Flanged ball valves for sewerage are a type of pipeline fittings that prevent a change in the direction of movement of the medium to the opposite. Such critical situations can arise due to operator error, a breakdown in the system, or destruction of a pipeline section. A check valve will avoid product leakage and cascading faults due to changes in the flow vector.

The tightness class of check valves is AA. Please note: they are not used as shut-off valves. Key characteristics for choosing a model are diameter DN and working pressure PN.

To order, contact us by phone +7 (499) 380-83-81, email or leave a request on the website. Our company’s specialists will provide assistance in selecting check valves and a set of mounting parts.

- Peculiarities

- Design and principle of operation

- Operating environments and applications

- Specifications

- Delivery throughout Russia and the CIS

Features of a check valve for sewerage

A check valve is necessary to shut off the flow of sewage waste. Apartments on the first floors of old houses are especially susceptible to this. All this is due to the improper use of toilets.

Therefore, the horizontal pipes in the basement become clogged. The result is that the waste rises, and having found the first exit, which will be the toilet on the first floor, it pours out into the room.

- It is worth noting here that not only apartments on the first floors can suffer from sewage waste, because this also happens on other floors.

- If the check valve is installed on the ground floor or there is a blockage between floors.

- The culprits in this situation are usually the apartment owners.

- By flushing unacceptable substances into the toilet, which form a blockage in the sewer. Therefore, feces can splash out on any floor.

The safest apartment, where such a phenomenon is unlikely, will be the living space on the top floor. On others, they advise protecting your apartments from surprises in the form of feces and installing a check valve.

As for private houses, their sewage system is designed in such a way that the return of waste is likely to be small. But still possible. Therefore, it is better to insure against an “unexpected invasion” and install a reverse-acting valve. Which has another advantage, protecting the home from the invasion of small rodents.

Product materials and sizes

When choosing a sewer check valve model, it is recommended to know what materials the device is made of, as well as the dimensions of the products. The most common materials:

- stainless steel;

- cast iron alloy;

- bronze;

- plastic.

In most cases, a check valve is purchased from the same material as the pipeline installed in an apartment or private building. It is not recommended, for example, to buy a plastic device for cast iron pipes. The most popular choice in terms of price/quality ratio is a valve made of high-quality plastic.

The dimensions of the device depend on the amount of free space. There is also such a characteristic as the connection method - horizontal or vertical. In most cases, devices for horizontal connections are used, but if there is not enough free space behind the toilet, bathtub and other plumbing fixtures, then vertical check valves are installed. If there is critically little space, then it is recommended to purchase a wafer type of mechanism. For its installation, only seals are required.

How does a non-return valve work in a sewer?

The main task of the valve is to prevent feces from returning through the toilet, polluting the toilet room.

And giving the owners of living space a lot of very unpleasant surprises.

- The system is a movable metal barrier.

- In its normal state, it is lowered down, closing the lumen of the sewer, which prevents reverse flow from passing through.

If feces appear, the flapper is moved back or raised and the flow passes unimpeded. The damper falls into place. How exactly the system operates depends on its type.

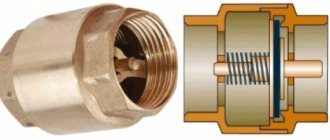

Scope of application of coupling valves

Most often, coupling valves are used in contact with cold water and steam, as well as with food liquids and aggressive media. This is possible thanks to the use of AISI 304 and AISI 316 stainless steel.

The device remains functional at temperatures from -10 to +250 degrees Celsius. The high anti-corrosion resistance of the material ensures a long service life, and the coupling (threaded) connection guarantees strength and ease of installation.

The valve can operate under pressure up to 32 atmospheres. You can buy a coupling valve in sizes from 1/2″ to 2″.

to our specialist:

Types of check valve

Manufacturers offer 4 types of check valves.

Rotary valve

This system consists of a so-called “plate”. It plays an important role in stopping sewage waste. If the feces go in the right direction, the membrane rises.

In the event that waste returns back, the “plate” blocks its path, closing the lumen of the pipe. These models also come with a manual shutter. It is an additional membrane that closes the pipe when you press a button installed on the system.

- The rotary valve is often called a "slam." Because the system lowers the “plate” if there is no waste activity.

- The valve has a fairly large diameter. Significantly exceeding the pipe itself.

- Therefore, the pipe first expands and then contracts. Allocating space for blockages to form.

It is to eliminate such defects that a cover is made on the top of the valve; when removed, the problem can be quickly eliminated.

Lift valve

The device works as follows. When the feces follow correctly, the closure system lifts the membrane upward. This occurs as a result of the pressure of the flow on the “plate” spring.

- If there is no waste, the membrane is closed. Those. even when the feces flow back, the membrane will not open and the waste will remain in place.

- The reliability of this design is confirmed by positive reviews from many customers.

- The only thing is that the system needs to be cleaned periodically.

For this, as in the previous design, a removable cover is provided. It is secured with bolts; when unscrewed, the cover is removed and defects are removed or any elements are replaced.

Ball valve

The system is made in such a way that the lumen of the pipe is blocked by a special ball. It closes the passage when waste passes properly.

And it does not allow feces to return back, being located in the body of the pipe.

- The ball valve is not as popular as the above options, since the ball and the walls of the pipes do not close tightly.

- Thus creating places for waste to penetrate.

- Therefore, there is a possibility that waste will return to the toilet. But the feces will remain in the toilet and there will be no massive flooding of the toilet.

Wafer valve

This system is famous for its miniature size. Representing a cylindrical container with a damper located inside. It can be of two types. This is a damper in the form of a “plate” or a membrane on a spring.

To prevent sewage waste, such a system is rarely installed. Because it does not retain feces well. And in order to clean the valve, you will need to disassemble the entire system. Therefore, the wafer valve is more suitable for water supply.

Installation rules

The main thing to consider is the direction of movement of the wastewater. It is indicated on the body by a large arrow. The device must be rotated so that the normal direction of the drains coincides with the arrow. Further installation features are as follows:

- Installation of a plastic check valve on a sewer is carried out in a standard way for this type of pipe: there is a socket and a rubber seal. The straight edge of the pipe is inserted into this socket. Such a connection is already airtight, but for greater reliability, the joint can be additionally coated with plumbing silicone.

- Installation of cast iron models - using sealing rubber bands and bolts that tighten the mounting plates, there are models with sockets - for traditional installation on tow and filling the seam with sealant.

- It must be installed so that there is free access to the lid - periodically the check valve on the sewer becomes clogged, so it needs to be cleaned. It will be necessary to provide access to the lid - install a removable grille

What are they made from?

The market offers such systems from two alloys - cast iron and plastic. Both materials are in demand among buyers.

- If the pipes are originally made of PVC, then you need to install a plastic damper.

- And vice versa, if the sewer pipe is made of cast iron, the damper is installed of a similar material.

- The main thing is to choose the right size. What these dampers have in common is that they are installed both vertically and horizontally.

- The difference is that the cast iron damper is heavier in weight and requires additional adapters for installation.

- All this makes the system significantly larger compared to a plastic damper.

Both cast iron and plastic systems are selected depending on the installation location. During installation, the rule is that you cannot install a damper smaller than the diameter of the pipe. To avoid restriction, which can be circumvented by properly sizing the valve.

For example, polypropylene dampers are used with a diameter of 110 mm. Made of plastic: 32, 40, 50, 90, 110 mm. Made of stainless steel 110 and 160 mm.

When and where to put

As already mentioned, a sewer check valve is a rather cumbersome device. In apartments, bathrooms are usually small, it’s difficult to find a place, but you have to - if you don’t want to have a geyser instead of a toilet.

The exact dimensions of sewer valves depend on the diameter of the pipe on which the device is installed. For example, for a 100-diameter sewer pipe, the minimum length is 40 cm, height and width are slightly less. Such a box must be installed in front of the entrance to the riser.

Non-return valve for sewer installed

In this case, you often have to break the floor, already laid tiles - you need to align the holes in the body with the pipes, center everything, and monitor the required angle of inclination. This prospect is especially pleasing if renovations have recently been made. In this case, there is also an option - to embed a check valve into the riser above your entrance. But such work involves interference with the general building system (installation of plumbing fixtures on your branch does not fall into this category), and they require written permission, you will have to notify residents, shut off the water, and representatives of the operating organization or water utility will work. In general, it’s still a hassle, which is why this method of solving the problem is used very rarely.

If there is no place for a common device, install sewer check valves on each plumbing fixture - separately on the toilet, bathtub, washbasin, sink, etc. This is if pipes from each of the devices go to the riser separately. If you have only two directions - to the toilet, and then to the bathtub-washbasin-sink, etc., then it will cost you to install two devices - one personal one on the toilet (the diameter coincides with the diameter of the outlet pipe) and the second - a common one, on a branch that goes to all other devices. Its size must match the diameter of the distribution pipe, and most often it is 50 mm.

See how to install a toilet with your own hands here.

Photo of a check valve for sewerage

Manufacturing Features

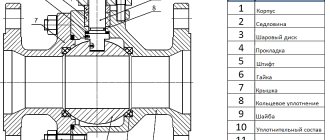

The basis for the production of valve bodies is cast iron, which is resistant to mechanical damage and wear. The design of ball check valves also includes:

- spherical locking element made of steel, cast iron or nitrile;

- seals that provide a high degree of tightness;

- connecting pipes.

The surface is covered with a protective layer that protects against moisture and prevents corrosion. To fix the fittings, use a thread or flange connection.

Design and advantages of ball type valves

The closing element of ball-type check valves, as mentioned above, is a ball, which can be made of cast iron, steel or aluminum. Quite often, to ensure greater reliability of such a shutter when closed, the ball is additionally covered with a layer of rubber. Ball check valves, which can be installed on both horizontal and vertical sections of pipelines, despite the simplicity of their design, are reliable in operation.

The ball check valve is highly versatile and is available for pipelines of various diameters, which makes it possible to use it to equip both domestic and industrial pipeline systems. Pipeline systems used for heating private houses and for heating large industrial facilities, pumping stations, as well as pipelines through which working media are transported for the needs of various industries are equipped with ball valves.

Ball type check valve device

Some models of ball valves are equipped with a removable cover, which allows minor repairs and maintenance of such shut-off devices without dismantling them. The cover is attached to the valve body using bolts, and a special sealing gasket is used to ensure the tightness of its connection. On large-diameter pipelines, elements of heating and pumping equipment, flanged ball check valves are most often used.

Installation location and requirements

- If the installation of a check valve needs to be done in a private household , then one common mechanism is installed for the entire sewer line.

- In apartment buildings, installation is carried out separately for each plumbing fixture.

- For sinks in the kitchen and bathroom , you can choose a model that has small dimensions.

The installed check valves must meet certain requirements:

- Mechanical strength of the device , absence of mechanical damage.

- The ability to carry out cleaning and minor repairs without dismantling the entire structure.

- The valve must be securely connected to the sewer line.

Immediately before installation in an apartment building, it is required to notify all residents of the entrance about the impossibility of using the sewer system for a certain time. Also, it is necessary to shut off the water supply to the entire riser. Work on installing the check valve should be carried out as quickly as possible and take no more than 2 hours.