Confirmation that the craftsmen manage to make a unique, practical and beautiful product is a knife from a chainsaw or motorcycle chain. The product really amazes with its uniqueness and pattern similar to Damascus steel. The practical use of a chain knife is possible in any conditions.

Homemade knife from a chain.

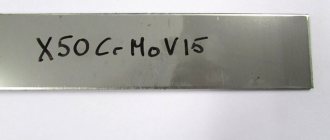

Selecting material for forging a knife

In machines and devices for various purposes, chains are used to transmit mechanical forces to related units. She bears a lot of physical stress. which a chain made of durable alloys can withstand.

A blade made of this metal will amaze not only with the beauty of its design, but also with its practicality.

The manufacturing process is not easy, you need to be patient. Metal forging experience is also required. Bicycle or car chains have different metal compositions. Depends on the load experienced by the “donor” used.

Professional knife makers advise using a high-alloy plate between two chain plates. A kind of “sandwich” is welded by forge welding, and a package of metals will result in excellent cutting qualities and the aesthetic appeal of the product.

Trick: welding a cutting edge made of knife steel to a chain blank will upset the blacksmith in the final form and reliability of the blade. The package option is definitely preferable. This will be discussed in this article.

Instructions for making a knife from a chain

In the package version of making a knife from a chain, the product is suitable for various mechanisms: a motorcycle, a car, a bicycle or a chainsaw.

Materials and tools

Having decided on the manufacturing method, you need to prepare the tools and materials:

- an anvil, two hammers - large and small;

- oven or forge;

- vices, angle grinders with discs for various purposes;

Knife from a chain.

tetraboric acid (borax);- Hydraulic Press;

- grinding machine;

- welding machine, steel chain;

- high carbon steel plate;

- motor oil and a container of water;

- drill, wooden block, epoxy glue;

- masking tape, sandpaper of different grains;

- Handle impregnation made from natural oils.

Tools and materials are professional in nature. From the very beginning it was stated that this was a job for experienced craftsmen. Beginners should not try this material. You need to start experimenting with simple preparations.

Forging blanks

A distinctive feature of the batch forging process is the work with several metal plates. Having everything you need, you need to start the initial forging of the blade:

- Using a cutting wheel on an angle grinder, cut the chain into several pieces of equal length. Having folded them into a single form, using welding, we “grab” them to obtain a solid workpiece.

- A rod is welded to the resulting rectangle for ease of holding. Having warmed up the oven, place the workpiece in it and heat it to 1100-1200 °C.

- Once the metal has reached a bright red hue, remove it and sprinkle it generously with borax. This will allow you to more reliably fasten the pieces of the chain together and get rid of voids in the links. Place in the oven for further heating.

- We take it out again, sprinkle it with borax and quickly move to the press. With its help, we gradually compress the workpiece from all sides. We monitor the temperature; when the part has cooled down, go back into the oven. The process performed by the press will help get rid of voids in the workpiece and forge weld it into a monolith.

- After making sure that the welding is sufficient, use a large hammer to flatten the workpiece into one plate. Cool the product in air, cut off the rod using an angle grinder. And with the same tool we halve the plate.

- Between the resulting halves we lay carbon steel, sprinkling the layers with brown. We carefully “grab” it with welding and return the rod to its place. Place in the oven and heat until bright red. Having taken out the plates, we forge them with a large hammer. The plates must be welded together using the forging method.

Knives from a chainsaw chain.

Then we forge the workpiece like ordinary knife steel. This method will provide excellent cutting properties of the blade.

Damascus steel uses a multi-layer forging method, thanks to which unique patterns are formed on the blade. In the described case, they will appear due to the structure of the chain.

Blade Shaping

Thanks to forge welding, the resulting package must be forged like ordinary knife steel. We heat the workpiece, forge the slopes and rise of the blade to the nose.

The inner plate will come out into the cutting edge, which is what was required. The final stages are:

- After the workpiece has cooled, the rod should be cut off. Holding it in a vice, use a grinder to mark and cut out the shank. The part is ready for processing on the grinding machine. We bring bevels along the entire length of the blade to the finishing stage - the article will help: “how to make bevels on a knife.”

- Using a grinding machine, you should go over the entire surface of the product - removing carbon deposits. It is necessary to make a cutting edge and pre-sharpen the knife.

- The process of hardening the product is required. Professionals advise doing it in oil and water. Having heated the blade to 800-900 °C, it is completely immersed in oil for 2-3 seconds, removed and dipped in water for a couple of seconds. The product will acquire the necessary hardness and will be able to withstand heavy loads.

- The blade requires tempering in an oven at a temperature of 200 °C for 2 hours. Let it cool naturally. At the end of the process, you need to go over the entire blade with fine sandpaper.

- We draw the cutting edge depending on the further purpose of the blade. And we sharpen it, a useful article on the topic: “how to properly sharpen knives on a machine.” To develop a chain pattern, it is necessary to etch the knife in a 5% ferric chloride solution for 20 minutes.

If we make a wooden handle

All that remains is to mount the handle. The article: “how to make a handle for a knife” will come in handy. In this case, the choice fell on the mounted type:

- A hole is drilled in a wooden block in accordance with the shank.

- Wrap the blade with masking tape for safety.

You can easily do without a wooden handle.

Epoxy glue is mixed, poured into the hole made, and the blade is inserted with its tail.- We leave the product to dry for a day.

- Then we process the handle on a grinding machine to the desired shape,

- We saturate it with special oils.

- Polishing the handle.

Finishing

We polish the blade until it shines. The knife from the chain is ready.

Original knives made from unexpected objects

Famous knife manufacturers are actively trying to convince us that a good and original knife can only be made from high-quality steel, equipped with secret additives. This immediately gives +50 points of corrosion resistance, +100 points of strength and + 500 points of pathos and show-off. Well, that because of this the price rises to mind-boggling heights - that’s true, details. Collectors will buy in any case, otherwise what kind of collectors are they?

Just don’t forget that a knife is first and foremost a tool. Our ancestors made them from some kind of crap iron, if not cast iron, but this did not stop them from actively using such knives. Go to any cultural museum and you will see knives with obvious signs of wear. Because you need to work with knives, and not give a damn about the quality of steel and exquisite design, which will come in handy throughout your life.

Seriously, knives can be made from any steel, even from one that has already been used. Some blacksmiths manage to forge things into quite original knives that initially have nothing to do with the concept of “weapon” and “knife”. And we will now show you the results of their creativity.

The content of the article

Knives forged from motorcycle and bicycle chains

These knives look especially beautiful, but due to the structure of the metal, they are not very reliable and durable. But they still cope with their tasks perfectly.

Original knives made of steel cables

Knives made from steel cables are somewhat visually reminiscent of the famous Damascus steel, but not as strong, of course. On the other hand, due to the orientation of the steel fibers, the strength is generally higher than what would be expected from ordinary steel.

Knives made from wrenches

Reforging an old wrench into an original knife is a great idea. Still, normal tool steel is a guarantee of strength and durability.

This knife was reforged from a universal wrench (the photo shows this same wrench for comparison). The knife retains the texture of damask steel, which is poorly visible in the photograph.

And this old Soviet key, apparently, could not stand the hard work, as a result of which one of the heads broke off, which was then reforged into a cutter.

A knife reforged from a classic gas key. As you can see, the author even preserved the thread and nut.

A wide variety of wrenches—socket wrenches, socket wrenches, open-end wrenches—can also become a “base” for creating a variety of knives.

And here the master made an incredibly stylish straight razor from a dialed spanner.

Knives from connecting rods from the engine

Well, everything is quite simple here - a connecting rod is taken from the crank mechanism of an internal combustion engine, and... But it is also quite reliable.

File knives

Knives made from files look really cool, but the blade blade has its pros and cons - it’s better to find out in advance. Overall, very durable, sharp and beautiful.

And for a “snack” - a knife forged from a bayonet from a Mosin rifle.