The operation of any enterprise is impossible without the generation of waste. This could be, for example, cardboard packaging or unnecessary documents. The low volume density of paper products requires large storage areas. The waste paper press creates paper compaction tens of times, which saves space in warehouses. In addition, pressed paper is convenient to transport. If your company periodically accumulates waste paper, it makes sense to purchase or manufacture a waste paper press.

Differences between balers and compactors

Typical all-in-one compactor

Balers and compactors are often offered by equipment manufacturers as identical or similar products. However, even though they do similar work, their functions are slightly different.

The primary function of balers in industrial manufacturing is to compact and bind or “bale” recycled materials. The output is dense bales or briquettes. Compactors are also sometimes used to accumulate and compact recyclables, but they are primarily used to reduce the volume of waste removed. Despite these differences, you will often hear the terms "baler" and "compactor" used interchangeably.

Typical vertical baler with manual strapping

Just twenty years ago, only a few models of baling presses were presented on the domestic market. These were most often manual or mechanically driven presses. Nowadays the choice has become so wide that it confuses buyers.

The market is filled with domestic, European and Chinese presses. To make an informed purchasing decision, you just need to understand the features of these devices.

Operation and operating conditions

When purchasing medium to large stationary equipment, the manufacturer or its representative will typically provide training to personnel on how to operate their equipment efficiently and safely.

In addition, the presses are equipped with safety and locking systems that prevent the system from being turned on while the operator is adjusting something in the working chamber, and allow the equipment to be stopped instantly in the event of an emergency.

Waste paper presses are capable of operating in a wide range of weather conditions, including subzero temperatures. To do this, they use special all-weather lubricants and working materials.

Equipment maintenance must be carried out in strict accordance with the manufacturer's instructions. This will ensure long and high-performance operation of the device.

Selecting a baling press for its intended purpose

The baling press must compress rags, waste paper, plastic bottles and other recyclable materials. Bales should be tied fairly easily to prevent them from spilling. Finished bales should be easy to move and transport. Depending on the purpose, the baling press can be used for:

- saving space when accumulating recyclables;

- accumulation of a transport batch;

- formation of a wholesale batch;

- ease of transportation

- reduction of transport costs.

The most widespread use of a waste paper press is for the accumulation of recyclable materials and ease of transportation.

Chain supermarkets, shopping centers, markets, business centers, industrial enterprises - wherever recyclable materials are collected and accumulated, should evaluate the feasibility of using a baling press to accumulate cardboard and other recyclable materials (office paper, plastic film, etc.).

By place of use

Depending on where the installations will be used, they can be stationary or mobile.

Stationary

Stationary ones have greater power and a permanent place of work where the material is supplied. The devices are installed at enterprises engaged in the reception and processing of recyclable materials or in places where paper and cardboard waste accumulates.

Distinctive features of stationary presses:

- permanent residence

- big sizes

- high power and performance

- additional functions and equipment

Mobile

Mobile units are designed to transport waste and work in required places. Such units are characterized by:

- low power and performance

- small dimensions

- no permanent location required

The mobile press moves to places where waste accumulates and can be installed on a cart or a passenger car trailer.

The device is most often used:

- Enterprises that are engaged in the removal of waste paper to order.

- Organizations with a large turnover of packaging containers.

- Companies specializing in the recycling of recyclable materials.

Types of baling presses for recyclable materials

Baling presses vary:

- by type of construction

- by download type

- by piston force and pressure of the pressing plate

- according to the size of the working chamber

A typical baling press consists of a working chamber, a piston and a drive. Compressible recyclables are loaded into the working chamber. A piston controlled by a hydraulic cylinder or other mechanical drive compresses the material. The finished bale is then tied with twine or wire.

Baling presses differ in the direction of piston movement into:

- vertical

- horizontal

Vertical balers are available with one or two cylinders and one or more working chambers.

Horizontal presses, in turn, come with one or two pistons (located perpendicularly), as well as with manual or automatic binding. Sometimes imported horizontal presses are called “channel” presses.

For temporary work, there are mobile designs of small presses in the form of trailers for cars.

By type of drive, baling presses are divided into:

- manual

- electromechanical

- hydraulic

Manual Baler

The simplest design of a baling press is a screw one. The pressing plate moves vertically using a screw rod.

In addition to a screw drive, a lever (rack and pinion) drive can be used. This drive is more convenient for the operator.

This type of press is the cheapest, does not require electricity and practically does not break down. However, the productivity of such presses is low, requires a lot of manual labor, and the bale density is not high.

However, with the help of such a press you can obtain a small bale of waste paper or plastic film, which will be convenient to transport to your destination.

Electromechanical baling press

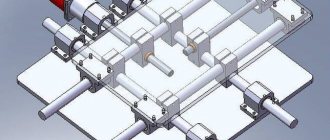

A more “advanced” type of baling press is electromechanical. Here the screw rod of the pressing plate moves with the help of a gearbox and an electric motor. Such a press will cost more than a manual one. For reliability and to avoid severe distortions of the pressing plate, guide rods are used.

An electromechanical press provides higher productivity and compression ratio than a manual one. The bales are denser.

Hydraulic Baling Press

A hydraulically driven press is a practical, productive and fairly reliable mechanism. It is more expensive than previous models, but it is the most popular type of baling press.

A hydraulic press can form a fairly dense bale of waste paper and other recyclables, because A hydraulic cylinder can develop much more force than a screw.

Baling presses with hydraulic drive are produced in a wide range of products. They differ in the size of the bale chamber, which affects the size of the bale formed. There is also a difference in the force of the press plate, which is usually expressed in tons or kilograms of force. The density of the bale depends on the force of the press and the area of the working plate.

Features of application

The press is designed to prepare paper and plastic waste for recycling. It can be used for the following materials:

- Paper products in the form of individual sheets, books, brochures, posters, drawings.

- Paper packaging.

- Corrugated cardboard.

- Canisters and bottles made of plastic.

Other materials that have low volume density and strength are also suitable for preparing for disposal using a press.

If you compress standard bags, they will occupy 20 times less volume and area than in their normal state. Therefore, delivering waste in this form to the disposal site is much easier and cheaper.

Design features of the work plate

In addition, baling presses differ in the design features of the working plate. Firstly, there are differences in the number of working hydraulic cylinders. There may be two or one. Secondly, there may or may not be guide rods. The guide rods make the structure more rigid and prevent the work plate from skewing. Thirdly, the slab may have its own guides, usually at the corners.

To push out the finished bale, a chain is often used, which is attached to the working plate on the rise. Tippers with a separate hydraulic drive can also be used, but this is usually used in large balers where a bale in excess of 80 kg is formed.

Technological capabilities of hydraulic presses

If you want to purchase a waste paper press in Moscow or other large cities, you need to study their key technical characteristics in more detail. The devices presented for sale differ from each other in several parameters, the most important of which are:

- chamber volume;

- equipment performance and drive power;

- pressing force;

- maximum density of processed raw materials;

- energy consumption level;

- dimensions;

- ease of transportation.

There are many varieties of such units. They may also differ in the type of installation and the drive used. Since all devices have their own characteristics, it is advisable to familiarize yourself with them in more detail.

What influences the size of the working chamber of a baling press?

The size of the resulting bales of waste paper and other secondary raw materials depends on the size of the working chamber of the baling press. Naturally, the larger the bale, the heavier it is. Small bales can be carried by hand. Larger bales have to be turned or transported on carts.

Bales of “industrial” dimensions weigh about 200 kg and are moved using forklifts. These large bales fit comfortably on a semi-trailer or wagon and allow for a full load.

It is unreasonable to buy a large press for a small store and then have the whole team turn the resulting huge bales into a truck. Therefore, presses with a small working chamber are most often purchased. The bale weighs only 20-40 kg.

DIY mechanical press

If you do not have the ability to operate machines, you can order the necessary parts from a turner.

Tools and equipment

To make the device you will need the following:

- Bulgarian

- drill

- welding machine

- screwdriver

- milling and lathe

- steel sheets

- bolts, nuts

- corners

Manufacturing and use

- The basis of the press is a frame made of corners, which is sheathed with metal sheets.

- From four metal corners or bars 80 cm long and four 60 cm long, fastened together, make two rectangles, which will be the lower and upper parts of the box.

- Metal rectangles are held together using vertical beams.

- The resulting box is sheathed with metal sheets and reinforced with transverse beams.

- A door is attached to one side of the structure through which the compressed paper briquettes will be removed.

- Next, you need to make a piston. To do this, metal channels 45-50 cm are connected to each other by welding from the sides. The finished piston should be reinforced with a beam.

- Weld a flange in the central part of the beam and insert a threaded rod into it.

- To form the final part of the frame, two channels or metal beams 10 cm long must be attached to the opposite long sides of the main box.

- In the upper part, on the sides of the channels, attach a couple of beams, between them place a bearing in a cage where the threaded rod will be located, then secure it to the piston flange.

- When the structure is assembled, a washer should be put on the rod, then a nut, which will set the piston in motion. The nut can be rotated using a lever.

Before using the press, moisten it with water and load a pile of waste paper into the device. Then set the piston in motion. Remove the material compressed under pressure and dry it.

A fairly simple method of using the design will help recycle paper waste even in a small room.

Working force of baling press

The greater the force, the denser the bale will be. But the main attention should be paid not to tons, but to the specific pressure of the pressing (working) plate, because it is the pressure that ensures the density of the bale. With the same piston force, more pressure will be created by a plate with a smaller area.

The force is especially important for forming bales of cardboard or plastic bottles, because... significant effort is required to compress them.

To protect the hydraulics, a pressure limiting relay or electronic control is used.

How much pressure is needed to compact paper?

One of the most significant parameters of such units is the pressure force. Budget and low-power models are capable of demonstrating force from 2 to 10 tons, which is enough for processing paper, cardboard, and polyethylene.

If it is necessary to compress more durable materials, units with an indicator of up to 15 tons will be required. Pressing thin metal sheets can only be done with a force of about 30 tons. It should be noted that in the waste paper processing process, more powerful types of equipment can be used, which will allow for increased productivity.

Occupational safety when working with a press

A hydraulic press is a dangerous machine.

If handled improperly, the press can damage your hands. A good baling press is equipped with sensors and switches that do not allow the press to be turned on when the working chamber is open. Many models have two start buttons to keep the operator's hands out of the work area.

Making your own hydraulic press

If you don’t have enough financial resources to buy a press, you can make a waste paper press with your own hands. To do this, you must be able to work with a welding machine and have metalworking skills.

Tools and equipment

To make a press, you need to prepare:

- welding machine with electrodes

- grinder

- steel profile 5 mm thick

- steel sheet 2 mm thick

- steel plate 10 mm thick

- hydraulic jack

- springs – 2 pieces

To work you need to be able to design. A drawing of a standard hydraulic press for waste paper is as follows.

Manufacturing and operation

First of all, a base in the shape of a rectangle is made. Next, you need to weld the racks to the side parts of the base, and the traverse will be located in their grooves. The upper part of the racks is connected by a crossbar. The traverse is attached to springs between the racks, a jack is placed on it, and a plate is installed below. A secure door should be attached to the open top of the box on one side.

Personnel must be trained before using the equipment. The installations must be equipped with a security system. To ensure the press operates in all weather conditions, you should stock up on special lubricants. To ensure high performance, it is necessary to maintain the device in accordance with established rules and observe safety precautions.

How to make your own machine

If you want to make a cardboard press with your own hands, you need to carefully familiarize yourself with various videos, instructions and drawings from the network. It is worth giving preference to manual hydraulic equipment, because it processes cardboard much better and more efficiently, acting on it with a working force of up to 3 tons. And also similar models have a high efficiency.

The main part of the homemade device will be a regular automotive hydraulic jack. You need to immediately decide on the dimensions of the product. For this purpose, precise drawings and calculations are carried out. It is also worth considering the length of the piston and the size of the pressed bale.

First, a sturdy platform for the machine is installed, which includes a plate, a large chamber for raw materials and mounts for a hydraulic jack. Experts advise making a unit to adjust the jack. This will allow you to get a universal type machine.

Next, metal racks are placed along which the stop and the plate will move. As they move, the solid waste will be compressed under the pressure of the hydraulic jack. Container doors and walls are made from tin up to 2 mm thick. This material will prevent equipment breakdowns during the production of pressed paper.