When you need to lift or move something very heavy and bulky from one place to another, and even alone, you can’t do without an auxiliary device.

In certain cases, a manual mechanical or electric winch can come to the rescue. But we recommend making a mini faucet with your own hands.

It can be used for a variety of tasks: to lift a car engine or to move some large piece of driftwood to a suitable place.

The design is suitable for garages and construction sites, and is also suitable for simply lifting heavy objects. Let's consider a homemade mini crane in 3 versions, with different lifting drives.

Assembling a goose tap with your own hands is not at all difficult. All the necessary drawings with dimensions can be easily found on the Internet.

The main thing to remember is that the garage crane must be reliable (made of metal), stable and have sufficient load capacity.

Structurally, a homemade crane consists of three main elements:

- a support (usually with wheels so that you can move it freely around the garage);

- vertical stand with a drive mechanism (jack, mechanical or electric winch, etc.);

- retractable telescopic boom.

Below you can see three different lift options.

What characteristics should a garage lift have?

Since the device will be used in the rather cramped conditions of a standard garage, certain requirements are put forward for it.

Firstly, it should not be too large - such a car lift, despite its high power, takes up a lot of space, which is very undesirable in such a small area. Secondly, it is recommended to give preference to mechanisms with a small vertical stroke, otherwise you risk running into the ceiling. The second requirement is carrying capacity. It is calculated based on the types of work for which the car lift is being developed. The dimensions of the mechanism also depend on the purpose. If a regular jack is suitable for regular wheel replacement, then for larger-scale work you will need a car lift with a platform, although for such important actions it is recommended to resort to the help of professional equipment.

Crane beam assembly

- the device supports are attached to the wall or ceiling;

- a carriage is installed on the prepared working beam;

- if the actuator is mounted on a support platform, then it is installed on the lift body;

- the assembled work beam is lifted and placed on supports;

- check smooth operation and adjust operating parameters.

Article on the topic: At what temperature can you paint a garage?

In the case of attaching the lifting mechanism to the support platform, the assembly is complete.

An assembled crane beam with a lift, which is fixed with a fastening hook by the lower bolt.

Making a simple lifting device yourself in your garage is not that difficult. It is necessary to carry out the calculations correctly and boldly get to work. At the same time, you need to remember about safety precautions - any lifting device is potentially dangerous. For example, according to the existing requirements of Rostechnadzor, the presence of more than 30% broken threads in a steel rope (cable) makes such a cable unsuitable for further use.

DIY crane assembly technology

If you have certain skills, assembling the mechanism yourself will not be difficult.

To do this, it is important to draw up a preliminary design drawing, choose materials wisely and strictly follow the assembly instructions

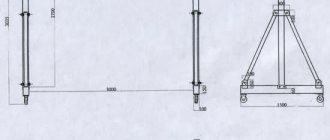

Schemes and drawings

Below are sample drawings of a hydraulic crane. You need to make accurate calculations yourself, based on the parameters of a particular garage.

Material selection

To build a garage lift yourself, it is recommended to first purchase all the required materials:

- 3 steel corners with parameters 7.5x7.5x0.8 centimeters.

- “Worm” gearbox, the minimum load capacity of which starts from 300 kilograms, and the additional indicator is 60 kilograms.

- A strong steel plate one centimeter thick. If you have an old metal cutting machine, you can take it from it; you won’t need outside help for this.

- About 10 matching bolts.

- 2 dense metal chains with a diameter of two to three centimeters. The crane is designed to work with very heavy materials - you should carefully monitor the quality of the metal.

- Hook.

- Steel cable with a diameter of 5 millimeters.

- 2 keys with different parameters in the shape of an asterisk.

Step-by-step construction instructions

The process of assembling and installing a homemade garage crane does not look complicated:

- steel corners must be installed on parallel walls;

- fasten the steel plate to them using M8 bolts;

- fix the “worm” gearbox on the plate;

- install a larger key on the drive shaft;

- drill a hole in a pre-designated place, insert a chain into it and close it into a ring;

- fix a smaller key on the output shaft of the gearbox;

- drill 2 more holes in the plate;

- pass the second chain through the holes, where one end is on a small key, and a hook is installed on the second.

Installing a faucet yourself has a number of important advantages. For example, the cost of a homemade mechanism is almost two times lower than a purchased one.

Do-it-yourself crane beam in the garage: manufacturing advice

To make a beam crane yourself, you need to have some plumbing and welding skills. Only a garage with sufficient area is suitable for the location of the finished crane. To get started, you must first purchase a pipe with a rectangular cross-section, a metal corner, a metal C-profile and sliding wheels.

When installing posts and rails, it should be taken into account that the walls of the garage most often are not even.

The frame is welded from a corner along the entire width of the building. Particular attention should be paid to ensuring that all ribs are located strictly parallel and perpendicular. To make the trolley, a pipe with a rectangular cross-section is used. The frame must be placed on wheels, which must coincide with the ribs of the frame.

Making Tips:

- It is better to attach the rollers to a strip welded overlapping where the rods are connected to the supports.

- To make the crane movable, rollers are welded to the racks, which can be taken from containers used in warehouses.

- To manufacture the lifting mechanism, a manual worm winch equipped with a steel cable is used.

If there is no winch, it can be replaced with a hoist. But in this case, for the manufacture of the rod it is necessary to use a double tee. A crane beam, manufactured taking into account all the rules, will allow you to easily remove the engine and lift the car body.

Installation of lifting mechanism

The main element of the crane is the lifting mechanism, which can be manual or automatic. The tefler consists of a cable and a winch installed on the side of the rack. The cable moves due to the rotation of the rollers. Additional fixation of the elements is not required; it is enough to secure the lift to the rack.

A self-made crane can be equipped with lifting equipment that is used in elevators. Such mechanisms are highly reliable and able to withstand massive objects.

To simplify repair work, it is possible to connect an electric drive to the lifting element. To automate the design, a motor with a power of 300-500 W is suitable. The electric drive is mounted to the base of the crane beam.

The design, equipped with an electric drive, is widely used in large-scale garage repairs and car disassembly for spare parts when a complex of work is required. According to the principle of operation, manual and automated cranes do not have significant differences.

Experienced car owners say that a crane beam is rarely needed in the garage, but if it is needed, there is nothing to replace it with. It is used for removing and installing the engine, and less often for moving other loads. Purchased mechanisms are expensive and take up a lot of space, so the best solution for a private craftsman is a do-it-yourself beam crane made from scrap materials.

In order to make a garage lift with your own hands, you will need:

- For racks - pipe with a cross-section of 100x100, length 2350 mm - 2 pcs.

- For the cross rod - a round pipe with a diameter of 100 mm and a length of 4150 mm.

- For supports – round pipe with a diameter of 110 mm and a length of 600 mm – 2 pcs.

- For bases and diagonal supports - corner 100x100 mm.

- M 16 bolts for attaching supports to rods.

- Wheels (for example, from a warehouse cart) – 4 pcs.

- Manual winch with a lifting capacity of up to 1 ton.

- Cable and rollers (for example, from an elevator door drive).

A beam crane is necessary for moving various loads

Crane beam device

The mechanism is a U-shaped structure (bridge) with a lifting mechanism. In large auto repair shops, both parts may be movable. The bridge moves on rails, the lift moves on a span beam. In garages, to save space, rails are not laid, and the bridge is equipped with wheels.

The crane beam device consists of supports, a span beam and a lifting mechanism. The supports are welded from metal pipes and channel bars. A manual or, less commonly, electric winch is used as a lifting mechanism.

Girder cranes are of the "floor operated" type, as opposed to those that are handled from a cab. To make the mechanic's work easier, the garage crane can be equipped with an electric winch

. This will increase manufacturing and maintenance costs, but if it is necessary to frequently dismantle engines and other heavy units, it will pay for itself. In rural areas where there are power outages, insufficient power or voltage surges, you should give preference to a manual winch. Especially if we are talking about a personal garage and not a private workshop.

Above we looked at what a beam crane consists of: supports, a span beam and a hoist. Manufacturing takes place in several stages:

- Weld the vertical supports in the shape of an inverted T with two diagonal supports.

- Weld the span pipe to form a U-shaped structure.

- Install the wheels.

- Weld a winch to one of the side supports.

- Install the lifting mechanism: fix the rollers, stretch the cable and hang the hook.

Ready-made drawings can be found online, but it’s easier to make it yourself by adjusting the product to the size of the garage.

Crane drawing

If for some reason this type of lift is not suitable, you can make a goose garage crane with your own hands - it will take even less time. The gooseneck crane has an L-shape, where the vertical stand is equipped with a jack rather than a winch. It is rolled under the car from the front and the engine is lifted by pumping a hydraulic jack. The boom moves upward and lifts the load.

Another interesting solution that will help save space is a suspended crane beam. Unlike the supporting structure described above, the span beam is attached to the ceiling by means of a rail (I-beam). This option requires sufficient ceiling height and strength of the building.

All devices must be tested with a load 20% greater than the maximum intended load.

Assembly instructions and drawings

The design was called the goose because of its L-shaped shape. The mechanism is easy to use, because thanks to it you can bring the boom to the engine compartment. This reduces labor costs for tying the engine, which reduces the time required to complete repair work.

The design of the goose is simple. The mechanism consists of a collapsible support equipped with wheels. With their help, it is easy to move it from place to place and roll it under a car.

The garage device has a vertical stand, on which a jack is installed. The goose has a retractable boom, which is equipped with a chain and hook. When the jack is activated, the boom goes up, lifting the load.

A hydraulic crane is most often used to lift an engine. The device can be made according to ready-made drawings, but most often a hand-created crane diagram is used; even beginners can draw it with their own hands.

First, the collapsible part of the pore is made; it is a butt part. After this, the vertical stand is welded. A spacer must be installed at the bottom. After this, they proceed to installing the jack; it must be securely fastened. The boom is made to reach full reach; it is needed to remove the engine. All parts of the structure are welded. The result is a reliable yet maneuverable device.

When the product is ready, tests must be carried out.

To do this, hang a load that should be 20% heavier than the one that needs to be lifted. If the mechanism can withstand the load, it can be used for work. The goose crane is collapsible, so it will not take up much space in the garage.

Garage hoist: drive manufacturing

You can make a hoist for lifting loads yourself. It is based on a brake lever that used to be on a truck. In a car, such a lever helps to supply the pads and reduce the gap between them.

To make a hoist with your own hands, you need to have skills in electric welding and turning.

The expansion knuckle shaft is cut to the required size using a lathe. The shaft is equipped with two washers. The entire structure is called a winding drum. One washer is equipped with a ring on the inside so that it does not interfere with the free passage of the cable.

Important Line of electric and petrol trimmers AL-KO (Alco)

How to make a drive:

Before manufacturing the lift, it is necessary to prepare drawings. The finished device can be used to lift and lower a centrifugal pump and other types of loads. As an alternative to this type of crane, you can make a hydraulic “Goose” crane.

To lift the engine and body in the garage, you will need a special mechanism. They are expensive, so you can save money by making them yourself. To do this, you must first familiarize yourself with the types of lifting mechanisms and their functionality. After choosing the type of mechanism, you need to start drawing up drawings and an assembly plan for the structure. For self-production, it is better to have turning skills and skills in assembling mechanisms.

Source

Mini crane made from scrap metal

Another version of a lifting mechanism made of metal “lying underfoot” was made by a portal participant with the nickname Petr_1.

According to Peter_1, the reason for the construction of the crane is that the house is getting higher and higher, and the blocks and concrete are getting heavier. Therefore, after revising the “unnecessary things”, the user manufactured a completely dismountable crane with a lifting capacity of 200 kg.

Article on the topic: How to pour a strip foundation for a garage

I think my crane can lift more, but I didn’t overload it. The crane can be disassembled into parts weighing 30-60 kg and can be easily transported in a car trailer. I carry an arrow on the trunk. Statically tested a structure weighing 400 kg. I usually lift up to 150 kg. This is quite enough for my construction needs.

The design of the crane is a hodgepodge of what was at hand. Let's list the main details:

- swivel unit - truck hub;

- the boom is made of a pipe with a diameter of 75 mm;

- outriggers and base - a rectangular pipe with a section of 8x5 and 8.5x5.5 cm;

- the base of the tower is the “200th” channel;

- worm gearboxes for boom and cargo winches.

- three-phase electric motor with reverse, power 0.9 kW, converted to power from a 220 V network;

The crane turned out to be mobile, and by lowering the boom, it can be moved from place to place, rolling on wheels along compacted soil. Level adjustment is carried out using screw supports.

Metal, gearboxes and rollers were purchased at a recycled metal shop. Only the cable and bearings are new.

The weight of the crane without counterweight is about 250 kg. The cost of the structure, taking into account the purchase of consumables - cutting discs for angle grinders, electrodes for a welding inverter and paint, is 4 thousand rubles.

Crane, + time for turning, + selection of components and fitting of components, I completed it in 3 working days. In the future, after finishing the work, I will completely disassemble it.

Complex block system how to calculate power gain

If the system is designed in such a way that one simple pulley pulls another simple pulley, then this is already a complex system of blocks. To theoretically calculate the gain in strength, it is necessary to conditionally divide a complex chain hoist into simple ones and multiply the values of the gain from simple chain hoists. For example, if the system consists of 4 blocks, and the first conditional simple pulley has a gain of 3. It pulls the second simple two-block pulley, also with a gain of 3. The total force that will need to be applied will be 9 times less. It is the 4-block complex chain hoist that is most often used by rescuers.

Methods for attaching a rope to a lifting mechanism

When creating complex pulley blocks, there are often situations when a cable of the required length for attaching the moving block is not at hand.

Crane for gas blocks

Methods for attaching a cable using general-purpose rigging:

- Using a cord. Using a self-tightening knot, the cord is tied to the main cable. As the load is lifted, the grappling knot moves along the main rope, thereby allowing the height of the load to be increased.

- Using clamps. In the case of using a steel cable, it is not possible to use a cord, so it is necessary to use special clamps.

Crane device

The cargo winch of my design is a worm gearbox with a 600 W electric drive, while the jib winch is a manual drive, organized on the same gearbox. Outriggers with screw stops are borrowed from construction supports. Drums for the winches were machined from rotors from electric motors, and suitable sizes were selected.

On the base of the mobile platform there are four wheels taken from the conveyor; thanks to them, the crane can be moved from one place to another without any problems, only if the outriggers of the crane are removed. This operation of removing and installing outriggers takes about five minutes. Therefore, the crane turns out to be quite mobile. But there is a small drawback: to move the crane, you need to lower the boom to zero, otherwise it becomes impossible to move the crane, since its balance is disturbed.

The boom itself has a length of 5 meters, the pipe was selected to be about 75 mm, and at the base of the boom itself there is a square profile made from two corners. There is also a portal for raising the boom, as well as a turning unit made from a hub from a truck. As a counterweight, a frame from a non-functioning machine was taken along with four tracks from a caterpillar mechanism. In this case, the brake in the winch is not provided, because it is not necessary. There is also no brake in the turn itself, due to the fact that the speeds are very low, and, therefore, there is practically no inertia.

The minimum thickness of the metal used in my crane is about 3 mm; a rectangular pipe with dimensions of 85 * 50 and 85 * 55 is used as an outrigger and base as a whole - this is a kind of remains of agricultural equipment. The base of the tower is made of channel 200. A powerful bearing is inserted into the hook cage, therefore, the hook is able to rotate regardless of the pulley, to avoid overlap or twisting of the cable itself.

The stop screws are 400mm long, allowing the crane to be installed on very uneven surfaces.

There is one small drawback related to the wheels. The thing is that the wheels used in this case, when moving on loose soil, simply bury themselves in it; on a hard compacted surface - everything is fine. This crane is considered disposable, that is, after completing the necessary work, it is disassembled for scrap or into a shelter until the next use. That is why this design has a low load capacity and not very outstanding strength.

The manufacturing time for such a crane will take about three days, taking into account the preparation of all the necessary components. In this case, the gearboxes were made from what came to hand; the gearboxes have the following gear ratios: 1/30 and 1/35. , output parameters on the shaft are 600 W, capacitor capacity is 80 microfarads. All installations without counterweights weigh up to 250 kg, the cost of such a design is 4,000 rubles. Mostly the components used are borrowed from other equipment; only the cables and bearings are new.

Such a crane can easily lift one and a half hundred kilograms of cargo; we have not yet been able to move more at home.

Preparation for design

So, after I customized the drawing I found on the Internet, I began to prepare the tools: grinder, wrenches, drill. I didn’t have a welding machine, so I had to beg my neighbor for one. After these steps, I began to prepare materials. I needed:

- 6 casters (2 swivel, 2 regular, 2 with brake);

- hook and chain;

- rectangular pipe 80x80 (approximately 7 meters);

- 3 round pipes (2 750 mm long and 89 mm in diameter, and 1 – 950 with 76);

- jack (ideal option - five-ton);

- 4 steel plates (thickness – 8 mm).

Advantages and disadvantages

Over the course of many years of operation, the GAZ-53 has managed to establish itself as a simple and reliable truck that is quite easy to repair. This is precisely what can explain the fact that this car, long out of production, is still widely used today. Especially if it has a crane-manipulator installation, which allows you to expand the scope of use of the truck. The car can be repaired in the field; a wide range of spare parts for the GAZ-53 is offered on the market.

The following can be considered problematic components of GAZ-53 car manipulators:

In addition, the disadvantage of manipulators on the GAZ-53 chassis can be considered high fuel consumption, since the car uses a carburetor engine. This problem can be solved quite simply by installing the MMZ D-245 diesel unit. Reduced operating costs in case of switching to diesel fuel can quickly recoup the cost of replacing the engine. It should also be noted that the GAZ-53 car has a fairly low price on the secondary market, which makes such a manipulator a profitable purchase for limited finances.

Machine structure

The operating principle of a crane is based on the physics of simple mechanisms. The simplest version of the crane is a stick placed on a fulcrum in such a way that the free ends have different lengths. Now if you hang a load on a short lever, it will take less effort to lift it. The most common design is one that uses, in addition to levers, a system of blocks.

A do-it-yourself crane is an indisputable assistant in small-scale construction. When constructing a private house, the use of bulky industrial cranes is not required. The height of the houses rarely exceeds 2 floors, and the weight of the lifted load is 200 kilograms.

Crane diagram

Although there are many variations of lifting mechanisms, a classic crane consists of the following parts:

An arrow with a block attached to its end. Depending on its length, the height to which the load can be lifted is determined. Platform. The boom and counterweight are attached to it

Important Technical characteristics of the New Holland loader (New Holland) and its modifications

It is the main part of the crane and is subject to significant loads. Therefore, when manufacturing the platform, it is important to pay special attention to its strength. Counterweight. Serves to stabilize the crane Determines the maximum weight of the load that the crane can lift

Stackable counterweight options are available to provide maximum stability. A guy wire connecting the boom and the counterweight. Allows you to adjust the tilt of the boom and move the load in both vertical and horizontal planes. Winch with cable. It is the lifting mechanism itself. The power of the winch determines how much weight the crane can lift. Stand with a rotating mechanism. It is necessary to turn the crane to the sides. The support cross, which is the base of the crane. Sets the stability of the entire structure. When manufacturing it, you should also pay attention to its strength.

terms of Use

To operate lifting mechanisms safely, certain rules must be followed.

Homemade Pioneer crane

These rules apply to any lifting device:

- The load capacity must not be exceeded. A load that is too heavy may damage the device.

- The base must be stable. Homemade lifting devices should be located on a previously prepared hard horizontal surface.

- In bad weather conditions, you should also refrain from working with the crane. Strong winds will throw the crane off balance, and poor visibility may make it difficult to see people under the boom.

- Before operating a crane or lifting device, it is necessary to conduct an external inspection to identify any malfunctions. If malfunctions are detected, operation of the crane is prohibited.

- It should be remembered that when working with the lift, you should not make sudden movements. The load must be lifted smoothly. And most importantly, do not stand under any lifted load.

How to use

The telescopic boom of the mechanism can be installed in several positions. The goose is maneuverable and can be controlled by 1 person. The equipment lifts quite heavy loads due to the installed jack; no additional accessories or devices for moving heavy loads are needed.

For full convenience of using your own garage, sometimes you need equipment for lifting heavy parts of the car. The best solution to this problem is a hydraulic crane. The unique structure allows you to rearrange small loads with little effort from the mechanic or car owner.

The hydraulic valve is made of durable metal and has a stable design. The main principle of the mechanism structure: stable support with low dead weight. This helps you lift loads of up to three tons with ease, but a maximum of two meters above the ground.

Garage crane is used for:

- removing the engine;

- lifting beams, bridges;

- movement of dimensional units.

The crane contains a hydraulic drive and operates through a system of communicating vessels. The method allows you to make the rise smooth.

Stationary

The stationary crane is installed in large car repair shops and is securely attached to a monolithic foundation. The mechanism has a boom with a rotating system and is equipped with a manual drive. Allows you to work on only one vehicle at a time.

Advantages

Among the advantages of a hydraulic crane installation are the following:

- Easy adaptability and ease of control. Such equipment does not require special skills. It facilitates repairs and maintenance work on automobile and truck components.

- Minimum amount of inertia and high level of smoothness of the operations performed.

- During operations with a load, the object being lifted is clearly fixed, which ensures its integrity and safety.

- Autonomy of work. For the operation of garage crane equipment, no additional power source is required.

- Compactness. This allows you to store and use the equipment in a small room. Also, due to its small size, the device can be rolled under any vehicle.

- Reliability of the design. The unit is made of durable metal alloy, the body is reinforced with special welded elements and seams, which increases its service life.

- Due to the fact that the running mechanism is securely attached to the base of the crane, during movement the equipment does not damage the underlying surface and does not emit unnecessary noise.

- High level of load capacity.

- Good level of extension of the working body.

- The design of the crane installation provides a high level of protection against angular loads, reducing the likelihood of the crane overturning.

- Low cost of equipment and spare parts.

Homemade mini crane based on a bottle jack

To make a hydraulic crane, we will use available materials that many people have in their garage.

We recommend: Stand for a small grinder made from an old bicycle

And even if you don’t find anything suitable at hand, everything you need can be purchased for pennies at a ferrous metal shop.

The lifting mechanism is useful both in the garage (for example, to raise and lower a car engine), and during construction work - for installing and dismantling various metal structures.

Basic materials that will be required to make a mini crane:

- profile pipe with a wall thickness of at least 3 mm;

- metal plate 5 mm thick;

- bottle jack (load capacity is at your discretion);

- swivel wheels;

- steel chain with hook.

Main stages of work

The first step is to make a support for the hydraulic mini crane. For this we need profile pipes.

Using a grinder, we cut pieces of suitable length and weld the base. After this, it will be necessary to weld a vertical stand to the support.

We weld two metal plates to its upper part, to which the lift boom is attached.

As a drive that will raise and lower the boom, we use a hydraulic jack with a lifting capacity of 12 tons (you can use another jack).

We weld a piece of profile pipe to the vertical post at an angle, which will serve as a stop for the jack.

We cut out a square plate from sheet metal and weld “ears” to it. Using a bolt and nuts, we attach the plate to the stop - this is a movable platform on which the sole of the jack will rest.

We weld a “glass” to the bottom of the boom for the support point of the jack piston. Next, we clean the welds with a grinder, after which we paint all the manufactured elements.

Assembling a load-lifting crane

We attach the bottle jack to the movable support platform on the vertical stand. We lower the boom so that the jack piston enters the “glass”.

We recommend: “Third hand” for welding small workpieces and parts

We install the retractable section of the telescopic boom, to the end of which we attach a chain with a crane hook.

This homemade lift is perfect for removing and then installing the engine from the car. It can also be used for other purposes - in the workshop and garage. The design is reliable and inexpensive.

For a step-by-step description of how to make a mini crane from a jack for a garage or workshop, watch the video.

Mobile mini crane for lifting and transporting heavy loads

The design of this device is practically no different from the previous version, but there is a small addition in the form of a manual lifting mechanism.

Let's get to work. First, the base of the crane (supporting part) is made from corrugated pipe.

Swivel wheels are attached to the bottom of the base so that the structure is mobile and can be freely moved around the garage or outside it.

After this, a vertical stand along with a stop is attached to the base.

Next, a telescopic boom is manufactured and installed. We install a bottle jack between the stand and the boom.

At the last stage, all that remains is to secure the hand winch to the vertical stand. We wind a steel cable (at least 4-5 mm thick) with a crane hook at the end onto the lifting mechanism drum.

This design is quite convenient to use and can easily lift a load weighing 200 kg or more.

The step-by-step process of making the lift is shown in the author's video - we recommend watching it.

Homemade A Small Mobile Crane For Workshop

Operating principles of various elevator systems

Elevator lifts are divided into the following main types:

1) Electric

(electromechanical). 2) Hydraulic

.

3) Pneumatic

(airlift).

DIY elevator guides

To move the elevator, some kind of power device is required, the most convenient and practical power supply for which is electricity. Therefore, electric motors are part of the drive, regardless of its type. However, it is customary to call the elevators of the most common cable system electric, probably because in them the engine force is directly transmitted to the cables that move the cabin.

1. Electric elevator

, which we use in multi-storey buildings, works on the principle of a counterweight: the cabin is fixed on cables, at the other ends of which a counterweight is attached. The drive mechanism, located in the upper part of the elevator (engine room), having received an electrical signal from the panel buttons, sets the system in motion through a pulley wheel. Thanks to the counterweight, cabin inertia is reduced to a minimum, which ensures smooth movement and allows you to get by with a significantly lower power electric motor.

2. Hydraulic lift

works on the principle of a jack. The electric motor creates fluid pressure in the system, and the hydraulic cylinder pushes the cabin upward. No electricity is consumed during descent. This type of elevator has no counterweights and is silent. But due to the high pressure in the hydraulic system, it requires qualified maintenance and a powerful power plant.

3.

Pneumatic elevator cabin

works like a piston. To move the elevator upward, a vacuum of air is created in the air shaft above the cabin by powerful fans. As a result, increased pressure under the cabin pushes it upward. To descend, the pressure at the top and bottom of the cabin is equalized, and it smoothly goes down.

DIY pneumatic elevator

Now let’s ask ourselves the question: how to make an elevator with your own hands in the house, is it feasible for your hands and wallet?

A pneumatic elevator requires components that are almost impossible to make with your own hands. If you buy ready-made ones or order their production, the very idea of making an elevator with your own hands is lost. And the final cost will be rounded up to such a figure that purchasing and installing a ready-made airlift will cost less.

DIY hydraulic lift

Now - hydraulics

. Alas, it is no less difficult and expensive. A high-performance hydraulic pumping station will be required, and it is not cheap. Well, and most importantly – the hydraulic cylinder. Even raising an elevator car one floor requires significant extension of the rods. Dump trucks have similar units, but even if we decide to install such a hydraulic cylinder, we will be faced with another problem - lowering the cab. Automotive-type hydraulic cylinders fold under the weight of the heavy load bed of the dump truck. The weight of the elevator car will not be enough here. Combining various other ready-made mechanisms will be no less difficult and expensive.

Important Guide for self-repair of working units of the T-25 tractor

The solution to the question of how to make an elevator yourself is obvious: make an electromechanical

Industrial development[edit | edit code]

Electrical engineeringedit | edit code

Once a sufficient amount of latex, red dust (), copper, iron and tin has been found, you can begin to manufacture a generator - the first source of electrical energy, as well as the first consumer of electricity - an electric furnace (), which works almost twice as fast as a conventional one. To create an electric furnace you will need copper and red dust, because you will definitely need an electrical circuit.

IndustrialCraft² recommends that mined ore be first crushed in a crusher and only then smelted. Thus, from one block of ore you get 2 ingots, instead of one. Therefore, the sooner the crusher is manufactured, the better. There is also an ore washing machine and a thermal centrifuge, which allows you to wash even more resources from crushed ore. Likewise, it is recommended not to melt latex in a furnace to make rubber, but to use an extractor, as it squeezes more rubber out of the latex. The crusher, ore washing machine and extractor are also consumers of electricity.

Miner's affairs | edit code

At the initial stage of development in this mod, when a lot of iron has been accumulated, it is worth stocking up on stone pickaxes and one iron one and going to the mine (cave or canyon). It is recommended to stay in it for an hour or two of real time, mining a pile of , various stones (stone, coal, lapis lazuli, obsidian, diamonds) and red dust, so that later, during any complex or not very difficult crafting, you do not have to run into the mine for new portions of useful resources.

Subsequently, a mining laser and a drilling rig (used for automatic extraction of resources) will be very useful in mining.

Agricultureedit | edit code

The agricultural complex can be effectively used for the player’s life thanks to perches (which simplify farming) and plant selection. For example, Ferrium yields a small pile of iron dust as a harvest, and Aurelia yields a gold nugget. A mug of coffee is extremely useful, as it gives the player more energy, making him move faster. A coffee mug () is crafted from coffee fruits.

How does a simple block design work?

Let's first consider a simple assembly pulley. It can be obtained by adding blocks to a support and a load. To get an odd mechanism, you need to secure the end of the rope to a moving point of the load, and to get an even one, we fasten the rope to a support. When adding a block, we get +2 to strength, and a moving point gives +1, respectively. For example, to get a pulley for a winch with a multiplicity of 2, you need to secure the end of the rope to a support and use one block that is attached to the load. And we will have an even type of device.

The operating principle of a chain hoist with a multiplicity of 3 looks different. Here the end of the rope is attached to the load, and two rollers are used, one of which we attach to the support, and the other to the load. This type of mechanism gives a gain in strength of 3 times, this is an odd option. To understand what the gain in strength will be, you can use a simple rule: how many ropes come from the load, this is our gain in strength. Typically, pulleys with a hook are used, on which, in fact, the load is attached; it is a mistake to think that it is just a block and a rope.

What's the result?

For myself, I realized that making a tap for removing the engine with my own hands is quite possible. In addition, its assembly does not require serious skills and knowledge. You just need to carefully follow the drawing. It also does not require much investment: in terms of time - it took me about a day, and financially - quite a bit. My soul is filled with joy when I see that in stores such mechanisms are sold on average from 20 thousand rubles, and for me it cost 3. Overall, I am very pleased with the result.

Question

Write in the comments what you think - does it make sense to make such devices manually, or is it better to go to the store?

Hydraulic garage crane drive

There are several types of hydraulic drive:

- with hydraulic cylinders;

- with hydraulic cylinders and manual winches.

When the operator increases the pressure level in the cylindrical block, the oil fluid acts on the piston part, pushing out the telescopic rod, at which time the boom equipment rises.

Based on the nature of the movement of the output link of the hydraulic power unit, the following types of drives are distinguished:

- Rotational movement. The design of such a mechanism includes a hydraulic motor equipped with a driven link with unlimited rotational movement.

- Forward movement. In this case, a hydraulic cylinder is used with a reciprocating movement of a driven type link (piston rod, plunger).

- Rotary movement. The crane mechanism is equipped with a rotary hydraulic motor, the driven link of which makes a reciprocating movement at an angle of less than 270°.

- Adjustable. In this case, the speed of the output type link can be adjusted by changing the crankshaft speed of the power unit, which activates the high pressure pump.

- With a closed circuit of working fluid circulation. This means that the fuel is returned to the suction hydraulic line of the pump mechanism. This drive is lightweight and provides high rotor speeds without the risk of air getting into the system.

Scissor crane

The scissor crane is a simple and easy-to-use design. Due to their versatility and functionality, these devices are used in installation and construction work. They can also often be found in supermarkets and warehouses.

A scissor crane lifts tons of loads every day. This technique, in addition to the construction industry, is regularly used in the maintenance of advertising billboards, facade signs, and elevators.

Their main advantages include:

- performance;

- high load capacity;

- compact dimensions when folded;

- wide range of applications;

- maneuverability.

Their advantages also include autonomy - they can operate on batteries. In addition, cranes can be equipped with different types of drives:

- electrohydraulic;

- diesel;

- electrical;

- hydraulic.

Most often, models with electric drives are used in construction. They are affordable, environmentally friendly and easy to use.

There are a large number of variations of devices of this type, but almost all of them consist of:

- lifting device,

- mobile platform;

- equal-speed drive wheels.

To build a scissor crane yourself, you will need to make the base and platform of the apparatus from a channel. To make scissors you will need:

- two-section distributor;

- bushings;

- pump;

- hydraulic cylinder;

- I-beams.

A DIY scissor crane is capable of lifting loads weighing up to half a ton. This device is installed on the UAZ, and after operation it is removed. The basis of the structure will be a thick square bolted to the frame, and the retractable pores will be held on the car bumper.

Hydraulic taps: features and benefits

It is important to note that such devices are used to perform various jobs; they are usually used in garages and construction sites, so today they are in demand and popular.

Garage crane folding hydraulic

- They are easy to operate, and in addition, they will not require special knowledge; such a device will be able to lift this or that vehicle component without problems, even if we are talking about a truck.

- There are several types of such devices, for example: folding, stationary devices, and each of these options is popular and in demand today, and is designed to perform various types of work.

- If we talk about a stationary hydraulic crane, it has a serious difference, compared with all other options, it is usually attached to the garage floor, it also differs in the rotating boom that is available.

- This crane is really convenient, especially when it is necessary to remove a large component of a car, etc. Now you should understand what you need to use when you need to remove, for example, a gearbox.

Hydraulic crane drive

I would like to note that such devices come in two types: hydraulics, as well as hydraulics equipped with a special mechanical drive. If you choose the second option, you need to know that it is considered more convenient. Speaking about the design of the hydraulic drive of the crane, know that it is similar to a hydraulic jack.

If you choose a folding hydraulic crane, know that it is convenient and accessible, which means that this option is truly one of the best, it is compact, mobile, and most importantly, load-lifting, which is important.

How to choose the right jack

Of course, when choosing a jack, it is so important to take into account important criteria and selection factors in order to truly purchase a product that is ideal for a particular job, and so that you know for sure that it is safe.

So:

- It is imperative to take into account the lifting capacity of the jack; it, in turn, must exceed the weight of the vehicle.

- It is also necessary to take into account the dimensions of the device; they must be optimal not only for storage, but also for transportation.

- I would like to add that many people do not want to purchase domestically produced jacks, thereby doing the wrong thing, it is worth choosing them, because they are often superior to their foreign counterparts in many parameters and characteristics, not only in price, but also in reliability.

So, if you carefully study all the selection criteria, you can easily choose a high-quality, reliable and safe jack. Garage taps are quite different and the specifics of their application are different. The instructions will help you make the right choice.

How a simple block design works

The pulley system or pulley system has been known to mankind since ancient times. The classic system design consists of pulleys and cable. One pulley is called a block. Depending on the method of fastening, the pulley can be movable or fixed:

- Fixed block. It is attached to the support and plays the role of changing the direction of movement of the rope. Does not provide any gain in strength.

- Movable block. It is located on the side of the load and gives a gain in strength.

The principle of operation of a pulley block is similar to the principle of operation of a lever in the physics of simple mechanisms. The role of the lever in this case is played by the cable itself. In the case of a simple block of two pulleys, the movable pulley divides the rope into 2 parts and in order to lift the load the same distance, a rope twice as long will be required. The work of lifting the load is performed in the same volume. And the effort, due to the fact that the length of the rope has become twice as long, becomes half as much.

If there are more than 2 pulleys in the system, the gain in strength is approximately equal to the number of blocks. In the case of 3 blocks, the effort will be 3 times less, and 4 blocks will require only a quarter of the original effort.

We create a simple lifting mechanism with our own hands

Construction of a crane is not a quick task and is justified if it is required frequently or the volume of work is large enough. In cases where the load needs to be lifted urgently or this is a one-time operation, you can use improvised means.

To create a simple lifting device you will need a cord and two blocks. One block and the end of the rope are fixed motionless on the support. This will be the highest point to which the load can be lifted. We attach the second block to the load using slings or a hook. We first pull the rope along the block attached to the load, then pass it through the upper block. The gain in power will be 2 times. Using your own weight, you can easily lift a load weighing 100 kilograms to the required height.

DIY mini crane

If you add the ability to move the upper block along a guide, for example along a rail, you can get a do-it-yourself jib crane. It is useful in garage conditions for moving heavy machine parts.

It should be remembered that when working with the lift, you should not make sudden movements. The load must be lifted smoothly. And most importantly, do not stand under any lifted load. The same rule applies to a crane - standing under the arrow is prohibited.