Every car enthusiast, both beginner and more experienced, must have a set with the necessary tools, the main one of which is a screw jack. This design allows you to change a wheel or lift the vehicle in order to carry out maintenance. Today there are many lifts, but the most popular is the mechanical screw jack.

Thanks to its small dimensions and simple design, the lifting mechanism can be transported even in the smallest cars. As for the cost of a finished jack, it is quite affordable, but you can make such a device yourself at home.

Mechanical jack

Design features of a car jack

Among the many lifts for passenger cars, the rack screw jack stands out, since it is the most compact and stable. The main advantages of this mechanism include the following:

- a vertical plane is used to lift the vehicle, due to which the car does not stagger in different directions;

- if the maximum permissible loads are observed, the structure will last for a long period of time without breakdowns;

- increased level of sustainability;

- compactness and maintainability.

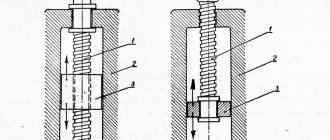

A car screw jack has a simple design that can be used to lift large loads to a certain height. The operating principle is that torque is converted into translational motion. The basic structure includes a gearbox, a nut and a screw.

Note!

When using a diamond-shaped mechanism with one loose nut, it is necessary to approach it with all responsibility and caution, and also monitor the level of lubricant and its quantity. If the frequency of use and maximum loads are exceeded, the mechanism will quickly become unusable.

Increased safety during operation of a hydraulic screw jack is achieved due to the self-braking function. The gearbox transmits torque to the support nut, after which the vehicle is raised to a height.

Specialists created a more modified screw jack using lifting rollers that were attached to nuts and screws. The upgrade is necessary to reduce the coefficient of friction for easier lifting and improve service life.

Screw jack diagram

Gearbox for lift

Currently, most lifting mechanisms use some kind of transmission mechanisms (gearboxes), most often of the worm type. This is due to the fact that the worm gear is unidirectional - movement in it can only be transmitted from the worm to the wheel, but not vice versa.

Thanks to this, the possibility of uncontrolled spontaneous movement of loads is almost completely eliminated - when a torsional force is applied to the worm wheel axis, it simply will not rotate.

In addition, the need to install gearboxes is also due to the need to change the gear ratio in order to change the speed of ascent/descent, as well as reduce the applied force (the latter is especially important in cases where human power rather than an electric motor is used to set the mechanism in motion).

What characteristics of a screw jack should you pay attention to?

When choosing a lifting mechanism, you should ask yourself whether it is possible to get by with a manual jack or whether it is better to purchase an electric drive. If you give preference to manual devices, then they do not require preliminary calculations. If you plan to use an electromechanical lift, you must first measure the weight of the vehicle for which you are purchasing the jack.

The calculation is needed in order to determine the power of the structure, and the initial height, working stroke and maximum lifting height should be taken into account. Before using hydraulic structures, you need to calculate the engine power and the forces that will be exerted on the handle.

When purchasing a jack, you should take into account the following basic characteristics:

- Load capacity must be selected in accordance with the brand of the car, and if the jack will be used as a universal device, it is recommended to give preference to more powerful models.

- Lifting height - the higher it is, the better.

Since the bottom of the car is equipped with special grooves and cells, you should buy the appropriate type of design.

A popular type of lifting device is the mechanical screw jack, which is easy to use and also inexpensive. Today, an adjustable screw jack for timber is included with every modern car, but to carry out this or that construction work, it is sometimes necessary to select a device separately.

You might be interested in this About jacks for the Niva: lifting height, which one is better than the standard one

When buying a mechanism, you need to carefully study all the technical documentation of the machine, especially that regarding curb weight. As for the power reserve, it is necessary, but excess reinsurance is not needed, since lifting devices have increased dimensions and weight.

Do-it-yourself gearbox for a lift

A worm gearbox is perhaps the most successful solution for any lifting mechanisms, and many people want to make it themselves. It should be immediately noted here that making the worm gear mechanism itself from scratch with your own hands is a very difficult task.

This requires a whole range of metalworking machines and appropriate qualifications - a worm drive is much more complex to manufacture than, for example, a gear drive. Also, if manufactured incorrectly, there is a very high probability of jamming or, conversely, the mechanism becoming loose during operation.

It is for this reason that it would be best to use a ready-made worm-type gearbox - either new or used (purchasing such a mechanism is not difficult). When choosing it, be sure to take into account the maximum load capacity of the unit, as well as its gear ratio.

How to choose a quality tool: comparison of manufacturers and models

When purchasing a quality 5 ton screw jack, you should remember that it can be either a lever-screw or a diamond-type one. A lever-screw jack can most often be seen in the trunk of those Russian motorists who drive domestic cars. These mechanisms are characterized by less longitudinal stability and shrinkage than rhombic lifts.

Lever-screw jack

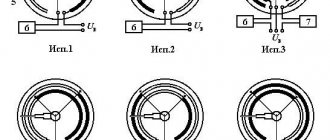

A diamond jack is a structure of four levers that are connected to each other using hinges attached to the platform and base.

Externally, the shape of the mechanism resembles a rhombus, which is why it got its name. As soon as the propeller begins to rotate, the angles between the arms change, after which the vehicle rises or descends. In addition to the main characteristics listed above, when purchasing a jack you need to take into account the following:

- device color;

- brand;

- dimensions.

These days, automotive supply stores carry helical lifts in colors like silver, red, yellow, and black.

Important!

The paint is not very durable and will peel off after a certain period of time.

The automotive market is replete with various manufacturers who offer different models of screw jacks, differing in load capacity, dimensions and cost. Popular brands include Zubr, Skyway and Airline, but experienced motorists do not recommend looking solely at the popularity of the manufacturer. This position is explained by the fact that there are situations when the driver overpays for a jack, an analogue of which can be purchased from a little-known company, but at a lower price.

Note!

Any telescopic screw lifting mechanism is a compact device, so the difference between the parallel hinges of rhombic jacks when folded does not exceed 10-15 cm.

Rating of the most popular and high-quality screw jacks:

- “Zubr 43040-1” is capable of lifting a load weighing 1 ton to a height of 383 mm. Ideal for compact passenger cars.

- STVOL SDR2370 is a more powerful mechanism, capable of lifting a load weighing 2 tons, but the lifting height is less than the previous model - 370 mm. An excellent option for small tonnage vehicles.

- Inforce T10202 is another model with a lifting capacity of 2 tons, but this device has a higher lift height of 395 mm.

You might be interested in this About High Jack jacks: features of the rack and pinion mechanism, selection criteria

Inforce T10202

Types of screw jacks

The group of lifting tools that operate by rotating threaded connections is quite large and diverse. There are also very budget models used for lifting cars and small household tasks, and expensive devices used in construction and large repair shops. In order to form a general idea, let’s briefly introduce each member of the group of screw jacks. Let us briefly touch on the scope, average cost and technical indicators of each representative.

Bottle lifters form the broadest subgroup of tools. These reliable and unpretentious devices are very popular in various fields. Car owners prefer a mechanical screw bottle jack for its compactness and low cost. In construction operations, equipment of this type ensures smooth lifting of fragile objects. The cost of bottle lifts starts from several hundred and reaches tens of thousands of rubles. Basically, the price is determined based on the carrying capacity, which ranges from 2000 kg to 100 tons.

Rhombic (or diamond-shaped) types of lifts are much less diverse, but in their field they are in much greater demand than bottle ones. Perhaps the lowest cost (around 1000 rubles) makes this manual jack a clear favorite for household tire fitting. In addition to car repair and maintenance, rhombic devices are periodically used for minor construction work. This type of lift does not have a large load capacity and can lift weights up to 3 tons.

Lever-screw jacks in one of their two variations are almost identical to rhombic jacks, although they have a slightly different lifting principle. The second design is even more compact and consists of fewer parts. Some car owners are captivated by the low cost and small size of the device, forcing them to choose it. Despite its dubious merits, this type of jack is the most unreliable and dangerous, therefore it is becoming less common on sale. The average price of a lever-screw lift is 600 rubles, and the load capacity varies within 700 kilograms.

Worm jacks belong to the class of professional equipment used in large industries: food, automotive, construction and others. Usually they operate from an electric drive, combined into systems of several pieces. They have a wide range of prices: from several hundred to tens of thousands of rubles. The load limits are no less extensive: from 1 to 200 tons.

How the device works

A screw mechanical jack is a simple, powerful mechanism whose operating principle is to convert torque into translational movements. This design consists of three elements:

- worm gearbox;

- nuts;

- pairs of screws.

The torque is supplied to the nut by a worm gearbox, due to which it is converted into translational movements, with the help of which the load is raised and lowered. In modernized screw jacks with a ball screw drive (ball screw), the design consists not of a pair, but of a triple - a screw, a roller or ball, and a nut.

Due to the added elements, the efficiency of the mechanism increases, which helps reduce frictional resistance.

Thanks to this, the lifting speed of the vehicle increases, as does the service life of the structure. But if we compare the cost of an improved lift with an ordinary screw device, it is slightly higher.

After the invention of the conventional screw mechanical jack, experts decided to invent a mechanism with a ball screw drive. Over time, there was an urgent need to lift very massive objects, as a result of which mechanical devices that had an electric drive were invented. With the help of such synchronously operating devices and their symmetrical transmission, it became possible to lift loads with an impressive mass.

Note!

Using double-screw jacks, you can lift vehicles weighing 3 tons to a sufficient height. As for the maximum lifting capacity of screw lifts, it reaches 16 tons, but such devices are used only at service stations.

Screw-type structures are usually equipped with a manual drive, but there are many models that have an electric drive, which makes lifting work easier. Electric lifts are controlled using a remote control that regulates lifting speed and height.

Electric screw jack

Gearbox for a lift: features, application

Worm gear is the most common type of gearbox, used in almost all construction hoists, as well as in many other industrial mechanisms: conveyors and conveyors, drives, mixers, pumps, in metalworking machines of all types and many others.

This is due to the fact that such a design combines simplicity, reliability and ease of use. The structure of a worm gearbox is quite simple - in fact, it includes two main elements: a worm wheel with teeth of a special profile, and a worm that engages with it. The latter is a special screw with a thread close to trapezoidal. The rotation axes of the worm and gear are located strictly perpendicular to each other. When the worm unwinds, the threads on it move forward and push the wheel.

Such gearboxes are marked based on the distance between the axes of the worm and the wheel, for example, Ch-100 is a gearbox with an axle spacing of 100 mm, and so on.