When using powered tools and equipment, the operation of which requires the use of working fluid under high pressure, one cannot do without such a technical device as a hydraulic oil station. There are various types of hydraulic oil stations, some of which, if you have the appropriate knowledge and certain skills, can be made with your own hands.

Portable oil station with electric drive for repair work

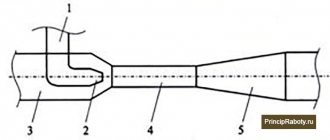

Design and diagram of a manual hydraulic pump

Diagram of a hydraulic hand pump

The manual hydraulic pump consists of two main parts, the pumping unit (1) and the hydraulic tank (2). They are connected to each other by a pin (3). You need to fill the liquid through the hole, having first unscrewed the plug that closes it (4). The handle (6) with the lever (7) drives the plunger (8) of the first and second stages, made as one part. The pumping unit has a two-stage structure. Stage number one, with reduced pressure and higher productivity, serves to accelerate the movement of the hydraulic cylinder plunger. Stage number two, at high pressure and lower capacity, serves to obtain the operating force of the actuator. Overload protection is provided by a safety valve (9). Pressure is released and hydraulic fluid is extracted from the cylinder cavity into the tank using a screw (10).

Pump equipment

It can differ both in its design and technical characteristics. One of the most important characteristics of a pump is the flow rate of the working fluid that it is able to provide. This parameter, depending on the type and specific model of pumping equipment, can be in the range of 3–300 l/min. The pumps that are equipped with hydraulic oil stations are one of the following types:

- lamellar;

- gear;

- radial plunger;

- axial piston.

Oil station pump Willy Vogel-DM7

Working principle of a manual hydraulic pump

Before starting to work with any pump, be sure to inspect the tool and if cracks and chips are found on the surface, do not use it. It is important to check whether the high pressure hose is tightly connected to the hand pump.

Work algorithm:

- We connect the pump to the hydraulic system with a quick-release coupling;

- Turn the valve all the way clockwise.

- Using progressive movements, pump the pump handle up and down. As a result, oil is pumped into the system from the pump. At the same time, pressure builds up in the system, and the piston of the hydraulic tool moves, into which we pump oil.

- In a situation where the working piston of the system into which oil is poured reaches its final position, increased pressure will be created in the system, as a result it will be impossible to pump oil. Then it is necessary to stop the pump to avoid failure of the device.

- In order to lower the pressure in the system, you need to slowly turn the valve all the way counterclockwise. As a result, oil from the system will flow back into the pump. This occurs due to the return of the piston to its original position.

- After finishing pumping oil, you should inspect the hydraulic system for oil leaks, and you should also inspect the pump. If leaks are found, they should be corrected immediately.

Hydraulic cylinder for a greenhouse - installation and best brands (85 photos)

What a hydraulic cylinder is is known to many, but not to everyone. For those who are first faced with the need to acquire a hydraulic cylinder for their greenhouse, this equipment can be characterized as a reciprocating mechanism, which in this case helps maintain the optimal temperature in the greenhouse.

There are many types of hydraulic cylinders for greenhouses on sale, but you can make and install one yourself, especially since there are many solution options. The hydraulic cylinder, as a technical element, is used in many mechanisms, and therefore, to use it for greenhouse ventilation, you can remove it where it is no longer in demand, and also create a completely independent system.

Hydraulic cylinder for a greenhouse - what is it?

So, what is this mechanism and what is its function? The task that the hydraulic cylinder solves is to ventilate the greenhouse automatically. That is, you no longer have to worry, especially in the hot season, that the plants will overheat; for a person, this issue can be solved by a hydraulic cylinder.

Malfunctions and their elimination

- The manual hydraulic pump does not supply pressure. The main reasons for this behavior may be the lack of hydraulic fluid in the tank or the drain valve is not closed. In any case, it is worth checking these versions; if the tap is still closed and there is liquid, then perhaps the reason is that the suction or discharge valve is clogged. Then you will have to disassemble and wash the hydraulic pump valves.

- Oil (hydraulic fluid) is leaking in the gap located between the body and the plunger. In this case, it is highly likely that the O-rings are worn out or damaged. It is recommended to replace them immediately to prevent failure.

- Does not produce the performance specified in the data sheet. Most likely the filter element of the manual hydraulic pump is clogged. It is recommended to thoroughly rinse the filter element.

- Does not develop the pressure specified in the technical data sheet. The safety valve is not adjusted correctly. You need to set the safety valve to the pressure indicated in the data sheet.

Related Posts

Please advise a hydraulic station for synchronous operation of hydraulic cylinders.

- Author: Daniil Gordienko

- February 15, 2022 1 comment

A hydraulic station is needed for the synchronous operation of hydraulic cylinders. Please advise what and how to choose?

Why does the hydraulic station not produce the required pressure, what should I do?

- Author: Kirill Erlikh

- February 15, 2022 1 comment

The hydraulic unit does not produce pressure, what should I do?

Questionnaire for ordering a hydraulic station: what parameters do you need to know to order and manufacture a hydraulic station?

- Author: Sergey Mikhailov

- February 15, 2022 1 comment

What parameters must be specified to order a hydraulic station?

Hydraulic power stations for hydraulic tools: features and differences

- Author: Alexey Kramarenko

- February 15, 2022 2 comments

What is the peculiarity of hydraulic power stations for hydraulic tools, how do they differ from conventional hydraulic power stations?

DC hydraulic station 12/24V for hydraulic press

- Author: Yakov Damsky

- February 15, 2022 1 comment

Please tell me, is it possible to use a 12/24V hydraulic station to operate a hydraulic press?

Consultation with a hydraulic engineer

- Author: Denis Tolstosheev

- September 11, 2022 no comments

Good afternoon, please tell me how I can get advice on the topic of hydraulic components? I am interested in issues related to the diagnostics of the hydraulic system and, in general, the purchase of hydraulic pumps/hydraulic motors/hydraulic distributors, selection of analogues, etc. I don’t want to make a mistake in choosing, but I have very little experience, I don’t know what to pay attention to.

Oil for hydraulic power station: what kind of oil should be poured into the hydraulic power unit? Can I use a non-hydraulic one?

- Author: Vladimir Volosatov

- February 20, 2022 1 comment

What kind of oil should I pour into the hydraulic station?

What is hydraulic fluid?

- Author: Vyacheslav Makarov

- February 11, 2022 no comments

Hydraulic fluid is a kind of energy transfer mediator used in all hydraulic systems. However, the functionality of hydraulic fluid is not limited to simple energy transfer. Although transmitting hydraulic power is the primary purpose of hydraulic fluid, it also performs four auxiliary functions: heat transfer, contaminant removal, sealing, and lubrication.

Under normal conditions, hydraulic machines produce enormous amounts of excess heat, often caused by inefficiencies in the components themselves, such as pumps and motors. Without the ability to dissipate heat from these components, they can easily overheat, causing damage to valves and internal components, especially in low local viscosity environments. When the oil returns to the reservoir, it passes through a cooler many times, which keeps it at an optimal temperature until it is returned to the hydraulic system. Conversely, hydraulic fluid can be used to provide heat to the system during idle starts when needed.

We turned off the tractor, started it up the next day - neither the steering wheel nor the hydraulics worked. What could be the reason ? Amkador 342v

- Author: Arthur Petrosyan

- 01 July 23:49

Good evening, can anyone help? Advice or something else? I worked all day. They turned off the tractor the next day and started it up. The steering wheel doesn’t work. The hydraulics have all failed! What could be the reason ? Amkador 342v

Hydraulics. Why does the grab rise by itself?

- Author: Zulfir Tukhbetov

- March 27 15:38

Hello guys, please tell me the hydraulics lifts the grab by itself

How to choose the right hydraulic manual pump?

Choice

Three main selection factors:

1. The hydraulic pump tank must be larger than the hydraulic cylinder capacity.

2. Manual hydraulic pumps come in two types: single-acting and double-acting, pay attention to this parameter.

3. The pressure level should match what you need for work. Select a hydraulic pump with a pressure equal to or greater than the maximum pressure of the hydraulic cylinder.

Filtration system

To ensure continuous operation of the hydraulic station without breakdowns, it is necessary to keep the working fluid clean and remove foreign particles and debris from it that have entered during circulation through the system. Otherwise, moving parts may jam and various elements may wear out too quickly. This reduces the power of the station and leads to unreasonably high repair costs.

Complex hydraulic equipment with a large number of control elements requires multi-stage oil filtration. The choice of filter characteristics and installation locations depends on the parameters of the hydraulic system.

The following options are possible:

- For general-purpose hydraulic power stations and one-time-occasional operation, it is possible to install filters with a cleaning fineness of 80 microns;

- For hydraulic power stations with more intensive operating modes, 25 micron filters are installed;

- For equipment with automatic control systems based on proportional hydraulic valves, 10 micron filters are required.

Filter elements are installed in the suction, drain or pressure lines, or in a separate cleaning circulation circuit. They are mounted in such a way as to provide easy access for dismantling and replacing the filter element. It is recommended to use devices with a contamination indicator, which simplifies monitoring the technical condition of the degree of contamination.

In the diagram, the filters are numbered 3 (pressure), 4 (suction) and 5 (drain).

Is it worth making a manual hydraulic pump yourself?

At the moment, hand-made pumps are almost never found. Despite this, you can make a hydraulic pump with your own hands. We will need a steel tank. The body will be made from it. To control the pressure in the tank you need a valve. It needs to be secured at the top with a washer. A lever is installed to control the closing valve. A cast iron pipe may be suitable. Use a pressure gauge to monitor pressure. In the end, you will end up with a device that will not withstand pressure of more than 4 atmospheres. With all this, a homemade hydraulic pump will take up a lot of space and be inconvenient to carry. The disadvantage of homemade hand pumps is their low efficiency; quite a lot of force will be required to activate the pump. Also, homemade devices are very unreliable. And if you take into account all the disadvantages, then spending resources on creating a homemade manual hydraulic pump is very ineffective. That is why they are not common.

Manufacturing process

When the drawing of your future hydraulic press is ready, and all the necessary materials, tools, equipment and components are available, we proceed directly to manufacturing. The first thing to do is to cut all the metal, guided by the dimensions indicated in the drawing.

One of the drawing options for making a press

Now you need to make the base of the press, for which prepared square pipes are welded together, and a steel plate is welded onto the rectangle formed from them. Then the side and top parts of the frame are welded together, carefully ensuring that the resulting U-shaped structure is smooth and has strictly right angles in the joints. Now the resulting structure should be welded to the base and we can assume that the frame for your hydraulic press is ready.

The next element that you will need to make for the press is a movable platform. To make it, you can use a channel, square or rectangular pipe. A piece of pipe is welded in the central part of the platform, which will serve as a socket for the head of the jack rod. To make guides for the working platform, you will need two steel strips, the length of which must correspond to the width of the press frame along its outer contour.

A variant of the press design with a movable lower platform, which is fixed with bolts

The strips are attached to the sides of the mobile platform using bolted connections, having previously brought it inside the frame. A removable stop is made using the same scheme, but holes are drilled in its guide strips opposite the frame posts to fix it at the desired height. The process of making a hydraulic press with your own hands is completed by installing tension springs and the jack itself. Such a hydraulic press is also convenient because you can always remove the jack from it (for example, if you need to use it to repair a car).

Appearance of a finished homemade press

One of the fairly economical variations of a hydraulic press, made with your own hands in your garage using simple devices, welding, a jack and channels.

Manual hydraulic pumps NRG

NRG hydraulic pumps are very reliable devices and are very common here in Russia as they are produced here. The NRG line of pumps contains devices with distributors. The letter “P” is usually placed at the end of the designation of such instruments. This letter means that the tool can work with double-acting hydraulic devices. Let's consider several models of NRG manual hydraulic pumps:

NRG pumps

- Model nrg-7020R. Creates a maximum pressure of 700 bar. And it has a nominal tank volume of 2 liters. The kit includes a hydraulic distributor that allows you to work with both single- and double-acting devices.

- Model nrg-7007. Also creates a pressure of 700 bar. The nominal tank volume is 0.7 liters. The advantages of this model are the presence of a safety valve, minimal force on the handle, and two stages of oil supply. This tool is designed for single-acting hydraulic tools with a spring return rod.

- Model nrg-67016R. The nominal tank volume is 14 liters. Handle force 55 kg. Pressure maximum 4 MPa. Capacity is 115 cubic cm. Such a device weighs as much as 30 kg and is quite large. Suitable for a small car service.

My homemade mini oil station.

My homemade mini oil station.

I wonder who made a mini-oil station for themselves? What kind of engine, what connections, oil tank volume, regulators, valves, high pressure hoses, pump, hydraulic motor, hydraulic cylinders were used? Where was it used?

10 (or more) years ago Posts: 186

Re: My homemade mini-oil station.

Petrovich DD Writes: ——————————————————- > I wonder who made a > mini-oil station for themselves? What > engine, what > connections, volume > of the oil tank, regulators, valve > on, RVD, pump, hydraulic motor, guide > were rotary cylinders used? Where > was it used? It would not hurt to immediately clarify why this station is needed, otherwise not everything is on topic, but I want to understand.

10 (or more) years ago Posts: 1,510

Re: My homemade mini-oil station.

I made myself several different oil stations for homemade machines and presses. What is it for?

11 (or more) years ago Posts: 39

Re: My homemade mini-oil station.

For example, take as a basis an internal combustion engine of 13-14 hp, and on this basis build a mobile mini-hydraulic station for rotating a casing string diameter 159 mm, for drilling holes diameter 250-300 mm with a depth of 1-2 meters, can be used for jacking (for blasting casing or tool wedge), and the application, on a drill, it is interesting to find out how it is made and works.

10 (or more) years ago Posts: 186

Re: My homemade mini-oil station.

Yes, it’s not a problem to make a hydroelectric station at all. You just need torque to rotate the drill rods, and the hydraulic motor is good with a planetary gear and is oh so expensive. and for a jack you can only use a hydraulic cylinder, because for this you don’t need an internal combustion engine, a 3 kW electric motor is enough

11 (or more) years ago Posts: 39

Re: My homemade mini-oil station.

I looked in the hydraulics section. There are some good tips there. I’m wondering how I can build a mini-oil station myself

10 (or more) years ago Posts: 10

Re: My homemade mini-oil station.

It’s not a question of doing this, the question is what pressure and amount of oil per minute is needed. This is known. Well, then the oil pump has the required performance. and pressure, a distributor, it usually has a pressure reducing valve and a consumer. Drive power per pump. Let’s say NSh-10 3 kW, three-phase with a nominal capacity of 60 atm., well, consider if you need more displacement. What kind of engine will be needed?

11 (or more) years ago Posts: 2,913

Summary, pros and cons of hydraulic hand pumps.

Pros:

- Easy to use;

- Do not require any additional energy source;

- High maintainability;

- Have high mobility;

Minuses:

- Low performance;

- Muscular strength of the operator is needed, therefore, additional load on the operator;

Bottom line, it is reasonable to use a manual hydraulic pump in small workshops and mobile services, where there is no need to pump in large volumes of oil and build up significant pressure. In general, hand pumps are very convenient, and most importantly, they are mobile since they do not depend on any energy sources.

Classification

Extensive experience in the creation and operation of various hydraulic drives has shown that only limited types of pumps can develop high pressure. These include piston and plunger types. The hydraulic pump drive comes in three design types:

- manual (muscular);

- mechanical;

- pneumatic.

The use of hydraulic drives with ultra-high pressure (over 70 MPa) makes it possible to significantly reduce the dimensions and weight of equipment and increase its specific performance. The development of high-pressure systems is one of the key factors in the creation of compact, powerful hydraulic drives and mini-equipment for various sectors of the economy.

Using the device at home

At home, you can use the device to perform a wide variety of tasks. The small size of the unit allows it to be placed in a garage or other small room and used when repairing a car or motorcycle. It can also perform the following functions:

Stamping;- Forging;

- Profile production;

- Creating bends;

- Pressing and pressing out bearings and other parts;

- Used for culinary purposes, such as making juice from vegetables and fruits.

There are many known cases when the press is used as an oil press, and also with the help of equipment they perform repressing of silent blocks. In addition to repair work, a hydraulic press can be used to bend metal, glue products using pressure, make briquettes from various types of waste, and also squeeze out oil and other liquids. Equipment for performing such tasks, even with a simple design, costs a lot of money, but the device can be made independently, using simple materials and tools.