Toilet paper is an everyday consumer product that is always in demand. Recently, not only large enterprises, but also small private firms that have launched the production of these products are engaged in its production. This business is not afraid of any crises or decrease in demand.

To create an enterprise for the production of this type of product, it is necessary to hire workers, purchase appropriate equipment and establish the process of producing goods. But first of all, you need to understand the basics of such a business.

Types of toilet paper

The range of this type of product is quite wide. The following types of paper are available on sale:

- traditional smooth;

- with various embossing;

- moisturized;

- multilayer;

- flavored.

Toilet paper comes in a variety of colors. Some manufacturers have launched production of products with drawings (crosswords, comics, jokes). The cheapest is ordinary gray paper, the cost of which is the lowest.

These products are also divided into the following types:

- without a sleeve (tight roll);

- with a cardboard sleeve (there is a hole in the roll).

Toilet paper manufacturing technology

semi-automatic machine for the production of toilet paper

Preparation of raw materials: waste paper is cleaned of impurities, crushed and moistened. It is served on a sieve, where small inclusions (glass, paper clips) are sifted out.

Washing of raw materials: the purified mass enters a container, where it is thoroughly washed. The price and quality of the finished product depends on how thoroughly the raw materials are cleaned.

Grinding: The wet raw material is ground into a homogeneous mass and transported to a pressure tank.

Achieving concentration: the mass is poured into a tank, where the required amount of water is added to give the raw material the necessary properties.

Production of roll blanks: the mass is fed in a uniform layer to the paper-making machine. Water flows through the nylon net, and the mass is transported through the net to the drying shaft. It rotates slowly, the mass is dried with steam at +120 degrees. The dried semi-finished product is cut with a scraper-type knife. Almost finished paper is dried and wound onto sleeves.

Rewinding and embossing: The reel is transferred to embossing equipment and rewinding into a long roll. Next, it will be packaged and cut into standard lengths.

Raw materials for production

Waste paper of different categories is used as raw material for the full production cycle:

- white lined paper;

- cardboard;

- book and magazine paper;

- White paper;

- newspapers.

Coated and glossy paper is not suitable as raw material. With the accelerated cycle, ready-made cellulose hygienic raw materials are used. Mini-production brings less profit than a full cycle.

Paperwork

To work legally, you need to register an enterprise. The available form of activity is LLC. Find a suitable premises and sign a lease agreement. In the documents, it is the address of the location of the production facility that will have legal status.

To register a business, please contact the following authorities:

- MFC;

- structures of state power.

Help: to register an LLC, you will need to develop a company charter and open a bank account.

Equipment for the production of toilet paper

The full cycle of manufacturing toilet paper from waste paper involves the use of the following machines:

- paper making machine, which consists of a pulper, an electric generator, a vibrating screen, a mill, a washing device, mixers, and cleaners;

- machine for cutting rolls;

- reel-unwinding equipment;

- packaging machine;

- pasting apparatus;

- machine for making cardboard sleeves.

If you plan a mini-production for processing paper blanks of sanitary-hygienic category, you can limit yourself to:

- rewinding machine;

- cutting;

- packaging

Examples of machines from domestic and imported suppliers

Automated models are presented in Russia:

- ALBP-1 (Nika LLC) - productivity per shift reaches 4 tons, the cost of the equipment is 4 million rubles.

- Omsk "OBM" - 4 employees are needed to service the complex, produces up to 1 ton of products per shift, the price is 1 million 900 thousand rubles.

The domestic market offers many automated lines. When choosing a supplier, an important point is not only the installation of equipment and startup work, but also the possibility of the same company carrying out repair work if necessary.

The Harbin plant produces equipment that produces up to 10 tons of paper every day. Price - 71.6 million rubles.

The most affordable price (24.8 million rubles) is a plant for the production of cardboard. Daily productivity - 20 tons.

The Hong Kong complex (ZS-E-1380) does not have a recycling line for toilet paper from waste paper. It is capable of producing 6 logs in 1 minute, the price of the model is 1 million 750 thousand rubles.

The Japanese have invented a machine that makes toilet paper from office paper waste. She is able to make 1 roll of 40 sheets of A4 paper and water in half an hour.

The price of the machine is 100 thousand dollars.

Production material (recycled materials).

Waste paper is divided into several types:

| Letter designation | Group | Description |

| MS 1 | A - high quality | Raw materials without adhesive tape, drawings, seals, glue, metal components are provided by industrial paper companies |

| MS 2 | Waste with stripes (black and white, varnish), trimmings, rejected products | |

| MS 3 | Documents from the archive, defective printing houses, forms printed on white paper | |

| MS 4 | B - average quality | Catalog and magazine products, books and notebooks without bindings and covers |

| MS 5 | New newspaper waste paper | |

| MS 6 | Newspapers read | |

| MS 7 | Cardboard products |

Do not use glossy or coated paper for recycling.

Sources of raw materials can be: printing houses, publishing houses, offices of large companies, the population, waste paper collection points, installation of containers for collecting paper waste.

Main Characteristics of Rewinding Machine

- The productivity of a full-cycle mini-plant ranges from 1 ton of finished products per day with an efficiency of up to 90%;

- all types of machines work with raw materials with a density from 13 to 40 grams per cubic meter;

- linear speed is about 200 meters per minute;

- water consumption is more than 3 cubic meters per day;

- the maximum number of layers of finished toilet paper is 3;

- most modern machines are equipped with perforation rollers;

- maximum width and diameter of the reel: width varies from 13 to 26 cm, diameter up to 110 cm;

- engine power from 5.5 to 11 kW;

- Three people are needed to operate the mini-plant.

toilet paper production line

Automatic lines for the production of toilet paper are equipped with options to stop movement in the absence of sleeves or breakage of the tape. As well as automatic tape cutting and sleeve loading.

Powerful machines are equipped with pneumatic devices for starting and stopping the perforation mechanism, approaching and removing calendering rollers, and loading the coil.

How to choose the right room, what are the requirements?

Choose a location away from residential areas. Please note the requirements of the sanitary service:

- total area - at least 150 square meters;

- height - from 4 m;

- water supply - with a supply of 3 cubic meters per day;

- sewerage;

- ventilation system;

- heating;

- three-phase electrical wiring, power supply - 300 kW.

Zone the room. Equip a warehouse for finished products and a raw materials warehouse. Designate a staff room and a place where you will store equipment.

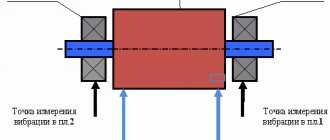

Main characteristics of the rewinding machine

The machine is used to rewind sanitary warps into logs of the required diameter. These are then used to make rolls of toilet paper or paper towels.

A reel with a base is attached to the shaft, which is passed through embossing rollers and wound into a log or onto a cardboard sleeve. The log (a long roll of paper ready to be cut) goes to a cutting machine where rolls are formed for sale.

Characteristics:

- maximum diameter and width of the reel;

- maximum width and diameter of the log;

- mains voltage and frequency;

- power and rotation speed of the electric motor;

- number of electric motors;

- method of changing rotation speed;

- dimensions and weight of the machine.

Using a rewinding machine allows you to achieve the following results:

- softening of finished products;

- more dense winding on the sleeve;

- paper embossing - improves appearance and quality;

- minor defects are removed.

For mini-workshops producing toilet paper from a ready-made base, it is advisable to purchase a reel-unwinding machine complete with a roll-cutting machine.

The first video demonstrates the operation of a semi-automatic line for the production of toilet paper, the second - an automated one:

Revenues and profitability

How soon will the investment pay off?

Experts say that the toilet paper business can be considered promising and profitable. The cost of one roll of paper is about 1.4 rubles. Wholesale price - not less than 4.9 rubles per piece. The net profit per roll is 3.5 rubles.

When working 22 days a month, the enterprise’s income is more than half a million rubles. Net profit - from 200,000.

Payback period is from 6 to 12 months.

Overview of mini-factories on the market

Paper making machine

| Machine type | Steam | Electric | |||

| Productivity | 1.5 t/day | 2 t/day | 1.0 t/day | 1.5 t/day | 2 t/day |

| Power consumption, kW/hour | 35,7 | 39,2 | 160 | 180 | 200 |

| Power consumption (steam), kg/hour | 300 | 300 | — | ||

| Paper speed, m/min | 25-30 | 30-35 | 18 — 35 | ||

| Weight of paper web, g/sq. m | 28 — 34 | ||||

| Width of paper web, mm | 1250 | ||||

Rewinding machine

Tax system and OKVED

The next step is to register for taxes. This can be done at the regional service at the place of registration of the enterprise. If you plan to manufacture and wholesale products, choose a simplified taxation option. In this case, the entrepreneur does not pay the following types of deductions:

- income tax;

- on property;

- VAT.

The available OKVED activity code is 17.1 - production of wood pulp and paper.

Opening a company and necessary permits

For the production of toilet paper, it is preferable to open a legal entity as a form of ownership (for example, LLC). It is more profitable for large suppliers to cooperate with a law firm than with a private entrepreneur. In addition, it is easier for a legal entity to obtain all the necessary certificates and permits.

The approximate cost of registering an LLC will be 10,000 rubles. To open production, you will need to obtain a license, which will cost 140,000 rubles.

The production of toilet paper in Russia is regulated by GOST “R 52354-2005”. To implement it, you will need to issue a sanitary-epidemiological report and a certificate of conformity, for which you will need the following documents:

- certificates for raw materials;

- lease agreement for production space;

- certificate of registration, charter of the enterprise, etc.

COMPLETENESS

| No. | Name | 3 t/day | 4 t/day | 5 t/day |

| 1. | Equipment for preparing waste paper pulp | |||

| 1.1 | Pulper with electric motor (GDV) | 1 | 1 | 1 |

| 1.2 | Submersible pump | 2 | 2 | 2 |

| 1.3 | Disc mill | 1 | 1 | 1 |

| 1.4 | Mass feed pump to headbox | 1 | 1 | 1 |

| 1.5 | Vortex catcher | 2 | 2 | 2 |

| 2. | Paper making machine BDM-PAR | |||

| 2.1 | Headbox | 1 | 1 | 1 |

| 2.2 | Mesh table frame with mesh | 1 | 1 | 1 |

| 2.3 | Press part | 1 | 1 | 1 |

| 2.4 | Bed of cloth part with technical cloth | 1 | 1 | 1 |

| 2.5 | Drying drum with steam and condensate system kit | 1 | 1 | 1 |

| 2.6 | Drying section frame with pneumatic pressure shaft | 1 | 1 | 1 |

| 2.7 | Frequency converter with electric motor | 2 | 2 | 2 |

| 2.8 | Gearbox | 2 | 2 | 2 |

| 2.9 | Device for winding paper into a reel (pneumatic reeling) | 1 | 1 | 1 |

| 2.10 | Vacuum pump with electric motor | 1 | 2 | 2 |

| 2.11 | Connection panel, general | 1 | 1 | 1 |

| 3. | Paper backing processing equipment | |||

| 3.1 | Rewinding machine, format 1700 | 1 | 1 | — |

| 3.2 | Rewinding machine, format 2100 | — | — | 1 |

| 3.3 | Roll cutting machine | 1 | 1 | 1 |

RATIONALE FOR THE CHOICE OF DESIGN

One of the main conditions for the technological process of producing base paper for sanitary purposes is dehydration of the paper pulp and its intensive drying. At a relatively high speed of movement of the newly formed web, it is necessary to evaporate moisture from it in the shortest possible time by interacting with the heated surface of the Yankee cylinders. Electric heating elements are used to heat the Yankee cylinders in this equipment configuration.

Personnel and raw materials

The number of staff depends on the quality and type of your equipment. If all your equipment is automatic, 2-3 people will be enough. If it is semi-automatic or manual, then you must recruit personnel as needed during production.

In addition to workers who will monitor the progress of production, it is also advisable to hire a technologist, accountant, driver, storekeeper and watchman.

It can be waste paper or cellulose:

Waste paper

This is recyclable. It is characterized by a darker color and low cost.

Pulp

This is already high-quality processing. Its peculiarity is the variety of colors and properties.

The weight of a base roll is about 200 kg, and from 15 to 20 tons will be required monthly. Its price can vary from 500 to 1.5 thousand dollars, depending on the quality of the base. You will also need glue, labels and cardboard tubes.

INSTALLATION AND PREPARATION FOR OPERATION

- Before installing the equipment, it is necessary to comply with the requirements for the technical characteristics of the premises specified in clause 3 of this Proposal, as well as ensure the presence of the necessary technological openings in the foundation according to the equipment layout diagram provided by the Supplier.

- Provide exhaust ventilation with local suction of water vapor from the work area.

- The Customer prepares the foundation with the selection of technological openings in the concrete floor for the collection of register water in accordance with the approved layout of the premises by the Supplier. The containers of the paper pulp preparation sections (Tank No. 1, Tank No. 2, pipelines, etc.) are assembled during the installation process by the Customer according to the Supplier’s drawings.

- To secure the frame of the Paper Making Machine in the floor of the production room, make recesses (wells) in accordance with the drawing documentation provided by the Supplier.

- The platform for placing the waste paper preparation tank and the pulper on it is rigidly fixed on supports reinforced with concrete pouring.

- Since paper production involves intense evaporation of moisture and, as a result, increased humidity in the production area, before starting up the equipment, ensure that welds are cleaned and exposed parts of the equipment are painted to prevent premature corrosion of the metal.

- The Supplier undertakes to install the equipment at the Customer’s premises, subject to payment for this service by the Customer.

DEVICE AND PRINCIPLE OF OPERATION

A mini-plant for recycling waste paper and paper waste from printing enterprises is a set of technological equipment that allows the production of toilet paper, consisting of the following main parts.

- Paper pulp preparation equipment

- Paper making equipment

- Equipment for further processing of paper

Technological process It is advisable to load the raw materials into a waste paper preparation container and fill them with water (not a mandatory step; it is possible to immediately immerse the dry raw materials in the pulper). Waste paper (or soggy paper) is transferred to a pulper (GRP), where it is diluted with water and ground, resulting in the formation of a mass of coarse fraction. The resulting mass is dumped by gravity into Tank No. 1 (paper pulp preparation tank), where it is enriched with water and brought to the required concentration. The pump-mill pumps the paper pulp into Tank No. 2 - the tank for preparing the paper pulp, in which it is in constant motion due to the operation of the Pump-mill, which pumps the mass into the Receiver Tank (Constant Flow Box). The paper pulp in both tanks No. 1 and No. 2 is maintained in suspension due to pumping and supply of compressed air into the tanks, discharged by the VVU-3 vacuum pump, which helps to accelerate the process of pulp formation. Excess mass flows by gravity from the Receiver Tank back to Tank No. 2, and the prepared mass flows through one or more vortex traps from the Receiver Tank to the Headbox of the Paper Making Machine, from where to the Mesh Table. Adjustment of the mass supply to the Headbox is carried out using valves located on the nozzles of the Receiver Tank. The mesh table has a constant movement and the paper pulp received on it, distributed evenly across the width of the table, enters the Couch Roll area, where spinning and preliminary calibration take place. During the movement of the mass along the Grid table, excess liquid is separated into the Register Water Collection (Pit). As it accumulates, the liquid is pumped by the Pump into Tank No. 1. After preliminary crimping by the Couch Roll, the paper pulp adheres to the Felt Conveyor, which moves the paper web to the dewatering zone through the Vacuum Dewatering Nozzle and then to the Heating Drum for drying. The released cloth of the first Felt Conveyor is cleaned by means of a Vacuum Cleaning Nozzle and the liquid removed by the Vacuum Pump enters the Paper Pulp Compilation Tank. When moving the paper web along the Heating Drum, the working surface of which has uniform temperature heating, up to 65% of the moisture is evaporated from it (the web). When entering the creping zone, the fabric is separated from the Heating Drum by means of a Scraper Knife and goes to the Drying Cloth. Moving along the drying cloth, the paper web covers up to 50% of the heated surface of the drying drum, through which it acquires output parameters. The finished paper enters the Receiving Device area, where, depending on the configuration of the mini-mill, it is wound into logs or reels of a given diameter. The bobbin obtained from the Paper Making Machine is moved to the bobbin unwinding machine, where it is rewound into logs - these are rolls as wide as a bobbin and with a diameter as a roll of toilet paper. Rewinding on a bobbin-unwinding machine allows you to obtain a denser winding in the roll and emboss the paper. Next, the resulting log is pasted over with a label (which is usually ordered from a printing house), and then cut into rolls on a roll cutting machine. The resulting rolls are checked and packed into bags or boxes for sale. All mini-mills are supplied with equipment for further processing of paper, namely a machine for cutting rolls (log saw) and a reel-unwinding machine.