Buy GOST 5210-67 - paper document

with hologram and blue seals. more details

We have been distributing regulatory documents since 1999. We punch checks, pay taxes, accept all legal forms of payment without additional interest. Our clients are protected by law. LLC "CNTI Normocontrol"

Our prices are lower than other places because we work directly with document providers.

Delivery methods

- Express courier delivery (1-3 days)

- Courier delivery (7 days)

- Pickup from the Moscow office

- Russian Post

Applies to hot-rolled steel of special profiles intended for the manufacture of files, rasps, chisels and cross-cuts.

Replacement data is published in UGS 4-84

What is a file and what is it for?

A file is a universal metalworking tool. Allows you to solve a whole range of problems.

- Cleaning parts from rust.

- Removing dirt and paint from the surface of parts.

- Bringing the workpiece to the required size.

- Tool sharpening.

- Cleaning power contacts of electrical equipment from carbon deposits.

- Surface grinding.

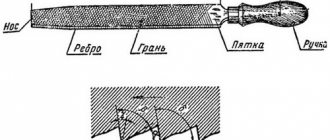

What is such a tool? This is a small piece of metal with notches . At one end there is a shank for a handle made of wood or plastic.

When making files, they are guided by GOST 1465–59 . It regulates the use of a certain type of metal in the production of these products:

- alloyed chromium steel (grade ШХ 15 or 13Х);

- improved unalloyed steel (grade U10A or U13A).

For high-quality processing of metal parts, there are metal files . Types of notches allow you to solve a wide range of problems. This includes processing not only high-strength alloys, but also working with ceramics, plastic, wood, rubber or leather. The requirements for precision and cleanliness of processing are also different.

Which notch to choose

- Simple (single). Suitable for processing soft metals or plastics. Such material is easily removed and can quickly clog the space between the notches. But not in this case.

- File with cross or double cut. Used for working with parts made of hard alloys. For example, cast iron, bronze.

- Rasp, dot notch. Based on the type of tooth, such a tool is called a rasp or hog file. It is always large in size (250–350 mm). Has a large notch. The shape is classified as semicircular, round or flat. Good for working with rubber, leather, wood. Not suitable for precision machining and grinding.

- There is an arc type of file notches. Used for processing wooden parts.

GOST 1465–59 regulates six numbers of notches :

- Large. These are No. 0 and 1. Used for rough surface treatment. Such a tool, also called a bastard file, removes a layer 0.05–0.1 mm thick in one pass. Not suitable for precision machining.

- Notches No. 2 and 3 allow you to work more accurately. Removes a layer of 0.02–0.06 mm. The processing accuracy will correspond to this parameter.

- Finish adjustment of the size is possible with notches No. 4 and 5. An accuracy of 0.01–0.005 mm is possible here. This is how much material is removed from the workpiece in one pass of the tool.

Now you can see that you can do quite a lot of work with this tool. It is unpretentious and versatile . Indispensable where a power tool is “powerless” and is always ready to help out a master in a difficult situation.

How to make a file handle

The handle of the tool should be comfortable. It’s easy to make with your own hands from wood. The sequence is:

- Plan or turn the handle on a lathe. Each master selects the size and shape individually. It should fit well in the locksmith's hand. The wood is taken dried, of medium density, non-fragile. The best option is pine.

- Finally, place a metal ring where the file shank will be inserted. It can be made by cutting 1 cm from a tube of suitable diameter. Without it, when placing the handle on the shank, the handle will crack.

- Drill a hole along the axis of the handle from the side of the ring to a depth equal to ¾ of the length of the file shank. The drill bit should have a diameter of ½ of the average shank thickness.

- When inserting the handle, make sure that the axes of the two parts coincide.

Read also: Luxmeter u 116 instructions

Often you have to process shaped surfaces with curves and sharp internal corners. To perform each of these works, select the appropriate tool, produced in accordance with GOST.

Stage 2: determination of carbon content in steel

How can you determine specifically whether, for example, a file is made of carbon or alloy steel? To do this, you should resort to a simple old method. Craftsmen noticed that small metal shavings obtained when processing metal with an abrasive wheel, when heated, produce a sheaf of sparks, which have their own characteristic features for each metal. The “straws” that make up a sheaf of sparks, each brand has its own special ones: long, short, continuous, intermittent, heaped and sparse, smooth or thickened; from each of them small bright stars can be separated, sometimes very abundantly; The brightness of the glow of the sheaf of sparks is taken into account, as well as color shades - from light yellow to dark red.

The higher the carbon content in the steel, the more bright stars there are in the sheaf of sparks. If the steel contains a little carbon, for example about 0.12%, then the sparks coming out from under the abrasive disk will fan out in the form of slightly curved lines of yellow-straw color, with thickenings in the middle and at the end (1, see Fig. on page 105). Steel containing 0.5% carbon and having an average hardness produces approximately the same sparks, but a small number of stars separate from the place of average thickening (2). Copious sparks with stars (3) are released from the high-carbon tool steel. Chromium steel has long, orange-red sparks; from them, like thin branches from the main branch, short sparks with stars at the end extend from them at different angles (4). Tungsten steel sparks intermittently, and also has small thickenings at the end (5). Chrome-tungsten high-speed steel produces both short and long sparks of a dark red color with thickenings at the end (6).

Purpose and types of files

- Flat. They are good for cleaning even parts of workpieces.

- Tool with square section. They are convenient for fitting parts with internal square or polygonal holes.

- Semicircular. Suitable for grinding concave surfaces with large diameters.

- Round. They will help to expand the hole of a small radius, and, if necessary, give it a different shape, for example, make an oval or ellipse.

- Triangular assistants are used for working with parts with sharp corners up to 60°.

- There are files with a rhombic shape. The angle between the working planes of such a tool is smaller than that of triangular “colleagues in the workshop”. They are used to process parts inside sharp corners. For example, for sharpening a fine-tooth hacksaw.

Advantages of a file

It is easy to use and cheap to purchase. If you use a power tool, for example, for sharpening, such a device will be difficult to use.

A tool sharpening machine will provide precise angles and high quality work, but it costs a lot of money.

Purchasing such a machine for rare use is not practical. A file can be used to process parts in hard-to-reach places . For example, holes of varying complexity.

Exterior surfaces with many angles and curves. Its performance does not depend on the availability of electricity. The file is relatively safe . Does not scatter chips, does not throw sparks, does not have dangerous rotating elements.

A file, unlike an electric tool, removes a small layer . Therefore, it is more difficult for them to spoil the workpiece. If precise fitting of two parts is required, a fine-tooth file should be used. Another classification of files is based on the density of the cuts.

File

- multi-blade tool for processing metals, wood, plastics and other hard materials.

It is a metal rod with a notch.

The process of processing material with a file is called filing.

By nature, the notch is divided into:

- simple (single) - used for non-ferrous metals.

- cross - for steel, cast iron and bronze.

- milled (arc) - for non-ferrous metals and wood.

- rasp (point) - for wood, leather, rubber. Rasp

- has a notch in the form of small burrs located separately from each other. Apparently, this is the most ancient version of the file. It is easy to make at home using a small triangular chisel. - stamped - holes with sharp edges protruding outward are pressed into a pipe or channel made of steel sheet (similar to a kitchen grater). Use like a rasp.

There are files (especially needle files) coated with diamond powder. They are used for processing hardened steel, glass, ceramics, etc. When working, they must be moistened generously with water.

Nadfil

(German Nadelfeile - needle file) - a small file for fine work.

Rifel

- a type of needle file. It differs in that the working part is curved (even hook-shaped). Used by jewelers to process curved surfaces. (They are always made only from magnetic alloys so that crumbled riffle particles can be separated from precious metal filings with a magnet).

Read also: Aluminum, a component not included in cast iron

According to the cross-sectional shape of the working part, files (needles) are:

- rectangular (flat),

- square,

- triangular equilateral,

- triangular obtuse,

- round,

- semicircular,

- oval,

- rhombic,

- knife,

- etc.

Stage 3: Tool Test

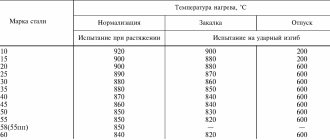

Now let's get back to the file. Before you start testing it, you must wear safety glasses and place a sheet of black-painted plywood near the sanding wheel. On a black background, the sparkling metal is visible much more clearly, and the eyes have to strain less. If we forcefully run a file over the emery wheel and get abundant sparks of a bright yellow color with many stars separating from them, we can conclude that it is made of high-carbon tool steel (U10-U13). Conversely, a sheaf of orange-red long sparks with branches and stars at the end indicates that the file is made of alloy steel (ШХ6, ШХ9, ШХ15). Of course, in this way only the approximate chemical composition of steel is determined, but for amateur practice this is quite enough. Knowing that the file is made of tool steel of the indicated grades, the heat treatment mode is determined from the table.

The table shows that the U11-U13 steel from which the file is made is annealed at a temperature of 750°C and then gradually cooled in air. Annealing is carried out in a muffle furnace, forge or in the firebox of a conventional furnace. It is convenient to anneal metal objects in an electric school muffle furnace, since the built-in thermometer makes it possible to monitor the heating temperature. But the depth of the muffle furnace is limited. If the file does not fit into it, it is wrapped in several layers of tarpaulin and broken with a strong blow of a hammer.

The broken file is removed from the tarpaulin, annealed in a muffle furnace, and then slowly cooled. The resulting scale often interferes with machining. Therefore, wearing glasses and mittens, they knock it down with a hammer and a chisel.

Annealed and processed tool steel becomes quite soft: it can be easily filed, sawn and forged. With minimal hardness, it has maximum plasticity and viscosity. This makes it possible to make from it gravers for engraving, embossing, chisels, cutters, punches, and other tools for the artistic processing of metal.

Having made the desired tool from a file, it is hardened by heating according to the table to 780°C, followed by cooling in water. After hardening, the steel becomes brittle, so it is tempered: heated to 180°C and cooled in water or machine oil. When tempering, the heating temperature of the metal is controlled by the so-called tarnish colors, which correspond to a certain heating temperature.

Special varieties [ edit | edit code]

A type of file (usually a diamond) is a nail file, which is part of manicure sets.

Jammed or otherwise damaged threads can be repaired using a thread file. Such files, as a rule, have several different working edges designed for cutting threads of various pitches.

To straighten knives, musat is used - a round, sometimes oval, rod with a notch, ribs along its length.

Name variations [edit | edit code]

In Dahl's dictionary there are the terms “terpug” and “derun” for a rasp; “matchy” for a personal file.

Sanding metal products is not always done with electric tools. Craftsmen often use various types of files for such work. They are much safer than electrical equipment. The worker can choose from a wide variety of tools the one that suits the material being processed. It’s not difficult to cope with this if you know the intricacies of the work, all types of files and their purpose.

Proper processing

The initial processing of the knife blade is performed with any available tool. Sharpening a knife from a file can be done on a grinding machine, which will speed up the process and make the blade more uniform across the plane. The initial sharpening does not require ideal parameters, since the etching process occurs after it.

Etching the blade in citric acid

Etching occurs chemically using ferric chloride, which can be purchased at radio components or hardware stores. It is necessary to completely lubricate the product with the solution, or lower it into a flat container with it. The process will give the blade a film formed on the blade, which will provide protection and it is highly not recommended to remove it. At home, you can use citric acid mixed with vinegar for etching.

What is a file?

This tool is a product consisting of two parts:

- Steel bar. Notches are applied to its surface using special patterns. They may have several options. The most common types of file cuts are rectangular, triangular and round.

- Wooden or plastic handle. With the help of a clamping ring that prevents it from cracking, it is mounted on a cone-shaped shank. Designed for ease of use of the file. If the handle breaks, it is easy to replace. Beech, birch and pressed paper are used to produce the part. Its length must be one and a half times longer than the file shank.

The tool can have different sizes. Standard lengths are 9, 10, 11, 12, 13 and 14 cm. Diameters: 12, 16, 20, 23, 25 and 28 mm.

Materials

To produce this tool, very hard, high-quality tool steel is used:

- Brands ШХ15 or 13Х. This is alloy chromium steel.

- U10A or U13A. These grades are improved unalloyed.

The files are processed by hardening, resulting in a hardness of 54-58 HRC. These grades are used for the production of files intended for working with metal products. For wooden and other materials, tools are taken whose steel is softer.

What kind of steel are files made of in the USSR?

Every craftsman needs a high-quality knife; it is possible to make a good knife at home. In the last century, when there was a shortage of knives, cutting tools were made from scrap parts. A file is made of hard metals that can withstand increased loads; it is from this tool that a knife is made.

Single cut tool

This notch (also called simple) is found in special files. The purpose of such a tool is to remove a small layer of metal during filing. Special files are used for processing narrow surfaces. They are convenient for sharpening wood saws. These products are designed to work with soft metals, wood and plastics.

Firing the workpiece

The files are made from U10 steel, which is enriched with carbon; a file made from this steel is fragile and can easily crack under load. In order for the metal to be hard and not crumble when struck, it must be hardened. Usually the procedure is carried out in a special oven, the temperature of which reaches 700 °C.

To harden a knife made from a file, which you made yourself, you can use a regular gas stove.

The combustion temperature on the stove is not high, reaching no more than 300 degrees. To achieve the required heat, you need to use a kind of screen. In the absence of a special thermometer, you can use ordinary table salt, its melting point is equal to the hardening of knife steel.

Hardening of the file is necessary only in the cutting part. Checking for uniform hardening occurs visually; after reaching the temperature, the knife should be uniformly reddish in color. The product must be kept at maximum temperatures for at least 4 hours. Cooling is done smoothly; if you cool the part right away, it will simply crack. Cooling of the part occurs through a gradual decrease in temperature; heating decreases every hour by a quarter of its initial intensity.

Files for metal. Kinds

GOST 1465-59 are the standards that are relied upon in the production of metalworker’s files. Depending on the size of the notches and their number per 10 mm of surface, the following tools differ:

- Drachevye. Tools with large notches. There are up to 5-12 of them on a 10 mm file surface. The smaller the number of notches, the larger the teeth. Consequently, more particles are removed when filing the product.

- Personal. Presented with products with a medium notch. The number of teeth is up to 25 pieces.

- Velvet. These are the instruments with the finest notches. There are 80 teeth per 10 mm surface.

Read also: Tool for measuring internal and external threads

For convenience when choosing the necessary tool, the types of files have their own numbers: quarrel files - No. 1, personal files - No. 2, velvet files - No. 3-6.

Classification of tools by shape

The processed parts have different shapes. To effectively work with such products, appropriate types of files are provided. They differ from each other in profile shape (cross section). The following types of files are distinguished:

- flat;

- square;

- trihedral;

- round;

- semicircular;

- special;

- knife-shaped or hacksaw;

- diamond-shaped;

- oval file.

What types of instruments there are are briefly outlined above. What are they for?

Stage 1: determination of steel grade

Having selected used tools (needles, files, rasps, braids, etc.), first of all you should determine what grade of steel they are made of. To keep your search as limited as possible, you should know what types of steel a particular tool is made from. Thus, files can be made of both tool carbon steel (U10, U11, U12, U13) and alloy steel (ShKh6, ShKh9, ShKh15). You can learn more about this from the list of tools below. The files presented in the KovkaPRO assortment are made of high-alloy steel with a hardness of 64-66HRC

Read also: Leifeld rotary drawing machine

Products made of tool and alloy steel:

Files – U10, U11, U12, U13, ШХ6, ШХ9, ШХ15 Needles – U10, U11, U12 Rasps – U7, U7A Scrapers – U10, U12 Chisels, chisels – U7, U8 Taps – U10, U11, U12, P9, 9ХС , Р18 Wood drills – 9ХС Metal drills – Р9, Р18 Reamers – Р9, Р18, 9ХС Mills – Р9, Р18 Chisels, screwdrivers – У7А, У8А, 7ХФ, 8ХФ Punches – У8, У8А Punch punches – У7А, 7ХФ, 8ХФ Sewing needles - U7A, U8A Hacksaw saws - U8GA Bow saw blades - U8GA, U10 Hacksaw blades - U8, U8A, U9, U9A, U10, U10A, U11, U12 Metal shears - U12A Hammers and sledgehammers - U7, U8 Axes - U7 Scythes, sickles – U7, U8 Forks, teeth (peckers) – U7, U8 rake Blacksmith tools – U7, U8

Purpose

A flat file is used to work on convex and flat external or internal surfaces. Square is used to work with square and rectangular holes and grooves. This tool is also called a whetstone. Its length is 35-50 cm. It is effective in cases where it is necessary to remove a layer of metal exceeding 1 mm. The triangular file is used when working on internal corners, grooves, holes and grooves. Round is necessary for filing concave surfaces. Used for working with round and oval holes.

Special files are used for processing corners, inclined and jagged surfaces. This type of tool produces narrow grooves and grooves. Brushing tools are equipped with the largest teeth and are intended for initial surface treatment, as they allow you to quickly remove a large layer (0.05-0.1 mm) from it. At the same time, these files have low accuracy. As a result, the working surface is processed roughly. Personal files are used for finishing filing. In this case, a layer 0.02-0.06 mm thick is removed. Velvet ones are used in the final grinding phase. The thinnest layer (0.01-0.03 mm) is removed from the surface of the sawn product. These files have high processing accuracy, which is 0.01-0.005 mm.

How to harden a knife from a file

After firing, you can begin to form the future product. The workpiece is secured in a vice, the parts are processed with a grinder and all excess slag and layers of metal are removed. The sharpening machine is used with a coarse-grained abrasive wheel. The degree and shape of sharpening is carried out according to the prepared sketch. On the handle compartment you need to drill one or two holes to attach the handle.

After the tool is hardened from the file, it is necessary to treat the entire surface except the handle. A burner can be a tool for hardening, since the temperature is higher and the knife will harden faster. Uniform tempering of a knife from a file will give strength to the future product. The correct hardening of a knife made from a file can be determined with a magnet; if there is no reaction with the metal, then it is suitable for further use. After the process, the metal needs to be cooled, just put it in a bucket of water.

File knife and drawing for it

There is such a thing as metal stress. With this action, the metal crumbles and crumbles. To avoid adverse consequences, it is necessary to heat the instrument in the oven at the maximum temperature for several hours.

Rasp

In addition to metalworking files, rasps, which are distinguished by their notches, are used for processing metal and other surfaces. Their teeth are large and shaped like pyramids, behind which there are special grooves. The section on this tool is placed in rows, perpendicular to the axis. Rasps are used when processing soft materials: aluminum and duralumin. Manufactured from steel grades U7A, U10A. Their hardness is 35-40 HRC. Standard length of tools: from 25 to 35 cm. Rasps come in four types: blunt-nosed flat, pointed-nosed flat, round, semicircular. The scope of application of the tool is medicine and the production of tin products.

General characteristics of a homemade knife

Knowing what kind of steel files are made from, it becomes clear why they are used to make knives. The material used is high-carbon steel of such grades as U10A, Kh12M, ShKh15. Due to its high carbon content, this material can be hardened to 64-66 Rockwell units. This provides it with sufficient hardness . That is why at home they make a knife from a file. A high-quality homemade knife can be made from:

- A thick drill for metal. It should be taken into account that the hardened part is only working. The shank is raw.

- Engine piston connecting rod.

- Socket wrench.

- Springs.

- File.

When making fincas on a professional basis, all these things are pre-forged. It is especially convenient to forge a file that has a suitable shape for this. During the forging process, the metal acquires the desired properties and becomes more elastic.

The thickness of the file is such that it requires removal of a layer of metal in order to properly form the bevel. During forging, the metal is not removed, it takes on a different shape. In order to forge a workpiece it will take much less time than when making it on a machine.

Files

Needle files are the smallest files. Designed to perform very precise work. For the production of these tools, steel grades U12 and U12A with a hardness of 54-60 HRC are used. Depending on the cross-sectional shape, needle files are:

- flat (blunt-nosed and pointed-nosed);

- square;

- triangular;

- round and semicircular;

- oval;

- diamond shaped;

- groove and hacksaw.

A DIYer does not need to have every type of file. It is enough to have three main ones - flat, triangular and round. It is also advisable to have a set of needle files and several rasps. With these tools, you can easily cope with any task related to metal grinding.

Making the handle

Before making a handle for a product, you should decide on the appearance, materials and shape. You can use any material that is at hand. A wooden handle is considered a harmonious option.

File knife handle

The process includes several stages:

- Selection of materials, it is possible to use different types of wood for a unique design.

- It is necessary to make a bolster, the lower part of the knife. The remainder of a file or other metal is used.

- Wooden pieces are placed on top of each other and glued together with epoxy glue.

- To glue the pieces together better and faster, you need to use a press.

- The excess parts are trimmed with a saw, after which they are processed with sandpaper to the required shape.

- When finished, the handle is varnished for greater preservation; it is possible to use stain to darken it.

It is important to understand that all knives, regardless of category, are considered edged weapons. However, a cutting product whose blade length is no more than 90 cm and whose thickness is more than 6 mm can be removed from the category of edged weapons.

Sharpening is done in the usual way on a grinding machine.

The handle can be made of leather, deer antler or other materials. Installation depends on the form; each type requires an individual approach. The leather belt is tightly placed over the handle area, glued with special glue.