Hook bender. Strip bending. Bending bracket. These are all names of a tool that can be used to bend a metal strip or gutter holder.

You can buy an industrial prototype of a bending bracket for 3-5 thousand rubles. and higher. For those who do not want to spend money on factory tools, we offer options for inexpensive homemade strip benders.

Homemade tool for bending hooks for a drainage system

I installed a drainage system on awnings. To do this, I bought metal holders for the gutter, which are made of good steel. First I bent the hooks in a vice. Inconvenient. Do not really clamp the workpiece. I started looking for a tool for bending strips to attach the drain. Prices start from 1500 rubles. and more expensive. I thought about it and made my own bracket bender for bending the metal gutter holders.

Instructions for making a hook bender for a drainage system:

A homemade bracket for a drain is made as follows:

The paint on the bracket is cracking a little where it bends, but the quality of the hook doesn't compare to bending a metal strip with a vice.

How to make a round bender with your own hands

When working with tin, two main tools are used. Metal shears and sheet bending machine.

Of course, when making a gutter for the roof of a barn, you can use the old-fashioned method - tap a galvanized sheet with a mallet on the edge of a workbench, or using a metal corner.

Examples of such work can be seen on roofing in the private sector. However, the quality of the product leaves much to be desired, and the metal is damaged at the point of impact.

In addition, artisanal bending of metal is suitable only for simple structures. If the bending profile has several multidirectional edges, you cannot do without a professional tool.

For example, the correct ridge for a roof “on the knee” cannot be bent, and its appearance will always remind you of the owner’s negligence.

Buying an industrial sheet bending machine is an unforgivable luxury. The craftsman is afraid of the work - we will tell you how to make such a useful device in a private household with your own hands.

Roller

The second name is three-roll. The machine is used to create smooth bent surfaces - large-diameter pipes, semicircular drains and other structures without sharp corners. It works on the principle of a rolling machine. The sheet is profiled between two support rollers and one thrust roller, the movement of which sets the bending radius of the workpiece.

Press brake

The workpiece is placed between two punches (templates), under great pressure they close, giving the required shape to the sheet of metal. Typically used for working with thick workpieces. Useless for household use.

Traverse mechanism

The principle of operation of the design is that the workpiece is clamped with a clamping ruler, and a movable traverse bends the edge to the desired angle. Perhaps the most popular type of sheet bending machine.

There are both industrial stationary machines and manual tabletop devices. In fact, it has no restrictions on the bend angle - from 0 to 180 degrees. The width of the processed sheet is determined by the length of the traverse.

This is the only design flaw. It will be problematic to bend a single rolled strip several meters long at home. But you can quickly make a composite structure of any length with bends for merging the ends.

With traverse structures, a bending knife is often used, which is included in the delivery package.

Roller-type end knives are designed for high-quality alignment of the edge of the workpiece.

Roller bending machine

It would be more correct to call it a manual end bender. Although, using a roller mechanism, you can bend workpieces far from the edge. The process is simply too inconvenient. Mainly used as an auxiliary device.

How to make a homemade sheet bender

The simplest design is to clamp the edge of the sheet between a steel corner and a rule (or two corners) using a clamp, and bend the workpiece by hand. This is how the simplest roofing elements are usually created.

However, it is quite possible to make a traverse sheet bending machine yourself. Precision markings and patience are required.

The design and operating principle are visible in the drawings.

Let's look at the assembly step by step.

To make a traverse sheet bender we will need:

- 4 meters of steel angle, side – 50 mm;

- Ball joint for car, with mounting bracket;

- The stabilizer rod is from the same, with a diameter of 10 mm;

- Grinder, drill, electric welding.

We cut the corner with a grinder into 1 meter pieces.

If there is a need to work with metal of a larger width, the length of the corners increases. At least 100 mm must be added to the width of the working surface. Using an angle grinder, we cut out two eyes from the ball joint bracket. These will be the working loops of the movable traverse.

From the stabilizer strut we make an axis on which the hinges will rest.

We carefully measure and mark a sample on the corner for attaching the axle.

We grind the flats strictly to size to install the axle shafts. This must be done as accurately as possible so as not to waste time and material on subsequent adjustments.

We apply the markings exactly in the center of the axis, and combine it with the top of the corner - the traverse. This point is important. because if the alignment is incorrect, the quality of the workpiece bending on the machine will deteriorate, or the sheet bender will be unsuitable for work.

We weld the axle shafts to the samples, maintaining parallelism to the top of the angle. To increase accuracy, you should use a jig when welding. For example, a vice and a clamp. The length of the protruding part of the axis does not exceed 1 cm.

The result should be a structure with perfect alignment at the ends.

Place the corners next to each other.

We mark the sample on the second corner strictly opposite the axes of the first corner.

The angles relative to each other should be located as follows:

We fold both traverses, keeping them flat, and fix them for welding. We weld the loops onto the second corner on both sides.

The corners should rotate freely relative to each other on their hinges. When turning 180 degrees there should be no snags or wedging. In this case, the gap between the traverses should be minimal.

The clamping angle will be positioned as follows:

Having previously marked, we use a grinder to cut out a sample around the axis on the clamping angle.

The lower side of the clamping angle is ground at an angle of 45 degrees.

Opposite the axes, mark and drill holes for 10 mm bolts. We weld the bolts with the threads up to the lower fixed cross-beam.

We also make a hole in the center of the traverse, but do not weld the bolt. This will be a removable element, so we weld the short axle to it in a T-shape.

Bolts are needed to press the workpiece to the crossbeam when bending. The central bolt is used when the workpiece has a width that is half that of the traverse. When working with wide workpieces, the bolt is removed.

From a 15-20 mm circle we cut two handles 30 cm long. A thinner rod will not work, since the force on the handles can be significant, and you can simply bend them.

We weld the handles from the bottom of the turning angle (traverse).

Next, we make a bed for the sheet bending machine. We weld the fourth corner to the lower fixed cross-beam on both sides for strength. We drill holes in the frame. The entire structure must be fixed on a stable surface, for example, on a steel workbench.

We screw the sheet bender to the workbench and check the free movement of the movable traverse.

The design allows you to work with iron sheets up to 2 mm thick and 92 cm wide. Bend angles can be selected to any size; the workpiece can be bent either in one direction or in steps. When working with a thick workpiece, the handle is extended with a metal pipe; the strength of the angle is always sufficient.

Do-it-yourself bracket bender is not inferior to the factory one

I needed a bracket bender for work. A factory tool for bending gutter holders costs about 5,000 rubles. I looked at pictures on the Internet and repeated the design.

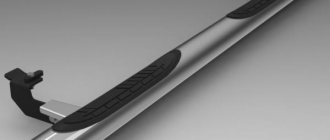

The device of the bracket bender is clearly understood from the photo below.

Tool at work.

According to the user, he bent many gutter hooks using a homemade bracket bender, and the homemade product showed only its best side.

How to fix metal gutters?

Modern metal gutters do not always have mechanical latches, and therefore their parts must be joined by cold welding or using special glue:

Let's look at the technology of fastening metal drains in more detail. So, all the parts necessary to assemble such a system are produced in the factory with high precision, thanks to which you can assemble the elements into a single system yourself and without much effort:

- Step 1. The first thing you need to do is take exact dimensions and make a diagram of the fastening of the future drain to accurately calculate the number of pipes with fastening parts, gutters and brackets, gutter plugs, funnels and their connectors. And purchase all this from a quality manufacturer.

- Step 2. To set the correct slope of the gutter (5.0-10.0 mm is enough), secure the first and last brackets, and then stretch the cord between them. Step 3. Now let's move on to the installation itself. First, we install gutters with the obligatory maintenance of the required slope along the roof slope. Install the mounting brackets around the perimeter of the roof at a distance of 0.50 m.

- Step 4. It will be easier for you to connect several parts of a metal gutter of the same length on the ground using rivets and a special sealant. Close the ends of the gutters that will not drain water tightly with plugs.

- Step 5. Next, install drainpipes, which should be fixed in the required places on the walls. Connect the pipe sections themselves using clamps.

- Step 6. Check the vertical placement of the pipes with a plumb line. metal roof gutters.

- Step 7. Now connect the gutters with pipes and funnels.

- Step 8: Finally, install the bottom drain elbows in the desired direction.

Fashionable copper gutters are attached according to the same principle as conventional steel ones:

But the most difficult thing is installing a drain of complex shape:

Be sure to check the installed drain for reliability and leaks by simply pouring water into it from a garden hose:

Three of the most budget homemade hook benders for drainage

Hook bender. Strip bending. Bending bracket. These are all names of a tool that can be used to bend a metal strip or gutter holder.

You can buy an industrial prototype of a bending bracket for 3-5 thousand rubles. and higher. For those who do not want to spend money on factory tools, we offer options for inexpensive homemade strip benders.

Homemade tool for bending hooks for a drainage system

I installed a drainage system on awnings. To do this, I bought metal holders for the gutter, which are made of good steel. First I bent the hooks in a vice. Inconvenient. Do not really clamp the workpiece. I started looking for a tool for bending strips to attach the drain. Prices start from 1500 rubles. and more expensive. I thought about it and made my own bracket bender for bending the metal gutter holders.

Instructions for making a hook bender for a drainage system:

A homemade bracket for a drain is made as follows:

The paint on the bracket is cracking a little where it bends, but the quality of the hook doesn't compare to bending a metal strip with a vice.

How to choose the right mount?

In total, to secure the drain you will need the following fasteners:

- Brackets on which you will attach the gutters. It will not be difficult for you to choose a suitable mount, based on the shape and dimensions of the purchased gutters.

- Clamps are special devices that allow you to attach drain pipes to the wall. This type of fastening is also selected depending on the type and size of the drain pipes. Also decide on the material for making the clamps: if it is plastic, then it has two attachment points, while metal ones have one, long hardware.

On sale you will find two types of hooks:

- The long ones are attached to the sheathing, to the rafter legs.

- Short ones - to the front board, according to the original plan or due to the fact that the roof is already installed.

The distance between the hooks should ideally be about 50 cm, maximum 60 cm. If you use long hook holders, it is better to screw them through the sheathing directly to the rafters, then the fastening of the drainage system itself will be more durable.

Upon completion of installation, both long and short hooks from above must be covered with a curtain rod.

Of course, according to all instructions, long hooks must be attached under the roofing directly to the sheathing. But there are often situations where it is not so easy to remove the old roofing covering, just as it is not possible to lift it up.

For example, it is old, so such hooks are often screwed even onto the hem of the cornice. Despite the illogicality of this method, in practice it often turns out to be rational and sometimes the only possible one.

Basically, according to the rules, metal hooks are used for metal drains, and plastic hooks for plastic ones. Today, copper hooks are rarely, but still used:

Do-it-yourself bracket bender is not inferior to the factory one

I needed a bracket bender for work. A factory tool for bending gutter holders costs about 5,000 rubles. I looked at pictures on the Internet and repeated the design.

Homemade bracket bender

The device of the bracket bender is clearly understood from the photo below.

Tool at work.

Homemade hook bender in five minutes and three kopecks

And this is the most budget-friendly and simplest version of a bending bracket, which was made by a portal user with the nickname Avalex.

To make the tool you needed:

Tool at work.

There is a topic on the portal that tells how to make an arched profile bender without a lathe.

On the topic of homemade tools, we recommend the articles: How to modify a garden wheelbarrow for transporting heavy loads and make a sawing table for a circular saw and a cyclone from a vacuum cleaner, DIY mini-forge: the most budget option and How to make your own device for bending reinforcement.

The video shows how to set up a workshop and the necessary set of tools for a self-builder.

Source

How to fix the gutter yourself?

When installing any drainage system, it is extremely important to take into account the thermal movement of the gutter and its structural elements, which, depending on the material of manufacture, work differently in tension and contraction.

According to the rules, the only movable such element should be a hinged complaint, which is mounted without additional gluing - only on a latch. Moreover, modern manufacturers take care of this by making a special, so-called expansion mark inside the gutter, which helps to assemble in accordance with the air temperature at the time of installation.

Here's how to properly attach a gutter directly to an eaves overhang:

Types of sheet benders

There are three types of sheet metal bending machines:

For bending sheet metal

To obtain radial bending of a metal sheet

All these devices are classified as sheet bending machines. The easiest way to make one with your own hands is the unit of the first group, a little more difficult - the third (rollers for sheet metal). So we’ll talk about them - from how to make a sheet bending machine with your own hands.

Simple manual

Shaped metal parts cost a lot of money. Even more than corrugated sheeting or metal tiles, therefore it makes sense to make a simple machine for bending sheet metal, and with its help make as many corners, ebbs and other similar parts as you need, and exclusively to your own dimensions.

If you're worried about appearance, you shouldn't be. On sale today there is sheet metal not only galvanized, but also painted. In all designs, the sheet is fixed tightly, so that when working it does not slide on the table, which means that the paint does not rub off or get scratched. It is also not damaged in places of bending. So the products will look quite decent. If you try, they will look even better than what they sell on the market.

Powerful sheet bending machine from brands

This sheet bending machine will require a flat surface (table), preferably metal, three corners with a shelf width of at least 45 mm, and a metal thickness of at least 3 mm. If you plan to bend long workpieces (more than a meter), it is advisable to take wider shelves and thicker metal. You can use brands, but this is for bending metal sheets of large thickness and length.

You will also need metal door hinges (two pieces), two large diameter screws (10-20 mm), wings on them, and a spring. You will also need a welding machine - weld the hinges and make holes (or a drill with a metal drill bit).

Where is edge bender used?

The device has found application in many areas of industry. In particular, it can be used to form seams in roofing iron, air ducts, and prepare product edges for welded joints. Today, car repair is given one of the first places in the use of the device, since cars are becoming the most popular among the population every year.

The principle of operation of the device is simple, it is enough to set the required width of the edge bending, then, between two rollers rotating towards each other, place the section of metal being processed and a bend will gradually form with translational movements. Therefore, doing the edge bending yourself will not be difficult. A mechanical hole puncher-edge bender allows you to make holes with a higher degree of quality than when drilling with a drill.

Sheet metal rollers or roller bender

This type of sheet bending machine can have three types of drive:

They make rollers for sheet metal with manual or electric drive with their own hands. Manual ones have 3 shafts, electric ones can have 3-4, but usually there are also three.

This machine needs a good solid foundation. This could be a separate bed or some kind of workbench or table. The basis of the structure is rolls. They are made the same size. The two lower ones are installed permanently, the upper one is movable, so that in the lower position it is located between the rollers. By changing the distance between the lower rollers and the upper one, the radius of curvature changes.

The machine is set in motion using a handle attached to one of the shafts. Then the torque is transmitted to other rollers through sprockets. They are selected so that the rotation speed is the same.

Hook benders and bracket benders

This personal data processing policy has been drawn up in accordance with the requirements of the Federal Law of July 27, 2006. No. 152-FZ “On Personal Data” and determines the procedure for processing personal data and measures to ensure the security of personal data taken by Stanko Format (hereinafter referred to as the Operator). 1.1.

The operator sets as its most important goal and condition for carrying out its activities the observance of the rights and freedoms of man and citizen when processing his personal data, including the protection of the rights to privacy, personal and family secrets.1.2.

This Operator’s policy regarding the processing of personal data (hereinafter referred to as the Policy) applies to all information that the Operator can obtain about visitors to the website https://stanko-f.ru.

Basic concepts used in the Policy

2.1. Automated processing of personal data – processing of personal data using computer technology; 2.2. Blocking of personal data – temporary cessation of processing of personal data (except for cases where processing is necessary to clarify personal data); 2.3.

Website – a collection of graphic and information materials, as well as computer programs and databases that ensure their availability on the Internet at the network address https://stanko-f.ru; 2.4. Information system of personal data - a set of personal data contained in databases, and information technologies and technical means that ensure their processing; 2.5.

Depersonalization of personal data - actions as a result of which it is impossible to determine without the use of additional information the ownership of personal data to a specific User or other subject of personal data; 2.6.

Processing of personal data – any action (operation) or set of actions (operations) performed using automation tools or without the use of such means with personal data, including collection, recording, systematization, accumulation, storage, clarification (updating, changing), extraction, use, transfer (distribution, provision, access), depersonalization, blocking, deletion, destruction of personal data;2.7. Operator - a state body, municipal body, legal or natural person, independently or jointly with other persons organizing and (or) carrying out the processing of personal data, as well as determining the purposes of processing personal data, the composition of personal data to be processed, actions (operations) performed with personal data;2.8. Personal data – any information relating directly or indirectly to a specific or identified User of the website https://stanko-f.ru;2.9. User – any visitor to the website https://stanko-f.ru;2.10. Providing personal data – actions aimed at disclosing personal data to a certain person or a certain circle of persons; 2.11. Dissemination of personal data - any actions aimed at disclosing personal data to an indefinite number of persons (transfer of personal data) or familiarizing with personal data to an unlimited number of persons, including the publication of personal data in the media, posting in information and telecommunication networks or providing access to personal data in any other way; 2.12. Cross-border transfer of personal data – transfer of personal data to the territory of a foreign state to an authority of a foreign state, a foreign individual or a foreign legal entity; 2.13. Destruction of personal data – any actions as a result of which personal data are destroyed irrevocably with the impossibility of further restoration of the content of personal data in the personal data information system and (or) the material media of personal data are destroyed.

The Operator may process the following personal data of the User

3.1. Email address;3.2. Telephone numbers;3.3. The site also collects and processes anonymized data about visitors (including cookies) using Internet statistics services (Yandex Metrica and Google Analytics and others). 3.4. The above data below in the text of the Policy are united by the general concept of Personal Data.

Purposes of processing personal data

4.1. The purpose of processing the User’s personal data is to inform the User by sending emails.4.2. The Operator also has the right to send notifications to the User about new products and services, special offers and various events.

The User can always refuse to receive information messages by sending the Operator a letter to the email address [email protected] with the note “Refusal of notifications about new products and services and special offers.”4.3.

Anonymized data of Users, collected using Internet statistics services, serves to collect information about the actions of Users on the site, improve the quality of the site and its content.

Legal grounds for processing personal data

5.1. The Operator processes the User’s personal data only if it is filled out and/or sent by the User independently through special forms located on the website https://stanko-f.ru.

By filling out the appropriate forms and/or sending his personal data to the Operator, the User expresses his consent to this Policy.5.2.

The Operator processes anonymized data about the User if this is allowed in the User's browser settings (saving cookies and using JavaScript technology are enabled).

The procedure for collecting, storing, transferring and other types of processing of personal data

The security of personal data processed by the Operator is ensured by implementing legal, organizational and technical measures necessary to fully comply with the requirements of current legislation in the field of personal data protection.6.1.

The operator ensures the safety of personal data and takes all possible measures to prevent access to personal data by unauthorized persons.6.2. The User's personal data will never, under any circumstances, be transferred to third parties, except in cases related to the implementation of current legislation.6.3.

If inaccuracies in personal data are identified, the User can update them independently by sending a notification to the Operator to the Operator's email address marked “Updating personal data.”6.4. The period for processing personal data is unlimited.

The User may at any time withdraw his consent to the processing of personal data by sending a notification to the Operator via email to the Operator's email address [email protected] marked “Withdrawal of consent to the processing of personal data.”

Cross-border transfer of personal data

7.1. Before the start of cross-border transfer of personal data, the operator is obliged to make sure that the foreign state to whose territory it is intended to transfer personal data provides reliable protection of the rights of personal data subjects.7.2.

Cross-border transfer of personal data to the territory of foreign states that do not meet the above requirements can only be carried out if there is written consent of the subject of personal data to the cross-border transfer of his personal data and/or execution of an agreement to which the subject of personal data is a party.

Final provisions

8.1. The user can receive any clarification on issues of interest regarding the processing of his personal data by contacting the Operator via email [email protected]

This document will reflect any changes to the Operator’s personal data processing policy. The policy is valid indefinitely until it is replaced by a new version.8.3.

The current version of the Policy is freely available on the Internet at https://stanko-f.ru.

Homemade tool for bending hooks for a drainage system

alp_rnd User FORUMHOUSE

I installed a drainage system on awnings. To do this, I bought metal holders for the gutter, which are made of good steel. First I bent the hooks in a vice. Inconvenient. Do not really clamp the workpiece. I started looking for a tool for bending strips to attach the drain. Prices start from 1500 rubles. and more expensive. I thought about it and made my own bracket bender for bending the metal gutter holders.

Instructions for making a hook bender for a drainage system:

The required bend angle of the bracket is limited by the height of the stop (angle) welded to the channel.

A homemade bracket for a drain is made as follows:

When bending, the bracket jams the block inserted into the profile pipe, so then we knock out the block with another block from the opposite end of the pipe.

The paint on the bracket is cracking a little where it bends, but the quality of the hook doesn't compare to bending a metal strip with a vice.

Hook bender for drain holders - description, scope and reviews + Video and Photo

Hook bender for gutter holders - description, scope.

For flawless roof installation, you should not use improvised means, but only special roofing tools, and also do not neglect roof installation technology. Typically, most of those who do not have sufficient experience use grinders with abrasives to cut metal tiles, which often only damage the polymer coating, which leads to corrosion and burnout of the metal. These negative consequences in total shorten the service life of the roofing material. To avoid such situations, you should use a number of special roofing tools, but in particular this applies to a hook bender.

Description, principle of operation

When using a hook bender, you will be able to create perfect, identical bends on any number of hooks. Due to this, the drain gutter will be placed on the hooks at right angles, which means that water will not pour out in different directions, as happens with improper installation.

Advantages:

- Identical bend angles for all brackets on the roof.

- Installation speed.

- There is no risk of damage to the brackets.

- You can make bends on the roof or scaffolding.

Do it yourself

Manufacturing instructions:

- Take a corner or channel. The wall thickness must be at least 0.6 cm.

- Using an angle grinder, cut a slot in the workpiece, the length of which should be equal to the width of the bracket. The width of the slot should be the same as the thickness of the hook.

- Take a profile pipe whose inner wall width is greater than the width of the bracket.

- Mark the desired bend location on the gutter brackets.

- Insert the holder into the profile pipe and select a wooden block so that it fits tightly inside the pipe.

As you can see, you can save money and make a disposable tool from available materials. Such a hook bender will help you do everything no worse than with a factory tool, but unlike it, it will not cost you anything.

Do-it-yourself bracket bender is not inferior to the factory one

Alex Nk FORUMHOUSE user

I needed a bracket bender for work. A factory tool for bending gutter holders costs about 5,000 rubles. I looked at pictures on the Internet and repeated the design.

A factory-made bracket bender that can be purchased at a hardware store. Homemade bracket bender

The device of the bracket bender is clearly understood from the photo below.

Such a tool can be made by any home craftsman who owns an angle grinder and an inverter welding machine.

Tool at work.

According to the user, he bent many gutter hooks using a homemade bracket bender, and the homemade product showed only its best side.

How to position the brackets correctly?

At this stage, you will have a completely expected question: how are gutters attached to the roof itself? Hooks for them are mounted to the front board, windshield, to the eaves overhang or directly to the rafters.

Fastenings are installed on rafter legs when there is no front board as such or it is important to leave it untouched for a certain aesthetic effect. But, if the roof is already ready, then the only rational option is to attach the fasteners to the front board:

Sometimes fasteners for the drainage system have to be installed directly to the roof sheathing. For this purpose, special elongated clamps are used, which are fixed at two points. The brackets are attached to the rafters (through the sheathing) only after being pre-bent.

Often home craftsmen try to save money and place the brackets too far from each other, although the distance between the fasteners should not exceed 60 meters. If this rule is not followed, over time the gutters will become deformed and gradually damaged under the pressure of the weight of water, ice and snow.

It is also important to guess the location of the brackets so that they are not too low or too high relative to the edge of the roof. If the hooks are located lower than necessary, rainwater from them will not flow well into the gutter, it will splash and streaks will appear on the facade.

Sometimes such an installation error even leads to breakage and breakage of the fastener itself. It is correct if the gutter protrudes slightly beyond the edge, at least half its width. If the drain is installed too high, then the mechanical pressure on it and its fastenings will be many times greater than normal, and the drainage system itself will have to bear the load of melting snow.

After completing the installation of the fastener, it is important to correctly install and align each hook:

Please also keep in mind that when installing metal tiles, an anti-condensation film with an allowance is also used: