Characteristics of the material. Steel St2sp.

| Brand | Steel St2sp |

| Classification | Structural carbon steel of ordinary quality |

| Application | non-critical parts requiring increased plasticity or deep drawing; lightly loaded elements of welded structures operating under constant loads and at positive temperatures |

Chemical composition in % of the material St2sp

| C | Si | Mn | Ni | S | P | Cr | N | Cu | As |

| 0.09 — 0.15 | 0.15 — 0.3 | 0.25 — 0.5 | up to 0.3 | up to 0.05 | up to 0.04 | up to 0.3 | up to 0.008 | up to 0.3 | up to 0.08 |

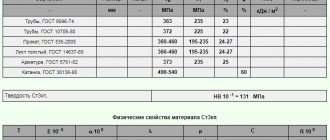

Mechanical properties at T=20oC of the material St2sp.

| Assortment | Size | Eg. | sв | sT | d5 | y | KCU | Thermal change |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| The steel is hot rolled. | up to 16 | 340-440 |

| Material hardness St2sp, | HB 10 -1 = 116 MPa |

Technological properties of the material St2sp.

| Weldability: | no limits. |

| Flock Sensitivity: | not sensitive. |

| Tendency to temper brittleness: | not inclined. |

Designations:

| Mechanical properties : | |

| sв | — Short-term strength limit, |

| sT | — Limit of proportionality (yield strength for permanent deformation), |

| d5 | — Elongation at break, |

| y | — Relative narrowing, |

| KCU | — Impact strength, [kJ/m2] |

| HB | — Brinell hardness, |

| Weldability: | |

| no limits | — welding is performed without heating and without subsequent heat treatment |

| limited weldability | — welding is possible when heated to 100-120 degrees. and subsequent heat treatment |

| difficult to weld | — to obtain high-quality welded joints, additional operations are required: heating to 200-300 degrees. during welding, heat treatment after welding - annealing |

Buy steel St2sp (steel 2 calm)

Pipe Angle Channel Strip Circle Hexagon Reinforcement Square Beam Sheet

Standards

| Name | Code | Standards |

| Ribbons | B34 | GOST 19851-74 |

| Sheets and strips | B33 | GOST 24244-80, TU 14-1-3579-83, TU 14-1-4431-88 |

| Steel pipes and connecting parts for them | B62 | GOST 3262-75, GOST 10704-91, GOST 10705-80, TU 14-3-1160-83, TU 14-3-1428-86, TU 1373-013-02949352-2003 |

| Ribbons | B24 | GOST 3560-73, GOST 6009-74, STP M309-74 |

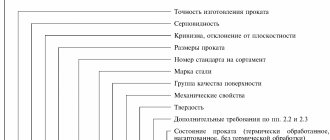

| Classification, nomenclature and general norms | IN 20 | GOST 380-2005 |

| Long and shaped rolled products | B22 | GOST 5422-73, GOST 5781-82, GOST 8278-83, GOST 8281-80, GOST 8282-83, GOST 8283-93, GOST 9234-74, GOST 10551-75, GOST 11474-76, GOST 19240-73, GOST 19425-74, GOST 30565-98, GOST 535-2005, GOST 30136-95, OST 5.9086-85, OST 5.9087-84, TU 14-2-341-78, TU 14-1-5283-94 |

| Sheets and strips | B23 | GOST 8568-77, GOST 14918-80, GOST 16523-97, GOST 16523-89, GOST 16523-70 |

| Blanks. Blanks. Slabs | B31 | OST 3-1686-90, TU 14-1-4944-90 |

| Long and shaped rolled products | B32 | TU 14-11-245-88, TU 14-136-367-2008 |

| Low carbon steel wire | B71 | TU 14-4-1813-97 |

Regular quality carbon steel

Formula for calculating the mass of 1 m of metal rod

To determine the theoretical weight of a linear meter of a steel circle, use the formula M = π*ρ*(D 2 /4) , in which:

π is a constant approximately equal to 3.14;

ρ is the average value of steel density, usually taken equal to 7850 kg/m3;

D – cross-sectional diameter, m.

If you need to find out the mass of a metal rod made of copper, aluminum and other metals, substitute the density of these metals, kg/m3, into the formula:

- aluminum – 2700;

- titanium – 4500;

- zinc – 7140;

- tin – 7290;

- copper – 8940;

- lead – 11340.

Description

Carbon steel, grades, types, properties and qualities

St5ps steel is used: for the manufacture of parts of riveted structures, bolts, nuts, handles, rods, bushings, rollers, wedges, axles, levers, stops, pins, pins, rods, sprockets, tubular grids, flanges and other parts operating in the range temperatures from 0 °C to +425 °C; forgings with a diameter of up to 800 mm. strength classes KP 175, KP 195; forgings with a diameter of up to 300 mm. strength class KP 215; forgings with a diameter of up to 100 mm. strength class KP 245; hot-rolled C-shaped profile for agricultural machines; knives of earth-moving machines (bulldozers, scrapers, graders and motor graders, as well as for knives of bulldozer and grader equipment of excavators, rollers and other earth-moving machines); double-headed, T-bar and P5 type rails intended for ground and overhead tracks.

Production Features

GOST 30136-95 carbon steel wire rod of ordinary quality. technical specifications

The properties of the finished material are determined by the substances that make up its composition and largely depend on what technologies were used in the production of a particular alloy.

The basis of the steel alloy is ferrite. It is a component of iron-carbon alloys. It is, in fact, a solid solution of carbon and alloying components. To increase its strength, the melt is saturated with carbon.

Impurities from which nothing but harm can be expected include phosphorus and sulfur, as well as their derivatives. Phosphorus, reacting with ferrite, reduces the ductility of the alloy when exposed to high temperatures and increases brittleness when exposed to cold. During the melting process, iron sulfide may be formed, which can lead to red brittleness. St3 steel contains no more than 0.05% sulfur and 0.04% phosphorus.

For the production of structural steels, two steelmaking technologies are used:

- open hearth;

- converter

The parameters of the St3 grade, obtained by one or another method, differ little from each other, but the converter technology is simpler and cheaper.

Deoxidation of St3 steel

The deoxidation process is performed to remove excess oxygen, which reduces the mechanical properties of steel. For this purpose, silicon or aluminum is used. They neutralize oxygen, and the resulting oxides serve as a stimulus for the formation of crystallization centers and thereby contribute to the appearance of a fine-grained structure. Steels that have undergone this operation are divided into three types:

- calm - sp;

- semi-calm - ps;

- boiling - ks.

What are their differences from each other? Calm steels get their name because they do not boil when poured. They have a more uniform structure, are better processed by welding and exhibit good resistance to dynamic loads. But, on the other hand, they are more expensive and that is why semi-quiet ones have become more widespread. They occupy a place between calm and boiling alloys. By the way, semi-quiet steels are most often used to create structures for various purposes. To obtain it, a smaller amount of deoxidizing agent is used, mostly silicon.

An example is the use of St3 PS steel to create building structures.

It should be noted here that the steel must meet the requirements of GOST 380-71. When purchasing this brand, the supplier must provide documents with the results of testing the material for chemical composition, strength characteristics, tensile strength, etc.

Rating: /5 — votes

III. Acceptance rules

18. Product quality checks during manufacturing and acceptance of finished products are carried out by the technical control department (QC) of the manufacturer. The quality control department checks the compliance of the dimensions, appearance, mechanical properties and chemical composition of steel with the standards specified in the relevant standards and departmental technical specifications.

Control and acceptance of products are carried out by the quality control department based on observations of the steel production process, records of test results carried out during its manufacture, and tests of finished products.

19. Steel of groups A and B is supplied either as whole heats or parts of heats, depending on the batch sizes and order conditions. For steel grades St.0, MSt.0 and BSt.0, float delivery is not required.

20. Lot sizes and the number of samples for testing are established in special standards or departmental technical specifications for individual types of rolled products.

21. In the event of an unsatisfactory result of any test, this test may be repeated, for which a double number of samples are taken. If the results of re-testing the steel are unsatisfactory, the manufacturer is given the right to subject the delivered batch to normalization or annealing and re-sorting and present it for delivery again.

Mechanical characteristics

| Section, mm | sТ|s0.2, MPa | σB, MPa | d5, % | d4 | d10 |

| Cold-rolled steel for enameled cookware according to GOST 24244-80 in the delivered condition (rolled drawing group, quality category is indicated) | |||||

| 0.5-1.5 | ≥250 | 270-368 | — | ≥30 | ≥36 |

| 1.5-2 | ≥235 | 270-368 | — | ≥30 | ≥36 |

| 2-2.5 | ≥235 | 270-368 | — | ≥32 | ≥36 |

| 0.5-2 | — | 255-362 | — | ≥28 | ≥34 |

| 2-2.5 | — | 255-362 | — | ≥30 | ≥34 |

| 0.5-2 | — | 265-382 | — | ≥26 | — |

| 2-2.5 | — | 265-382 | — | ≥29 | — |

| 0.5-2 | — | 265-382 | — | ≥25 | — |

| 2-2.5 | — | 265-382 | — | ≥28 | — |

| Hot-rolled bars and shapes in delivery condition | |||||

| ≤10 | ≥195 | 305-390 | ≥35 | — | — |

| ≥100 | ≥165 | 305-390 | ≥32 | — | — |

| 10-20 | ≥195 | 305-390 | ≥35 | — | — |

| 20-40 | ≥185 | 305-390 | ≥34 | — | — |

| 40-100 | ≥175 | 305-390 | ≥32 | — | — |

| The sheet is in delivery condition. No heat treatment | |||||

| — | — | 310-400 | ≥33 | — | — |

| Hot-rolled thin sheets in delivery condition. Strength group OK300V | |||||

| ≤2 | ≥215 | 300-480 | — | ≥21 | — |

| 2-3.9 | ≥215 | 300-480 | — | ≥23 | — |

| Cold-rolled thin sheets in delivery condition. Strength group OK300V | |||||

| ≤2 | ≥215 | 300-480 | — | ≥24 | — |

| 2-3.9 | ≥215 | 300-480 | — | ≥26 | — |

Foreign analogues

| Europe EN 10027-1 (EN 10027-2) | S235JR (1.0038) |

| Germany DIN | RSt37-2, USt37-2 |

| USA (AISI, ASTM) | A238/C |

| France (AFNOR) | E 24-2 |

| UK BS | 40B |

| Czech Republic (CSN) | 11375 |

| Poland PN/H | St3SV, St3SJ, St3S4U |

Chemical composition

Each category of steel is characterized by its specific chemical composition. It largely determines the scope of application of the workpieces being created and the difficulties that arise during heat treatment.

The key points regarding the chemical composition are the following:

- As previously noted, the main chemical elements are iron and carbon. The first element has a concentration of 97%, carbon is only 0.14-0.22%. It is carbon that determines the hardness index and some other physical and chemical properties of the structure.

- The structure includes a relatively small amount of alloying elements. The main elements are chromium and nickel, the concentration of which is 0.3%. Copper is included in the composition at the same concentration.

Chemical composition

With a large number of varieties of steel, the concentration of harmful impurities, which are phosphorus and sulfur, is strictly controlled in the one under consideration. In addition, the composition contains nitrogen in high concentrations, which accounts for about 0.1 mass.

Alloy steels

When marking alloy steel, the letter designations of alloying elements are used (Table 2). These letters combined with numbers form the steel grade.

In the brand, the content of the alloying element, if it exceeds 1...1.5%, is indicated by a number (mass fraction in whole percent) following the corresponding letter. If there is no number behind the letter, then the content of this element is about 1%. An exception is made for some elements (V, Ti, Mo, Nb, Zr , B, N, etc.), the presence of which in steels, even in thousandths of a percent, has a significant effect on the properties of steel (microalloying).

Table 2. Symbols of alloying elements in metals and alloys

| Element | Symbol | Designation of elements in grades of metals and alloys | Element | Symbol | Designation of elements in grades of metals and alloys | ||

| black | colored | black | colored | ||||

| Nitrogen | N | A | — | Neodymium | Nd | — | Nm |

| Aluminum | A1 | YU | A | Nickel | Ni | — | N |

| Barium | Va | — | Br | Niobium | Nb | B | Np |

| Beryllium | Be | L | Tin | Sn | — | ABOUT | |

| Bor | IN | R | — | Osmium | Os | — | OS |

| Vanadia | V | f | To you | Palladium | Pd | — | front |

| bismuth | Bi | In and | In and | Platinum | Pt | — | Pl |

| Tungsten | W | IN | — | Praseodymium | Pr | — | Etc |

| Gadolinium | Gd | — | Gn | Rhenium | Re | — | Re |

| Gallium | Ga | Gi | Gi | Rhodium | Rh | — | Rg |

| Hafnia | Hf | — | Gf | Mercury | Hg | — | R |

| Germanium | Ge | — | G | Ruthenium | Ru | — | Pv |

| Holmium | But | — | GOM | Samarium | Sm | — | Myself |

| Dysprosium | Dv | — | DIM | Lead | Pb | — | WITH |

| Europium | Eu | — | Ev | Selenium | Se | TO | ST |

| Iron | Fe | — | AND | Silver | Ag | — | Wed |

| Gold | Au | — | Evil | Scandium | Sc | — | From km |

| Indium | In | — | In | Antimony | Sb | — | Cv |

| Iridium | Ir | — | AND | Thallium | Tl | — | Tl |

| Ytterbium | Yb | — | ITN | Tantalum | Ta | — | TT |

| Yttrium | Y | — | THEM | Tellurium | Those | — | T |

| Cadmium | Cd | CD | CD | Terbium | Tb | — | Volume |

| Cobalt | Co | TO | TO | Titanium | Ti | T | TPD |

| Silicon | Si | WITH | Kr(K) | T\'liy | Tm | — | TUM |

| Lanthanum | La | — | La | Carbon | WITH | U | — |

| Lithium | Li | — | Le | Phosphorus | P | P | F |

| Lutetium | Lu | — | Leung | Chromium | Cr | X | X(Xp) |

| Magnesium | Mg | Sh | Mg | Cerium | Ce | — | Xie |

| Manganese | Mn | G | Mts(Mr) | Zinc | Zn | — | C |

| Copper | Cu | D | M | Zirconium | Zr | C | TsEV |

| Molybdenum | Mo | M | — | Erbium | Er | — | Erm |

If there is no number at the beginning of the brand, then the amount of carbon is 1% or higher. For structural steels, two numbers in front of the grade indicate the average carbon content in hundredths of a percent. For tool steels, one number at the beginning of the grade means the average carbon content in tenths of a percent. The bulk of alloy steels are smelted of high quality. The difference in the designation of high-quality, high-quality and especially high-quality steels is that at the end of the grade of high-quality steels the letter A is assigned, and for especially high-quality steels - the letter Ш. For steels used in the form of casting (in casting), the letter L is assigned at the end of the grade. high-quality steels there are deviations from these rules. Thus, in grades of tool alloy steels, as well as steels and alloys with special physical properties, the letter A is not indicated, since all of them are always high-quality (or especially high-quality). Some groups of special-purpose steels contain additional designations: grades of ball bearing steels begin with the letter Ш, high-speed steels with the letter P, electrical grades with the letter E, magnetically hard steels with the letter E, machine guns with the letter A. More details on the marking of these steels will be provided reported in the relevant sections.

Characteristics of the material. Steel St2kp.

| Brand | Steel St2kp |

| Classification | Structural carbon steel of ordinary quality |

| Application | non-critical parts requiring increased plasticity or deep drawing; lightly loaded elements of welded structures operating under constant loads and at positive temperatures |

Chemical composition in % of the material St2kp

| C | Si | Mn | Ni | S | P | Cr | N | Cu | As |

| 0.09 — 0.15 | up to 0.05 | 0.25 — 0.5 | up to 0.3 | up to 0.05 | up to 0.04 | up to 0.3 | up to 0.008 | up to 0.3 | up to 0.08 |

Mechanical properties at T=20oC of the material St2kp.

| Assortment | Size | Eg. | sв | sT | d5 | y | KCU | Thermal change |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| The steel is hot rolled. | 20 — 40 | 330-420 | 32 |

| Material hardness St2kp, | HB 10 -1 = 116 MPa |

Technological properties of the material St2kp.

| Weldability: | no limits. |

| Flock Sensitivity: | not sensitive. |

| Tendency to temper brittleness: | not inclined. |

Designations:

| Mechanical properties : | |

| sв | — Short-term strength limit, |

| sT | — Limit of proportionality (yield strength for permanent deformation), |

| d5 | — Elongation at break, |

| y | — Relative narrowing, |

| KCU | — Impact strength, [kJ/m2] |

| HB | — Brinell hardness, |

| Weldability: | |

| no limits | — welding is performed without heating and without subsequent heat treatment |

| limited weldability | — welding is possible when heated to 100-120 degrees. and subsequent heat treatment |

| difficult to weld | — to obtain high-quality welded joints, additional operations are required: heating to 200-300 degrees. during welding, heat treatment after welding - annealing |

Buy steel St2kp (steel 2 boiling)

Pipe Angle Channel Strip Circle Hexagon Reinforcement Square Beam Sheet

Standards

| Name | Code | Standards |

| Steel pipes and connecting parts for them | B62 | GOST 3262-75, GOST 8639-82, TU 14-3-1160-83, TU 14-3-1428-86 |

| Rails. Overlays. Linings. Crutches | B42 | GOST 3280-84, GOST 7056-77, GOST 8194-75, GOST 12135-75 |

| Ribbons | B24 | GOST 3560-73, GOST 6009-74, STP M309-74 |

| Classification, nomenclature and general norms | IN 20 | GOST 380-2005 |

| Long and shaped rolled products | B22 | GOST 5422-73, GOST 5781-82, GOST 8239-89, GOST 8240-97, GOST 8278-83, GOST 8281-80, GOST 8282-83, GOST 8283-93, GOST 8320.0-83, GOST 8509-93, GOST 8510-86, GOST 9234-74, GOST 10884-94, GOST 11474-76, GOST 12492.13-90, GOST 17152-89, GOST 19240-73, GOST 19425-74, GOST 19771-93, GOST 19772-93, GOST 535-2005, GOST 2590-2006, GOST 2591-2006, OST 5.9086-85, OST 5.9087-84, TU 14-2-949-91, TU 14-1-5254-94 |

| Sheets and strips | B23 | GOST 82-70, GOST 14637-89, GOST 14918-80, GOST 16523-97, GOST 19903-74, GOST 16523-89, GOST 16523-70, GOST 103-2006, GOST 19903-90, TU 14-1- 3023-80 |

| Metal forming. Forgings | B03 | GOST 8479-70 |

| Blanks. Blanks. Slabs | B31 | OST 3-1686-90, TU 14-1-4944-90 |

| Thermal and thermochemical processing of metals | B04 | ST TsKBA 026-2005 |

| Sheets and strips | B33 | TU 14-1-4431-88 |

| Long and shaped rolled products | B32 | TU 14-2-849-89, TU 14-11-245-88, TU 14-136-367-2008 |

Other alloys from the category Structural carbon steel of ordinary quality

| Alloy grade | GOST | Chem. compound |

| VSt2kp | GOST 380 - 71, the latest version does not contain material | Fefrom 98.3%Mn0.25-0.5%C0.09-0.1%… |

| VSt2ps | GOST 380 - 71, the latest version does not contain material | Fefrom 98.2%Mn0.25-0.5%C0.09-0.1%Si0.05-0.1%… |

| VSt2sp | GOST 380 - 71, the latest version does not contain material | Fefrom 98%Mn0.25-0.5%Si0.12-0.3%C0.09-0.1%… |

| VSt3Gps | GOST 380 - 71, the latest version does not contain material | Fefrom 97.5%Mn0.8-1.1%C0.14-0.2%… |

| VSt3kp | GOST 380 - 71, the latest version does not contain material | Fefrom 98.1%Mn0.3-0.6%C0.14-0.2%… |

| VSt3ps | GOST 380 - 71, the latest version does not contain material | Fefrom 98%Mn0.4-0.65%C0.14-0.2%Si0.05-0.1%… |

| VSt3sp | GOST 380 - 71, the latest version does not contain material | Fefrom 97.8%Mn0.4-0.65%C0.14-0.2%Si0.12-0.3%… |

| VSt4kp | GOST 380 - 71, the latest version does not contain material | Fefrom 98%Mn0.4-0.7%C0.18-0.2%… |

| VSt4ps | GOST 380 - 71, the latest version does not contain material | Fefrom 97.9%Mn0.4-0.7%C0.18-0.2%Si0.05-0.1%… |

| VSt5ps | GOST 380 - 71, the latest version does not contain material | Fefrom 97.7%Mn0.5-0.8%C0.28-0.3%Si0.05-0.1%… |

| VSt5sp | GOST 380 - 71, the latest version does not contain material | Fefrom 97.5%Mn0.5-0.8%C0.28-0.3%Si0.15-0.3%… |

| VSt6ps | GOST 380 - 71, the latest version does not contain material | Fefrom 97.6%Mn0.5-0.8%C0.38-0.4%Si0.05-0.1%… |

| VSt6sp | GOST 380 - 71, the latest version does not contain material | Fefrom 97.4%Mn0.5-0.8%C0.38-0.4%Si0.15-0.3%… |

| St0 | GOST 380 - 2005 | Fefrom 99.6%… |

| St1kp | GOST 380 - 2005 | Fefrom 98.3%Mn0.25-0.5%C0.06-0.1%… |

| St1ps | GOST 380 - 2005 | Fefrom 98.2%Mn0.25-0.5%C0.06-0.1%Si0.05-0.1%… |

| St1sp | GOST 380 - 2005 | Fefrom 98%Mn0.25-0.5%Si0.15-0.3%C0.06-0.1%… |

| St2kp | GOST 380 - 2005 | Fefrom 98.3%Mn0.25-0.5%C0.09-0.1%… |

| St2ps | GOST 380 - 2005 | Fefrom 98.2%Mn0.25-0.5%C0.09-0.1%Si0.05-0.1%… |

| St2sp | GOST 380 - 2005 | Fefrom 98%Mn0.25-0.5%C0.09-0.1%Si0.015-0.3%… |

| St3Gps | GOST 380 - 2005 | Fefrom 97.5%Mn0.8-1.1%C0.14-0.2%… |

| St3Gsp | GOST 380 - 2005 | Fefrom 97.3%Mn0.8-1.1%Si0.15-0.3%C0.14-0.2%… |

| St3kp | GOST 380 - 2005 | Fefrom 98.1%Mn0.3-0.6%C0.14-0.2%… |

| St3ps | GOST 380 - 2005 | Fefrom 98%Mn0.4-0.65%C0.14-0.2%Si0.05-0.1%… |

| St3sp | GOST 380 - 2005 | Fefrom 97.8%Mn0.4-0.65%Si0.15-0.3%C0.14-0.2%… |

| St4kp | GOST 380 - 2005 | Fefrom 98%Mn0.4-0.7%C0.18-0.2%… |

| St4ps | GOST 380 - 2005 | Fefrom 97.9%Mn0.4-0.7%C0.18-0.2%Si0.05-0.1%… |

| St4sp | GOST 380 - 2005 | Fefrom 97.7%Mn0.4-0.7%C0.18-0.2%Si0.15-0.3%… |

| St5Gps | GOST 380 - 2005 | Fefrom 97.3%Mn0.8-1.2%C0.22-0.3%… |

| St5ps | GOST 380 - 2005 | Fefrom 97.7%Mn0.5-0.8%C0.28-0.3%Si0.05-0.1%… |

| St5sp | GOST 380 - 2005 | Fefrom 97.5%Mn0.5-0.8%C0.28-0.3%Si0.15-0.3%… |

| St6ps | GOST 380 - 2005 | Fefrom 97.6%Mn0.5-0.8%C0.38-0.4%Si0.05-0.1%… |

| St6sp | GOST 380 - 2005 | Fefrom 97.4%Mn0.5-0.8%C0.38-0.4%Si0.15-0.3%… |

Physical properties of VSt3ps steel

| Temperature 0C | E 10-5 (MPa) | a 10 6 (1/Deg) | l (W/(m deg)) | r (kg/m3) | C (J/(kg deg)) | R 10 9 (Ohm m) |

| 20 | 1.94 | |||||

| 100 | 1.92 | |||||

| 200 | 1.87 | |||||

| 300 | 1.83 | |||||

| 400 | 1.78 | |||||

| 500 | 1.67 | |||||

| 600 | 1.59 | |||||

| 700 | 1.46 | |||||

| 800 | 1.2 | |||||

| 900 | 0.99 |

Characteristics of the material. Steel St1sp.

| Brand | St1sp |

| Classification | Structural carbon steel of ordinary quality |

| Application | parts of high viscosity and low hardness, anchor bolts, connecting sheathings, non-critical fittings, rivets and boiler connections |

Chemical composition in % of material St1sp

| C | Si | Mn | S | P |

| 0.06 — 0.12 | 0.15 — 0.3 | 0.25 — 0.5 | up to 0.05 | up to 0.04 |

Mechanical properties at T=20oC of the material St1sp.

| Assortment | Size | Eg. | sв | sT | d5 | y | KCU | Thermal change |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| 320-420 | 190-220 | 30 |

Designations:

| Mechanical properties : | |

| sв | — Short-term strength limit, |

| sT | — Limit of proportionality (yield strength for permanent deformation), |

| d5 | — Elongation at break, |

| y | — Relative narrowing, |

| KCU | — Impact strength, [kJ/m2] |

| HB | — Brinell hardness, |

Buy

Pipe Angle Channel Strip Circle Hexagon Reinforcement Square Beam Sheet

steel St1sp (steel 1 calm)

Assortment

- Channels are parallel (P), with sloped flanges (U), equal-flange bent;

- round sections circle and reinforcement;

- VGP pipes, electric welded (ES), seamless (BGD);

- I-beams, wide-flange, column, special, with flange slopes;

- steel square;

- corners equal and unequal;

- square and rectangular profile;

- sheet steel: hot-rolled, corrugated, expanded metal, strip.

Types of delivery

- Hot rolled sheets, including strip and tape;

- forgings;

- rails;

- pipes;

- rod and wire.

Application of steel St3

The technical parameters of St3 allow it to be used for the production of loaded elements of welded structures and parts of machines and mechanisms operating at positive temperatures.

Some types of rolled products, in particular those of the fifth category, are used in the production of metal structures that can operate at temperatures from -40 to 425 degrees Celsius under alternating loads.

After constructing complex structures, it makes sense to carry out heat treatment, in particular annealing. This operation is necessary to relieve stress arising after welding work.

In addition, this material is used in the production of At400s construction reinforcement.

Sheets made from this steel are used for the production of parts produced using cold stamping technology. It is used to produce troughs for collecting coolants and waste oils installed on machines, containers of various sizes and purposes, covers for machine equipment, casings, etc.

Steel circle weight calculator

A steel circle is a type of round rolled metal, which is made from carbon, high-alloy and low-alloy steels. This material is widely used in the production of power and protective structural elements and parts.

The steel circle weight calculator from KALK.PRO allows you to calculate the weight of a bar based on a known cross-sectional diameter and rolled length in a few clicks. Our calculator also performs the reverse calculation - converts weight into length. GOST 2590-88 “Hot-rolled round steel” is used as a source.

Using the calculator, you can find the weight of all possible types of assortment, for example, a circle of 6, 10, 12, 16, 18, 20, 30 mm, etc. If necessary, you can immediately use a metal grader or look into GOSTs, the relevant tool tabs.

The default weight is 1 meter of a steel circle.

Calculate the weight of a circle

- Select the metal type (default is Steel ).

- Confirm the type of assortment - Circle / Rod / Bar .

- Select the calculation method – Weight calculation .

- Specify the grade of metal (default Steel St3sp ).

- Enter the rolled diameter, mm .

- Enter the length of the circle, m .

Converting a bar from tons to meters

- Select the metal type (default is Steel ).

- Confirm the type of assortment - Circle / Rod / Bar .

- Select the calculation method – Length calculation .

- Specify the grade of metal (default Steel St3sp ).

- Enter the rolled diameter, mm .

- Enter the weight of the circle, kg .

Formula for calculating the weight of a bar

The weight of round steel can be determined independently using GOST formulas and tables:

Formula for calculating the weight of a circle: m = ρ × (π × D 2 / 4)

Source