Grinding machines - types and features of units

There are 3 types of grinders, which differ in specialization and functionality:

- use tape to remove large layers from large areas;

- surface grinders are used for finishing;

- eccentric ones work on the verge of polishing.

Many craftsmen who are professional grinders have the entire set of these tools in their arsenal. The vast majority of devices operate on 220 V. They are heavy and overheat. A pneumatic machine is lighter than an electric machine, but requires a source of compressed air. Such units are produced by a few companies, the most famous being Bosch.

Tape machines are “tanks” among similar devices

Such a grinding unit, with its working body in the form of an endless ring, resembles a tracked machine, and is also similar in shape. It is relatively powerful, its design is simple but reliable. From the engine, the sanding belt is driven through a gearbox and V-belt drive.

Works with all kinds of materials: wood, metal, polymers, minerals. Removes a few millimeters from the plane, makes curves and edges. The quality is not the best - an orbital (eccentric) or surface (vibratory) sander is required for finishing.

Performance directly depends on motor power. LSMs have motors of 0.5–1.2 kW. Another important indicator in the technical characteristics of these units is speed. A fast device will do more, but it will not be possible to press it due to the high torque. In addition, in this case there is not enough power. Responsible manufacturers have the most balanced indicators; the capabilities are often regulated by electronics.

Fast devices are usually low-power. If they are given more power, it will be difficult to operate, the cost will increase significantly, and if used inappropriately, it is easy to damage the part. High-speed lightweight machines can easily process large areas in a short time. If the upcoming load on the grinder is unknown, professionals recommend choosing a lower speed for home use that can be pressed down (the usual range of devices is 150–550 m/min). Even more convenient is a tape option with a pre-set speed mode, for example, Dewalt DW433.

Surface grinding units - the importance of the platform in the design

The devices occupy an intermediate place between belt and orbital tools in terms of processing purity. They are popular because of their affordable cost, the availability of additional equipment, and the ability to finish quite large areas, including corners. The motor is usually 150–300 W, but there is enough power.

The main thing in such an ESM is the plate moving in the forward-reverse direction with a high frequency. Key Features:

- The amplitude of the sole stroke, which is mainly 1–3 mm. There are models where it reaches 5–6 mm. Increasing the indicator leads to faster processing, but of lower quality.

- Platform stroke frequency. A thicker layer is removed at high rates, but when they are lower, grinding is more precise. Some devices, for example, Bosch GSS AEL-BOXX, have a speed of 20 thousand strokes per minute.

- Plate material and dimensions. According to the latter indicator, there are standard and mini (100 mm2). Budget models have a steel or plastic platform. Better made of porous polymer with low vibration.

Emery is attached differently. Velcro is more convenient, but they are more expensive. Spring-loaded clamps are more complex, but you can use paper cut by yourself.

Eccentric (orbital) machines – a guarantee of high-quality processing

They work both with a flat surface and with a profile, volumetric, curved, except for angular ones. The design is similar to the PShM, but the plate moves not only along the axis, but also orbitally with a slight amplitude, which is set by the eccentric. Complex movement and high speed ensure high-quality surface processing. Motors are usually 200–900 W: the more powerful, the greater the sole pull.

The speeds (amplitude and orbital) are also different. The same rule applies here as for other types of units: higher speed means more processing area per unit of time, but worse quality. The eccentric grinder is rich in electronics, which are used to perform various functions: frequency support, brake, limiting starting currents.

DIY Grinder From Drill

Grinding accessories

There are various devices for manual, non-mechanized grinding. Our client can only divide them into two main types.

- Tools that specifically perform the processing of the part itself. hand-held devices, which include sanding blocks (pads, whetstones), not grinding attachments for a drill or another grinder, which are various support plates, not drums.

- Devices that ensure the desired position of the grinding tool relative to the part. guides, supporting surfaces, etc.

A separate type includes devices for dust removal, which, due to the abundance of non-harmful grinding dust, should also not be abused.

Hand sanding tools

More common hand-held devices include sanding pads, which naturally go by names: sanding blocks, sanding bars, etc. Based on their shape, they are used to process both flat and non-shaped surfaces.

The simplest grinders based on low-power electric motors

Somewhere in the far corners of the garage there may be a weak motor stored, which was forgotten as unnecessary. And it can be turned into a small section. a device that is useful in some cases. The alteration is simple, the main thing is the grinding wheel. In its role, they use a factory one, adapted to the device, or make it independently from a suitable material.

Winchester from a computer in an unusual role

An old, outdated PC, which is covered with dust as it is no longer needed, will now surprise no one. But it contains a unit that will still serve in the household - this is a hard drive. It is equipped with an electric drive, which is used to manufacture the simplest electric machine.

Winchester grinding machine - installation sequence

The steps are simple:

- Disassemble the device, remove the cover and remove everything that is on the left side of the disks.

- Draw a 9 cm circle on abrasive paper and cut it off. Where the compass leg stood, make a hole the size of the spindle. Place double-sided tape on the hard drive plate and secure with sandpaper.

- To protect the operator's eyes, a screen made of aluminum can is installed. Connect to the computer's power supply.

The design will not surprise you with its power, but you can sharpen a knife or a small drill.

Polishing device from a car electric motor

You may find fan motors in the garage. It can be used to make cosmetic repairs to your car and for other household purposes. A neat little sander will eliminate the need to buy an expensive orbital unit to smooth out a small scratch or chip yourself, then paint.

There is a power source in the garage - it's a car battery. Multi-core copper wiring is required of such length that it reaches anywhere in the machine. The engine is powered by placing alligator clips onto the battery terminals or through the cigarette lighter socket. A toggle switch is screwed to the motor with electrical tape to control the device.

A car electric motor is useful for a small electric motor

The working body is a circle. It is better to use a ready-made one with Velcro, which is sold for an angle grinder. Only the fastening needs to be done differently. There are many options, but in any case it is necessary to grind the sleeve. Its internal diameter must correspond to the size of the electric motor shaft, and the mating must be the same - key or thread.

When you plan to use the device not only in the garage, they make a portable version. A household battery is used as a power source. Both the motor and the switch are mounted on a piece of plywood, the wires are fixed with staples. With this device you can sand wood and metal surfaces and perform body work.

Proper Use

High-quality polishing and grinding of a vehicle can be achieved by following these recommendations:

- divide the surface into several sections and process each of them in turn - this will prevent the abrasive or polishing agent from drying out;

- at the beginning of work, the speed should be minimal and after distributing the abrasive over the surface, it is necessary to turn on increased speed;

- during operation, it is necessary to periodically turn off the grinding machine - this will allow the car body to cool and prevent it from overheating;

- when carrying out body treatment, it is necessary to ensure uniform pressure on the sole area, and movements should be smooth;

- during the manipulation process, the grinding wheels are periodically cleaned with a brush;

- If an uncharacteristic sound appears during operation of the tool, it is necessary to thoroughly check, clean and lubricate it.

Despite the fact that a sander speeds up and facilitates repair work, its use still requires care and attention, because if the tool is used incorrectly, it may be necessary to completely replace the car’s paintwork.

The appearance of your four-wheeled friend primarily depends on the condition of the body paint, which, as a result of exposure to external factors, can acquire defects such as scratches, abrasions, chips, etc. It is to eliminate the above defects that polishing is used. However, anyone who decides to carry out this operation on their own needs to know that this process is quite labor-intensive and requires not only theoretical, but also practical skills.

List of tools and components for polishing

A car body polishing tool is a fairly simple and inexpensive set of tools and materials that can be purchased at almost any hardware store. That is why many decide to purchase and further use everything they need for its intended purpose.

So, to implement our plan we will need the following:

- Car polishing machine. This specialized device is the most convenient and practical for work, but in order to save money, the availability of additional devices, as well as small amounts of work, it can be replaced with an ordinary drill.

- An adapter for a drill is a specialized device onto which a polishing wheel or attachment is safely and securely attached, if the choice nevertheless fell on the above tool.

- Wheels and attachments for car polishing.

- Adapters used when it is necessary to replace a wheel or attachment on a disk.

- Applicator for uniform application of polish, wax or abrasive.

If you have acquired practical skills and decided to make money by polishing cars, then you definitely need to have a grinder in your arsenal of tools, which is ahead of a drill in many respects (ergonomics, power, safety in operation).

Practice shows that it is best to purchase tools for polishing a car body in specialized stores, where you can get professional advice on application. Also, when purchasing, you need to pay attention to the presence of instructions included with high-quality equipment and devices, which describe in detail the procedure and scope of application, which will help you save nerves and money.

Remodeling household power tools

Almost every owner has an angle grinder. It can be used for rough finishing - cleaning rust from metal and walls before plastering. Not suitable for delicate work, for example, bodywork - the speed is too high. One careless movement and there is a hole in the car. If you equip it with a voltage regulator, which is found on professional models, then delicate grinding will be possible for a household angle grinder.

Anyone who has at least a little knowledge of radio engineering will assemble the device with their own hands. You will need running parts that can be easily purchased or soldered from old products. No explanation is needed for anyone who can read electrical diagrams.

Diagram of a homemade speed controller for an angle grinder.

The operating procedure is as follows:

- soldered using a printed circuit board or surface mounting;

- thyristors are installed on radiators;

- carry out testing with a 40–60 W light bulb (it should smoothly change brightness when turning the trimming resistor);

- After successful testing, the device is mounted under the tool housing.

The proposed circuit is simple; it is connected to the mains power supply of the angle grinder.

Homemade wood sanders

All materials in any production, in addition to manufacturing, require additional and finishing processing. Vivid examples of such treatments include grinding and polishing the product. These two types of mechanical action on the surface of the part bring its appearance to perfection.

However, everyone knows that performing these operations by hand will take a lot of time and effort, and even processing can only be ensured by a very experienced craftsman. To facilitate this kind of work, people have come up with various devices and mechanisms to help them.

Some of them will be discussed further.

General purpose and types of machines

The machine is intended for final processing of parts and workpieces made of different materials by exposing them to an abrasive or diamond-coated surface. The machine, its component mechanisms and devices make it possible to maintain the accuracy of size and shape, and also ensure the creation of an ideal surface for a part or workpiece.

Using the machine, you can process flat parts, surfaces outside and inside, parts of various geometric shapes, grind or polish threads and gear teeth. According to their characteristics, grinding machines are divided into:

- Cylindrical grinders.

- Internal grinding.

- Centerless grinding.

- Surface grinding.

- Special machines (for grinding threads, gears).

Belt grinder from an angle grinder - device ideas

The drive is a small angle grinder, which costs a little, and almost everyone has. The manufacturing work is simple: you need to make a frame to mount the tool. They are different, so the bed will be different in each specific case. Other important components: the drive shaft and wheels for sandpaper - all made from waste materials, no turning required. All you need is some profile pipes, sheet metal, a welding machine and a grinder.

Schematic diagram and operation

The sanding belt in the device moves on rollers, to which rotation is transmitted from an electric motor. In this case, the grinder acts as the drive, but you can just as successfully use a drill or any suitable motor. They are attached to the frame with reliable fasteners.

The principle of the tape attachment

To prevent the belt from sagging, a tensioning mechanism with a spring is used, which is pulled onto one of the rollers. The stationary unit differs from the manual unit in the table for fixing the workpieces. Safety is ensured by a transparent acrylic screen.

Industrial model

There are factory-made tape attachments for grinders on sale. They give the impression of solid, powerful designs, but users complain about poor mounting, an excessively long belt, which requires a powerful motor to drive. So, for purely practical reasons, and not just because of the high cost, many people prefer to make the console themselves.

DIY Car Ideas

There are many creative options for recycling household power tools to expand functionality. How to make a belt sander from a grinder is shown in the drawing below.

The implementation of the second idea is more difficult. You first need to make a bracket for the drive - the shape and dimensions may be different. They measure the tool and think about how to secure it. For production, steel plates are used, which are bent with the letter “P”. The parts are welded. The main task of this unit is to securely hold the angle grinder.

The bracket is attached to the frame on hinges

The following photo shows a general view of the product. Here it is important to pay attention to 2 parts that serve to adjust the tool. This is a spring between the base and the bracket, which is used to tension the working tape. There are also bolts in the mount. They are needed to change the angle of the angle grinder. This is necessary in order to achieve a position where the abrasive belt will be in the center of the drive wheel and will not fly off it.

Next they make driven rollers - there are two of them. Take closed bearings, which are put on a bolt of suitable diameter and length, and secured with a nut. Cover the top with a piece of plastic pipe. The leader is a bicycle stand, which is installed to perform various tricks.

Leading video

The following photo shows the general appearance of the product. In front is a table made of a piece of sheet iron welded to the base. Parts are processed with fixation on it.

The device is ready for use. Legs are attached to the frame; the bottom can be covered with rubber.

Abrasive tape – where to get it?

It is better to use factory tapes, which have standard dimensions of length 610, 915, 1230 mm, width 50 and 100 mm. Then you won’t have to think about making it yourself. Any version of the emery belt must meet the requirements:

- have an elastic fabric base;

- have a durable abrasive;

- do not heat up during prolonged operation;

- stretch out, but remain intact.

The dimensions of the factory sanding belt can be larger, but for a homemade device you should not take anything longer than 1230 mm. Otherwise, the dimensions of the product increase significantly, and these are unnecessary problems.

Making your own grinding machine is quite possible. Implementing the options is not particularly difficult, the main thing is to choose a suitable drive.

Do-it-yourself grinding machine ⋆ Proraboff.rf

A do-it-yourself sanding machine is made from actually very necessary “trash”, which is found in every workshop or pantry. The tool is used for final processing of parts, grinding, and rounding corners.

There are several types of such devices. The most common is a grinder with a vibration operating principle. One of its main elements is a flat sole attached to the base. It transmits movement from the motor to the abrasive surface. The harder you press the device, the more powerful the vibration movements will be. This type of machine operates at a low speed, it is noisy, and your hands get tired quickly, but at the same time, such a tool is cheap and compact.

A subtype of such a device is a device with a deltoid sole, which is moved forward.

Grinding machines types and purposes

Tape devices. This machine works on a different principle. A belt of abrasive material (sandpaper), glued into a ring, rotates on spindles. When working with it, you do not need to use much force, since the rotation of the tape is quite fast.

Such machines have speed control functions and a soft start system. For more precise work, tape machines have a support frame. When operating such a tool, a lot of dust arises, so they often have a dust collector or the ability to connect to a vacuum cleaner.

Cutting a routing slot to disconnect the disk

Using a router, I cut a slot in the faceplate to provide access to the set screw on the rim hub.

I make trunnions

The purpose of the trunnion is to make the emphasis for the workpieces rotating. I cut out 2 hemispheres from hardwood and cut slots in them. I try them on the body.

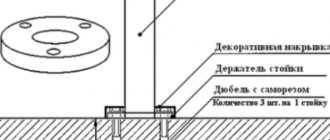

Assembling the table mount

To be able to replace the sandpaper, I make the table mount dismountable using a spline connection.

I screw the boot to the body

First I attach the front part of the case, and then the boot and secure it with a few screws. Later I add thickness by cutting out another boot according to the template. I attach it with glue and leave it to dry, clamping it with clamps.

Assembling the base

I cut out a base from plywood on which I install the engine mount. I use glue and self-tapping screws, having previously drilled holes for them with a thin drill.

Necessity at work and at home

Today, grinding machines are used constantly in production shops. Depending on the scale of production, either one machine or all its varieties in complexity and size can be installed.

However, there is always a use for this equipment in everyday life. Some people have a bench sanding machine for metal processing in their garage. Others have several wood grinding machines of different designs installed in their workshop. Still others own a universal, combined machine. There are power tools for manual grinding: drum type, belt grinder, band saw, small machines or large machines. And they are all in demand.

The market offers a fairly wide range of all kinds of similar equipment from many manufacturers. And their prices are quite reasonable. But these are general purpose machines. And if a person runs his own business, or has a hobby, then he needs a specially specialized machine. Here the price has already increased several times.

For this reason, or based on their own desires, many craftsmen make homemade products. Mainly for processing wood, plastic and metal, less often for cutting and grinding stone. And, in general, this is correct. After all, even simple sharpening of kitchen knives is easier and faster to do on a machine than by hand using a whetstone. Fortunately, its very simple design allows you to create a homemade machine for wood with your own hands.

I'm assembling the case

To cover the engine and raise it above the tabletop, I make the side parts of the housing. I screw them to the mount using self-tapping screws, smearing the edges with wood glue.

Making a motor mount

Using a compass, I transfer the dimensions of the engine onto the plywood. Using a band saw, I cut the plywood into pieces, then clamp the motor and tighten it with clamps.

Selecting the disk shape

Using a piece of chipboard, I draw a circle the size of sandpaper. Then I find the middle of the disc and mark the locations for the screws to secure the disc to the hub.

Using a Forstner drill bit, I drill out the recess for the T-nuts. Then I attach the hub to the disc and cut off the extra length of the bolt.