Currently, all electronic devices contain a complex design consisting of many components. From time to time there is a need to repair such devices.

Repair usually consists of replacing faulty parts with new ones. And if earlier it was possible to simply use a soldering iron for this, then with the advent of components in BGA packages, even the use of hot-air soldering is not always successful.

Experts use an IR soldering iron or soldering station that emits infrared waves.

Description of the IR soldering process

The challenge when working with BGA components is the need to heat and melt large numbers of solder balls at once.

When they are heated, some heat is transferred to the circuit board due to the thermal conductivity of the materials. The heat provided by the soldering station is no longer enough.

Increasing the heating time or increasing the temperature does not have the best effect on the microcircuit. It may overheat and fail.

The solution suggests itself - you need to preheat the circuit board from below, without exposing the chip to heat. It can be heated either by air flow or by calm infrared radiation.

As a result, as the temperature of the board material rises, the heat dissipation from the pin legs will decrease and it will take less temperature and less exposure time to melt the solder balls.

When using infrared soldering, special devices are used for bottom heating - heat tables. This is the operating principle of an infrared soldering station.

Infrared soldering has many advantages over hot air soldering. If with hot-air soldering it is possible to control only the speed of air flow from the nozzle and the temperature of the heating element, and it is completely impossible to control the outflow of air, then with infrared soldering the temperature of the solder can be controlled throughout the entire work cycle.

The use of an infrared soldering station allows for more precise impact on a specific area of the board, which is difficult when soldering with hot air.

And during repair work, the task is precisely to replace one or more components of the circuit without affecting others at all.

From the history of soldering and metallurgy

Soldering is widely used in industry and everyday life. Thus, in the mechanical engineering field it is used in the production of turbine blades, disks, pipeline systems and many other products. Soldering is used in the production of electronic equipment for various purposes.

Soldering electronic equipment

The advantages of this technological process include the following:

- Low temperature heating of connected parts. this allows you to preserve the structure and mechanical parameters of the materials.

- This method allows you to ensure the mechanical cleanliness of the seam and this allows you to avoid additional mechanical processing.

- Modern soldering methods make it possible to connect parts made of steel alloys, non-ferrous metals, etc.

Soldering is one of the oldest methods of metal processing. Its use helped solve many problems in the manufacture of dishes, weapons, jewelry, etc.

Several thousand years ago, soldering was already widely used by artisans. Thus, during excavations on the territory of Babylon, gold items were discovered, in which individual parts were soldered. And on the site of ancient Rome, lead pipes were found that were part of the water supply system and assembled using tin-lead solder. Moreover, some researchers are convinced that the legendary Monomakh hat, kept in the Kremlin, is assembled from several thousand elements made of gold and connected by soldering.

Arc welding

Before the advent of electric arc welding, soldering was used along with welding performed in a forge to create permanent connections between metal parts. In principle, we can say that the advent of electric welding significantly stopped the development of soldering and its transformation into a technical process for joining metal parts.

Brazing Technology

But the emergence and rapid development of aviation construction, astronautics, and microelectronics has led to the emergence of a high and stable demand for the use of this method of assembling parts. In particular, soldering is used to create complex components in mechanical engineering and the construction of various devices. In some cases, soldering turned out to be the only way to connect parts.

Model IK-650 PRO

One of the most common professional-level infrared soldering stations is the IK-650 PRO. In Russia, this device was one of the first capable of successfully repairing equipment with BGA circuits.

The soldering is done so well that a strong opinion has arisen about the absolute reliability of devices whose boards were mounted using this infrared soldering station.

The software allows you to very accurately maintain the temperature profile, which is important for creating strong, reliable contacts. After all, for high-quality soldering it is necessary not only to create a temperature sufficient to melt the solder, but also to raise it smoothly and then smoothly lower it, avoiding a sharp cooling of the contact.

Only then will a strong crystal lattice be created in a drop of solder connecting the contact of the microcircuit with the mounting patch.

The infrared station has a modular design and allows you to assemble many possible configurations for preliminary and auxiliary work:

- it is possible to use various types of thermal tables;

- connecting an electron microscope;

- automatic control of heating and cooling temperatures;

- There are additional modules for restoring BGA pins (this is called reballing).

The soldering station also includes vacuum tweezers, which are convenient for installing small parts on the board.

The cost of the infrared soldering station IK-650 PRO is currently more than 150,000 rubles. It is professional equipment and, of course, is practically inaccessible for amateur use.

Parts for a homemade device

Commercially available infrared soldering stations of domestic and foreign production are very widely available on sale, but their prices start from 20,000 rubles.

And at the minimum price, it will not be a tool of the best quality. If you need to work with BGA packages in conditions of limited funds, a homemade infrared soldering station can be a solution.

It can be assembled from parts of infrared stations available for sale, as well as from scrap materials and old devices that have expired.

A heat table for a soldering station can be made from a lamp or heater with halogen lamps, which will heat the board to the required temperature. The top heater and soldering station controller will have to be purchased from spare parts, buying them new or used.

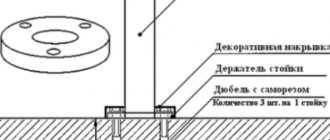

A tripod for the upper heating block can be made from the support of an old table lamp.

For the heating table, you need to stock up on halogen lamps and reflectors. They are placed in a housing that can be made independently from aluminum profiles and sheet metal.

In addition to the lamps, it is necessary to provide a place in the housing for attaching a thermocouple, which will “supply” information about the temperature of the lamps to the control module.

The temperature must be maintained precisely so that the boards do not crack from excess heat and sudden temperature changes.

A little theory

At normal temperatures, the peak of electromagnetic radiation occurs in the infrared region. Things that burn emit both more intense and more energetic (shorter) infrared radiation. When it gets very hot, they start to glow red. The hotter they become, the more orange and yellow they become, then blue.

Many organic molecules absorb infrared radiation intensely, which causes the object to heat up. Heat is the kinetic energy of the translational motion of atoms and molecules. The light emitted by an atom has a wavelength. As a result, the heated body also emits light, and the more heated the body is, the shorter the wavelength of the emitted light.

For information. According to Wien's displacement law, it happens that the thermal radiation of objects near room temperature is in the infrared region. This includes light bulbs and even people.

So, infrared radiation is not heat, and it does not (directly) cause heat. It is emitted by the heat of an object at a certain temperature range.

Infrared radiation

Visual shades of light are determined by the wavelength and its direction, starting with infrared, then red, orange, yellow…. violet and ending with the wavelength of ultraviolet radiation. And back too. Irradiation of a body with light causes an increase in the movement of its molecules, any light, but infrared, as the longest wavelength, is most effective.

A DIY IR soldering station is an infrared heater that releases heat into the environment through infrared radiation.

Assembly

An infrared head with a power of about 400-450 W must be mounted on a tripod using fasteners, the elements of which can be easily purchased in a retail chain; to control the temperature of the upper heating unit, a second thermocouple must be used.

It must be installed together with the heater. The cable can be laid in a flexible metal hose. The soldering station tripod must be mounted in such a way that the IR head can move freely over the entire surface.

It is necessary to provide brackets for fixing the board on the body of the thermal table. It should be located a few centimeters above halogen lamps. Suitable aluminum profiles can be used for the brackets.

The controller for the infrared soldering station is placed in a housing that can be made independently from sheet metal, preferably galvanized steel.

If necessary, you can build into the case the same cooling fans that are used in the computer case.

After assembling the structure itself, the entire circuit of the infrared soldering station will need to be debugged. This is done experimentally by repeatedly running the circuit and taking measurements. The process is not easy, but after setting it up it will give its results - the soldering station will work correctly.

Contactless soldering iron

If there is no urgent need to use an infrared soldering station, then an infrared soldering iron can be successfully used for soldering. Outwardly, it is similar to a regular one, with the difference that instead of a sting it has a heating element.

Application and device

An infrared soldering iron is used in conditions where contact with component leads is unacceptable. It is also convenient to use it for soldering radio components, since often with a regular soldering iron carbon deposits form on the tip and the connections are of poor quality. The carbon deposits have to be cleaned off, and these actions sometimes take quite a lot of time.

In a home workshop, you can make a simple homemade infrared soldering iron from a car cigarette lighter. The heating element of this device is perfect for making tools.

Since normal operation of the cigarette lighter requires a direct current of 12 Volts, corresponding to the on-board electrical network of the car, you will need an electrical converter so that you can use a household AC network. For these purposes, you can successfully use a power supply for computer cases.

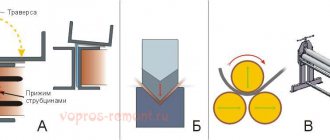

Types of heating elements of soldering irons

Electronic technology is constantly being improved and in one microcircuit you can count millions of parts, for example, transistors. The improvement of these elements makes it impossible to use traditional mounting schemes; the reason for this is that the parts are located very tightly on the board.

Heating elements of soldering irons

That is why soldering stations, which are more suitable for working with boards, have become widespread.

Hot air gun soldering station

As already noted, most stations are designed for assembling boards, that is, you can solder any part with their help, but unsoldering it is quite difficult.

To solve this problem, a device called a hot air gun is used. It allows you to perform work using hot air.

Infrared heater

They are used in a large number of devices, ranging from simple heaters to various technological equipment that use local heating.

In particular, heaters of this type have found their application in the operation of soldering devices for working with printed circuit boards.