Sometimes it is easier for a driver to make a device for car repair with his own hands than to constantly spend money on the services of service stations. In addition to saving money, the car enthusiast will be able to repair the car carefully and with all his diligence. For high-quality and efficient work on the car body, drivers use a painting booth. This is a unique device that allows you to independently update the color of your car and do it no worse than professionals. The user receives a high-quality result, which, with careful and careful handling, is preserved for many years.

Requirements for the premises of paint booths

A paint booth is a unique room in which paint and varnish materials are applied to the surfaces of cars, motorcycles and other metal products. They come in different types and sizes, different materials are used in their construction, and they are aimed at performing specific tasks.

Car painting room

Among the requirements for the camera premises, it is worth highlighting the following:

- The air in the room must be purified.

- The camera should be equipped with good lighting, close to daylight.

- Quick achievement of the set temperature and stability of indicators over a certain period of time are the key to a high-quality result.

- The air in the room must be purified at the inlet and outlet.

- The spray booth must be safe and use energy, fuel, and other materials economically.

One of the main requirements is the choice of dimensions. The convenience of work and the ability of the master to place all the necessary tools at hand depend on the correctly selected dimensions of the camera.

Do-it-yourself hood box in the garage

The modern construction of a spray booth must take into account the main point - ventilation. Indoor air purification is very important to remove dust, dirt and other paint particles.

Such systems are divided into single-engine and dual-engine. In the first case, air is pumped from above using a fan, and then removed independently through holes in the floor. In the second case, another fan is installed in the floor, and the system becomes forced. It is also more expensive, which also needs to be taken into account, although the efficiency also increases.

A well-thought-out ventilation system allows air masses to calmly and smoothly enter and exit the room. If mistakes were made at the design stage, then turbulence, turbulence and so-called “dead zones” where dirt will accumulate may occur. Therefore, air pressure must be taken into account. And for this purpose, filters on the ceiling are placed evenly along the entire length. If they are controlled from an automatic remote control, this is only an additional plus of ventilation.

Advantages of a homemade car painting booth

A do-it-yourself paint booth is a very real task, and every driver can do it. It will save significant money and only requires compliance with safety rules and techniques for applying paints and varnishes.

The main advantages of the camera are:

- Independent selection of drawings and systems execution diagrams.

- Economical.

- The ability to connect expensive devices with cheap parts made by yourself.

- Simplifying the functioning of systems or the ability to replace them with more efficient ones.

DIY spray booth

Its main advantage is that a do-it-yourself car painting booth is easy to maintain, and the result is much cheaper than painting at a service station.

Installation of floor and ceiling filters in the ventilation system of the paint shop

It is necessary to take care of the availability of air filters. Moreover, they must be very powerful and highly productive. All this is done to ensure that there are no paint and dust particles in the air that create defects on the paintwork of the car.

Important! Ideally, two-phase filters should be used.

They initially catch the largest particles of dirt, and then purify the air from the smallest remnants of pollutants. The performance of the ventilation system plays a decisive role. It should be equal to an average of 20-25 cm per second of air flow.

Filters are responsible for cleaning not only incoming but also outgoing air masses, since this is strictly regulated by certain sanitary and hygienic indicators. This is why it makes the most sense to use multi-stage cleaning. At the same time, you need to understand that the bottom filter, whose role is to remove air from the room, will quickly become dirty. And therefore it should be changed frequently.

Paint booth lighting is an important parameter when painting a car.

For efficient and high-quality work, the room for painting must meet a number of requirements, one of which is lighting. Having organized the process correctly, the master will be able to paint the body like a real professional. It should be noted that during operation there is a strong spraying of paint, which automatically impairs visibility several times.

Before starting work, it is recommended to calculate the number of lamps and place them correctly. To ensure excellent illumination and visibility of all defects, it is necessary to focus on an illumination standard of 1000–2000 lux. You can use one of the lighting schemes: ceiling, ceiling-wall, or enhancing the lighting of the rear wall of the room. The second scheme is considered the most convenient and effective.

Since daylight (close to sunlight) light in the chamber is one of the most important aspects when painting a car, it is recommended to place the lamps in several rows so that they are at different levels. This will improve visualization and, as a result, provide excellent painting. The minimum recommended number of lamps is 24 pieces.

Lighting in the spray booth

The user can purchase incandescent lamps, LED lamps or fluorescent lamps. All three options differ in power and cost. Depending on the characteristics and expected budget, everyone chooses the most acceptable option.

Room ventilation, air purification and drying

A prerequisite for the proper functioning of the spray booth is the presence of ventilation. It is important that the room has the required level of humidity, cleanliness and air movement - all this is ensured by the ventilation system.

Ventilation allows:

- clear the air of steam released during work;

- remove dust and small particles and prevent them from getting on fresh paint;

- regulate temperature and humidity.

In order for the camera to perform its functions and provide excellent results, certain conditions must be met:

- Air movement should be uniform and directed.

- Compliance with temperature conditions (ideal values are considered to be 22–24 degrees).

Ventilation allows you to clear the air of steam

- Maintaining optimal humidity, namely 50–70%.

- Using a vertical ventilation system.

Before installing ventilation, you should decide on the choice of device. There are single-engine, dual-engine and supply and exhaust system types. For large volumes of work, the latest type of ventilation is used. For the average user, a dual-motor system with high performance is suitable for high-quality air purification.

The supply and exhaust ventilation system perfectly circulates and cleans the air, ensures optimal temperature conditions and drying of finished products.

Air filtration and distribution

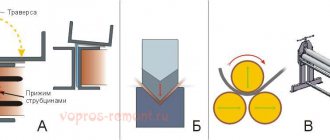

In a proper paint booth, there should be a continuous, complete renewal of air. Therefore, it is more logical to place the hood at the bottom and the supply fan at the top. It is incorrect to place the air outlet openings only above the painting area, however, the use of a correctly oriented supply plenum, the principle of use of which is shown in this drawing, will allow you to better manage the space.

An adjustable gas burner can be used to heat the air, which is connected during the drying stage. The heating element is located after the filter and fan, sometimes outside the pipe. In any case, the design of the paint room must provide for reliable insulation of the heater from explosive gases, so the air through the heater must move strictly in one direction, and through the attic space (pipes, plenums) at such a speed as to prevent reverse movement. When the fan is turned off, the heater must stop operating immediately. The placement of the filter over the main area of the ceiling assumes a uniform distribution of air over the area, but with a weak fan it may simply not be enough - preliminary calculation is important to determine the area of the grilles (plenums) and their location without the formation of turbulence zones.

The incoming air is purified by several filters, with a coarse filter located before the fan, and a fine filter directly at the boundary of the box. Cotton filters are often used as the latter, which are sheet (roll) material placed on top of the ventilation grille. Pocket (cellular) filters that meet the DIN 53438 standard (pre-filtration), the European standard EN779 and DIN EN 779 (class F5 internal filter) have the longest service life. In the above project drawing, the primary filter is indicated by the number 2, and the air intake by the number 1.

What does a paint booth consist of?

Before thinking about the question: “how to make a spray booth?”, you should decide what the structure should consist of.

The main element is the enclosed space. This is the chamber in which the coating and drying of the machine is directly carried out. The second element, but not least important, is the ventilation system. The chamber must also be equipped with a heating unit and an exhaust hood with filters.

The spray booth should have sealed doors, good lighting, suitable dimensions and high-quality wiring (preferably made of copper). All lighting fixtures must be positioned so that the surface of the product to be painted is illuminated as much as possible.

No element of the paint booth should be neglected. Since the performance and health of the master and, of course, the quality of the surface coating depend on them.

The spray booth must have sealed doors.

Principle of operation

With the correct organization of the work process, painting and drying in a specialized room takes up to two hours, not counting the preparatory stage. And the use of the most advanced technology speeds up the process to an even greater extent. Be that as it may, painting a car is painstaking work that requires care and precision. The step-by-step process looks like this:

- a design project is created and suitable paints are selected;

- body parts that prevent direct spraying are removed;

- the surface of the car is cleaned of old paint and rust;

- the metal is covered with primer and puttied;

- paint and varnish are applied in layers;

- drying and polishing is carried out.

It is better to mechanically remove previous layers of paint outside the camera. Otherwise, you will have to do a general cleaning to remove dirt and dust. The paint is applied with a spray gun to the body and, separately, to the dismantled elements, in hard-to-reach places - with a hand brush. Drying takes place in the chamber.

Arranging a garage space for a simple paint booth

DIY painting is a reality! Today, many car enthusiasts are thinking about building a camera themselves. Alternatively, you can use the garage space and convert it into an ideal place for painting work. The camera can be used constantly or occasionally, for business or personal purposes. This is absolutely unimportant; it is important that the design and safety requirements are met.

To operate safely and efficiently, your garage should be assessed before you begin your garage conversion. As noted above, the size of the room is very important for comfortable and productive work, so the height must be at least 2.8 m, the area, in turn, at least 6 × 4 m. The room must be insulated with non-flammable materials and painted white. It is recommended to make tiled walls matte. But the main evaluation criterion is tightness. If you cannot create it, it is better to abandon the idea.

The floor of the chamber must consist of a multi-level frame

Where to start:

- Lighting. It is recommended to install a ceiling-wall light to ensure the most comfortable working conditions. The sources can be LED lamps or fluorescent lamps. In addition, you must have a rotating lamp on a long leg. It will provide additional local lighting of any part of the body.

- Ventilation. The system must be installed at the location of the paint bath. After making calculations, the user will be able to determine the ventilation power and purchase devices in sufficient quantities. It is most effective to have two fans: the first extracts air from the room, and the second blows it from the outside, providing an influx of purified air from the outside. As a rule, the device operates in three modes: cleaning, circulation and heating to the desired temperature, drying is carried out when heated to 60 degrees.

- Equipment for the floor of the room. The floor should consist of a multi-level frame. This is necessary for laying ventilation pipes. Conveniently, if there is an inspection hole, you can cover it with a reinforcement grid and put boards under it.

The hood can be installed under the car, but getting paint on the device is highly undesirable.

Drying

In the “Drying” mode, only one fan operates in the paint drying chamber. Almost all the air circulates inside the working volume of the chamber (only a small part is taken from the street). Thus, a fairly rapid heating of the chamber to operating temperature is achieved at low energy consumption. Redistribution of air flows is carried out automatically. In the “Drying” mode, the built-in timer works. At the end of drying, the chamber automatically switches to the “Blowing” mode. View diagram >>

Homemade or automatic mode control system

It is worth understanding the automatic process control system at the design stage of the premises. Having it provides tangible benefits. Automation makes it possible to improve the entire work scheme and significantly speed up the process while increasing its quality. But this can also significantly affect the budget of the entire enterprise.

However, you get a more advanced system that is all about making time-consuming operations easier. And if you are going to do this, then you need to make the remote control panel from materials that are resistant to various substances. In addition, it must be accessible to every employee, not get in the way, and be exactly in its place. All operations from it are necessarily simple and easily perceived by an ordinary person without much special training.

You can also add a timer that controls all operating modes. With its help, you can ensure that all processes occur literally with the precision of a clockwork mechanism. Everything is reliable, fast, clear and verified.

Automation is a useful thing, but it is also worth thinking about how to easily switch to manual operation if necessary. Operations cannot always be trusted to automation. Some of them should be done manually to improve quality. And for this, all processes must have two control systems, both automatic and manual. Moreover, the transition from one form of work to another is carried out quickly, conveniently and without problems.

Consumables

To paint a vehicle, you will need to purchase other consumables. It is necessary to study their features in advance.

To paint a vehicle, you will need to purchase other consumables.

Cardboard pleated filter

Necessary to catch varnish, paint and other substances in the paint mist. This way the waste is collected without affecting the speed of air masses.

Necessary to catch varnish, paint and other substances in the paint mist.

Floor filter in rolls

Fiberglass material that absorbs small particles of fog; in terms of thickness, the best option would be a 7-centimeter option. Convenient to use, fire resistant.

Fiberglass material that absorbs small particles of fog; in terms of thickness, the best option would be a 7-centimeter option.

Fiberglass filters in cardboard frame

They are suitable for dry chambers and are installed in the 2nd level of filtration. They are distinguished by a good degree of air purification and durability of use.

They are suitable for dry chambers and are installed in the 2nd level of filtration.

Coconut fiber filters for water cabins

Suitable for high humidity, usually installed for the third degree of air purification. They can be washed several times for reusable use.

Suitable for high humidity, usually installed for the third degree of air purification.

Ceiling filter (for supply ventilation)

Required for the third stage of cleaning the intake air flow. They decide which type to choose based on the requirements for air purity. The filter also helps to equalize air masses.

Required for the third stage of cleaning the intake air flow.

Adhesive coating for dust protection

Necessary for removing dust particles during drying, painting and sanding the surface. It is distributed with a roller over the base; when the effectiveness decreases, a new layer is made.

Necessary for removing dust particles during drying, painting and sanding the surface.

Water Cabin Paint Remover

If you introduce the product into a water cabin, solid particles of material will bind, which will help remove paint waste without draining the water from the cabin. This ensures that the strong odor from the paint is eliminated.

If you introduce the product into a water cabin, solid particles of material will bind, which will help remove paint waste without draining the water from the cabin.

A powder paint booth or other paint booth helps provide the necessary conditions for high-quality painting, as well as safe work. In order to save money, you can make such a room yourself.