Hi all. I want to share an interesting selection of designs for forging. I am constantly in search of all kinds of patterns and ornaments. And then one day I came across such a collection. I don’t do much ironwork myself, but I also liked the designs and solutions for various products. Please note that the pictures and drawings are in vector format, that is, you can’t just look at them; to view and work you need a vector program, a vector graphics editor such as CorelDRAW, Adobe Illustrator. It’s more convenient and easier for me to work in Korel. The fact that the drawings are vector makes it possible to work with them and change anything. You can also enlarge the drawing to real size without losing quality and print elements in natural size. You can download it from this link from Yandex disk

There are about two dozen folders in this folder and each contains a hundred pictures, a total of 212 MB.

A few pictures to understand what is there...

There are about two dozen folders in this folder and each contains a hundred drawings. 212 MB. You can download it from this link from the Yandex disk yadi.sk/d/4FTfpT3-3R54xG

This collection was found on the Internet without copyright and is posted “as is”

A beautiful entrance to the yard will emphasize the good taste of the owner, and the site will become recognizable. Patterns on metal gates will make the fence elegant and unique. They are applied in various ways, from paintings on self-adhesive film to drawings with a brush. Craftsmen working with metal use forging elements and turn the gate into a masterpiece. Any pattern made by yourself will look unique.

Products: gates, benches and others

Cold forging technology is ideally suited for the production of large-scale products , i.e. differing in medium and large sizes. This is due to the fact that it takes a blacksmith a lot of time , which ultimately negatively affects the final cost of the item .

To work with metal using cold technology, equipment is used that reduces labor costs and saves time , which guarantees affordable solutions. Thus, the cold forging method most often produces:

- gates, fences and gates;

Transparent fence, cold forging. Photo Integral

- fencing;

Wrought iron lawn fencing. Company Favorit

- awnings and canopies;

- porch;

- benches and benches;

- stairs and other products.

Basic patterns

Since iron can change shape during heat and physical treatment, there are various examples of forged patterns. All of them can be divided into three main groups:

Undoubtedly, the most popular of them are floral forged ornaments. The artful interweaving of branches, flowers and leaves has always inspired artists to create fantastic works. Blacksmiths are no exception in this series. They also often use plant motifs in their work.

For cold working, metal rods are most often used as the main material. They are bent, twisted, flattened, minted, milled and forged. The end result is magnificent works. Here are the main elements and techniques for this type of metal work:

- Curls. The most popular element. It has a huge number of different options and modifications.

- Spirals. Single, double, spatial and others. This is also a very popular technique that makes patterns for forged products memorable and original.

- Cool. Twisting iron bars can be the most incredible experience. The imagination of some authors is amazing.

- Top. A decorative insert or special atypical treatment of the ends of the rods can greatly diversify and decorate any ornament.

- Coinage. The use of chisels and hammers for decorative inserts in forging patterns is a long-proven and often used way to add creativity to a future creation.

- Headings. Cylindrical, cone-shaped, spherical elements made of rolled metal, attached to the end of a rod.

These are not all the techniques in the arsenal of a good master. By skillfully combining them, craftsmen create real masterpieces from ordinary iron.

Elements

Cold forging also produces elements of various shapes and sizes. Often, to manufacture or decorate a metal object, a large number of identical parts . In such cases, the cold method is the best solution.

Overlay, stamping. Photo ArtMetal

The workpieces are given the desired shape through bending and pressing . Such decorative elements, called stamped ones, are characterized by low cost and standard design . However, with their help it is possible to assemble (weld) interesting compositions that perfectly complement various products.

Equipment

To process metal workpieces, equipment of various technical characteristics, as well as tools and devices, is used.

The most popular among craftsmen are manual machines for cold forging: snail, twister, wave, globe, bend . Each of these mechanisms is designed for the manufacture of certain elements and bending of workpieces with a cross-section of specific shapes. For example, a device for forging profile pipes is especially in demand among performers, since the frame of many products and structures is made from this material.

Snail-type machine PROMA, Photo VseInstrumenty.ru

The machines do not have a complex structure, so such devices are often assembled independently. Depending on the needs, the performer produces with his own hands a snail for curls, a torsion bar for twisting strips and rods, a globe for bending volumetric parts, etc.

Machines with electric drives are characterized by greater productivity, which makes it possible to produce a fairly significant number of elements. Therefore, such devices are used in production in small companies . Electric machines are also often assembled by hand.

Globe (volumetric) machine for cold forging. Photo ForgingPRO

However, not all craftsmen have the free time necessary to independently produce machines. Some performers do not have enough knowledge to assemble devices with their own hands. In such cases, it is better to purchase a factory-made mechanism: with manual or automatic control, a snail or other machines.

Universal equipment has an even greater degree of automation - units with manual (lever) control or installations supplemented by a control panel.

Universal forging machine Blacksmith UNV2. Photo VseInstruments.ru

Tools and devices, among which conductors are especially in demand, are hand-held objects and mechanisms, respectively, which in most cases are produced independently.

The availability of equipment, tools and devices allows you to produce cold forging products with your own hands, without turning to specialists for help.

History of the forge: description of cold forging

Forging is a process of processing metal to give it the desired shape, turning a blank (blank) into a product. For people who are unfamiliar with the peculiarities of metal work, the word “forged” is associated with a forge, where a blank is heated from 800 to 1000 ° C and processed with a hammer to give shape. But in everyday life, items made by cold forging are more often used. Pots, teapots, patterns on gates and doors, metal stands are made by deforming metal under pressure without preheating.

Beautiful forged elements can be created even at home without the presence of special expensive equipment

Cold forging is an easier, safer and more ergonomic processing method than hot forging. Main advantages:

- equipment for cold metal forging is cheap and ergonomic;

- low labor intensity;

- quick job training, low qualification requirements;

- the ability to create a unique ornament from basic elements.

The downside is the limited working surfaces and materials: rods, sheets and plates.

Cold forging is one of the ancient methods of metal processing

Hand-made cold forging is historically older than hot forging. The first products were discovered in Egypt and Mesopotamia and date back to the 4th-3rd millennium BC. Initially, ore was used, which was deformable after being hit by a stone. Cold forging was used to make gold jewelry. Soft metal was easy to process with stone hammers. The oldest product was found in Egypt, it was made 8 thousand years ago.

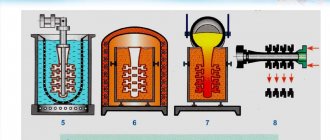

Several centuries later, by observing volcanoes, people learned that high temperatures made it much easier to shape metals. They began to build blast furnaces and the profession of a blacksmith appeared. The Stone Age gave way to the Iron Age, and not only jewelry, but also dishes, weapons, and garden tools entered people’s lives. The principle of operation of the forge is still preserved, but the equipment for cold forging has been modernized.

Using modern equipment you can create products with a large number of forged elements

Basic tools for cold forging at home

The creation of a unique product always begins with material calculations and the development of a detailed work plan. The easiest way to think through the moves is to create scale sketches of forged products, write down the dimensions and select the necessary tools. The choice of material deserves special attention. The metal should be strong, but bend easily.

Important! Hardened sheets or rods cannot be used. Under the influence of temperature changes, the structure of the metal changes, it becomes brittle and can break under pressure.

There are two types of do-it-yourself metal forging - rolling (working with rods) and stamping (extruding sheets under a press). At home, the first option is more often used. To press sheets, you need to make a special blank for deformation. Common rolling tools: bender, snail, twister, wave and flashlight.

Cold forged elements can be used to decorate stairs

A bender is a basic tool used for bending rods at different angles. The spiral elements of cold forging are twisted using a snail. For shaping, it is best to choose rods with a diameter of 10-12 mm. Choosing a material that is too thick can significantly complicate the work of the master.

A twister machine is used to twist rods along the longitudinal axis. The wave, accordingly, is intended to create wave-like elements. The flashlight tool is used to work with several rods at once. They are installed on the equipment and bent by rotating the lever.

Where to buy, order

Cold forging products made by professionals are of higher quality and reliability. You can purchase a finished item from employees of companies present in the “Where to buy or order forged products” section. Specialists offer various design solutions for interior, building architecture and landscape.

Buyers of companies that are presented in the “Where to buy forged elements” section are most in demand for stamped leaves, volutes, curls, overlays and other parts.