A saw is often used to process wooden blanks and change length and shape. This tool is represented by a combination of a working part and a handle. In this case, the working part is represented by a metal plate with cutting elements, which are located in a certain sequence relative to each other. Only with proper and timely maintenance can the possibility of product wear be eliminated. An example is the setting of the teeth, which is performed from time to time to ensure smooth movement of the tool along the resulting cut.

Device for setting saw teeth

Setting the cutting edge in different directions eliminates the possibility of the blade getting stuck during operation. An example is the case when, when cutting a thick log, the blade cannot be moved and removed. Also, the saw can jam due to the heating of the metal and its expansion, the hot part can heat the resin and turn it into a kind of glue.

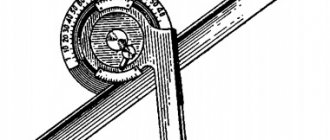

You should use a tool for setting the teeth of hacksaws in order to avoid such problems. Do not forget that mistakes made during work can lead to even bigger problems. The procedure in question can be carried out using the following tools:

- There are special mechanisms. They allow you to manually shift individual elements relative to each other. It is worth considering that this version is manufactured for specific products.

- Mechanical wiring is most often used. They allow you to change the angle of position, as well as their width. This tool is characterized by higher efficiency in use.

- The improvised version is not intended for working with a hacksaw on wood, but can be used for this purpose. An example is pliers and other improvised tools found in almost every workshop.

If sawing is carried out frequently, then experts recommend purchasing a special device that allows you to quickly set the required angle.

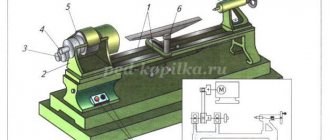

Turning process step by step

When manually sharpening with a file, it is easier to control the material removal and set the correct edge angles. The blade must be clamped in a miter box or vice, ensuring that the teeth protrude above the jaws by about 30–35 mm. Setting is done before sharpening for three reasons:

- so that the cutting edges are not subsequently damaged;

- so that a slightly stronger spread is ensured in advance, which is compensated by removing a certain amount of metal from the teeth;

- so that the direction of the cutting edges and the teeth set are uniform.

The most important rule for sharpening wood hacksaws is: the tooth must have a flat side on the side in which it was set. Thus, the cutting edges of adjacent set teeth are directed towards each other, that is, inside the channel formed by the set.

After clamping the blade, it is necessary to clarify the sharpening angle of the cutting edges. Ideally, it should be determined by the hardness of the wood being processed, but since a hacksaw is used for sawing various types of wood, a universal value of 60–75° from the plane of the tooth is set for all types of profiles. There is a certain difficulty in determining the sharpening angle relative to the plane of the blade in order to confidently control the position of the tool. This can be done using a flat metal plate, choosing the least worn tooth as a standard; usually this can be found closer to the handle.

When sharpening, you need to process those teeth that have their edges facing you. Maintaining the correct angle between the edge of the file and the blade, and also slightly tilting the file towards the edges, you need to remove 2-3 material from the cutting edges, applying pressure while moving away from you. After each pass, you need to ensure that the metal is removed over the entire surface of the edge, adjusting the position of the file if necessary. To ensure uniform sharpening, the number of file movements on each tooth must be the same. A good result of sharpening is considered to be uniform lightening of the blade descent over the entire area.

Sharpening a blade on an abrasive wheel is more difficult due to the fact that the blade does not have a stop. However, with proper skill, you can achieve accurate removal of metal from both sides of each tooth. As with hand sharpening, the movement of the cutting tool should be directed towards the flat part of the tooth, thus the entire blade is sharpened twice with a revolution.

How to properly spread the teeth of a hacksaw?

A fairly common question is how to set the teeth of a hacksaw on wood. If they are offset in one line, the cut is narrow and the working part gets stuck in one place. In this case, the metal quickly heats up, due to which it begins to expand. In order to set the teeth efficiently, it is recommended to use special mechanisms. Recommendations for the work being carried out are as follows:

- The saw is clamped in a vice for secure fixation. You can eliminate the possibility of damage to the working part by using plywood as a lining.

- All cutting elements are bent one at a time to the recommended angle.

When considering how to make a cut on a hacksaw, we note that several elements deflected at a larger angle can make sawing more difficult.

A good machine is the key to success

Let's look at this process in more detail.

The adjusting machine must perform the following functions:

- accurately and equally for any width of the band saw for all its teeth, set the height of only that part of the tooth that needs to be set apart;

- bring each saw tooth under the pusher in exactly the same place;

- when setting each tooth, first ensure that the body of the band saw is clamped in such a way that it does not have the opportunity to bend when the pusher presses on the tooth (to eliminate the “swing” effect);

- bend the tip of the saw tooth by a certain amount along a broken line, and not along a radius;

- push the band saw body away from the stationary plate after returning the body clamping mechanism to its original position, so that when the next tooth is fed for setting, its cutting edge does not cut the indicator tip;

- be able to press the tooth being set again to check and, if necessary, adjust the resulting set.

When pressing multiple times to check the misalignment of even one tooth, the difference in the indicator readings should be a maximum of one or two divisions.

If the setting machine fails to perform at least one of these functions, the teeth of the band saw can only be set poorly or very poorly. But 99% of adjustable machines are manufactured in such a way that they do not perform one or more functions, and besides, they themselves are of very poor workmanship.

Therefore, you can use a band saw on them only on a whim, which very rarely works out well. Accordingly, she saw and sawed like that.

Requirements for hacksaw wiring

In order to carry out the wiring correctly, you need to pay attention to the basic requirements. They are as follows:

- The procedure is carried out while fixing the instrument.

- The required angle must be strictly maintained; deviation from it causes a decrease in the quality of the resulting cut.

- At the time of work, care is taken to ensure that the surface is free of defects.

It is worth considering that too high an indicator causes an increase in the cutting width, which reduces the productivity indicator. That is why a special device must be used to set the teeth.

Setting teeth at home

Today, at home, you almost never find special devices designed for servicing hacksaws for metal. However, even in its absence, it is possible to carry out the work with improvised tools. The recommendations are as follows:

- To begin with, the hacksaw must be securely fastened in a vice. This is due to the fact that bending requires a lot of force.

- You can bend it using pliers. In order to maintain the correct angle, you must first create a template.

- You cannot skip more than one element of the cutting edge. In this case, attention should be paid to the condition of the surface, since identified defects indicate that the wood hacksaw cannot be used.

Even at home, in the absence of a special mechanism, you can carry out the correct wiring and significantly extend the service life of the wood saw. In this case, it is important to maintain the required angle, since a cut that is too wide causes a significant decrease in productivity, while a cut that is too narrow leads to heating of the working part and its severe wear.

Some companies provide services related to such work. Note that the cost of a special mechanism is relatively small, so it is best to purchase it and the procedure can be carried out repeatedly.

If you find an error, please select a piece of text and press Ctrl+Enter.

When working with wood in various ways, a tool such as a hacksaw is actively used. Over time, the cutting surface of the tool wears out, and the process of sawing wood becomes more and more difficult. Wear of the working edge is as follows:

- the pointed tops of the teeth are rounded;

- their side cutting edges become dull.

As a result, the tool loses functionality and needs to be sharpened.

How to saw with a two-handed saw - detailed instructions with description

At first glance, the process of sawing with a two-handed saw may seem easy and straightforward. However, as soon as a beginner takes up a hacksaw, it immediately becomes clear that this is a job for real and strong hands. However, you don’t have to have a mountain of muscles to properly cut wood with the Druzhba-2 saw. To do this, you need a little experience and also understand the principle of operation.

This is interesting!

Even if you have experience working with short-stroke hacksaws, a beginner who picks up a two-handed saw for the first time will be unpleasantly surprised.

If an experienced sawyer stands at the other end of the saw, then a beginner will have a hard time until he masters the principle of operation of the device. Instructions on how to cut logs and trees with a two-handed saw are as follows:

- First, the log must be secured by placing it on the “goats”. It must be taken into account that it is most convenient to carry out the work while standing on your feet, so even if the log lies on the ground, then in order to cut it correctly, you should place it on a special stand - sawhorses

- The section of the log that is sawn off from the main part should hang above the ground

- Both sawers take a comfortable position with their feet shoulder-width apart. The main thing here is to firmly support your feet, otherwise the possibility of injury cannot be ruled out.

- Ideally, it is recommended that one of the sawers position himself slightly higher than the other, for example, by placing a tray. This will speed up the cutting, but is not at all mandatory.

- By holding the handles of the tool, you can begin. The main thing when working with a two-handed hacksaw is synchronized work with your hands. The effectiveness of achieving the final result depends on smooth hand work.

- The principle of pair sawing is as follows: it is necessary to apply force only in one direction - to pull the blade towards you. There is no need to push the tool away from you, since this task is assigned to your partner. While the partner is pulling the blade towards himself, the hand of the first sawyer is resting

- In this way, not only work efficiency increases, but also rapid fatigue is eliminated

The speed of achieving results is influenced by many factors, such as the thickness of the log, the length of the blade, the quality of sharpening the teeth, as well as the synchronized work of the sawmills. It is worth noting that with the right approach to sawing, it is possible to achieve fast sawing comparable to the operation of a chainsaw.

This is interesting!

If the blade has signs of corrosion deposits, then before carrying out work it is recommended to clean the surface with fine sandpaper (to speed up the work, you can use a hand brush for metal), and then apply machine oil to reduce resistance when working with the tool.

How to determine when a hacksaw needs sharpening?

People with extensive experience can easily determine this moment by the sound made by the tool during operation, as well as by the change in color of the teeth. Beginners need to pay attention to the following signs:

- working with a hacksaw becomes difficult and requires great physical effort;

- it becomes very difficult to make perpendicular cuts in wood;

- it becomes difficult to hold the canvas along the line during operation, it begins to deviate in different directions;

- The hacksaw blade often jams.

What is a "stapler"

If desired, a tool for cutting teeth on a hacksaw blade can be made at home in the workshop. The main component of the tool is a matrix with a triangular cutout resembling the shape of a saw tooth. Of course, you also need a punch included in the matrix, which can rotate around its axis. To adjust the height of the cut teeth, the tool uses an adjustable stop that moves to the right or left. Its parameters change using several holes and fixing bolts.

Important: the matrix and the punch must extend into each other with a minimum gap, and the working edges of both parts must form an angle of 90 degrees

Teeth setting

The setting of the saw is the deviation of the tops of the teeth from the plane of the blade. The teeth, one after another, are deflected in different directions: odd teeth in one direction, even teeth in the other.

You need to know that the quality of the wiring has a strong influence on the sawing process. Therefore, all teeth must be bent in different directions alternately by the same amount, otherwise:

- if some teeth are deflected at a greater angle than the rest, they will interfere with the movement of the tool and wear out faster;

- if the deviation is less than necessary, then the width of the cut will not allow the blade to move freely.

Sharpening a hacksaw

- vice;

- hammer;

- calipers;

- pliers;

- emery block;

- sandpaper.

You should also have the following types of files in your arsenal:

- flat and diamond-shaped with a medium-sized notch;

- triangular file;

- triangular with velvet notch;

- needle files with notches of different calibers.

For sharpening, a special device is used that allows you to fix the blade at angles of 45 and 90 degrees. If you need to sharpen a cross saw, proceed as follows:

- the canvas is fixed at an angle of 45 degrees;

- sharpening is carried out with a triangular file with an apex angle of 60 degrees;

- the file is directed onto the hacksaw tooth at an angle of 60 to 75 degrees;

- first, with several movements of the file away from you, the left edges of the odd teeth are processed;

- After this, the hacksaw is turned over and the left edges of the even teeth are processed.

When sharpening a longitudinal hacksaw, proceed as follows:

- the canvas is fixed vertically;

- for sharpening, a rhombic file with a fine notch is used (needles can be used);

- during sharpening, the file is directed strictly parallel to the table;

- otherwise the process is similar to the previous one.

Burrs that appear on the edges of the teeth must be removed using an emery block or a file with a velvet cut.

The process of sharpening a saw for the first time is quite difficult, so it is better to carry it out in complete silence and with maximum concentration. It’s worth doing this a few times, and then things will become habitual and go “like clockwork.”

Narrow canvases always come apart. It must be remembered that only the tips of the teeth should be set apart, approximately 1/3 of the tooth height for sawing hard rocks and approximately 1/2 of the height for sawing soft rocks.

If the teeth are set to their full height, this will lead to the formation of a wavy base line and, as a result, the appearance of cracks.

Too large a setting leads to greater efforts and loads when sawing and poor quality of the cut surface. A large amount of loose sawdust will remain on the cut, and characteristic nicks and scratches will remain on the surface of the board. With a small spread, the saw will heat up, and tightly compressed hot sawdust will remain on the surface of the board. You can't think of anything worse for a saw. The sawdust should be warm to the touch, not hot or cold.

A saw that is set too far will likely cut jerkily; and if diluted insufficiently, it will leave waves on the board. As a rule, on narrow strips, every third tooth is left unset. This makes the most sense when cutting fresh softwood. These teeth act as clean-up teeth, clearing the cut and guiding the saw. It should also be noted that in the place where the band saw is welded, the teeth located to the right and left of the seam do not move apart. This is done to eliminate excess stress on the weld.

Example: You are sawing a log with a diameter of 30 cm at a good feed and the sawdust is warm to the touch. But don’t think that this saw will cut a log 60 cm in diameter just as easily with the same opening and feed. After all, you now need to remove twice as much sawdust from the cut. Therefore, it is necessary to increase the divorce rate by 20%. The conclusion suggests itself: logs should be sorted by thickness before sawing.

And finally, you will get the best divorce only experimentally. There is no need to look for formulas to calculate it.

It is necessary to mention the importance of regularly checking the indicator on your adjustable device. It's very easy to set it off. The indicator works in an extremely stressful mode, judge for yourself: your saw has approximately 220 teeth, you sharpen the saw 15 times; It turns out that during the life of the saw, the indicator is triggered when setting it at least 3.5-4 thousand times (often you have to set the tooth in several steps). The indicator wears out, so its installation should be checked more often.

© PiloramService LLC 2004–2019

The information on the site under no circumstances constitutes a public offer. When using materials from this site, a link to it is required!

How to sharpen a hacksaw for wood correctly

Despite the abundance of power tools for woodworking, hand hacksaws are still popular among home craftsmen. The advantages are obvious - low price, small dimensions and instant readiness for work (especially if there is no source of electricity).

Any cutting and sawing tool must be sharp; not only work efficiency, but also safety depends on this. If you exert enormous force when working with blunt equipment, you can lose control and cause injury to yourself. In addition, the quality of the cut made with a sharp hacksaw will be higher.

To understand how to properly sharpen a hacksaw for wood, let’s look at the structure of a popular tool:

It would seem that nothing could be simpler - an iron strip with cut teeth. But any design is developed individually; the shape and placement of the cutting parts depend on the type of wood.

If you do not follow this rule, the tool will jam in the cut as it goes deeper into the material. This means, at a minimum, you need to separate the teeth of the hacksaw. The cutting edge also has features - and this directly depends on the hardness of the wood and the cutting method.

New machine - correcting manufacturing inaccuracies

After reading everything described above, you can independently check and, if possible, correct your adjusting machine. However, it is easier and cheaper to buy a good new one. The only way to check the machine is to check the resulting pattern. When pressing multiple times, the difference in the values on the indicator should be a maximum of two divisions. As an example, I’ll tell you what we had to do when one of our clients asked us to bring his machine to working condition.

Externally the machine looked very beautiful. But when we tried to run a band saw on it, it turned out that almost all the components were made poorly. The spread of the values obtained when pressing again was more than ten units, which did not allow making a high-quality determination on it.

1. The movable plate was not perpendicular to the base plane (small vertical and horizontal deviation).

The body of the saw was clamped somewhere in the middle and more strongly from the right edge and only part of the plane of the ends of the thrust pins. The upper part of the saw body remained free. "Swing" effect.

The plate was ground.

2. The springs of the thrust pins are long and too stiff, preventing the pins from completely moving into the grooves of the movable plate.

The body arched. "Swing" effect.

The springs were cut and stretched.

3. The tooth pusher was in the form of a cone made of non-hardened material.

It quickly flattened at the end, making divorce difficult.

Replaced with a pusher with a ball at the end.

4. The indicator stop is not parallel to the plane of the band saw, the plane of its end is not trimmed (the indicator readings changed depending on the location of contact).

The end is not hardened - a pothole will appear very quickly, and if hit, it will also result in an inaccurate mark.

The indicator mount has been changed. The end plane is leveled. The pusher tip is ground and hardened.

5. Lower non-adjustable supports for the back of the saw. It is impossible to set the required height of the part of the tooth being set. The divorce turned out not along a broken line, but along a radius. Instability in the cut.

Movable lower supports are made with convenient adjustment.

6. There was no three-tooth pusher with stops for accurate tooth feeding. It is impossible to carry out a divorce in one place on each tooth. Inaccurate divorce.

Manufactured and installed.

And even after we corrected all the manufacturing inaccuracies, only band saws with non-hardened teeth or hardened teeth, but with weak fixation in the body, could be made well on the machine (types of band saws were discussed in previous articles). When setting up other types of saws, a “swing” effect immediately appeared.

Classification of hacksaws

- Canvas length. The comfort of work depends on this value (you make the least amount of reciprocating movements), and the teeth on a long hacksaw do not clog as actively. A generally accepted rule is that a hacksaw blade for wood should be twice as long as the size of the workpiece.

Tooth size. The speed and quality of the cut depends on this parameter. At the same time, the aspects are mutually exclusive. A hacksaw with a small tooth produces a high-quality and clean cut, but the speed is lower and more effort is required. It is quite possible to assemble a wood band saw with your own hands using ready-made drawings. A large tooth cuts faster and easier, but the edges of the cut will be “ragged” and rough. In the parameters, the tooth size is indicated in “TPI”, the number means the number of edges per 1 inch. The higher the value, the finer the teeth

Tooth shape. This parameter determines the direction of the cut (along or across the grain), the type of wood, and the vector of the applied force (from yourself or towards you). Obviously, there are universal canvases. Correct sharpening of the hacksaw is carried out in accordance with the shape of the tooth

Blade steel type. Systematization of the material is a separate topic; we are interested in the processing method. The canvas can be hardened, not hardened or combined. In the latter case, only the teeth are hardened. Why sharpen? How to tell if it's time to sharpen your hand saw for wood. This can be determined by the color of the metal - hardened steel is blacker.

This “disadvantage” is compensated by the slow process of dulling. If you don’t come across a nail or a hard knot, the hardened blade will last a long time. True and the cost is appropriate.

Characteristics

Band saws have three distinctive features. They are made only from special grades of tool steel, which ensures high strength and wear resistance of the teeth. Russian manufacturers usually use steel categories 9ХФ and В2Ф, foreign companies prefer the C75 series. In any case, the hardness of the material must be at least 45 HRS.

The cutting width of a band saw blade is much narrower than that of its circular saw counterparts. As mentioned above, this is a fundamental factor when processing valuable wood and industrial wood.

Saws can easily handle workpieces of any length and diameter. At the same time, a properly sharpened band saw ensures high production productivity.

It should be clarified that the reliability of closed saws is explained by the heterogeneity of the material used to make the blade.

In particular, the body of the sawing tool is usually made of spring steel, which has incredible resistance to tension and dynamic loads. The cutting edge is made from steel grades with a high content of tungsten and cobalt. The individual parts of the fabric are welded together by high-frequency currents. Tools made using this technology can be used for sawing metal.

Sharpening a hacksaw for wood with your own hands

If the annotation for the blade does not indicate clear characteristics, the layout is done according to the general rules: The width of the cutting edge overhang should be 1.5 - 2 times the thickness of the blade. Wider routing is done for damp wood, or in the case of cutting along the grain. If, when processing such wood, the width of the teeth is small, the blade will jam in the cut.

On the contrary, with a wide spread, it will be awkward to process normal wood across the grain. The cut will be uneven, and you will have to put more effort into passing the saw.

Read:

There are convenient tools for setting teeth, with which you can straighten a long blade in a couple of minutes. But such pliers are not cheap.

Related Posts

Sharpening and setting the saw

The main cutting element of any hand saw. a series of teeth cut on the blade and representing cutters in the form of wedges. Wood, in the process of making various products from it, is sawn along, across and at an angle Θ to its fibers; for this reason, transverse, longitudinal sawing and sawing at an angle to its fibers are distinguished, and in this case, a corresponding type of saw is used, which differs from others in shape teeth

When cross-cutting, cross-cut saws are used, the cutting edges of the teeth of which, when moving through the wood, cut its fibers like a knife and form a cut. Longitudinal sawing differs from cross-cutting in that the direction of movement of the saw is parallel to the grain of the wood. The front edges of the teeth of longitudinal saws plan wood, like knives in planes, and, going deeper, form a cut. When sawing wood at an angle Θ to its fibers, universal (mixed) saws with teeth are used, which are the intermediate form of the teeth of transverse and longitudinal saws.

Three ways to separate the teeth of a hacksaw with your own hands.

How to properly dilute

and

sharpen a hacksaw with your own hands Playlists: Fishing.

Most home craftsmen use classic adjustable plates the old fashioned way, with manual adjustment and stop.

The blade is clamped in a vice, or pressed against the workbench using a long block and clamps. The teeth are aligned one at a time, first one side, then the other.

Then you need to level the height of the cutting edges. To do this, place a sheet of paper on a soft, even board, and vertically press the blade against it (with the cutting part). The imprint will show which teeth have different heights.

Sharpening a hacksaw on wood with your own hands video from the master handyMEN

It is advisable to adjust the size to one level, otherwise you will have to put more effort when cutting. Obviously, if one or two teeth are more sharply ground, it is unreasonable to align the others to this height. If most of the incisors are discordant, you need to greatly equalize their sizes.

After leveling, you can start sharpening the hacksaw on wood. The easiest to maintain is a hacksaw with a large tooth. For sharpening, you can use a ratfile with a small notch and an ordinary vice.

How to properly sharpen a hacksaw with a file

The instrument is held relative to the tooth at an angle of 60°-75°. First, even incisors are traversed so as not to change the position of the hand. Then the blade is rotated 180°, and the procedure is repeated for odd teeth. Since time immemorial, large saws for cutting firewood have been sharpened this way. True masters did this “by eye” with the highest quality.

A saw for preliminary work can be sharpened using this method. But tools for carpentry and carpentry require greater care. Not everyone can afford to purchase a machine for sharpening hacksaws. If you have small-sized emery, you can make a homemade bed that will work no worse than the factory one.

You can sharpen a hacksaw using a grinder. The power tool is fixed at a certain angle to the workbench. The hacksaw moves manually along guides so that each tooth is brought to the sanding disc in the same plane. A sharpening depth limiter is installed.

Read:

The principle is the same as for manual sharpening. First, the even teeth are passed, then the blade is unrolled and the odd row is processed.

Such machines are useful when you regularly dull the tool while performing large construction projects or repairing wooden products. If the question “how to sharpen a saw ” arises once or twice a year, use a simpler device. There are various file or needle file guides available for sale that allow you to hold it at a given angle.

This device is especially useful for sharpening compact blades, when an error of a couple of degrees leads to damage to the tool. If you want to save even more, you can make the guide yourself.

The general principle is shown in the figure.

The blade is fixed at a certain angle, a stopper is installed for the file or needle file parallel to the workbench, and alternately 2-3 passes are made for each tooth. Then turn the canvas (without changing the angle of the guide), and pass the second side. The advantage of such devices is that they can be used to set and sharpen teeth.

Again, such devices are suitable for simple hacksaws, with a traditional cutter shape.