Angle grinder (grinder) AEG 451403 WS 8-115. Photo 220Volt

There are many models of grinders with different technical characteristics . One of the determining factors for the purpose of a power tool is the diameter of the working disk. This parameter is the basis for classifying grinders according to weight and dimensions. One of the groups represents standard sizes related to small angle grinders. Information about this group is in this article.

What is the name of

Actually, the technically correct name for an angle grinder is an angle grinder . Angular because the axis of the working spindle is at right angles to the axis of rotation of the electric motor.

Angle grinder (grinder) EINHELL TE-AG 125 CE. Photo 220Volt

“Bulgarian” is the most common colloquial name for an angle grinder. It came into circulation during the existence of the USSR with the advent of the first samples produced in Bulgaria (hence the name “Bulgarian”). The grinder also has other informal names such as:

- “Fortuna” - after the name of the first models of Bulgarian manufacturers;

- “Turbine” - similar to the sound when working with a functioning aircraft turbine;

- “Flexi” is a common alternative to the name grinder in Europe, derived from the name “Flex” of the first European models, which served as the prototype of an angle grinder.

Micro, mini and small: disk size/diameter, power, how many watts and other characteristics

BOSCH GWS 12-76 V-EC cordless angle grinder (grinder). Photo 220Volt

In practice, manufacturers and trading companies unofficially use the classification of grinders according to the size of the attachments used in their work. Classic angle grinders are divided into small, medium and large. The closest thing to small angle grinders in terms of technical parameters are micro and mini power tools, which have the following values.

- Micro. The disc size of this power tool does not exceed 50 mm. Most often used in precision jewelry and dental practice. The power of a micro angle grinder does not exceed 500 W. In design, most modifications are made without a reduction gear, which distinguishes micro angle grinders with increased working spindle speeds (50 thousand rpm - 70 thousand rpm).

- Mini. These angle grinders are functionally practically no different from the classic versions, the only difference is the compactness of the design. The power of mini-angle grinders is from 0.5 kW to 0.8 kW, the spindle speed reaches 20,000 rpm.

- Small ones. The diameter of the cutting disc on such angle grinders is 115 and 125 mm. Of all the classic versions, grinders have the maximum rotation speed of the working disk - about 12,000 rpm. The optimal power for performing work with small angle grinders ranges from 0.8 kW to 1.3 kW.

Why you can’t install a large disk 150 mm or more

Theoretically, on a small grinder designed to work with a maximum size disc, for example, 125 mm. You can remove the protective cover and install a disk with a diameter of 150 mm. Actually, this very action is already a gross violation of safety regulations , leaving parts of the human body unprotected from sparks and fragments.

Important: there are restrictions on the linear speed of the disk; it should not exceed 80 m/s. A disk with a diameter of 150 mm or more, placed on an angle grinder with a maximum allowable size of 125 mm for safe operation, will have a linear speed of more than 80 m/s, which will entail a sharp increase in vibration and destruction of the attachment.

Purpose, scope of application

The difference between the possibilities of using mini angle grinders and classic angle grinders is associated with the size of the working tool used. Basically it's the same functionality.

- Cutting blanks , the thickness of which, for example, for a circle with a diameter of 75 mm. does not exceed 15 mm. (0.2-0.3 diameter sizes).

- In construction work, it is possible to make a groove size that allows the installation of electrical wiring.

- Cleaning surfaces (grinding, deburring and other similar work) for further technological actions. Bringing surfaces to the required cleanliness using grinding and polishing wheels. This functionality of mini grinders is widely used in auto repair shops.

- Using diamond wheels and various cutters you can sharpen cutting tools.

- After minor modifications to the working spindle and selection of appropriate equipment, a mini-power tool can be suitable for engraving work.

Types of nozzles used: circle 75, 76 mm and more

The types of attachments for mini-grinders differ little in their functional purpose from the working tools of classic grinders. The main difference is the size of the consumables. If cutting wheels with a diameter of 115-125 mm are used on small grinders, then mini grinders use sizes 76 mm (from the manufacturer BOSCH), 75 mm. (from Chinese manufacturers, for example, SKRAB) and other similar sizes.

Angle grinder (grinder) SKRAB 56001. Photo 220Volt

The versatility in the use of mini-grinders increases with the use of grinding, grinding, and polishing wheels suitable for the dimensions of mini-grinders and standard sizes. Various designs of wheels increase the range of processed workpieces , where in addition to metal, concrete, ceramics, plastic and other materials can be processed with high quality.

The possibilities of using mini-angle grinders are increased by equipment in the form of collet clamps. They are inserted into a specially made cavity of the working spindle and serve as a good mount for drills, cutters and burrs for engraving work.

Purpose: on wood, metal and more

Small grinders with a circle of 115 mm. due to the small working surface of the cutting wheel (about 25 mm) and its wear during operation, they are ineffective for cutting workpieces. To a greater extent, such grinders enjoy priority when performing grinding work. Depending on the type of attachments, they can be used to grind a wide range of different materials (metal, glass, wood, porcelain and others).

Angle grinder (grinder) VORTEX USHM-125/900. Photo 220Volt

Angle grinder with a 125 mm wheel. solve a much wider range of problems. Possibility of cutting workpieces with a thickness of about 35 mm. make them indispensable for performing work in domestic conditions. The retail chain has a wide variety of attachments of this size, thereby increasing the number of tasks in relation to various materials that can be solved by a small angle grinder with a 125 mm circle.

Advantages, reviews

The main advantages of small grinders are as follows:

- Light weight allows a small angle grinder to perform any work without strain: at heights, holding the angle grinder suspended with one hand, being in an awkward position, performing other similar actions.

- Compactness in size helps to carry out work in hard-to-reach places where it is impossible to carry out work with angle grinders of medium and large dimensions.

- It will not be difficult for the user to make an accurate cut or create the most effective pressure during grinding

Angle grinder (grinder) Kolner KAG 125/1000 V. Photo 220Volt

There are a lot of reviews on the Internet from users of small grinders. They highlight the above advantages . Among the models that deserve good reviews are those in which the small size of the wheel interacts with the increased power of the electric motor of a small angle grinder.

Features, advantages

Compactness and light weight are the main differences between mini-grinders and ordinary household and professional models of angle grinders. Small workpieces with a small surface to be processed are sometimes impossible to process with conventional grinders. A mini-grinder with a reduced diameter of the working tool and the ability to work without a protective casing allows you to solve the problem of creating comfortable conditions for processing small workpieces . In some cases, bringing the tool into hard-to-reach places is only possible with the help of a mini grinder.

The weight and dimensions do not strain the user ; the hand holds the power tool freely without feeling tired for a long time. Moreover, in most cases there is no need for an additional handle , which requires additional space that is not always available. The hand freely covers the body, without any effort, the optimal position for effective processing is selected.

Grinder ROYCE RDG-500S

Mini-grinders, combined with low weight and overall dimensions, and small size of the working tool, do not have high power . vibration phenomena do not occur during operation which significantly increases the possibility of high-quality performance of high-precision work.

Light weight creates conditions for increasing the mobility of power tools . Using rechargeable batteries as a power source gives even more freedom of use. Working under the ceiling or vice versa in a lying position when processing hard-to-reach places is done without much effort using a mini-grinder with an independent power source.

Battery and other types of manual angle grinders

Depending on the power source, the following types of manual angle grinders are distinguished.

- Electric, the most productive of all types. The disadvantage is the mandatory presence of an electrical network.

- Rechargeable , have an autonomous power source, which increases the possibilities of their use; there is no need for the presence of an electrical network. Battery life increases with the use of brushless (instead of brushed) electric motors, which consume less energy.

Cordless angle grinder Metabo W18 LTX 125 + 3.5 Ah LiHD + charger ASC 55 T0333. Photo VseInstruments.ru

- Small pneumatic angle grinders are used for performing minor repair and installation work in the field, where there is only a mobile compressor.

With speed control, soft start and other functions

Equipping small grinders with additional functionality increases the range of work performed by the same power tool.

Small grinders have high spindle speeds with a working tool. mechanisms with a speed controller on them . In this option, it will be possible to perform high-quality grinding work, cut off low-melting materials, for example, plastic, which are produced at lower speeds, set using the rotation speed controller.

To a lesser extent, small angle grinders require a “soft start” installation , which is effective for high-power angle grinders.

Bulgarian Interskol 125/700. Photo 220Volt

There are many additional options that make working with an angle grinder easier (restart blocking, automatic balancing, protection against overload and dust formation inside the angle grinder body, as well as many others). Providing additional options should not become an end in itself. This leads to an increase in the cost of power tools. You should select only those that are necessary for specific operating conditions.

Safety precautions

Any grinder, including a miniature one, is a very dangerous tool. It is necessary to strictly follow the requirements of the power tool manufacturer, as well as safety regulations.

Basic provisions for safe work.

- Use a protective cover that will protect against fragments of a broken disk. Mini-grinders can, if necessary, perform work without a protective casing. In such cases, it is necessary to install the working tool strictly in accordance with the manufacturer’s instructions and follow the operating rules specified therein.

- Having the skill to work with a mini angle grinder will make it safer.

- The presence of protective equipment in the form of a mask or glasses will prevent sparks from entering.

Popular brands

Manufacturers well-known on the power tool market produce almost any standard size of grinders. Below are examples of some models of small grinders from popular brands among users.

BOSCH GWS 18-125 V-LI

powered model . On one charge it provides maximum cutting performance among other grinders with similar parameters. The special 4-pole design of the electric motor ensures its reliability and long service life. Lightweight, weighing about 2.3 kg, ensures comfortable work with the tool in an overhead position.

Cordless angle grinder Bosch GWS 18-125 V-LI 0.601.93A.30B. Photo VseInstruments.ru

Metabo WEV 10-125 Quick

The power of the model best matches the loads experienced by 125 mm. work tool. Equipped with speed control with stabilization function under variable load. The design includes a quick-release nut for changing attachments .

Angle grinder (grinder) METABO WEV 10-125 Quick 600388000 (in box). Photo 220Volt

AEG WS 13-125 XE

A powerful and at the same time compact model weighing about 2.4 kg. Can be used with one hand. Equipped with a soft start system and speed control from 2800 rpm to 11500 rpm. The absence of vibration during operation, the presence of a quick-release nut, and the simple design of fixing the protective housing (lever system) are additional advantages of this model.

Angle grinder AEG WS13-125XE. Photo VseInstruments.ru

DeWALT DCG414N

Model with battery power supply. According to user reviews, it is distinguished by the power required for operation and reliability. The convenient location of the power button provides additional comfort during operation.

Hitachi G12SR4

The power of the 730 W model is sufficient to work in a 115 mm circle. Equipped with a high-quality dust protection system.

Sparky M850E HD

Small grinder with speed control (3000 rpm - 10000 rpm). a magnesium alloy gearbox in the design of the gearbox reduces the weight of the grinder to 1.7 kg. To increase operating comfort, the package includes an anti-vibration handle.

Angle grinder Sparky M 850E HD. Photo VseInstruments.ru

Bison USHM-115-800 M3

An inexpensive small model (circle diameter 115 mm), light weight (2.4 kg) made in China from a Russian company.

Whirlwind angle grinder 115/650

Despite the low power of the model (650 W), it is quite useful for household and garage work.

Makita 9562 CVH

The 1.2 kW model cuts almost any material with a thickness corresponding to a 125 mm circle. during operation . The model has excellent protection from dirt and dust - you can effectively operate this angle grinder in dusty conditions.

Angle grinder (grinder) MAKITA 9562 CVH. Photo 220Volt

HAMMER USM 1200E

A universal-use model with variable speed control and high power (1200 W) ensuring stable operation of a circle with a diameter of 125 mm.

Interskol angle grinder 125/750

One of the lightest models of small grinders weighing only 1.75 kg. Used when working in hard-to-reach places, it is possible to work confidently with one hand.

How to choose for home and other purposes

Angle grinder AEG 451410 WS13-125XE in operation. Photo 220Volt

The main approach when choosing an angle grinder is that it is selected for specific types of work. The scope of application depends on the following characteristics of the angle grinder.

- First of all, when choosing, you should pay attention to the maximum size of the cutting tool working in tandem with the grinder. If its use is limited to cutting profiles, sheet metal, kitchen ceramic tiles, cleaning rusty surfaces and solving other household and garage problems, then a small grinder will be the best option. To cut thick-walled pipes, channels, beams, concrete structures and other similar work, you should use a grinder of medium and large categories.

- Power. This parameter is directly related to the size of the nozzle. When performing complex long-term work, professional grinders with a large circle size and high power are used. For working in hard-to-reach places, lightweight compact small angle grinders with low power ratings are suitable.

- When choosing cordless angle grinders, the main criterion will be the battery capacity. The higher the capacity, the longer the operating time before recharging. For short-term work, it is enough to use small cordless angle grinders with small batteries and minimal capacity.

- The use of pneumatic angle grinders is associated with the speed of supply of compressed air and, accordingly, with the power of the compressor. For small grinders, an air pressure of about 6 atm and a flow rate of about 100 l/min are sufficient for operation. Large pneumatic machines are effective at delivering up to 540 l/min.

Rating of top models with battery and more, characteristics

There is information on the Internet that, from a huge range of various modifications of grinders, based on expert opinions, contains data on the best, in their opinion, models. It is quite subjective, but you can use it as a starting point when choosing an angle grinder for purchase. According to experts at the TechnoPro store, the following are worth attention among small Bulgarians in 2022.

BOSCH GWS 18-125 S. Power 900 W, circle diameter 125 mm. Weight 1.8 kg, lightweight, can be held with one hand. Low noise level during operation, vibration is practically not felt. The spindle speed is 11,000 rpm, adjustable for high-quality grinding work. It is well suited not only for home work, but also with the appropriate equipment, for example, with a wall chaser attachment, for professionals.

Angle grinder (grinder) BISON UShM-125-950 M3. Photo 220Volt

BISON USHM-125-950 MZ. Unlike the BOSCH model, it has an inexpensive price and a fairly high power of 950 W for the category of small angle grinders. Increased requirements for dust protection guarantee high reliability during operation. Rotation speed 11000 rpm.

Which is better, good options to choose from

Each of the angle grinder models is designed to perform a specific type of work. This is where the classification of angle grinders comes from: household, semi-professional, professional. Therefore, the concept of “the best grinder” is not global. According to a user survey, the following were recognized as the best small angle grinders with a 125 mm circle in 2022:

- BOSCH GWS 9-125 S;

- Metabo WEV 850-125;

- Makita 9565HZ;

- DeWALT DWE4119.

Angle grinder (grinder) BOSCH GWS 9-125 S. Photo 220Volt

Small, mini and micro hand-held angle grinders

Grinders using small-sized consumable tools are classified into the following groups:

- small, with a circle diameter of about 115-125 mm;

- mini-grinders, which use circles with a diameter of about 75 mm;

- micro manual angle grinders, where the working tool does not exceed a diameter of 50 mm.

Small angle grinder (grinder) METABO WEV 850-125, circle diameter – 125 mm. Photo 220Volt

The above classification is not official , but in practice it reflects the real state of affairs, which confirms its use by many reputable manufacturers.

Do it yourself

A small grinder with 115 or 125 mm circles. can be made from an ordinary hand drill . It should immediately be noted that the disadvantages of the homemade product are the low rotation speed of the wheel, which impairs the productivity and quality of the cut. However, in case of an emergency, you can use a small grinder from a drill to saw off some small part.

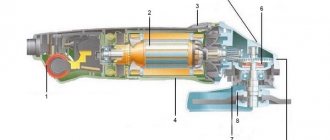

How to disassemble an angle grinder, gearbox, angle grinder head, disassembly process

If the angle grinder has malfunctions that affect stability in operation, it should be diagnosed to identify their causes. To do this, the power tool must be disassembled; you can do this yourself. The disassembly process (separation of the plastic housing from the gearbox) is shown in the following video.

After checking the functionality of the gearbox mechanics, if necessary, it is disassembled and repaired, as shown in the video.

How to change bearings

Wear of the bearing units of the angle grinder leads to increased backlash, which contributes to the failure of the entire angle grinder as a whole. Therefore, a preventive inspection of the angle grinder is required for the presence of play and, if necessary, replacing them as shown in the video.

How to make it yourself, homemade angle grinders from a screwdriver, motor and other options, drawings

The grinder is such a popular tool that many DIYers want to make it with their own hands. The craftsmen find the selection of suitable material from the surrounding auxiliary material. Some options for such creativity are presented below.

Mini grinder made of screws

For such an angle grinder you will need at least an old screwdriver. The following video shows the process of making it yourself from an unnecessary attribute for tightening the fasteners of a mini-grinder for performing simple cutting work.

For normal operation of the angle grinder, you will need to install a battery of the required capacity . The seat is made by modifying the screwdriver body using thermoplastic plastic and epoxy resin.

The performance of a homemade angle grinder is also ensured by the presence of the required spindle rotation speed. The author achieves the required speed by altering the screwdriver gearbox , however, there is no information in the video about how this is done. This requires an engineering approach using calculations and drawings.

After giving it a marketable appearance, a homemade mini grinder made of screws is ready for cutting small profiles, thin-walled pipes and, if there is an urgent need, small-diameter fasteners.

Mini angle grinder using a motor

A motor from an old cassette tape recorder or from a battery-powered toy will do; after all, it can be purchased inexpensively at a specialty store. As a power source, you can use a rechargeable or simple battery , as well as an AC power supply from a mobile phone.

Important: the current and voltage must correspond to the characteristics of the motor.

The procedure for assembling such a mini-power tool using a motor with a homemade cutting disc is shown in the following video.