Circular saws, which produce sawing with circular saws, are one of the most common in sawmilling. Circular saws carry out longitudinal and transverse sawing of logs, beams, boards and slabs.

In general, the design of such machines is simple, and the acting inertial forces in them are completely balanced. The machines provide high-quality processing of wood surfaces at high feed rates.

In a simplified form, the design of a circular saw can be represented as one or more shafts with circular saws attached to them. Technological requirements determine the location of circular saws relative to the material being cut and the required number of saws. The saws can be located on several shafts in height and in the feed direction.

According to their technological purpose, sawmill circular saws are designed for longitudinal or transverse sawing. Longitudinal sawing is required for cutting logs, beams, slabs, thick and wide boards to length. On cross-cutting machines, boards with flaws and defects are cut, boards and slabs are trimmed.

Types of machines

An electric stationary circular saw is a fairly large-sized sawing unit with significant productivity and power coefficients. They are usually used in medium and large industries and factories for auxiliary operations. And in a home workshop and small production workshop, such equipment can also be useful as the main woodworking machine. The high speed of rotation of the saw shaft of these machines is ensured by a fairly powerful motor, which makes it possible to cut even hard material without overload.

A tabletop circular saw, like many woodworking machines for the home, can be installed on a workbench, and then, without any difficulties or associated problems, dismantled for use in another place or for storage. Typically, the weight of this equipment does not exceed 25 kilograms, which confirms its mobility.

Stationary household circular saw Bosch PTS 10

Both stationary and desktop versions include household and professional grade equipment. The differences between professional machines, in addition to cost, usually lie in their higher quality performance, and accordingly they have a longer working life, the presence of some additional accessories, and so on.

There are also multi-blade circular saws. They are usually used when it is necessary to longitudinally saw 2-edged and 3-edged beams with circular saws into edged boards and 4-edged beams. On multi-saw circular machines, you can make workpieces of different sizes by pre-setting the position of the saws. An important advantage of multi-rip circular saws is the fairly high cutting accuracy. This was achieved thanks to a significant increase in the strength of this equipment.

Stationary equipment

Stationary circular saws are quite large. They are suitable for use by industrial companies performing impressive volumes of lumber processing. The engine has great power. The cast iron bed lasts a long time because its strength is above average. It is permissible to process hard wood when it is necessary to cut with a depth of 70–125 mm.

Equipment for the production of lumber

Designs on an extended bed represent a middle-class category, complemented by a convenient stand - a practical extension table on which a plane can be placed very easily. Such a unit is distinguished by significant power when compared with household analogues, and the cutting depth reaches 80–90 mm, that is, workers can easily saw workpieces of impressive sizes.

It is better not to buy the offered equipment on the markets. It must be guaranteed to be safe. It makes sense to look for professional stores that offer long-lasting models that will last for several years with intensive use.

Purpose of circular saws

A circular saw for wood is equipment that is used for transverse, longitudinal sawing of wood, as well as for its oblique sawing. In addition, if you have special discs, it is possible to work with other materials - plastic, aluminum profile, etc.

This equipment is best suited for cutting boards to size, making edges at 90º angles to each other, chamfering at different angles and creating almost all types of material joints.

Design Features

A sawing machine for wood, in principle, is a rather simple tool in its design, but it is still a high-precision tool, which is also a source of increased danger, so for its correct and safe operation it is necessary to have a good understanding of the design features of this unit.

So, there are four main types of circular saws:

- Manual portable cutting machines,

- Tabletop mini-circulars,

- Medium-sized circular saws with folding or removable stand,

- Large industrial stationary circular saw machines.

Manual portable cutting machines are not stationary equipment intended for use directly in the hands of a craftsman for cutting small boards, mainly on construction sites. This device weighs little and is quite compact and convenient equipment.

Tabletop mini-circular saws are also quite mobile equipment, since they do not have a heavy frame. Such a machine is installed on the top of a table or a homemade workbench, and after use it can be hidden in a pantry or utility room. These types of circulars are only suitable for amateur and household use due to their limited functionality.

A medium-sized circular table with a removable or folding stand, in most cases, is also equipped with prefabricated legs. This model is very compact and transportable and at the same time has greater capabilities than the previous type of machines.

Large stationary circular saws are used exclusively in large and medium-sized enterprises. For obvious reasons, such machines are absolutely not transportable and have all the functions necessary for professional use.

It is also important to note the fact that circular saws differ in the principle of saw blade arrangement:

- Vertical saw - a circular saw in which the working circle is located perpendicular to the working surface of the machine,

- Horizontal circular saws are equipped with a disk located parallel to the working surface,

- Coal sawing machines are equipped with two circles, which are installed at right angles to each other.

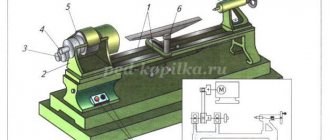

In any case, regardless of the type of circular, its design is based on a standard arrangement of elements. It consists of a frame on which a work table with a narrow oblong slot is mounted, through which part of the working cutting disk protrudes.

Depending on the configuration, the circular saw can be equipped with control and adjustment levers for the working elements of the machine, additional guides and stops, as well as measuring rulers, protection covers and other design elements designed to facilitate work and ensure safety standards.

bed

The bed is the basis of such a unit; its main task is to provide an even, stable and rigid support for the operation of the equipment. Depending on the type of machine, it is designed on one of three main types of bed:

- Cast - used for the manufacture of heavy industrial machines. It is made by casting metal from cast iron or heavy steel. Such a stand is practically non-transportable, heavy and bulky, therefore it is absolutely unsuitable not only for amateur use, but is also unsuitable even for small and medium-sized enterprises. This type of frame is installed on a very durable coating made of concrete and iron.

- Welded - made of thick-walled sheet steel. The weight of such a base is significantly less than the weight of a cast one, it is more mobile and is used to create equipment, mainly of the middle class, intended for medium and small-sized enterprises and workshops. It is not necessary to install the machine on such a frame on reinforced concrete; the base, however, must be quite strong and stable.

- Prefabricated structure made of metal profiles. This type of base is used in the manufacture of amateur equipment. It weighs little, and often even comes in a collapsible type. A machine built on the basis of such a frame can be placed in any type of room and on any surface. Mainly used on circular saws used in small home mini-workshops.

It is also important to note the fact that, regardless of the type of bed, in particular, and the circular machine, the most convenient to use is equipment with a sufficiently large working surface area, or the ability, if necessary, to expand it.

Working surface

The worktop tabletop is in most cases made of metal. It can be polished cast iron, steel or aluminum. Often, such a surface is supplemented with auxiliary guides and measuring equipment, which facilitate the work and increase its accuracy and quality.

In most cases, the part of the working surface directly with the working slot for the saw is a removable block, which is necessary for access to the saw for its adjustment, cleaning and maintenance.

The slot itself should be small in size to prevent excessive clogging of the saw and shaft with sawdust and dirt. If this condition is not met, and too much sawdust gets inside, it makes sense to make a homemade removable part from wood or plastic, and make the slot with the saw itself during the installation process. It is important to be extremely attentive and careful.

Disk

Depending on the type of circular saw and the type of lumber being processed, circular saw wheels of various diameters and with different tooth configurations can be used.

The diameter of such a circle can vary from 140 to 300 mm. On professional equipment, circles with a size of 250 mm or more are mainly used, and for amateur use, smaller circles are used. The main factor that determines the size of the wheel is the maximum depth of cut of the material being processed; it also depends on the height of the protrusion of the wheel above the working surface. In most cases, the height of the disc protrusion is no more than 1/3 of the diameter of the disc itself.

Most models on the circular saw market provide the ability to tilt the blade at an angle of up to 45 degrees. But in this case, you need to be extremely careful, since in some models this requires lowering the wheel to a certain level, or even removing the removable part of the worktop, so you should first read the operating instructions for such a machine.

To increase the service life of the saw blade and perform a higher-quality cut, you need to adjust the disk so that its teeth protrude above the lumber during operation at an average level of 7-9 mm.

Protective equipment

As already mentioned, a circular saw is not only useful equipment, but also very dangerous. It is for this reason that almost all models of such devices are equipped with a special protective casing. This detail is designed to prevent dangerous contact of the material being processed with parts of the body of the master working with it. The casing is mounted on a special bracket, which allows you to adjust the height of its landing, or remove the casing altogether if necessary.

Safety riving knife

In some cases, the material being processed has hidden invisible defects and differences in the strength of the layers. This may be a consequence of the natural characteristics of the wood or a violation of the technology of its drying and storage.

In such cases, the board being sawed can split and jam the disk rotating at fairly high speeds, as a result of which a very sharp ejection of material can occur directly onto the master. To prevent this from happening, manufacturers have included a special wedging element in the design of the circular saw, which is installed directly behind the disk and does not allow sawn parts of wood to connect.

Rip fence

Wood circular saws are used to cut wood at different angles and in different directions. Therefore, they are also suitable for longitudinal dissection of logs into boards or beams, as well as for cutting various wood boards such as chipboard or OSB into long strips.

In order for longitudinal cutting to be smooth and accurate, the manufacturers of such machines have included in their design such a device as a stop for longitudinal cutting.

The stop must be securely and stably attached to the working part of the machine at at least two points, and not bend or bend during operation. The design of this device should include the ability to adjust the distance from the working disk to the stop; ideally, a sheet of chipboard or other similar material should be placed between them.

Stop for cutting at an angle

This device is located perpendicular to the saw blade, with the ability to adjust it at different angles ranging from 90 to 45 degrees. For ease of regulation, a special graduated scale should be provided.

With the help of such an element it is possible to accurately determine and adjust the angle of the transverse cut of lumber. The emphasis must also be stable and reliable and attached in several places.

Powerplant and drive

As with any other power tool, one of the factors determining the functionality is the power of the machine’s power unit. After all, to work with large-sized lumber and sawing hardwood, you need a fairly powerful engine and a reliable drive.

In most cases, circular machines are equipped with fairly powerful motors ranging from 1200 to 3000 W. For the manufacture of low-power circular saws, electric motors with a power of 1200 - 1500 W are used, and for middle-class machines and large industrial saws I use motors of 1500 W and higher.

The power plant and drive of an electric circular saw consists of an electric motor, a shaft on which the saw blade is mounted, and a drive connecting these two components. For low-power hand-held cutting saws, a gearbox with a gear drive is used.

Technical characteristics of circular saws

Main technical characteristics that you should pay attention to when choosing a circular woodworking machine:

- power;

- depth of cut;

- spindle rotation speed;

- desktop size;

- bed (steel, cast iron, stamped sheet);

- saw tilt, (90º, 45º);

- voltage (220 V, 380 V).

Now let's look at some of them separately.

The greater the power, the greater the amount of work that can be performed on a circular saw; this also allows you not to reduce the speed when sawing, install disks of increased diameter, if the design of the equipment allows them, and in addition, the working life of the product increases.

The depth of cut affects the size of the workpiece and miter cuts.

The number of rotations of the spindle - the higher, the higher the quality and cutting speed of the sawing machine.

The size of the workpiece that can be processed depends on the size of the work table.

An important characteristic of circular machines is the material of the machine bed. More powerful, heavier and professional models usually use a closed steel tabletop, which improves dust collection and reduces noise from the saw blade and electric motor. Lightweight circular saws are often equipped with cast iron frames. The weighted design reduces vibration and keeps settings accurate longer than those with stamped steel fenders.

Voltage. Electric motors over 2 hp Usually they use three phases of 380 V power supply; less powerful ones most often make do with single-phase 220 V power supply. Therefore, before choosing equipment, you need to clarify how many phases you have at the connection point of this machine.

Safety precautions for those working with a circular saw

Before you start using the mini-version of circular equipment, you will need:

- check whether the starting toggle switch of the circular device, casings, and electrical wiring are in good condition;

- Make sure that the saw teeth are in proper condition and check their alignment.

- examine the condition of the tool: are there any cracks, damage, or chips on the surface; if at least one tooth is missing, the cutting element is thrown away;

- choose a shaft that will not hit, but should move towards the workpiece being processed.

At the stage of working with the tool you need:

- deliver raw materials to the sawing equipment after the cutting element has reached speed, this can be understood by a special sound;

- it is necessary to feed the material slowly and smoothly, avoiding bumps and jerks;

- move the workpiece along the work surface only using hooks, and it is forbidden to grasp the end with your hands;

- check in time whether the chips have been removed from the gap, wait until the disk completely stops rotating, use special devices.

- as soon as the trimming is completed, remove your foot from the pedal;

- remove remaining waste from the work surface using equipment designed specifically for this (hooks);

- All kinds of service activities are allowed only when the working disk is stationary.

Safety instructions

Not allowed:

- make attempts to stop the saw blade by pressing something on it;

- be within the standard workpiece ejection;

- make attempts to remove chips from behind the guard of the cutting element while it is still moving;

- work simultaneously on several workpieces without using a clamp;

- be opposite the end of the bar if it moves in the device;

- try to process lumber in an icy state;

- remove protective covers or attempt to open them.

By purchasing equipment from professionals, you are guaranteed to work in safe conditions. You shouldn’t take risks if you come across an option on the market at a lower price. These savings can be deceptive. Real circular saws last a long time, are easy to use and do not pose a health hazard.

Benefits of contacting us

- We design and manufacture machines ourselves. We control quality at all stages of production: from project development to installation and commissioning. We carry out modernization at the request of the client.

- We offer affordable prices. The cost of equipment from the Tyumen Machine Tool Plant is 3-4 times more profitable than foreign analogues.

- We guarantee quality. We use 100 years of experience in our company and provide a 1-year guarantee on all products.

- We will arrange delivery. We deliver throughout Tyumen and the region using our own transport; we organize transportation to other regions of Russia with the help of transport companies. We select the appropriate transport and calculate the shortest route.

- We provide related services. We sell spare parts, provide service and repair not only for our machines, but also for installations from other manufacturers.

Manufacturers rating

The choice of circular saw is determined by a number of factors:

- volume and nature of the proposed work;

- the possibilities of the room in which the unit is supposed to be installed;

- requirements for noise levels, mobility and electrical safety;

- product price.

The most popular manufacturers of such equipment are well-known, reputable companies: Bosch (Germany), Makita (Japan), Metabo (Germany), Hitachi (Japan), Interskol (Russia), JET (Switzerland).

Reviews for the equipment of these manufacturers are not always unequivocally enthusiastic, which is natural: people have many preferences and the ideal product is unlikely to ever be created, however, it is these five that currently lead in the number of positive statements from both specialists and buyers, using their products in the household.

- Japanese models are distinguished by the highest quality of assembly, including moving structural elements, the presence of additional functions that prolong the operation of the saw (soft start), and high safety requirements. The highest performance and ease of settings are a distinctive feature of equipment produced under Japanese brands. However, the use in some models of even high-strength plastics for the manufacture of moving transmission elements on the saw shaft may not work in their favor.

- German models, as a rule, have greater power, however, the widespread use of plastic for the manufacture of the machine body often causes distrust among buyers. These products are also distinguished by the highest quality settings.

- Russian products are distinguished by high reliability, widespread use of tool steel, however, power often suffers - in this indicator our saws are often inferior to Japanese and European brands. There is also no slow start function, which can cause failure of individual components or the electric motor. The price of Russian models is significantly lower than their foreign analogues; It is also necessary to take into account the maintainability of domestic saws.