Guillotine shears are a metal-cutting machine that uses the combined action of a sharp blade and high mechanical pressure in its work. Guillotine knives are driven by hydraulic cylinders or mechanical levers, depending on the type of shear.

Guillotines are used mainly for longitudinal and transverse cutting of sheet metal, the thickness of which can reach 60 mm. Many models of industrial metal shears can cut both foil and sheets 0.2 mm thick, as well as reinforcement and shaped steel. The industry produces more than 100 standard sizes of knives for various types of guillotine machines.

Guillotine knives.

| We supply knives for guillotine shears of domestic and foreign production. Knives are produced according to the Customer's drawings or according to GOST 25306-82. Knives are made of steel 6ХВ2С, 6ХС. Tolerances for geometric dimensions in accordance with GOST 25306-82 ensure complete interchangeability of guillotine knives without additional adjustment and grinding. |

Guillotine knives, models and sizes.

Model

| Model

|

If you don't find what you need? Call us at 8 (812) 424-18-16. Or send a request.

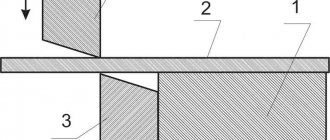

Guillotine shears are designed for cutting sheet material. Transverse cutting of a sheet, the thickness and width of which corresponds to the technical characteristics of the guillotine, is carried out in one stroke of the guillotine knife, longitudinal cutting - by a series of repeated cuts when moving the sheet along the cutting line. Cutting with sheet metal scissors can be done according to the markings, or without it - using the back stop. An important criterion for proper operation is adjusting the gap between the guillotine knives. The gap should be 1/15 - 1/30. It should be remembered that the accuracy and reliability of the scissors depends on the quality of sharpening and grinding of the guillotine knives.

Maintenance of guillotine knives

Maintenance of metal-cutting tools involves monitoring their condition and timely sharpening. Double-sided guillotine knives are sharpened on both sides and when one becomes dull, they are turned over to the other.

When working with polymer materials, knives require additional maintenance. This is due to the fact that in the process of cutting plastic products, the substance sticks to the working surface of the knife, as a result of which the quality of processing decreases and there is a need to frequently stop the production line to clean the elements.

To solve this problem, MODENGY 1007 anti-adhesive coating is applied to the surface of guillotine knives for cutting polymer products (excluding the cutting edge).

It forms a stable, smooth layer that facilitates the sliding of the cutting tool and prevents polymer material from sticking to it.

The product is also suitable for protecting guillotine knives operating at high temperatures. Thanks to the use of MODENGY 1007, long-term uninterrupted operation of equipment is ensured without the need to update the coating.

Knives for press shears.

| We produce knives for combined (varietal) press shears, shears for cutting scrap metal, flat knives for edge crushers, crushers, production lines for recycling rubber waste and tires . Knives are produced according to the Customer's drawings or manufacturer's specifications. Knives are made from forgings of steel 6ХВ2С (manufacturer's certificate is issued). |

Knives for combination scissors, models and sizes:

Scissors model

| Scissors model

|

If you don't find what you need? Call us at 8 (812) 424-18-16. Or send a request.

Applicability of various steel grades for guillotine knives.

High-alloy steels 6ХВ2С, Х12МФ, 45NiGrMo16 are used for cutting metal using various guillotine, section and rebar shears.

Steel 6ХВ2С, having high wear resistance and increased toughness, is used in the manufacture of knives for cutting metal on any shears with a mechanical, hydraulic and pneumatic drive. Knives for guillotines and knives for press shears made from steel 6ХВ2С are used for cutting metal of ordinary steel grades with a thickness of 1 to 32 mm.

X12MF steel is characterized by high wear resistance and is used in the production of knives for cutting thin sheet metal (up to 3 mm) using mechanical and hydraulic shears. X12MF steel is perfect for cutting electrical and stainless steels.

German grade steel 45NiCrMo16 , specially designed for cutting knives, has a set of unique properties:

- high wear resistance, like X12MF steel,

— excellent viscosity, exceeding the viscosity of steel 6ХВ2С,

– excellent hardenability (up to 500 mm),

- wide temperature range from minus 30 to plus 400 degrees Celsius.

All these properties make 45NiCrMo16 steel a universal material for making knives for cutting ANY metals. The steel has proven itself to be excellent for cutting high-strength metals (with a tensile strength of up to 1000 N/mm2), reinforcement, scrap metal and stainless steels.

Our company offers to purchase guillotine knives and press shear knives made from the above steels. Passports are issued for knives. The cost and production time of specific batches of knives can be found out by calling or sending an email.

Source

Knives for reinforcement machines.

| We produce knives for chopping and cutting reinforcement to the machines SMZH-172, SMZH-172A, SMZH-172BMA, SMZH-175, SMZH-172BA. We produce knives of different types and sizes - any shape, width according to the drawings and technical specifications of the Customer. The steel used in production is 6ХВ2С, 6ХС, with a hardness of 54…58 HRCе. | ||

Main dimensions:60x60x20, 110x40x18, 110x50x42.5, 110x110x24, 110x60x15, 110x40x24, 110x60x42, 110x110x13, 110x40x13, 160x50x42.5, etc. | Fitted with a bolt with M10, M12 thread, without thread with a 12 mm hole, countersunk under the head. | |

Electrohydraulic sheet benders: purpose and modifications

offers industrial and large construction companies to purchase a professional sheet bending machine with a hydraulic drive.

When performing work on bending sheet metal, the possibilities of hydraulics are maximum. Equipment of this class is capable of bending […] read more

Production process technology

Knives for crushers.

| Knives for crushers rotary, hammer and agglomeration types of production for domestic and imported equipment are manufactured in accordance with GOST and meet all the requirements of technical regulations. We produce both standard and non-standard knives for crushers. | |||||||||||||||||

We offer the following types of standard knives:

| We produce knives according to the Customer's drawings: Crushing knives for PET rotary crushers (plastic shredders) and polymer recycling machines. Knives for crushers are used in the processing of non-metallic materials - for crushing cardboard, paper, wood, and plastics. Crushing knives for shredder. Shredder knives and crown knives are used for grinding and processing large waste thermoplastics: films, pipes. Crushing knives for agglomerator. Agglomeration knives are designed for crushing PET bottles, thin-walled polymer packaging, and for recycling film waste. | ||||||||||||||||

Disc knives.

| Disc knives and round knives are used for cutting metal, paper, polyethylene, fabric, and gauze. We supply all major standard products. Circular knives have an increased service life, thanks to the high-quality materials used in their manufacture. |

Main standard sizes of manufactured knives:

|

|

Service

Constant contact with hard materials, and especially metal, inevitably leads to the gradual dulling of knives during operation. Even knives made of high-hardness steel have limited service life. To restore the cutting properties of guillotine knives, they must be sharpened promptly and regularly. This work should be entrusted to professionals who have the necessary equipment and knowledge. Sharpening and grinding knives on special machines allows you to completely restore the performance characteristics of the tools, the main thing is not to violate the original sharpening angle provided by the manufacturer, because this can directly affect the efficiency of the cut and the service life of the product.