Schematic diagrams of axial piston hydraulic machines

An axial piston pump is a technical device that belongs to the category of hydraulic machines, the mechanical energy of the working body of which is converted into the energy of a moving fluid flow. If such machines perform the opposite action (in other words, the energy of the fluid flow is converted into mechanical energy), they are called hydraulic motors. Both hydraulic motors and hydraulic pumps began to be used quite a long time ago, and today they are actively used almost everywhere.

Axial piston pumps are installed on dump trucks, bunker trucks, multi-lifts and other equipment

Axial Piston Hydraulic Pump A hydraulic motor is one of the types of rotary piston hydraulic machines.

a brief description of

The inventions are widely used in industry and agriculture because they can withstand enormous overloads.

Hydraulic pumps and motors are found in technical enterprises and are used to supply water to areas, houses and apartments. There are known cases of the introduction of these machines during the construction of spaceships. Hydraulic units operate under the influence of changes in the size of the working surfaces. The latter have a direct connection with the outgoing and incoming pipes. Chambers and pipes are connected gradually and sequentially, through strictly designated time periods. Devices of this type of action have specific names:

- Axial piston pumps.

- Gear hydraulic machines.

- Piston pumps.

- Screw hydraulic units.

You should definitely read about what sizes the M12 bolt comes in.

What does it include?

Axial piston pump

In a traditional assembly, industrial pumps of this type include a specialized cylinder block, which is additionally equipped with pistons, as well as a thrust disc, drive shaft, connecting rods and a distribution unit. During the operation of the hydraulic pump, simultaneously with the start of rotation of the shaft, the cylinder block also begins to work, and it is worth noting the fact that the pistons will not only rotate, but also move along the axis of this block, making reciprocating movements. It is thanks to this operating principle that these industrial pumps are called axial piston pumps.

Advantages and disadvantages

An axial piston hydraulic motor and hydraulic pump of this type, when compared with radial and steam devices, have the following advantages:

- With a fairly compact size and light weight, such devices have impressive power and decent performance.

- Due to their compact size and light weight, pumps of the axial piston type create a small moment of inertia during operation.

- The rotation speed of the output shaft of an axial piston hydraulic motor is very easy to adjust.

- These devices operate effectively even at a sufficiently high pressure of the working fluid and at the same time create the appropriate torque of the output shaft.

- In such installations, it is possible to change the volume of the working chamber, which cannot be achieved when using hydraulic pumps and radial piston hydraulic motors.

- The frequency with which the output shaft of hydraulic motors of this type rotates, depending on the model, can be in the range of 500–4000 rpm.

- Unlike radial piston pumps, which can operate at a working fluid pressure not exceeding 30 MPa, axial units are capable of operating at a pressure reaching 35–40 MPa. In this case, the loss of such pressure will be only 3–5%.

- Since the pistons of axial pumps are installed in the working chambers with minimal clearances, high tightness of such installations is achieved.

- When using pumps of this type, both the direction of flow and the pressure of the working fluid can be adjusted.

Read also: Speed controller of the commutator motor from a washing machine

Adjustable axial piston hydraulic motor used on loaders, excavators and truck cranes

Like any other technical device, axial piston pumps have disadvantages:

- Such pumps are quite expensive.

- The complexity of the design makes it much more difficult to repair axial piston hydraulic pumps.

- Due to the not very high reliability, hydraulic mechanisms of this type should be operated only according to the instructions, otherwise you may encounter not only the low efficiency of such a device, but also its frequent breakdowns.

- When using pumping equipment of this type, liquid is supplied to the hydraulic system with large pulsations and, accordingly, is consumed unevenly.

- Due to the high pulsation characteristic of the operation of such pumps, the hydraulics with which the pipeline system is equipped may not work correctly.

- Hydraulic mechanisms of the axial piston type react very critically to a contaminated working environment, so they can only be used with filters whose cell size does not exceed 10 microns.

- Axial-piston hydraulic devices, due to the peculiarities of their design, produce significantly more noise during operation than models of pumps and hydraulic motors of the vane and gear type.

The axial piston type, as mentioned above, can include not only hydraulic pumps, but also hydraulic motors. The operating principle of the hydraulic motor is almost identical to the operating principle of an axial piston pump. The main difference is that such work is performed in the reverse order: liquid is supplied to the device under a certain pressure, which forces the pistons of the hydraulic motor to move, causing its output shaft to rotate.

Design and principle of operation of a circulation pump If you don’t know what the principle of operation of a circulation pump is,...

How to choose a pump for a pool: a comparative review of different types of units. You want to equip your own pool by creating…

The simplest pump from plastic bottles A simple pump for pumping liquid can be made in just a few minutes...

Hydraulic pumps today are widely used in a wide variety of industries: from households to mechanical engineering. Due to their high performance characteristics, they are used to provide water supply to private and apartment buildings, supply fuel to equipment at industrial enterprises and space stations. The most common are axial piston-type hydraulic pumps.

Read also: Gates made of corrugated sheets drawings

Recommendations and selection criteria

In order to select the right piston pump, it is necessary to take into account its scope of application and future conditions of use. Thus, for work in extreme conditions associated with hydraulic shocks, high-pressure pumps are suitable. The adjustable piston hydraulic pump is an ideal choice for installation in mini excavators, various drive shafts and work ports. Non-adjustable models, as a rule, are chosen for installation on the power take-off in truck cranes, municipal vehicles and other special equipment.

When choosing between a swashplate pump and a swashplate pump, consider:

- Equipment dimensions. Due to the absence of a bulky bearing assembly and cantilever shaft, inclined disc pumps are more compact.

- Life time. Under the same conditions, disk ones will work longer than devices with an inclined block by 3-5 thousand hours.

- Efficiency Machines with an inclined block are considered more efficient. At the same time, pumps with inclined discs are inferior to them by only 2%.

- Working fluid requirements. Devices with inclined blocks require a more viscous working medium (in the region of 15-25 microns), resistant to increased temperatures.

To choose the right axial piston pump, you need to watch a training video and consult with the seller.

In addition, it is important to know that pumps with an inclined disk part are characterized by a low number of high-precision parts and metal consumption per unit of production. This is of great importance when making equipment yourself

This is explained by the fact that models with an inclined block are equipped with a more complex and developed piston group. In addition, such devices contain various synchronizing devices.

Axial piston pumps are widely used today in many areas of household and industry. They are distinguished by high performance indicators, among which are their durability, high performance and compact size. There are several types of axial hydraulic pumps. The choice of equipment is influenced by its technical characteristics and scope of application.

Pros and cons of an axial piston pump

The structure of such hydraulic machines has a main difference from other devices: here the working chambers, located in a cylindrical block, have the form of barrels with a spiral thread. The compartments are located axially (parallel) to the piston system and the main axis. These barrels change their volume due to the fact that the reciprocating parts move in the chambers. As a result, water is sucked in or released during operation of the unit.

- The advantage of the axial piston device is its low weight and compact shape with sufficient energy capacity.

- The operating principle of the design is due to low inertia, since the parts of the unit have small dimensions.

- While using the machine, it is possible to change the rotation speed. They are designed in such a way that they can perform work under dangerous pressure (35 to 40 MPa).

- The rotation range of axial piston pumps varies from 500 to 4,000 rpm. These figures are significantly higher and wider than those of hydraulic motors or radial piston devices.

Negative characteristics include the following among designers and workers:

- Due to the above advantages, the unit is expensive.

- Axial piston pumps are designed according to rather complex drawings.

- If the machine is not used according to strict operating rules, frequent breakdowns are possible. Repairing an axial piston pump is expensive and will take a long time.

- During operation, high energy consumption and significant pulsation of flow and pressure are noted throughout the entire area of the unit.

Device

The plunger pump has a relatively simple design. Among the features we note the following points:

- Working chamber. It is represented by a sealed case, which has a mirror surface in the inner part. Due to this, the movement of the moving element is significantly simplified. The working chamber is a part of the cylinder, which is determined by the maximum stroke of the rod. The surface of the cylinder is made using a material that is highly resistant to liquids.

- The pressure and suction tubes are designed to drain and supply liquid. They can have different diameters. In addition, such a structural element may have a valve system, which significantly increases the efficiency of the mechanism.

- The piston creates pressure in the system. The piston pump device has a piston, due to which the liquid is pumped. It is manufactured using several sealing materials. Due to this, the piston can move along the cylinder and at the same time create a vacuum. It is on the surface of the piston that serious pressure is exerted. Some versions are collapsible, allowing for repairs. For example, with prolonged use, seals wear out, which can be replaced if necessary to significantly extend the service life of the mechanism. However, there are also non-separable versions, the repair of which is possible only in special workshops.

- The force is transmitted to the piston through the rod. In the manufacture of this element, high-quality steel with increased rigidity and strength is used. In addition, the materials used are characterized by high corrosion resistance, which significantly extends the service life of the structure. This element is connected to the drive through which force is transmitted. If the load is too high, the rod can become significantly deformed.

Pump device

The reciprocating motion is transmitted from the electric motor through a special mechanism that converts the rotation. Modern versions are compact and can be installed for outdoor or indoor use. In addition, in the manufacture of the case, metal is used, which has high protection from environmental influences.

The device of the double-sided model has quite a large number of features:

- There is a cylinder and a piston, as well as a rod. These elements are slightly different compared to those used to create a one-way mechanism.

- Unlike the previous version, this one has two working chambers.

- The two working chambers have their own discharge and suction valves.

https://youtube.com/watch?v=xV-cwbgCyIw

Despite the significant increase in the efficiency of the piston pump, its design is quite simple. In this case, each stroke involves the suction and expulsion of liquid. This significantly increases the efficiency value.

What is an axial piston type hydraulic pump?

An axial piston hydraulic pump, like a radial piston one, is a positive displacement device that operates by changing the volume of the working chambers. In hydraulic pumps of the axial piston group, such working chambers are formed by borings, which are made in a cylindrical block. Unlike radial piston pumps, axial piston machines have internal working chambers located parallel to the pistons and the axis of the device itself. As the pistons of such a pump move and the cylindrical block rotates, the volume of the working chambers increases or decreases, which allows the device to suck in and release the liquid it pumps.

Operating principle [edit | edit code ]

Axial piston pump and radial piston pump

When the hydraulic machine shaft rotates (Fig. 1), the plunger located at the bottom (at the bottom dead center) moves upward, and at the same time moves along the axis of the pump “from the edge” of the cylinder block - suction occurs. At the same time, the plunger that was at the top moves down and moves “towards the edge” of the cylinder block - injection occurs. The plungers that are currently pumping are connected together by one groove - and form a high-pressure cavity; and those plungers that are currently performing suction are connected together by another groove - and form a low-pressure cavity. The high and low pressure cavities are separated from each other. The point at which the plunger transitions from the high-pressure cavity to the low-pressure cavity is called the top dead center, and where the reverse transition occurs is the bottom dead center. At the moment the plunger passes through one of the dead points, locked volumes are formed.

Axial piston pump: operating principle and structure

The cylindrical main block houses a system of pistons and connecting rods connecting the crankshaft and the reciprocating part. The design also includes distribution devices and stop disks. Since the cylindrical block is placed in the unit tightly pressed to the distribution mechanism, this allows problems to be avoided in most cases.

- The operating principle of the pump is based on the rotational movements of the drive shaft, which transmits impulse to the area of a specific cylindrical block.

- Next, the pistons begin reciprocating movement towards the main axis.

- The frictional force in such a system generates suction and then expulsion of liquid elements.

There are special holes in the distribution device that serve as a kind of plane for the interaction of opposite lines of work. Jumpers inside axial piston pumps provide greater reliability for specific openings. Throttle grooves placed on jumpers (mounts) are designed to reduce hydraulic shock on component parts. These elements allow the machine to smoothly increase the operating pressure inside the unit.

Design features and principle of operation

The axial piston type hydraulic pump consists of the following elements:

- pistons, also called plungers, which are part of the cylinder block;

- connecting rod type elements;

- drive shaft, which is also called the main shaft;

- mechanism that performs distribution functions.

Design of an axial piston pump with an inclined block

The principle by which an axial-type piston hydraulic pump operates is based on the fact that its main shaft, when rotating, imparts movement to the elements of the cylinder block. The rotation of the main shaft of axial piston type pumps is converted into reciprocating movement of the pistons, performed parallel to the axis of the cylinder block. It is due to the nature of such piston movements, which are axial, that the pump got its name.

Operating principle of an axial piston hydraulic pump

As a result of the movement performed by the pistons in the cylinders of the axial plunger pump, alternate suction and subsequent injection of liquid occurs through the corresponding nozzles. The connection of the working chamber of the pump with its suction and discharge lines occurs sequentially, using special windows made in the distribution mechanism. To minimize the risk of malfunctions during the operation of the cylinder block of axial-piston type hydraulic pumps, as well as to ensure reliable operation of such a device, its distribution mechanism is pressed as tightly as possible to the cylinder block, and the windows of such a block are separated from each other by special sealing gaskets. Throttle grooves are made on the inner surface of the windows of the distribution mechanism, the presence of which makes it possible to reduce the amount of hydraulic shock that occurs in the pipeline system during pump operation. The presence of such grooves on the inner surface of the windows of the distribution mechanism helps to increase the pressure of the working fluid created in the cylinders as smoothly as possible.

As it becomes clear from the above-described design of an axial piston hydraulic pump, its working chambers are cylinders located parallel (axially) to the axis of its rotor, and the displacement of liquid from such cylinders is carried out due to the reciprocating movements of the piston.

Pump operating principle

Displacers in axial piston machines can be pistons or plungers .

Read also: Making a machine for sharpening drills at home: making a sharpener with your own hands

Pumps with plungers are sometimes called axial plunger . However, often the names do not reflect this feature, and the pump is called axial piston , regardless of whether the displacer is a piston or a plunger.

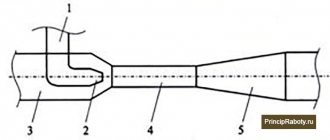

In axial piston pumps with an inclined block, the axes of the working bodies are at an angle to the axis of the drive shaft. This angle determines the stroke of the pistons. Its value is less than 45°. In most designs, the angle of inclination is 20°-30°.

When the shaft rotates, the rotor or cylinder block is also driven into rotation through pistons pivotally mounted on the drive shaft.

The rotor is pressed against the spherical surface of the distribution disk, on which two crescent-shaped grooves are made.

When the drive shaft rotates, each of the pistons moves in the rotor holes. The amount of movement depends on the angle of inclination of the block.

When the piston moves, increasing the volume of the working chamber, liquid is sucked through the crescent-shaped groove and fills the chamber.

When the piston moves in the opposite direction, the volume of the working chamber decreases. The liquid is forced out through another crescent-shaped groove. The holes in the rotor in which the pistons move are evenly distributed. At that moment, while some pistons are displacing liquid, others are moving in the opposite direction. This ensures a continuous supply of pump fluid with significantly reduced pulsations.

In axial piston pumps with an inclined disk, the axes of the working elements are parallel to the axis of the drive shaft. The movement of pistons or plungers inside the rotor is ensured by an inclined disk on which the plungers rest through pushers.

The rotor is fixed to the shaft with a key, therefore, when the drive shaft rotates, the rotor rotates, and with it the plungers.

Read also: Simple potato hiller from an old bicycle: do it yourself

The plungers, when the drive shaft rotates, move in the rotor holes.

As the working chamber increases, liquid fills it. When the plunger moves in the opposite direction, liquid is forced into the pressure line.

Fixed axial pumps

In unregulated pumps, the angle of inclination of the block or disk does not change.

Axial piston pump with inclined block

When the shaft 1 of the pump, mounted in bearings 2, rotates, the inclined block 3 is driven into rotation by articulated pistons 4. During operation, the pistons move linearly relative to the block. The length of the piston stroke depends on the angle of inclination of the block. The distribution disk 5 has crescent-shaped grooves 6, one of which is connected to the suction line, the second to the discharge line.

Calculation of the flow of an axial piston pump with an inclined block

The theoretical flow of a positive displacement pump is proportional to its working volume q and shaft speed n:

The displacement of an axial piston pump can be calculated using the formula:

- where d is the piston diameter

- z - number of pistons

- h - piston stroke

The piston stroke of an axial piston pump with an inclined block depends on the angle α of the block inclination and the diameter of the pistons D:

To calculate the actual flow, it is necessary to multiply the theoretical one by the volumetric efficiency (0.9. 0.98 for piston pumps):

Axial piston pump with inclined disc

Cylinder block 2 is installed on drive shaft 1. Pistons 4 installed in shoes 3 rest on an inclined disk (or washer). When the shaft with block 5 rotates, the pistons, due to the tilt of the disk, will perform a reciprocating movement relative to the block. The distribution disk 6 has crescent-shaped windows that connect to the suction and discharge lines.

Calculation of flow of an axial piston pump with an inclined disk

The design diagram is shown in the figure.

To calculate the pump flow, you need to know its displacement and drive shaft speed:

The piston stroke depends on the geometry of the swashplate pump.

- where D is the diameter of the pistons

- α - angle of inclination of the washer

You can order an axial piston pump, the price of which is very affordable, of several types. Such devices can operate in open and fully closed hydraulic machines.

Types of devices

Axial piston pumps come in two types.

The first includes products with an inclined washer. In the design of such devices, the crankshaft is combined with a cylindrical block, secured with bearings. The piston system is located in the area of the main chambers and rests directly on the swashplate. This disk and the axis of the tank with cylinders form a perpendicular to each other.

This angle allows the pistons to generate reciprocating impulses as the rotor begins to rotate. Consequently, the volumes of the chambers decrease or increase, which naturally provokes the absorption or release of liquid through the holes. In order to adjust this axial piston pump, the angle of the disc must be changed. Such units are used for medium and heavy load work.

The second type includes adjustable axial piston pumps with an inclined cylindrical block. The main difference between such a device and radial piston machines is that the drive, mounted on bearings, is designed in a T-shape. The cylindrical block rests on the second axis and is located at an angle to the main shaft. In the center of the structure there are parallel bores, inside of which there are pistons. The latter are connected to the main shaft using a connecting rod system.

The block communicates movement simultaneously with the start of rotation of the rotors. Thanks to the angle formed from the connection of the main lobes, some of the pistons extend beyond the rotor, while others enter. Thus, the liquid is pumped or reduced in the working chambers. Water, in turn, enters the cylindrical block through a special hole at the bottom and moves through the vessels inside the body.

On a note!

The design of an axial piston pump with an inclined block allows you to change the size of the piston stroke. This helps to vary the working volume in the chambers.

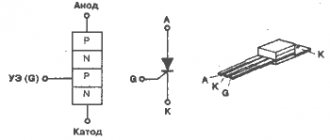

Design features of Axial Piston Hydraulic Pumps Hydraulic Motors

Axial-plunger and axial-piston hydraulic machines differ in that the former use plungers as displacers, and the latter use pistons. The most widely used are axial plunger hydraulic machines.

Hydraulic machines are produced with an inclined disk (washer) and with an inclined cylinder block.

To avoid resonance phenomena and to reduce supply and flow pulsations, the number of plungers is always odd.

In the design of the first, the crankshaft is combined with a cylindrical block, securing it with bearings. In this case, the piston system rests directly on the washer. This angle allows the pistons to increase the movement of fluid during rotational movements. Adjustment of such a device occurs by changing the angle of the disk.

Main varieties

According to its design, a piston hydraulic pump, like an axial-piston type hydraulic motor, can belong to one of the following categories:

- devices with a washer installed at a certain angle;

- axial piston pumps or hydraulic motors equipped with an inclined cylinder block.

The cylinder block of hydraulic motors and hydraulic pumps of the axial piston type, equipped with an inclined washer, is installed coaxially with respect to the drive shaft and is rigidly connected to it. The pistons moving in the grooves of the working chamber rest with their end surface on a washer, which is installed at an angle to the axis of the drive shaft. The principle of operation of such an axial piston pump is that when the drive shaft and swashplate connected to each other rotate together, the pistons of the device begin to move back and forth, thus reducing or increasing the volume of the working chambers.

When the volume of the working chambers begins to change, the liquid pumped through the pump is sucked in and pushed out. Devices with a swashplate are classified as adjustable hydraulic pumps, since by changing the angle at which the working surface of the swashplate is located, it is possible to change the flow parameters of the pumped liquid. Moreover, with the help of such a pumping device it is possible to reverse the water supply by changing the direction of the angle of inclination of the washer to the axis of the drive shaft to the opposite. Axial piston pumps equipped with a swashplate are installed in hydraulic systems operating under medium to high loads.

Schematic diagrams of axial piston hydraulic machines

The body of axial piston hydraulic pumps equipped with an inclined cylinder block has a V-shaped configuration, and their drive shaft is designed in the form of the letter T. The angle at which the cylinder block of the axial pump in question is located to the axis of the drive shaft can range from 26 to 40 °, and the number of pistons reaches 7 pieces. The operating principle of such an axial piston pump is as follows: when the drive shaft connected to the pistons through connecting rod mechanisms begins to rotate, the inclined cylinder block is also rotated, and the pistons located in the axial grooves begin to perform reciprocating movements, thereby reducing or increasing the volume of working chambers.

The process of suction and injection of the pumped working medium in axial piston pumps of this type is carried out through special openings-windows made in the distribution device, which is located motionless relative to the rotating inclined cylinder block. Unlike steam and radial piston pumps, in devices of this type the volume of the working chamber can be adjusted. This problem is solved by adjusting the angle of inclination of the cylinder block relative to the axis of the drive shaft using special mechanisms.

Axial piston pumps use a unified oscillating unit

Depending on how the design of an axial type plunger pump is implemented, it can be one of two types:

- In devices equipped with a double non-power cardan, full compliance of the angles measured between the intermediate, drive and driven shafts is achieved. When hydraulic pumps of this category operate, their shafts (drive and driven) move synchronously, which reduces the load on the cardan shaft, which, interacting with the disk, transmits torque.

- Axial piston type pumps have a design in which the pistons point contact with the surface of the inclined disk is implemented. This device does not have cardan and connecting rod mechanisms, which simplifies its design. The most significant disadvantage of axial piston pumps in this category is that to start them, it is necessary to force the piston elements out of the working chambers and then press their end part against the surface of the inclined disk. Meanwhile, due to the simplicity of the design, regular maintenance and repair of hydraulic pumps of this type is not very difficult.

Main disadvantages

Along with numerous advantages, there are also a number of serious disadvantages. When selecting an axial piston pump, it is important to consider the following features of the device:

Design of an unregulated axial piston pump

- very high price;

- complex design complicates maintenance and repair work;

- if used incorrectly, frequent breakdowns are possible, which indicates low reliability;

- water supply occurs unevenly, with large pulsations;

- supply pulsation occurs throughout the entire water supply system served by such a mechanism;

- the complexity of the design implies lengthy repairs in case of breakdowns;

- the need to purify the working fluid from impurities larger than 10 micrometers;

- high noise during operation.

Repair of equipment

The unit with closed holes is removed and washed with kerosene. Next, each individual pump element must be cleaned with a soda solution. To repair the holes of a cylindrical block, a special tool is used - a split cast iron lap. A mixture of diamond powder, oleic acid and stearin is applied to it. Pistons lubricated with industrial oil are processed without the use of abrasive pastes.

To restore the spherical surface of the cylinders, grinding is used on a specific machine. The end is restored by grinding the main holes with corundum stone and diamond powder. The work surface is repaired in the same way. When restoring the structure, you must make sure that all parts are cleaned of dirt and corrosion, and also lubricated with a special liquid.

Under the following circumstances, repair of faults is not possible:

- If the pump body, flange or door is cracked, dented or chipped.

- Deep scratches on the surface of the cylindrical block or the support axis do not allow repairs.

- If distortions are found on the connecting rods and pistons, restoration is impossible.

Adjustable axial piston pumps (H and S series products)

Units from this series, equipped with an inclined disk, are often installed on large-volume water pipelines, where in addition to sediment, the system contains a hydraulic motor. Both work in a closed circuit. In addition, such sediment is installed in road compactors, combines and automatic concrete mixers. They are easy to operate and small in size. When the inclined disk is turned, the flow of working fluid rotates in opposite directions, which determines the operation of the device.

Thanks to the presence of a hydraulic distributor in the form of a module, it is possible to connect control systems (CS) of the following types:

- Electric three-position control system (ER). This system is used to drive in a three-position system (these positions are: on - off - on).

- Hydraulic control system (HD). It is a kind of control lever. It supplies hydraulic signals to all mechanisms of the unit, due to which the inclined disk is held in the desired position. This control system is used in units of complex layout.

- Hydromechanical control system (MS). Provides maintenance of the inclined disk in the required position, due to which the pump operates in the specified mode.

- Electric control system (EP). This system, by changing the current strength on several proportional magnets, allows for a smooth change in the working volume of the unit.