Wheel balancing is the elimination of imbalance of a car wheel by shifting the center of rotating masses as close as possible to the axis of its rotation. The need for such a procedure arises when the mass of tires and wheels is displaced relative to their axis of rotation. Because the imbalance is transmitted to the car’s suspension elements.

Balancing the wheels on a car prevents excessive vibration of the steering wheel and body while driving, and also helps prevent deterioration in handling and premature wear of wheel bearings, ball joints and suspension silent blocks.

In this article we will talk in detail about when you need to balance wheels, how this procedure is carried out and whether you can do it yourself, as well as answer other frequently asked questions about wheel balancing.

When it is necessary?

Experts identify several basic requirements regarding wheel balancing.

This work must be performed in the following cases:

- When replacing tires from winter to summer (and vice versa). Usually, at normal service stations, when “re-shoeing” a car, balancing is done immediately and is included in the cost of the service. If you change the tires yourself, you will also have to do the balancing work yourself;

- In case of hitting a curb, falling into a hole or passing a concrete policeman at speed. Such situations rarely end without a trace for the car's drive. Even a minimal defect can lead to wheel imbalance. Therefore, contacting a tire service is also mandatory;

- Every 15,000 kilometers. Few car enthusiasts cover such a distance within one year, so balancing when changing tires seasonally is sufficient. But there are also “truck drivers” who have to do this work twice a year;

- Every 7000-8000 kilometers – for those who like fast and aggressive driving;

- Before a long trip (1.5-2 thousand kilometers and above) and after it. This requirement is based on safety reasons.

How to make a stand (machine) for balancing

Build a homemade product by first making a drawing of the device. Find the wheel hub in working condition, remove the boot from the bearing.

A do-it-yourself wheel balancing device is a metal structure consisting of a frame and vertical profile posts mounted on it.

Install the hub on the frame between the racks so that the ramp can rotate freely. Please note that dynamic balancing of wheels on a homemade machine is impossible: “eights” are eliminated at professional stands in car repair shops.

What is the danger?

It would seem that what can happen if wheel balancing is not done in a timely manner? We often forget that each wheel has its own individual weight, pressure, technical characteristics, oval shape and defects. Therefore, the issue of balancing it is very important.

If this is not done, the consequences may be as follows.

The braking distance of the car increases.

This is easy to explain - the contact area between the tire and the asphalt decreases, grip deteriorates, and traffic safety decreases.

Controllability decreases.

The reasons are the same as in the previous case.

There is a beating in the steering wheel.

The imbalance in the wheel is transmitted to the suspension, and then to the steering wheel. The stronger it is, the greater the vibrations the driver feels. In this case, driving a car is very dangerous.

Suspension wear accelerates.

Poor balancing (or lack thereof) most affects the suspension bearings and hubs. Due to imbalance, these elements of the chassis system may even collapse. The result is loss of controllability and the likelihood of an accident.

Increased tire wear.

The reasons are uneven distribution of forces and the appearance of vibration. Essentially, the tires will be “eaten up” on one side.

What does improperly balancing the wheels of a car lead to?

Neglecting to balance a vehicle's wheels can be costly for a car owner. Its consequences can hit the wallet of the average car enthusiast very hard.

We can highlight the following negative aspects associated with incorrect actions to establish wheel balance:

Safety.

Poorly balanced car wheels lead to a significant lengthening of the braking distance. All this can lead to emergency situations on the roads. Often the contact area is reduced and the level of adhesion of the tire to the asphalt drops.

Controllability decreases.

The vibration of the steering wheel when driving a car is not only annoying, but can also reduce controllability. This phenomenon is especially dangerous at high speeds. The chances of getting into an accident increase many times over.

Suspension load.

Improper balancing of vehicle wheels leads to accelerated wear of the vehicle's suspension components. Individual elements may even be partially destroyed during long-term operation of the machine.

Tire wear.

Uneven tire wear on wheels is the first sign of imbalance. Even new high-quality and expensive tires can be ruined in a relatively short period of time if measures are not taken in time. As practice shows, wear occurs on the outside or inside of the wheel.

In total, we can distinguish two types of imbalance associated with violation of the vehicle wheel balancing procedure:

Dynamic.

The incorrectly distributed weight of the wheel when it moves creates oscillatory movements. It begins to wiggle from side to side. The phenomenon occurs if the weight was unevenly distributed on both or one side of the wheel centerline.

Statistical.

An imbalance occurs if the wheel has a too heavy or, conversely, light section. Uniform rotation in this case is simply impossible. Oscillatory movements occur up and down.

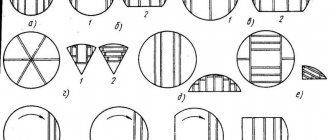

Types of imbalance

Today there are two main types of wheel imbalance:

- Static imbalance. This implies an uneven distribution of the mass of the product along the axis; the wheel begins to “beat” in the vertical plane. In fact, there is no center of gravity on the wheel axle at all. This problem sooner or later leads to destruction of the suspension.

- Dynamic imbalance is unevenness in the plane of the wheel. In this case, there is a center of gravity, and it is on the axis of rotation (where it should be). The only difference is that the axis of inertia and the center of gravity do not coincide.

The cause of the imbalance may be the design features of the wheel (tread pattern, location of the valve hole, inaccuracies in geometry, dimensions, and so on).

In this case, the greatest imbalance can be caused by the car tire itself. Here, a lot depends on the rubber material, weight, structure, and so on.

Final balancing

Final balancing is performed on wheels that are already installed on the car. The advantage of the work is that not only the wheels are adjusted, but also the brake discs, CV joints, hubs and axle shafts.

This type of balancing ensures a real smooth ride, improves wheel grip and allows you to achieve a number of other positive aspects.

Signs of poor quality work

Wheel balancing is not always done well. There are several factors by which this can be determined:

- The service station does not take any measurements before carrying out work. A good mechanic should definitely check the wheel and tire runout parameters. At the same time, it is advisable to do this as accurately as possible, taking into account radial and lateral runout;

- All dirt from the tire and excess elements from the tread must be removed. If this is not done, then balancing becomes a completely useless exercise. Before starting work, the wheel must be perfectly cleaned;

- Pay attention to the appearance of the balancing machine. If it is dirty, then it is very difficult to count on accurate data and high-quality balancing.

How to balance a wheel yourself using a cone

You will need : a cone, which can be made from a construction pin and several washers of a certain diameter.

The old-fashioned way of balancing a wheel:

- Secure the cone strictly in the center of the wheel.

- Place the wheel on a protrusion (for example, a stump) with the tip of the cone.

- Place a weight on the side of the wheel that is higher.

- Rock the wheel a little and wait until it stops.

- If one of the sides of the wheel is higher, repeat the procedure from point No. 3 until the wheel is balanced.

Video example:

This is interesting: Do-it-yourself replacement of front shock absorbers

We do the work with our own hands

To perform balancing, you need to prepare a special set of weights (you can buy it in the store).

At the same time, for cast and forged wheels, balancers are sold that are glued to the wheel (they should be given preference).

The sequence of actions is as follows.

Raise the wheel with a jack and make sure it rotates easily. If there is friction, loosen the hub nut slightly. Clean the wheel from dirt and remove all stones from the tread (they will interfere with balancing).

Be sure to check the tire pressure. It must be in accordance with the recommendations specified in the car's operating manual.

Remove the old balance weights.

After this, spin the wheel counterclockwise and wait until it stops completely. Now you can mark the top point with chalk (this is the easiest place).

Next, rotate the wheel clockwise and place the mark again (also at the top point). Between the first and second mark is the lightest part of the wheel.

Glue balancers weighing 30 grams on both sides.

But that is not all.

Spin the wheel in any direction and see that after it stops, the weights should be at the bottom. With this we found out the point of lower balancing. If the result is different, select heavier weights, but do not overdo it.

Having achieved the result, move the weights to the right or left from the last point. It is necessary to ensure that the wheel stops at different positions of the point.

Now move on to the rest of the wheels and proceed in the same sequence.

But to balance the rear wheels, it is recommended to put them in place of the front ones, although not everyone does this.

Errors during the procedure

If the balancing process is carried out in violation of the technology, then the vibration problem, at best, will not be solved, and at worst, it will further worsen. The most common mistakes:

- Balancing when there is dirt on the wheel. Even pebbles stuck in the tread can be disrupted by additional imbalance. The overall picture, even with precise equipment, will be disrupted, and it will not be possible to bring the wheel to zero.

- Balancing a wheel with a broken tire or wheel geometry. If the disc has even minor dents or distortions, it must first be rolled on a special machine. Straightening the disc with a hammer or other impact instruments is unacceptable.

- Incorrect torque of the hub bolt on the balancing machine. Excessive force will lead to the wheel being misaligned and the balancing will be incorrect.

- Violation of technology for installing a tire on a disk. Often, even experienced installers perform work in violation of technology. As a result, the wheel is given additional inertia.

- Misalignment during installation of the wheel on the vehicle axle. This problem occurs due to incorrect tightening of the bolts. Even if a properly balanced wheel is installed skewed, it will vibrate.

In order to avoid such troubles, you need to carefully choose a car service and supervise the work of the technicians. Qualified specialists guarantee their work and show the balancing results on the machine display. If the master prohibits the presence of the car owner during work or does not provide a guarantee, it is advisable to refuse his services.

Wheel balancing is an important element of monitoring the technical condition of a vehicle. A timely procedure will help not only improve safety and driving comfort, but also extend the life of the vehicle by preventing premature wear of chassis parts.

- Author: Andrey

Rate this article:

- 5

- 4

- 3

- 2

- 1

(12 votes, average: 4.5 out of 5)

Share with your friends!

Home →

With your own hands →