The welding machine Resanta SAI-220K is designed for manual electric arc welding with direct current with a coated electrode. This device can be used in both the household and industrial segments.

Specifications

| Welding current adjustment range: | 10…220 A |

| Maximum power consumption: | 6.6 kW |

| Maximum current consumption: | 30 A |

| Input voltage range: | 140…260 V |

| Maximum electrode diameter: | 5 mm |

| Length of cable with electrode holder: | 2 m |

| Ground cable length: | 1.5 m |

| Duration of loading: | 70% at welding current 220 A |

| Open circuit voltage: | 80 V |

| Arc voltage: | 28.8 V |

| Anti-stick protection: | ANTI STICK function |

| Overheat protection: | automatic |

| Hot start function: | There is |

| Cooling: | forced |

| Protection class: | IP21 |

| Ambient temperature: | -10…+40 °С |

| Overall dimensions, L×W×H: | 285x170x160 mm |

| Weight, no more: | 4.5 kg |

| Warranty period: | 24 months |

Principle of operation

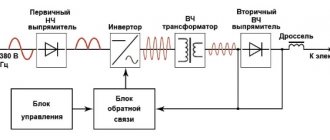

It consists of converting alternating mains voltage with a frequency of 50 Hz into a direct voltage of 400 V, which is converted into high-frequency modulated voltage and rectified. Pulse width modulation is used to regulate the welding current.

Device SAI-220K

The product is made in a metal case, on the plastic front panel of which there is:

- Regulator of welding current value. Using the welding current regulator, you can set the desired current depending on the thickness of the welding electrode.

- Power connectors for connecting welding cables.

- The “network” indicator lights up when the device is turned on.

- The “overheating” indicator lights up for a few seconds when the AIS is turned on and when the device overheats and turns off after it has cooled to operating temperature.

- Power switch (installed on the rear panel).

Hot start (HOT START)

To ensure better ignition of the arc at the beginning of welding, the inverter automatically increases the welding current. This will greatly facilitate the start of the welding process. Thanks to this function, the device can be used not only by experienced welders, but also by beginners. This function is installed on all Resanta welding machines.

Anti-stick (ANTI STICK)

When starting welding, the arc must be ignited. This often leads to the electrode sticking to the product. In this case, the inverter itself automatically reduces the welding current, and the electrode easily comes off. Subsequently, after the stuck electrode comes off, the inverter resumes the set welding parameters. All SAI series welding machines are equipped with this function.

IGBT

Without exception, all Resanta inverters are made using IGBT transistors. The effect is that due to them the service life of the device increases by 7 times. In addition, weight and dimensions are reduced. With IGBT, the board is located vertically, dust does not settle on it.

The power of the welding machine is one of the main characteristics that you need to pay attention to when choosing it.

In order to better understand all the intricacies associated with welding devices and understand the main points for calculating this parameter, it is necessary to clarify several important aspects. The information will be useful to know for all those involved in welding.

How many kilowatts does the Resanta 220 welding machine consume?

There are several types of these units. Transformer welding machines are quite heavy and of impressive size, but they are reliable and durable. They supply alternating or direct current through a transformer. Can be used when cutting ferrous and non-ferrous metals. A small inverter welding machine has been on the market in Krasnodar not so long ago. It works using electrodes and is little dependent on the input voltage. Used in professional activities, in cutting titanium, cast iron, stainless steel.

Semi-automatic welding machines are universal welding machines that work with inert gas. They will carry out high-quality welding of aluminum and iron. In most cases they are used at home. Generator welding machines are devices consisting of an engine running on gasoline or diesel fuel and an alternating current generator. These are indispensable assistants in welding various materials. At RosProkat23 you can rent any welding machine in Krasnodar at the lowest prices!

Owner reviews

Cheap, very easy to use. I bought it not for work, but for farming. I shared it with my friends, and everyone praised it, you can easily weld 4 mm metal. Indispensable at the dacha. The body is metal and the weight is light.

Kirill G.

I bought a Resanta inverter for my garage and am very pleased. As an amateur, it is easy to work with him. Pleased with the non-stick electrode. Compact and affordable.

Sergey P.

The device is not heavy, and it is easy to carry it to the desired point, the work itself is just a fairy tale, but the cable is a bit short.

Peter K.

Consumption calculation

To find out how much an inverter-type welding machine consumes, carefully read the instructions for your machine. Or find another source where you can find out the technical specifications of your model. From the TX you will learn all the necessary initial data.

So, for calculations, we need to know the power factor, the maximum current value, the maximum welding arc voltage, the efficiency of the device and the operating time of the device (this parameter will be useful to us later). We will calculate using the following formula:

Max. zn. current x max. zn. eg / efficiency = power consumption (during welding time)

The power factor is similar for most home inverters and is 0.6. Just remember this number and use it in your calculations.

The maximum current value will be 160A as an example. You must enter the value from your technical specifications.

Let the maximum arc voltage be 25 V. Enter your value.

Let the efficiency of our device be 0.90. And the operating time is 60% of 100% welding work (3 minutes of work and 2 minutes of rest).

Now we calculate the electricity consumed by our welding inverter. 160 A x 25 V / 0.90 = 4445 Watts. This is approximately 4.4 kW. Please note that this is the inverter power consumed only during operation.

But welding is not always carried out continuously. Sometimes it is necessary to replace electrodes, change the welding current, or prepare the following parts. Therefore, our calculation is not accurate enough. To solve this problem we will need the device operating time. We wrote above that for our device it is 60%. Now multiply 4.4 by 0.6 to get a more accurate figure. In our case, 4.4 x 0.6 = 2.7 kW. The result obtained is the average power of the inverter that it consumes during the entire welding period, taking into account pauses.

We repeat once again that these calculations were made taking into account our characteristics, which we chose as an example. You need to substitute your values if they differ from those described above.

That's all. By performing simple calculations, you can easily find out how many kW inverter welding consumes and whether you can provide yourself with comfortable working conditions. We did not mention the calculation of consumption when welding with semi-automatic welding. Since the power consumption of a semi-automatic device is a topic for a separate article. Let’s just say that this figure will be 20 percent higher compared to inverter welding.

Calculation by formula

Now let's look at how to calculate the power factor. For this purpose, the formula is used: the duty cycle in minutes is divided by the sum of the operating time before and after stopping. We multiply the resulting number by 100. Let’s say the device welded metal regularly for 6 minutes without interruption. Then the protective mechanism was activated, it stopped the working process, the device “rested” for 4 minutes, after which it started working again. We calculate the coefficient using the formula:

6/(4+6) x 100 = 60%

The power factor for inverter devices of the amateur and semi-professional classes does not exceed 70%. As a rule, this figure is in the range of 60-70%. Data that may be required to calculate the power consumed by an inverter device is available in the technical documentation. The necessary information is posted on the manufacturer’s website, in the instruction manual, or directly on the page of the online store where you are going to buy the tool, in the Characteristics section.

Let's look at how to calculate power using the example of a unit with the following technical parameters:

- voltage MIN – 160V;

- voltage MAX – 220V;

- current strength – 160A;

- arc voltage – 23V;

- Efficiency – 0.89%;

- PV – 60%.

First, let's determine the maximum power. It is necessary to multiply the welding current by the working arc voltage. The resulting value is divided by the efficiency. Here's what happened:

160A x 23V / 0.89 = 4135 Watts

This is an indicator of the power required to power the unit directly during the welding process. To calculate the average value, you need to multiply the maximum power by the duty cycle and divide by 100%.

4135 x 60 / 100 = 2481 W.

The result is the nominal value of power consumption. Why is the rated power taken for calculations? The welding inverter will not operate at maximum current all the time. It stops welding at a lower current, so it is not advisable to buy a model with a power that is almost twice the required value.

By the way, you don’t have to calculate the power consumption yourself; the manufacturer has already done it for you. This characteristic is indicated in the technical documentation along with other indicators.

Main characteristics of welding machines

Any welding machine, regardless of its design, has one important parameter - the on-duration (ON) in accordance with different values of the welding current. Manufacturers of welding machines use different measurement techniques. However, when working on a welding machine, no one operates it continuously and at full power, burning several electrodes in a row, and our managers will be able to help in choosing the most suitable option.

The next equally important characteristic of a welding machine is the range of current changes during welding operations. The value of this indicator is an indirect indicator of equipment power. The wider the range, the larger electrodes can be installed, and, accordingly, the longer the duration of switching on the welding machine will be in the case of using small electrodes at the same current strength.

No-load current is also an important parameter of a welding machine. Its indicators are in the range of 60–85 V, and the higher this value, the easier it is to ignite an electric arc.

Description of devices and diagrams

Next, we will talk about four popular Chinese welding inverters from the Resanta brand. It is Chinese, and not Latvian, as many people confuse.

Resanta SAI 220

The Resanta SAI 220 machine is one of the most popular welding inverters from the entire SAI line. At the same time, one of the most expensive among its “brothers”. The only more expensive model is the SAI 250PROF, which we will talk about later.

The Resanta SAI220 model is designed for welding using coated electrodes. The device is not suitable for professional use, only for domestic use. However, this welding inverter successfully copes with simple repairs in the country house or garage. It is also suitable for learning the basics of welding.

Now about the characteristics. Resanta SAI 220 produces up to 220 Amps of welding current, which is more than enough for a beginner or a practicing welder. By the way, looking at the name of the devices in the SAI line, it’s easy to guess what current strength a particular model has

Types of inverter devices

First of all, we recommend that you familiarize yourself with the types of inverter units. All models of this type are divided into three large groups. Each has its own characteristics. Let's take a closer look.

- Household or amateur. This includes models that are powered by a conventional single-phase 220V network. At maximum power, welding with such a unit can only take 20-30 minutes. Afterwards you need to give the device a chance to rest. This time is quite enough to perform one-time operations at home or in the garage. In addition, household inverters are inexpensive, compact in size and light in weight.

- Semi-professional. More powerful devices compared to units from the first category. They are capable of working for up to 8 hours without a break; they are purchased for use in auto repair shops and small enterprises.

- Professional. Welding equipment is designed for frequent use in difficult conditions. They are purchased for large enterprises and factories for the production of metal structures. They effectively weld parts from different metals, work for a long time without interruption, do not overheat, and are powered by a three-phase 380V network. But the models are also expensive.

If you buy equipment for use in the household, take into account one important nuance: the maximum load current should not be higher than 160A. Power circuit breakers and electrical fittings, which are installed in private houses and apartments, are not designed for a current higher than this value.

You cannot connect equipment with a current strength exceeding 160A to the household network. This can lead not only to the operation of the machines, but also to burnout of contacts or fire of electrical wiring. It's better not to let this happen. There are enough amateur-class models in the manufacturers' lines; choose a device from this category for home use, and buy professional ones only if you can connect the equipment to a 3-phase 380V network.

Resanta welding inverters: SAI, SAI PN, SAI K, reviews, prices, operation

The Resanta brand is of Baltic origin - the company is registered in Latvia. Factories, as has become common, are located in China. Welding inverters of several lines are supplied to the Russian market:

- Semi-automatic devices Resanta SAIPA.

- Welding inverters Resanta SAI.

- Inverters operating at reduced voltage AIS PN.

- Units with argon-arc welding function SAI AD.

- Professional ruler with adjustable arc SAI PROF.

- “Compact” line - SAI-K.

- Inverter plasma cutter - IPR.

- Inverter welding operating from 380 V - SAI 315.

The product, according to reviews, is generally quite good, with its pros and cons. If you need a welding machine for home use, Resanta is a worthy choice. As the pros say: its arc is not as heavy as other brands in the same price category. But the quality is unstable: for some, under constant load (in workshops and in production), it works for years, while for others, it takes it for repairs every two to three weeks (also in production). Only production and welders are different. And those who use Resanta welding inverters for domestic purposes - in a private house, in a rural area, in a garage - respond positively to the operation of the units.

The operating mode of welding machines of any line is 70% to 30%. Which means that when working at 140 A, out of 10 minutes you can cook/cut 7, but 3 will have to rest - wait until the device cools down. The ratio is not the worst and the mode is generally convenient.

Advantages of the device

The mobility of the device is achieved by its relatively low weight, equal to 4.3 kg, as well as a special shoulder strap, which makes it very easy to carry and allows you to perform work at heights.

The main advantages of the inverter welding machine Sai 140 are:

- mobility;

- ease of operation;

- safety;

- affordable price.

To quickly form an electric arc, a special Hot start function has been implemented, which makes it easier to perform the work thanks to the automated conversion of an increased current pulse.

When welding, the master often encounters the problem of electrode sticking, but in Resant this problem is eliminated, since the device includes an anti-stick function. By using it during operation, you can automatically reduce the current value. After using the option, the system quickly restores the parameters to continue operation. Those who use the Resanta Sai 140 welding inverter in reviews describe it as convenient and reliable. The advantage of this device is its low energy consumption, in comparison with more powerful ones in its line.

How to choose a Resanta welding machine

For domestic use, it makes sense to choose a unit from two lines - SAI and SAI PN.

Resanta SAI is a standard modification that operates at 220 V in the network with minor deviations. The declared range is: +10% (up to 242 V) and -30% (from 154 V). It seems that such characteristics should be enough, but in reality it works normally at 190 V. If it drops even lower, problems begin and you have to install electrodes of a smaller diameter.

This is a welding machine Resanta SAI 220 - small size and weight

In rural areas, the voltage is often below 190 V. With such network parameters, not all welding machines can operate normally. If you have such a situation, you need to choose an inverter from the SAI PN line. It welds normally even at 140-160 V.

There is another line - “Compact”. It is even smaller in size and weighs a kilogram and a half less. When designating models of this line, the letter “K” is assigned to the number indicating the maximum welding current. If weight and size are critical for you, choose a welding inverter from this line.

All others are more suitable for professional or semi-professional use. For domestic use, their “bells and whistles” and increased power are useless. If you can buy them, it’s not for beginners in welding.

Model selection

After you have decided on the ruler, you need to select the maximum welding current. It is placed in the name of each model after the abbreviation SAI. For example, SAI-160 has a maximum welding current of 160 A, SAI 220 can produce 220 A.

How to choose power? Based on the work for which you are purchasing or the size of the electrode you prefer to work with. For example, devices with 140 and 160 amperes are suitable for working with 3 mm electrodes. But 140 will work at the limit, and 160 in normal mode. You can also consider purchasing 190, but it can already work with 4 mm electrodes. And power reserves are always good. True, you have to pay extra for it.

More powerful models SAI 220 and 250 can work with electrodes of 5 mm and 6 mm, respectively. If you don’t need such power, then there is no need to pay for it. But the choice, as always, is yours. Maybe you prefer to work with a 3 mm electrode but with a higher welding current - 190 and higher... It’s rare, but such welders do exist.

To make the choice easier, the table contains the most important characteristics of the Resanta welding inverters of the SAI and SAI PN, and SAI K lines.

Selecting electrodes for a welding inverter

The power and current also determine which electrodes can be used with the unit. The range of consumables is very wide. Installing an unsuitable electrode leads not only to deterioration in welding quality, but also to breakdown of the inverter apparatus. We have compiled a table that will help you select electrodes.

| Thickness of metal workpiece (mm) | Current (A) | Electrode diameter (mm) |

| 1-4 | 20-90 | up to 2 |

| 5-7 | 90-130 | 3 |

| 8-12 | 140-180 | 4 |

| 12-16 | 180-220 | 5 |

| from 15 | from 220 | from 6 |

Consumable electrodes used for inverter welding must comply with the requirements of GOST 9467-75. Only such consumables can be considered safe to use; they ensure high quality of the welding process and leave behind neat, even seams. Electrodes are classified into those used for welding conventional (ANO) and critical (USSI) structures.

OZS-12 are popular electrodes that allow you to work at low currents. They can be used to work with low-carbon and carbon steels. ANO-36 is also often used; their surface is treated with a rutile cellulose coating. They light up easily and are recommended for those who do not yet have sufficient experience in using welding machines. Such electrodes are suitable for welding parts made of stainless and high-alloy steel. Consumables for welding aluminum sheets, cast iron and other metals are available for sale. The speed and efficiency of welding, as well as the quality of the seam, depend on the correct choice of electrode.

Technical characteristics of welding inverters Resanta SAI and SAI PN, SAI K

| Welding inverter model | Maximum current consumption, A | Open circuit voltage, V | Arc voltage, V | Maximum electrode diameter, mm | Weight, kg | Price |

| SAI-140 | 20 | 75 | 25 | 3,2 | 4,3 | 110 $ |

| SAI-160 | 22 | 80 | 26 | 4 | 4,5 | 120 $ |

| SAI-190 | 25 | 80 | 27 | 5 | 4,7 | 155$ |

| SAI-220 | 30 | 80 | 28 | 5 | 5 | 180$ |

| SAI-250 | 35 | 80 | 29 | 6 | 5,2 | 220$ |

| SAI-60PN | 22 | 80 | 26 | 4 | 5,7 | 170$ |

| SAI-220PN | 25 | 80 | 27 | 5 | 6,4 | 200$ |

| SAI-250PN | 35 | 80 | 29 | 6 | 7,7 | 250$ |

| SAI-160K | 28,5 | 85 | 4 | 3,4 | 130$ | |

| SAI-190K | 32,5 | 80 | 5 | 4,3 | 155$ | |

| SAI-220K | 36,5 | 80 | 5 | 4,5 | 180$ | |

| SAI-250K | 42,5 | 80 | 6 | 4,6 | 210$ |

Power table

When choosing a welding inverter, it is necessary to take into account other factors besides the kW consumed. This is especially true for professional models. They are subject to higher demands than household versions.

It is necessary to take into account the thickness of the materials being welded. The power of the inverter welding machine and the thickness of the electrodes will also depend on this criterion. The required parameters are shown in the table below.

It greatly simplifies the calculation of power consumption depending on operating conditions. In addition, this table will be useful for beginners who often wonder about choosing an electrode of the correct diameter.

| Metal thickness, mm | Welding current, A | Electrode diameter, mm |

| 1,5 | 30-50 | 2 |

| 2 | 45-80 | 2,5 |

| 3 | 90-130 | 3 |

| 4 | 120-160 | 3 |

| 5 | 130-180 | 4 |

| 8 | 140-200 | 4 |

| 10 | 150-220 | 4-5 |

| 15 or more | 160-320 | 4-6 |

The intensity and volume of work is the criterion by which a device with a certain duration of operation is selected. As already described above, this parameter shows how long the device can work with wire of a certain thickness under given conditions.

The operating conditions of the inverter determine its protection class. If the device is to be used indoors, then IP21 certification will be sufficient, but if used outdoors, when the temperature is low or there is high humidity, IP21 protection will be required.

Power supply for Resanta inverters

The main advantage of these welding machines is that they operate from a 220 V household power supply without making any special requirements. The main thing is that the outlet is grounded. The protection class of all units is IP 21, which means that the device is grounded through the power cord. Therefore, to protect against electrical damage, it is necessary to power the inverter from a grounded outlet.

SAI-160s work normally on 10-16 A machines, but on ten-amp machines you cannot set the maximum welding current. If you plan to operate SAI 190, you will need at least a 16 A automatic machine.

Reviews

All reviews about Resanta inverter welding machines can be roughly divided: before 2012 and after. Until the age of 12, all the reviews are very good, and not from beginners, but from those who use welding in their professional activities. Further - worse. In 2012, the price of these devices dropped significantly—almost by half. It seems good, but as it turns out, the quality has also decreased significantly. After this date, there are different reviews, although positive ones still prevail.

In our workshop, Resanta 250 (SAI) worked every day for a year until someone attached her legs. There were no complaints about the work, only the cables were a bit short. That's why we bought a new one just like it. This one, after 3 months, just suddenly stopped cooking. The service didn’t ask any questions, they just repaired it and that’s it. Now everything is fine, we work like adults. Apart from the cables, no complaints.

Vitaly, Kineshma, 2013

I am a technologist and I am responsible for purchasing tools. We needed an inverter for welders - we worked with a transformer, so I decided not to buy an expensive one for now - in case it didn’t work for them, so I bought a Resanta SAI 250. For two years of intensive work, not a single problem. The transformer is now standing, but this one is always busy. Both specialists and those who have only seen how to work properly use it to cook. Nothing, it's plowing. They say that with Resanta it’s a lottery. Looks like we got a good ticket. We just replaced the welded cables - we installed 10 meter ones with a cross section of 25mm2: the previous five meter ones were inconvenient.

I have repaired it for the fourth time... I have a Resanta 220. All previous repairs were enough for two weeks of work. The last time I repaired it was due to pull (it got to me) in another service center. They supplied, as they said, a normal fee. Worked for a month, so far so good. I used to blame the quality of the device, but now I’m confused, maybe the service is like this? Did they install crappy parts so that I would pay them? There is not enough evil.

I have Resanta 190. I have been using it periodically for three years. Everything is fine, you only need to set the minimum welding current when turning it on and off, as stated in the instructions. It’s not difficult for me, and I do it. I also periodically clean it from dust. For such devices this is critical.

Vitaly Sergeevich, Sergiev Posad

I have been using Resanta 220 for three years now. It works. All this time I only changed the cooler. But I clean it regularly, I try not to cut it, and I don’t let it into the wrong hands. I don’t use a grinder or grinder near welding - they create a lot of dust, and it’s very harmful for inverters. If I need to work with an angle grinder, I use Resanta. If all this is a burden to you, look for another device. There are Europeans, they are not so demanding about working conditions, but they cost several times more, and they don’t want to work with our dancing voltage. So if you need a European who works in our conditions, you also buy a stabilizer. Something like this.

Resanta is not a welding machine, but a bunch of g...a. I'm tired of taking it for repairs. It breaks down all the time. It just stops cooking and that's it. I'll take another one.

I bought Resanta SAI 190 in May 2014. In November it got better. The warranty workshop said that there was a lot of metal dust, which is why it burned. They wanted to reduce it to a non-warranty repair (at my expense), but after a dispute they repaired it under warranty. Now I take care of it. But I don’t know how it will work further.

As you can see, positive reviews about Resata SAI prevail, although there is also some negativity. From operating experience, some conclusions can be drawn regarding how to make welding work without problems.

Operation of Resanta welding inverters

In the operating instructions for these welding machines, the requirements and recommendations are as follows:

- Do not use a grinder, electric saws, grinders or other tools near the unit that generate a large amount of dust when working.

- Do not cover the case during operation: forced cooling using coolers (fans). If you close the air flow, the device will overheat and may burn out.

- Do not work in damp areas or in the rain.

- If you bring the inverter into a warm room from frost, you must wait at least two hours until the condensation dries.

Switching order

Before turning on the device, check that the switch is in the off position. Connect the power cable and workers, plug it into the outlet. Set the minimum welding current on the regulator, then press the “on” button. Shutting down is carried out like this: first turn it to minimum, then turn it off with the toggle switch, and then from the network. If the work is finished, disconnect the wires and put them back in place.

When unrolling cables or using an extension cord, make sure that all wires are fully unrolled and do not intersect. Do not leave cables spooled; this creates an inductor that will negatively affect the equipment.

Practical recommendations

Resanta SAI inverters have overheating protection. It automatically turns off the device when the temperature approaches critical. But it’s better not to let it turn off. Work in intermittent mode: cook for 7 minutes, let the unit cool for 3-5 minutes. There is no need to turn it off during these intervals.

There is no need to turn off the power when switching off due to overheating. Just wait 5-7 minutes. Do not turn it off even if you have a short break in your work: the less often you turn on the equipment, the longer it will last. Inrush currents, although there is a “soft start” function, have a bad effect on this type of equipment. Therefore, turn off the inverter only if the break is more than an hour.

If you want Resanta SAI to work normally, periodically clean the insides of dust. Especially if you worked close to a source of dust or after a long period of inactivity.

You need to cook stainless steel with Resanta using reverse polarity.

If you are going to lengthen the working cables, increase their diameter, the voltage will drop less. If you place it at 10 meters, the cross-section is preferably 25mm 2.

Practical advice for repairing Resanta welds

If you are skilled in such work, then the diagrams below will help you. There are also several recommendations based on DIY experience.

After a year and a half of operation, Resanta 220 began to shut down due to overheating if operated at currents greater than 140 A. The warranty had expired, so I went and looked at it myself. All that happened was that the input cable was not properly tightened. By the way, it was worn out - it worked every day for a year and a half. I replaced the cable, tightened the terminals in an unladylike manner, and also vacuumed it.

Timofey, Primorsky Krai

I bought myself Resanta 250 Prof. The seam holds perfectly and cooks smoothly. I like. Only after a month of work (1 kg of troika a day, but not always, it happened less), after a pop inside, he died. I sent it in for repair and waited 45 days. After the repair, a breakdown occurred a month later. It happens if the electrical wire is not clamped in the holder. I didn’t want to wait another 45 days, I promoted it myself. There were almost no wires attached to the board. Only baited. And how did the service people look? Or are they specialists? A piece of the board has burned out. I soldered the wire to the terminal and screwed it on. Works. True, at sub-zero temperatures the indicator now shows something unthinkable, but it works.

Vitaly, Krasnodar

My Resanta SAI 220, after a month of working in threes, stopped showing signs of life. I opened it, checked, two FGH40N60SFD transistors burned out. I found them, bought them, changed all four, even though two burned out. At the same time I replaced the 12 W resistor with a 51 Ohm one. It worked, but not for long. The transistors burned after several turns on. Apparently, the batch was defective. I bought others, installed them, and they work fine. Yes. The scheme from 250 was more suitable for my 220 - with minor discrepancies. What can I say, the board is made normally, the tracks do not peel off. Though it pleases. Although the parts could have been tested before they were put into production.

Anatoly, Nizhny

Welding masks Resanta

It is impossible to work with welding without a welder's mask - you will immediately get a retinal burn, which is called a “bunny burn.” Light filters protect the eyes from damage from infrared and ultraviolet radiation. Protect the body of the mask from flying splashes and scale. Both must be reliable and provide maximum protection.

Resanta welding helmet: MS-1, MS-2, MS-3 and MS-4

Resanta produces several types of welding helmets:

- MS-1 - with an automatic light filter based on liquid crystals TSK-3201. There are two modes: welding and grinding, a dimming regulator, which allow you to use the mask both for welding and as a protective shield when working with an angle grinder or other similar tools. Price 1500-1800 rubles.

- MS-2 - with TCK-4000 filter. There are three adjustments: degree of dimming, sensitivity, delay time (how quickly it responds when the brightness of the light changes). Step change in darkening. Price 1900-2100 rubles.

- MS-3 - TCK-3202 filter, the adjustments are the same as in MS-2, but the change in transparency of the filter is smooth. Also, the adjustment range for Resant MS-3 is 9-13DIN, while for Resant MS-2 it is 10-12DIN. Price 2600-2800 rubles.

- MS-4 is the cheapest (price 1200-1400 rubles) and the simplest mask. Light filter TSK-2101. It works only at positive temperatures, even with a slight decrease it begins to “slow down”.

All main technical characteristics of Resanta MS welder masks are given in the table.

Technical characteristics of masks

And a video review of the Resanta MS-1 welding mask.

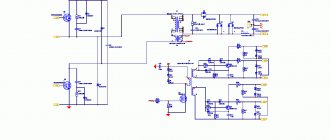

Several welding inverter circuits:

Diagram of the Resanta SAI 220PN inverter welding machine

Diagram of the Resanta SAI 160 inverter welding machine

Diagram of the Resanta SAI 220 inverter welding machine

Resanta welding inverter: which one to choose?

Any Resanta welding inverter is designed for manual arc welding with a coated stick electrode. Adapted to Russian climatic conditions, it is able to operate stably at temperatures from -10 to +40 degrees, and also has an electrical protection class of IP21 (the device can be used in industrial (unheated) premises under canopies, since they are not protected from water, but prevent the appearance of condensate).

To ensure that the device lasts as long as possible and does not damage other electrical devices in the house, you should study the electromagnetic compatibility card, which can be found on page 3 of the inverter passport.

General information about the manufacturer

The headquarters of the Resanta company is located in Latvia; the devices are assembled partly from Chinese components. The company specializes in the production of welders for various fields of activity:

- Household. They can be used both in the country house and in the garage to perform a small amount of work. Connect to a 220 V power supply. Recommended for beginners and those just learning to cook. The welding current range ranges from 120-200 A. Some models are equipped with smooth arc adjustment.

- Professional. Allows you to obtain a higher quality seam. Popular among small car repair shops and ordinary housing and communal services employees. Ideal for repair work in harsh conditions. They have an increased time of continuous operation when compared with household models, which are designed for intermittent short-term operation. Welding current varies between 200-300 A.

- Industrial. They are used in welding critical structures made of various materials, when high demands are placed on the quality of the weld. The power of the devices varies between 250-500 A. It is allowed to use welding wire on a reel with a diameter of 0.5 to 0.8 mm.

The line of welding machines is represented by plasma cutting devices, as well as inverters of the following lines:

- Compact;

- PN (ability to operate on reduced voltage);

- PROF (professional with extended continuous operation time).

In addition, the company is engaged in the development and production of stabilizers (which may be required to ensure stable operation of a welder in a country or garden area), thermal equipment, and measuring equipment.

According to research by MegaResearch for the period 2014-2015, the Resanta trademark was recognized as the best in the domestic market of welding and stabilization equipment.

Recommendations for working with the device

The device is used for effective welding of carbon alloys, as well as stainless steel. If there is a need to weld small parts, you can connect the device to a household outlet.

It is not recommended to close the ventilation openings while working with the device, as this will lead to overheating.

To ensure full operation of the device, it is best to properly prepare it for welding. Before turning on the unit, you need to determine that the network switch is in shutdown mode. Grounded wires and an electrical holder are connected to the power connectors. At the next stage, the inverter is connected to the power grid.

Initially, the lowest welding current is set. To start the unit, you need to click on the Network toggle switch. After this, the current is adjusted. After welding, the current is reduced to a minimum. The switch turns off the device, and after that the welding cables and wires are disconnected from the power supply.

Features of Resanta welding machines

Due to the fact that inverters are equipped with Chinese circuits and boards, they have a low cost when compared with German or Italian-made units of similar power and functionality, this makes them accessible to most of the population.

Extensive service support covers most of Russia. The company constantly analyzes shortcomings identified during operation and eliminates them, improving the functional component of the equipment.

Advantages of inverter units

- Maximum stability during voltage surges guarantees excellent seam quality;

- Minimal splashing. When welding, a smaller layer of slag is formed, and therefore less time is required to bring the welded surface to the proper condition;

- Smooth adjustment of the welding current. Allows you to select the optimal value for each specific alloy;

- Universal. Suitable for working with different materials: stainless steel, aluminum;

- Light weight makes it easy to transport from one object to another;

- Reduced power consumption.

You might be interested:

Welding aluminum at home is possible, but you need to know some nuances that relate to both the work being done and the welding machine used. You can find out how aluminum welding works are performed here.

Tips on choosing a welding machine for argon-arc welding, operating principle, advantages and main differences from conventional welders - read our detailed article at this link

Flaws. Among the shortcomings, one can highlight a poorly branched system of service centers, which carries out repairs of units directly upon presentation of a warranty card on the territory of the service center. In small towns where there is no specialized center, it is almost impossible to repair the device.

The sale of spare parts completely stops in the summer, which causes certain inconvenience to both small retail stores and customers from nearby settlements (the minimum period for a device to be repaired is 3 weeks).

Advice. If your cooling fan (12-24V) has failed, you can pick up a duplicate at a regular computer center or service center, the cost ranges from 120-400 rubles.

Device malfunctions

If the inverter is used incorrectly, malfunctions may appear in the form of:

- Overheating and failure of the power supply. If this breakdown occurs, you need to contact a service center, especially if the device is under warranty.

- Turn off the fan. It is recommended to stop the operation of the device, otherwise the unit will overheat.

- Long flashing of all indicators during initial startup of the unit.

- Equipment stops after a clicking sound. You can carry out repairs yourself. The adjustable linings and all relays are checked in accordance with the diagram. If one of the ends of the wiring is burnt, this may cause a problem.

- Punching through the mass when turned on. It is recommended to check the wiring, which may be damaged.

- Two indicators blink, the relay activates and the fan turns on. After one second, the unit turns off and the process repeats. To eliminate the problem, the resistance and output transistors are checked.

- Excessively weak material used to make the fan, causing it to break into pieces.

You can fix a large number of inverter malfunctions with your own hands. But, if you need to replace spare parts, then in the absence of appropriate experience and knowledge, it is recommended to seek help from a specialist.

The lineup

The Resanta range of inverters includes a large number of different devices that differ in power and purpose. Let's look at several of the company's most popular welding inverters.

Resanta SAI 220

The welding inverter Resanta SAI 220 is a powerful unit for a professional workshop. It is popular among companies engaged in casting and processing of metal of various grades and thicknesses. The maximum welding current is 220 A, which allows you to work with an electrode with a diameter of 5 mm.

Need to know: the operating power of the device is 6.6 kW. Therefore, a fixed home network may not be able to withstand such a load.

There is the possibility of smoothly adjusting the current from 10 to 220 A. Continuous welding is allowed, with a one-time load of 70% for 7 minutes. The cost in retail stores can reach 9,000 rubles.

Resanta SAI 190

Resanta SAI 190 is a compact welding inverter for home and production workshop. Designed for manual arc welding with a coated electrode with a diameter of up to 5 mm. The maximum thickness of the workpiece is 8 mm. Operating power is 5.5 kW. This is a fairly powerful unit, so it is very often used in the foundry industry.

Capable of working at reduced voltage, up to 160 V. It is possible to smoothly adjust the welding current from 10 to 190 A. Built-in indicators allow you to control the work process and protect against overload. It has built-in functions: anti-stick electrode, hot start, and tunnel cooling. The cost varies from 5800 to 7000 rubles.

Resanta SAI 250

Welding inverter Resanta SAI 250 is a reliable and heavy-duty unit for manual arc welding of the MMA type, for work you can use a coated electrode with a diameter of 1 to 6 mm. The power of the device is 7.7 kW, which allows for smooth adjustment of the welding current from 10 to 250 A.

Inverter technology guarantees a stable arc and the highest quality seam, as well as maintaining functionality when the network drops to 160 V. Therefore, this welder is suitable for both experienced and home craftsmen. Equipped with an automatic shutdown function in case of overheating or short circuit. The cost of the unit is 9400.

Resanta SAI 160

The welding inverter Resanta SAI 160 belongs to the household line. Designed for manual welding with a 1.5-4 mm electrode. It has a built-in welding current regulator from 10 to 160 A, with a stable arc voltage of 26 V. Ideal for a stationary 220 V network, weight is 4.5 kg.

Equipped with a forced cooling fan, which prevents overheating and also reduces breaks between approaches to a minimum. The absence of a bulky transformer makes it lightweight, virtually silent and compact. The market value of the unit is 5800-6000 rubles.

Complete set of inverter devices

The basic equipment of the units is standard and includes:

- Ground clamp cable;

- Electrode holder;

- Transport strap;

- Instructions and box.

Some models may be supplied in a plastic case with space for a welding helmet.

Specifications

The installation is made using an inverter type. In order to ensure the operation of the equipment, an electrical network is needed to which it is connected. The mains voltage must be at least 220 W. The installation consumes 6.6 kilowatts of power.

The device is used for manual arc welding. The open-circuit voltage is 80 V. A direct current is generated at the output of the equipment, which makes it possible to perform electric arc welding. To do this, the coated electrodes are melted.

The device has a protection class of IP21, which ensures safe operation. The weight of the equipment is 4.9 kilograms. At peak load, the installation consumes a current of 30 amperes.

The equipment has excellent technical characteristics, which allows it to be fully used for welding various metals.

User reviews

Based on reviews that are posted both on specialized forums and on the pages of online stores, we can conclude that in most cases the characteristics declared by the manufacturer do not correspond to reality, namely, some models of the PN series do not work with a voltage deviation of 15%, although according to the established regulations, they must function normally from 140 V, which can cause certain difficulties when welding in a summer cottage or garden, when it is almost impossible to obtain a stable voltage in the network.

Conventional household-grade welders are more stable, they are excellent for welding various alloys with a stick electrode, but before this it is advisable to clean the material; at a distance of 10-20 mm from the seam, the metal must be cleaned of dust, paint, water or rust, otherwise the seam may collapse.

If you believe the comments of the craftsmen who repair inverters, it is almost impossible to find spare parts in the event of a breakdown, since they are supplied by the factory to a certain volume, there is no surplus for repairs.

The official representative office refuses to supply spare parts to private clients, and specialized service centers refuse to sell. They explain the reason for the refusal - an order from above. The only option to restore the unit is to give it for repair to a professional technician, who will be able to remake the fastenings for fixing individual elements of the system and will install analogues, followed by checking the functionality of the device.

Conclusion

If we discard all the imperfections of post-warranty service, the Resanta welding inverter is a fairly reliable, functional and highly commendable device, since the defect rate (my own observation) is no more than 8 units per 100 units sold.

It must be remembered that it is prohibited to operate the unit during rain (outdoors) or in a damp room, or if the cable insulation is damaged. If the inverter has been at sub-zero temperatures for a long time, then before turning it on, it is necessary to keep the unit for at least two hours in a warm room to prevent condensation.