Check valves are installed on hot and cold water pipes. As an example, consider a standard city apartment in a multi-story building. The following are connected to the riser with cold and hot water:

- Washing machine,

- Kitchen sink,

- water heater,

- Bathroom,

- Bathroom and washbasin.

Problems you face

A typical situation for an apartment building: different pressure in each of the risers. In a pipe with cold water, the pressure may be higher than in a pipe with hot water and vice versa. The pressure can easily increase at any time, but more often than not it drops unexpectedly due to a leak or even a pipeline break. The effect of the difference in flow pressure is often noticeable when two taps are opened in one apartment at once. For example, the faucet in the kitchen is open, hot water flows from it, and at the same time cold water begins to flow from the sanitary shower head. One stream replaced another.

In many houses with centralized water supply, hot water is turned off for at least two weeks in the summer. During this time, in apartments where heating devices are installed, the liquid supply valve from the central system is closed, and hot water from the boiler is released through the same pipes. Sometimes residents forget to turn off the valve on the water heater, including the water supply from the central riser. Cold liquid with high pressure blocks the flow of warm liquid, squeezing it out. As a result, only cold water is supplied from all taps. Then it goes to the central riser, in a few minutes all residents will be washed with cold water.

The second option is more common and can happen in any apartment. When using a shower mixer, a situation similar to the one described above occurs. If the pressure in the hot water riser is higher than in the cold pipe, you will get boiling water in both taps. In this case, the meter will spin very quickly, counting cubic meters even if water is not used. There will be hot liquid not only in the riser, but also in all apartments below and above.

There is one more reason that completely excludes the influence of the human factor. This situation occurs as a result of failure of the valve on the mixer. Inexpensive Chinese taps fall into disrepair every one and a half to two years. They are affected by water quality: chlorine, rust and other impurities. As soon as the shut-off lever breaks, water will rush into the adjacent pipe and the liquid will be displaced. A single-handle faucet in the kitchen can have the same effect. When the mixer handle is lowered, it opens both valves; if the pressure of hot or cold water is higher, one liquid displaces the other, spreading throughout the system.

In all the described cases, at the end of the month you will receive a very decent bill for the cubic meters of water pumped up by the reverse flow. Another trouble awaits children: injuries are possible as a result of supplying a hot stream to a cold tap. In addition, things can be damaged; instead of cold water, liquid at a temperature of up to 80 degrees is supplied to the washing machine through a hose.

Mechanism objectives

The working mechanism of most water meter devices is a multi-bladed impeller that does not have a locking element and rotates in both directions.

Some consumers, refusing to install a valve, pursue a selfish goal - rewinding the water meter readings. To rotate the impeller in a different direction, perform the following actions:

- the supply of liquid flow to the mixer is shut off;

- the remaining water is drained;

- Air is supplied through the hose of the vacuum cleaner connected to the mixer.

Despite the apparent simplicity of the procedure, there are several nuances that do not meet the expectations of consumers:

- manipulations take a long time;

- requires significant energy consumption;

- too little air pressure will leave people living in the house without water for the whole day;

- too much pressure can damage the impeller;

- To connect, you need to find a Soviet-made vacuum cleaner; most modern devices cannot supply air outside.

Whether a check valve is required on a water meter follows from the law of connecting vessels. Water supply systems (cold and hot) organized in apartment buildings converge many times in mixing devices. It is almost impossible to maintain the same pressure level in pipelines.

When the taps are opened simultaneously, both flows are mixed, the liquid flows from the system with increased pressure into the pipeline of lower pressure. The hot water meter can also determine the flow rate of cold water, which will affect the size of the water bill. In a situation where a “cold” water meter begins to determine the flow of hot water, there is also no benefit. Its elements are not intended for use in a hot liquid environment; the water meter will quickly fail.

An equally important factor explaining why a water meter with a check valve is needed is the operating conditions. The service period specified by the manufacturer is achieved only if the measuring chamber is constantly filled with water of proper quality.

Primary purification of the liquid from large particles is carried out using a mesh filter. In a flowmeter with a check valve, the chamber is not completely emptied.

A non-return valve is installed in faucets, but when the water supply is temporarily interrupted, a situation often arises when an impatient consumer opens the valve in the hope that it will turn on soon. The water located in the gap between the shut-off valve and the mixing device flows into the sewer pipe. If a water meter with a check valve is installed, only liquid will flow from the area from the mixer to the valve. The reason is that the valve turns on only under the required pressure. It doesn’t matter if the shutdown was short and the residents managed to turn off the water in time. If the water supply is interrupted for a long time, not only the water meter may be damaged, but also the neighbors will be reimbursed for repair costs - there is a risk that the pipe will burst.

When installing a boiler in an individual house, installation of a check valve is required. When water is heated in the working chamber of the water heater, the pressure increases significantly, leading to squeezing of the input flow. The water flows back.

The heating system of an individual home may include not one circuit, but two or more. For example, the first is intended for heated floors, the second for the boiler, and the third for the heating system itself. Each of them is equipped with a separate pump and has its own operating pressure. To prevent the reverse flow of water and its movement from one circuit to another, it is also necessary to install a check valve.

The data sheet for water meter models without an additional element indicates that a check valve should be installed after the meter.

Check valve installation

To avoid the problems described, it is enough to simply install two check valves. They are mounted after the ball valve on both risers of the apartment. If for some reason you do not yet have a strainer installed after the shut-off ball valve, be sure to install it. The check valve is always installed after the meter. When installing, you must follow the correct direction. If placed backwards, it will not be able to perform its functions. Some meters are already equipped with built-in valves. As a rule, they are not highly reliable. Miniature check valves are inserted into the opening of the half-flush or installed at the outlet of the meter.

Appearance: thick elastic band and a plastic circle with a crosshair inside. Due to their compact size and poor workmanship, they can leak. Therefore, it would not be superfluous to install another check valve.

Nuances of proper installation

During the installation of shut-off valves, several rules should be strictly followed:

- The valve is installed strictly in the direction of coolant flow. To avoid mistakes, the product body must be marked with an arrow indicating the working direction.

- Paronite gaskets can be used to seal connections, provided that they do not reduce the diameter of the passage hole. Otherwise, the valve will exert more hydraulic pressure than intended.

- The device must be installed so that other elements of the heating system do not exert additional pressure on its body.

- It is highly advisable to install a mesh in front of the check valve for rough cleaning. This will make it possible to prevent solid particles from entering the locking mechanism, which, in turn, can lead to a violation of the tightness of the device when closed. Or use special valves with mesh.

Another important point: before installation, you need to once again make sure that the valve is selected correctly.

For example, for schemes with forced circulation, any type of device is suitable, but for gravitational systems, only a rotary petal device without a spring. Since the coolant moving by gravity will not be able to cope with the resistance of the spring.

Installation Features

There is an arrow on the surface of the product indicating the movement of water. The valve body itself consists of two parts: the nut is screwed onto the base using a thread, tightening occurs clockwise, and unscrewing counterclockwise. When installing or dismantling the check valve, hold the nut from which the arrow extends.

Frequent errors and problems during installation

Among the most common mistakes made when installing a check valve on water are:

- placement of the device without taking into account the direction of flow;

- insufficient tightness of the connection points, which may result in leakage of medium when the valve is closed;

- The diameter of the device is too large, so it knocks during operation;

- the valve is placed too close to the pump, which leads to a rattling sound;

- use an excessively large amount of tow when packing a threaded connection - the coupling may burst;

- During installation, they forget to remove the through hole plug or the valve lock.

In what cases is a check valve installed?

The valve is installed to prevent the reverse flow of water, the return of liquid to the pipeline, or the replacement of one flow by another due to the difference in pressure. Valves should be installed:

- In front of the boiler

- After the counter,

- Along with the installation of pumping stations.

If you use a pump to pump out water, thanks to the check valve, water immediately flows into the tap and does not go back into the system. This valve prevents the meter from rotating in the opposite direction when using closed loops. In factory products, check valves can be found in the water meter in front of the mixer eccentric. When installing a water heater, the valve is installed on the cold water inlet, as well as on the hot water riser.

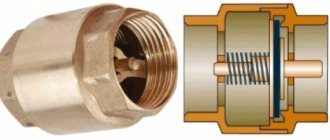

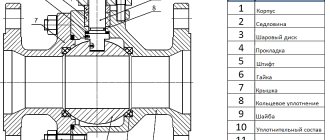

Valve device

- Gate,

- spring,

- One or two rubber bands

- Metal pipe with or without washer.

In the standard position, the shutter is closed and supported by a spring. There are two shutter options: plastic and metal. Products with a metal shutter are used in heating systems, plastic ones in the general water supply system. A metal diaphragm check valve requires a lot of pressure to open. Therefore, if the system is low pressure, be sure to use only a plastic valve mechanism. Valves with metal shutters are longer than their plastic counterparts. The difference is 1 cm. When replacing already installed valves, this technical feature must be taken into account.

Varieties and selection options

Check valves installed in water supply systems are available in several types:

- disk;

- petal;

- ball;

- lifting;

- two-bladed.

Disk devices are distinguished by their compactness. The principle of operation of the device is simple - under the pressure of the liquid, the disc valve moves, freeing the channel. When the pressure decreases, the disk returns to its original state due to the action of the spring; in this position, reverse flow of water is impossible.

Double-blade valves, which are large in size, are installed in complex water pipelines. As an example, we can imagine the water supply systems of individual houses equipped with a pump - if it breaks down, there is a high probability of reverse movement of water under pressure. The principle of operation of a two-bladed device is also not complicated: the shut-off element folds in half under the influence of liquid, and when the reverse current flows, the valve unfolds, completely occupying the passage.

A ball can be used as a shutter, moved to the open position by the action of a fluid flow. When the pressure decreases, the element returns to its original position, closing the working passage. Such valves, like taps, are called “ball” and are installed in water pipelines made of pipes of various diameters.

Lift valves use a shut-off bowl (spool). Under the pressure of the liquid, the bowl rises, freeing up space for the flow to pass through. When the pressure decreases, the spool moves to its original position, closing the passage. Such devices can only be installed on horizontally located pipes.

In petal-type devices, the shutter consists of petals that move apart under water pressure and open the channel. When the liquid moves in the opposite direction, the petals move.

When selecting a valve, you should pay attention to the material it is made of: high-quality devices are made of CW617N brass.

You also need to consider special markings:

- The designation of permissible pressure is carried out with the letters PN or RU and the numbers following them. For example, RU-20 means the device’s ability to operate under pressure up to 20 bar. In central water supply systems, the standard pressure is up to 6 bar for cold water and up to 50 bar for hot water.

- The diameter of the passage is marked with the letters DN or RU, for example, RU-20. Based on this parameter, the valve is selected taking into account the passage size of adjacent elements to prevent increased loads and decreased pressure.