and the area created on the pump wheel also increases, which causes the water to quickly rise upward.

It doesn't take a physicist to understand that the efficiency of such equipment will suffer due to the fact that it has to return part of the water back to the well. Speaking in numbers, it could work 30-35% more efficiently without an ejector, but you always have to put up with something; no one has yet been able to defeat the laws of physics.

Ejectors in pumps are internal and external

Conventional pumps are equipped with a built-in ejector, which forms part of their housing. We described such equipment earlier; it is precisely this equipment that cannot overcome the lifting mark of 9 m. What other features are characteristic of such equipment?

- The productivity of such pumps is 3-5 cubic meters per hour, which is enough even for a large house with a large number of residents.

- The operating pressure in the system is 4-6 bar - this is enough for the normal operation of all types of plumbing fixtures and household appliances. Important! The pump's performance is calculated not only by the depth from which it needs to lift water. The length of the water supply pipe and the number of water points in the house play a very important role.

- These pumps are very noisy, so they are installed outside the room, for example in a well caisson, or in the basement, where it will not be heard.

Caisson for a well Pump

models with a remote ejector operate much quieter, which must be remembered if you choose equipment that will be installed in close proximity to residential premises.

Surface and submersible types

The surface pump is mounted outside the well. A pipe comes out from the bottom and goes to the equipment that pumps water. A significant advantage of this model is that it is easy to install and maintain. Thanks to this, if it fails, you do not have to resort to the help of specialists.

The main disadvantages of these pumps:

- Low power reserve.

- Using a fan as a cooling tool, while submersibles cope with overheating using the water around them.

- Limited functionality.

Submersible models are divided into ordinary and deep. They differ in their maximum immersion depth. The advantages of immersion-type products are ease of cooling and the fact that they do not freeze in winter. The design of a water pump of this type, its repair and maintenance are quite problematic, but the frequency with which they have to be used is quite low.

Working principle of a water pump

The main component of the water pump, which carries out the main work, is the rotor or impeller (impeller). Typically, the rotor is made of steel, copper or cast iron. It consists of two disks connected to each other. Between them are curved blades running from the center to the edges. The bend is directed against the axis of rotation of the wheel itself. In the center of the wheel there is a neck (hole), the diameter of which is equal to the diameter of the pipe through which water or any other liquid is sucked in. The pipe and the wheel have a tight connection so that the blades have contact with the incoming water. The rotor blades are located so as to prevent fluid from flowing into the cracks, and there was only free space in the disc grooves.

There are several types of rotors:

- Open (open blades located on one disk);

- Closed;

- Stamped;

- riveted;

- Cast.

To use a water pump, you do not need to have special skills.

The open type rotor differs from the closed type in that the blades are placed on one disk and do not have a covering. Open type rotors are used for pumping very thick liquids and suspensions at low pressure, because These blades are easy to clean. A closed-type rotor, made of one monolithic part, is often installed in simple pumps. Stamped rotors are installed in large and powerful pumps.

Centrifugal and vibration

Centrifugal pumps are more suitable for home use, since their operation scheme is simpler and more efficient. Its design includes a shaft on which the blades are located. In this case, all the pressure force is concentrated at the edges of the blades. But to use this equipment, it is necessary to install a filter, because it does not react well enough to pollution and loses power because of it.

Knowing well the purpose and design of a centrifugal water pump, you can choose the appropriate model. You can check the availability of additional components in the design with the seller.

Vibrating ones do not lose effectiveness due to poor-quality and sand-contaminated water, but constant vibrations lead to silting of the source. As a result, the performance of these devices is less than that of vortex devices.

Frame

It is made in the shape of a spiral with a decreasing radius, similar to a snail shell. The cavity of this body does not remain the same throughout. The flow area increases as you approach the pressure pipe.

Where the volute casing ends and the discharge pipe begins there is a protruding wedge called a cutwater .

It physically separates the volute housing from the discharge port and ensures that fluid leaves the pump rather than simply spinning around in the volute housing.

The flared part of the volute casing is very important, because with the help of it the pump creates pressure.

Control option

Automatic models can be used over a long period of time without intervention from the user. They have many sensors:

- pressure;

- dry running;

- short circuit protection.

If there is a threat of a short circuit, clogging or any other problem that could lead to equipment failure, the control circuit turns off the pump.

Manual type models are used in a completely different way. Their structure also differs from other species. Repairs to such a unit are required much more often. Therefore, automatic control is more suitable for domestic use. It may cost more, but over time this choice pays off.

Grundfos models

It is unlikely that there is a person who has not heard of the products of this company. Now it is the most widespread and largest manufacturer of such equipment, which supplies submersible, vortex, circulation, drainage and vibration models. The buyer, in turn, gets a large selection and can choose any pump depending on his needs.

All equipment from this manufacturer is equipped with many sensors to protect against breakdowns. The range includes pumps of all types of power - both low power for wells and more powerful ones for mine wells. Models are of good quality, from parts to assembly itself.

Areas of application

It is difficult today to find a sector of everyday life or industry that uses liquid media and does not use centrifugal pumps. The most popular areas of application are:

- Water supply of all levels and scales - from water intake stations to industrial enterprises and from residential buildings to wastewater treatment plants.

- Pumping of process fluids in industrial installations and between production facilities.

- Coolant circulation in heating systems, centralized or local.

- Water circulation in washing machines and dishwashers.

- Irrigation of agricultural crops.

- Supplying water to drinkers and pumping milk on productive farms.

- Antifreeze circulation in the cooling system of a car engine and air conditioning systems.

- Filling and draining ballast tanks on surface ships and submarines.

- Transportation of raw materials in the food industry and mass production of beverages.

Centrifugal pumps in industry

Using a centrifugal pump in gardening

Circulation pumps are used wherever liquids are used and ultra-high pressure or suction force is not required. For special applications, other types of devices are used - vibration, rotary, piston or induction.

Consumer Reviews

To select a suitable pump, you need to know well the conditions of its use and the characteristics of the model. But it doesn’t hurt to study what consumers think about them. The problem is that all manufacturers praise their products, but not everyone can boast of good reviews. Many people have bitter experiences with the chosen product. They can share it completely free of charge.

It is not worth buying equipment from a Chinese manufacturer, because the quality leaves much to be desired. This is the opinion of users. But buyers report that there will be no difficulties with equipment from Vilo, the main supplier from Europe. And SAER pumps are repaired in service centers for a long time and often. It is better to look for a middle ground when good price and quality are combined.

Review of domestic products

Domestic manufacturers cannot boast of quality. An example would be the “Bison ZNVP-300−25”, popularly called “Rodnichok”. It is perfect for shallow wells - up to 5 meters. This vibration type pump can deliver 1400 l/h at a head of 60 meters. This is quite enough for home use.

Another simple model from the Russian one. It has similar characteristics to the previous model, but demonstrates low productivity - 700 liters per hour. 0.2 kW - this is its power, this explains the low productivity. The only good thing is the price: with the listed characteristics it does not exceed 1100 rubles. This is an excellent choice for those whose well is shallow (no deeper than 10 meters).

Classification by liquid quality

Different types of pumps have different requirements for water purity. All devices can be divided into three types.

- For clean water. The content of solid particles in it should not exceed 150 grams per cubic meter. These models include surface pumps, as well as well and borehole pumps.

- For moderately polluted water. Insoluble inclusions from 150 to 200 grams per cubic meter. Drainage, circulation and self-priming types. Also some fountain models.

- For dirty water. Solids from 200 grams per cubic meter. Drainage and surface sewerage models.

Equipment from Karcher and Vilo

German equipment is valued all over the world. These are good pumps with excellent performance and last a long time. The only drawback is the price. For example, SPP 33 Inox 1.645−409 costs 13,000 rubles.

Pumps from the Vilo brand used in everyday life are almost universal. The price is lower than its German counterpart , but the quality is identical. Millions of users of such equipment are convinced of this, whose messages can be seen on thematic forums and various websites.

When choosing a pump, such characteristics as pressure, power, service life, and quality are important. It is better to trust good domestic products. Buying a European pump is more expensive, but it does not always last long. It is important to pay attention to how the equipment will be installed and how well it will be maintained.

Correct installation of the suction line

When installing a water supply system, it is important not only to install a self-priming pump or pumping station, but also to install a suction line.

The pressure value (7-8 m) is calculated taking into account the height of the water rise and the parameters of the hydraulic resistance that occurs during the movement of liquid

When creating a sealed water supply system, you should check the ratio of the diameter of the pipeline to the diameter of the pipe, and also shorten (if possible) the length of the entire line as much as possible.

The longer the suction line, the higher the resistance and, accordingly, the lower the pressure. The presence of leaks can lead to equipment breakdown - this condition is relevant for centrifugal models that are not intended for pumping air-liquid media.

Pay attention to the location of the pipes. The suction line should not have kinks, kinks, or a complex prefabricated structure that rises above the level of the pump; otherwise, air pockets may form that disrupt the suction process and are difficult to remove from the system.

Try to position the suction line so that it is a simple configuration with straight pipes and one angle, that is, it resembles the letter “L”

As additional equipment installed directly on the main line, a check valve (or a simple non-return analogue) and a filter are used. Thanks to the valve, water is retained in the pipeline and does not flow back, thereby protecting the pump owner from repeated fillings.

The filter protects the equipment from the ingress of bottom sediment with large inclusions, pieces of aquatic plants, and clay impurities.

Is it possible to replace a self-priming model with a conventional pump? If there is no other way out of the situation, then they do so - during repairs or purchase of new equipment.

However, do not forget about some nuances:

- you will have to completely fill the pump chamber and line with water before turning it on;

- it is necessary to avoid the entry of air, otherwise the equipment will fail;

- filling should be done after each “accident” caused by depressurization of the water supply system.

Practice shows that users of self-priming pumps are in no hurry to switch to conventional ones, especially since the choice of equipment is often dictated by optimal suction conditions.