Brass LS59-1 is a multicomponent copper alloy, the chemical composition of which is specified by GOST 15527-2004. This GOST indicates that such an alloy may contain 57–60% copper, 37.05–42.2% zinc and 0.8–1.9% lead. Other chemical elements present in the LS59-1 alloy as impurities may be contained in it in an amount of no more than 0.75%.

Brass ingots brand L59-1 are intended for subsequent processing

Although the alloy of this brand belongs to the category of brass, which is well processed by pressure, most often products made from it are processed on high-speed metal-cutting machines. Because of this, LS59-1 is also classified as an automatic weapon. The characteristics of brass of this brand are determined by lead, which is included in its composition as an alloying element.

You can familiarize yourself with the GOST requirements for brass alloys by downloading the document in pdf format from the link below.

GOST 15527-2004 Copper-zinc (brass) alloys processed by pressure. Stamps

Mechanical characteristics

Due to the presence of lead in the composition of LS59-1 brass, when processing products made from it by cutting, small chips are formed, which allows such processing to be performed at high speeds. A distinctive feature of the alloy in question is that lead constitutes a separate phase in its internal structure. This makes such a material highly susceptible to plastic deformation. Meanwhile, if we compare LS59-1 brass with two-component alloys, it is significantly inferior to them in its ductility, so it is better to process such material by cutting.

The range of products made from LS59-1 brass includes:

- rods with different cross-section profiles;

- sheet material – strips, sheets, plates;

- wire;

- profile rolled products;

- pipe products.

Main characteristics of L59-1 brass

Brass of the LS59-1 brand is distinguished by good anti-friction characteristics, which allows the use of such material for the manufacture of products operated in conditions of high friction. From this alloy, in particular, sliding bearings are produced, used to complete various mechanisms and machines. In addition, the abrasion resistance that LS59-1 is characterized by allows this brass to be used for the manufacture of guides for machine tools for various purposes.

Technological properties of alloy L59-1

Since brass of this brand has a multiphase structure, products made from it are characterized by increased fragility. Parts made from LS59-1, on which surface cuts are made, cannot be used as load-bearing elements, since they can break under significant pressure. In addition, the increased fragility of this brass leads to the fact that when exposed to shock loads, the surface of products made of this material can become covered with cracks, which does not allow them to be processed using such a technological operation as forging.

Advantages

Nickel silver: alloy composition, application, characteristics

Like many other types of rolled metal, bronze rod has a number of advantages:

- No rough surface. This effect is achieved by long-term processing of products on the machine. Thus, any relief on the profile almost completely disappears.

- High level of strength. This in turn affects the service life of the rods. They withstand both kinks and various moderate stretches well.

- Low wear. For many other types of rolled metal it is more significant.

- Affordable price of rolled metal. This can be achieved through well-functioning, reliable production and the use of the latest technologies.

- Optimal level of heat and electrical conductivity. These properties of the product can be modified by adding some other substances to it, such as nickel, copper, iron, etc. In this way, both low and high electrical conductivity can be achieved.

- Versatility. A large number of types of rods allows them to be used in completely different areas.

- Increased flexibility and ductility. As a result, bronze rods are often used in the production of various parts and devices of both simple and complex shapes.

- Resistance to climatic conditions. This significantly increases the service life of the product and its functionality.

Corrosion resistance

Due to the presence of lead in the chemical composition of brass of the brand in question, a separate phase is formed in its internal structure, which has a positive effect not only on its workability, but also on its resistance to corrosion. Compared to other brass alloys, LS59-1 is more resistant to corrosion. Products made from such brass are not subject to cracking and oxidation when used in conditions of high humidity and temperature changes.

However, there is no need to talk about the exceptionally high corrosion resistance of LS59-1: in this parameter, this alloy is similar to brasses of other brands. In particular, it is not recommended to use it in cases where it will come into contact with products made of iron, aluminum and zinc. In addition, the corrosion resistance of LS59-1 will be poor when:

- simultaneous exposure to high humidity and high pressure;

- contact with fatty acids;

- operation in hydrogen sulfide environment;

- contact with ore waters and mineral acids;

- constant interaction with oxidized solutions and chlorides.

The characteristics of brass allow the metal to be used for the production of shut-off and connecting valves operated at temperatures above 100 degrees

LS59-1 demonstrates its corrosion resistance well under the following operating conditions:

- atmospheric air, including that saturated with sea salt vapor;

- dry steam;

- liquid medium characterized by a very low content of salts and acids;

- freon, alcohol solutions and antifreeze;

- salty sea water in a sedentary state.

It should be borne in mind that the interaction of LS59-1 brass with a gaseous or liquid medium characterized by a high content of ammonia, oxygen and carbon dioxide has a very negative effect on the corrosion resistance of the alloy.

Dezincification of brass

Characteristics of dore alloy

Brass, in addition to general corrosion, is also subject to special types of corrosion: dezincification and “seasonal” cracking. Dezincification is a special form of corrosion in which the surface of the brass product is first dissolved in a reagent. The solution in which brass is dezincified contains more zinc than copper. As a result of exchange reactions in the cathode sections, copper is electrochemically deposited in the form of a spongy film. Brasses with a high zinc content (L60, L63) undergo dezincification faster, since in two-phase brasses there is a preferential dissolution of the β-phase, which is the anode, and the α-phase, the cathode. The dezincification process is observed when brass comes into contact with electrically conductive media (acidic and alkaline solutions). As a result, brass becomes porous, reddish spots appear on the surface, and mechanical properties deteriorate.

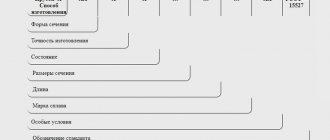

Rental products

Various rolled metal products are manufactured from the brass of the brand in question, the requirements for the chemical composition and mechanical characteristics of which are specified by GOST 15527-2004. The range and parameters of the latter are regulated by other regulatory documents. Pipes for the manufacture of which this alloy is used can be produced either by plastic deformation or by continuous casting. At the same time, the production of pipes from brass LS59-1 by casting is much cheaper than the production of similar products obtained using deformation processes.

Brass pipe is easy to install by welding or soldering

The plastic deformation method for brass of this grade is used in the production of wire and rods, which can have a round, hexagonal or square cross-section. In this case, the manufacturing material itself must also meet the requirements established by GOST 15527-2004 (for products that are made from it, the standards are specified by GOST 1066).

Sheets are produced from LS59-1 brass, characterized by high density, hardness and, accordingly, wear resistance. Due to their characteristics, they are successfully used in the manufacture of guide machines for various purposes. In addition, special technologies make it possible to produce soft, semi-hard and hard sheet materials from such brass. In this case, both the density and specific gravity of such products will correspond to similar parameters of the source material.

Brass sheets are used to make plumbing and electrical products, cladding panels and signs

Rods with different cross-sectional shapes made from LS59-1 brass are very actively used in industry. Their distinctive features are high strength and good machinability. It is also important that the production of such products (for this purpose, rolling or drawing technology can be used) is characterized by low cost. Depending on the manufacturing technology and scope of use, rods made of LS59-1 brass can be produced in soft, semi-hard or hard versions.

Mechanical properties of L59-1 brass rods

Assortment of brass LS59-1

| Brass bushing LS59-1 | Size 50-1000 mm, price - check |

| Brass square LS59-1 | Side 5-60 mm, matte, semi-hard, price from 389 rub./kg |

| Brass circle LS59-1 | Diameter 3-160 mm, drawn and pressed, matte, price from 360 rub./kg |

| Brass tape LS59-1 | Thickness 0.1-2 mm, cotton, price - check |

| Brass sheet LS59-1 | Thickness 0.5-25 mm, cold-stained and hot-stained, matte, price from 489 RUR/kg |

| Brass wire LS59-1 | Diameter 0.8-6 mm, drawn, price from 575 RUR/kg |

| Brass pipe LS59-1 | Diameter 5-200 mm, drawn and pressed, price - check |

| Brass hexagon LS59-1 | Diameter 5-41 mm, stretched, matte, semi-solid, price from RUB 363/kg |

The sizes and prices of LS59-1 brand products are constantly updated, so contact our managers to quickly and correctly place your order.

Areas of use

The wide range of applications of products made from LS59-1 brass is explained by such characteristics as:

- low cost;

- high hardness and strength;

- good machinability;

- wear resistance and corrosion resistance.

All this allows this alloy to be successfully used for manufacturing:

- elements of gear and worm connections;

- bushings and liners for various purposes;

- fastening elements;

- pipe products.

Assortment of brass LS59-1

| Brass bushing LS59-1 | Size 50-1000 mm, price - check |

| Brass square LS59-1 | Side 5-60 mm, matte, semi-hard, price from 389 rub./kg |

| Brass circle LS59-1 | Diameter 3-160 mm, drawn and pressed, matte, price from 360 rub./kg |

| Brass tape LS59-1 | Thickness 0.1-2 mm, cotton, price - check |

| Brass sheet LS59-1 | Thickness 0.5-25 mm, cold-stained and hot-stained, matte, price from 489 RUR/kg |

| Brass wire LS59-1 | Diameter 0.8-6 mm, drawn, price from 575 RUR/kg |

| Brass pipe LS59-1 | Diameter 5-200 mm, drawn and pressed, price - check |

| Brass hexagon LS59-1 | Diameter 5-41 mm, stretched, matte, semi-solid, price from RUB 363/kg |

The sizes and prices of LS59-1 brand products are constantly updated, so contact our managers to quickly and correctly place your order.

Standards

| Name | Code | Standards |

| Wire made of non-ferrous metals and their alloys | B74 | GOST 1066-90, GOST 1066-2015, OST 4.021.105-92, OST 4.021.112-92, OST 4.021.116-92, TU 48-21-409-79, TU 48-21-493-75 |

| Ribbons | B54 | GOST 15527-2004, GOST 2208-2007, OST 4.021.078-92, TU 48-21-541-76 |

| Non-ferrous metals, including rare ones, and their alloys | B51 | GOST 28873-90, OST 4.021.009-92, TU 48-21-642-79 |

| Pipes made of non-ferrous metals and alloys | B64 | GOST 494-90, GOST 494-2014, OST 4.021.123-92, OOP 5.9243-87, TU 48-21-667-79, TU 48-21-77-72, TU 48-21-798-86 |

| Rods | B55 | GOST 6688-91, GOST 2060-2006, GOST R 52597-2006, GOST 31366-2008, OST 4.021.020-92, OST 4.021.037-92, OST 4.021.041-92, TU 48-21-381-74 , TU 48-21-559-76, TU 48-21-603-78, TU 48-21-93-77, TU 48-0810-119-86 |

| Sheets and strips | B53 | GOST 931-90, OST 4.021.050-92, OST 4.021.067-92, TU 84-320-78, TU 1845-069-07515308-98 |

| Long and shaped rolled products | B52 | TU 48-21-434-84 |