Design and functionality

The Resanta SAI 190 welding machine is enclosed in a rectangular body, the dimensions of which are 350x140x250 mm. It is made of durable high-quality steel, and the surface is protected by a layer of paint. Thanks to its large flat base, it is stable on any surface, including slopes. There are slots on both sides of the body that serve for unhindered air penetration. The casing meets IP21 protection class requirements.

A switch and an input for the power cable are installed on the back cover, and a control panel is assembled on the front. It is characterized by the simplicity of the device and even a beginner can understand the functionality. There is a rotary current regulator, a network indicator and an overheat indicator. There are also terminals for connecting welding cables. At the top there are fasteners for a shoulder strap.

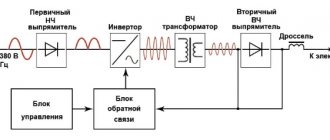

Components and elements are located inside the housing. The main element is a transformer that converts the input current with a frequency of 50 Hz into direct current. After this, the current is again converted to alternating current, but its frequency is much higher and amounts to 20 kHz. Thanks to this chain of transformations, it is possible to increase the current strength to 190 Amperes. The voltage in this case is 85 V. The transformer itself has cooling fins on the surface made of light alloy. For better air circulation, two fans are provided.

Reliability of operation and complete safety of operation is ensured by a built-in protection and warning system. Temperature sensors are installed that monitor the temperature increase and warn the user if a dangerous threshold is approaching.

The principle of operation of the welding machine is to ignite a high-temperature arc between the metal surface and the electrode. In this environment, a high temperature is reached, which causes the metal to melt. The melt of the joined edges is mixed, forming a durable monolithic surface. “On-board” functions of anti-sticking and hot start are provided by automatically adjusting the strength of the operating current.

To quickly activate the arc, a powerful electrical impulse is applied when the electrode approaches the metal surface. After the arc ignites, the current decreases sharply, eliminating sticking of the electrode. The electrode coating burns and forms a closed environment, preventing the melt from coming into contact with atmospheric oxygen and nitrogen. This improves the quality of the welded joint.

Characteristics of the welding inverter Resanta SAI 190

To operate the manual arc welding machine SAI 190, it is recommended to purchase electrodes with a diameter of up to 5 mm. The maximum welding current is 190 amperes (technical data). However, practitioners note the fact that the figures are overestimated. It is almost impossible to achieve such values in practice, and they are somewhat lower.

The inverter is small in size and light in weight – no more than 5 kg. This is convenient if you have to frequently transport equipment. For example, take it with you to the dacha and pick it up when you return home. Wide operating temperature range: from -10 to +40 degrees Celsius, which is very practical for our climate zone.

It is worth noting the very modest configuration of the welding inverter. The price includes welding and power supply cables. All other equipment will have to be purchased. On the other hand, the equipment comes with a two-year warranty, which gives you confidence in its reliability.

Selecting electrodes for different materials

Before starting work, you need to remember that products made from different materials require certain electrodes. If you plan to work with high-alloy or stainless steel, then it is best to use TsL-11 rods, which are manufactured according to state standards 9466-75. But if you plan to weld workpieces made of carbon steel, then OZS-4 electrodes are best suited.

If you are still deciding which welding electrodes are best to choose for an inverter, then you should pay attention to ANO-6. They are intended for products made of low-carbon steels. In this case we are talking about rods with ilmenite coating.

Low-carbon steels can also be welded using ANO-4, which have a rutile coating. Different grades of cast iron can be connected using OZCh-2. When purchasing electrodes, you should ask whether they have epidemiological certificates that guarantee high-quality welding. The use of material manufactured according to state standards also speaks about the safety of work.

Advantages and disadvantages

The Resanta SAI 190 welding machine is endowed with many advantages, one of which is noticeable from the first steps: ease of connection. Simply insert the plug into a household power socket to get started. It is important that the voltage in the network does not vary greatly, and its minimum value does not fall below 200 volts.

The second undoubted advantage is the fact that the “filling” is made on the basis of IGBT transistors. It is thanks to this that the device turned out to be compact, lightweight and with impressive additional functionality.

Now let's take a closer look at its main features. The device is reliably protected from overheating. It has a built-in “anti stick” function, better known among users as “anti-sticking”. No less popular is another feature of “hot start” - quick start, which allows you to ignite the welding arc almost instantly. The presence of these two functions greatly simplifies welding work.

In order to start working with an inverter, it is not necessary to study the theoretical part of electrical engineering. All controls and control buttons are located on the front panel, intuitively understandable and labeled. The large font of the signatures is visible even from a great distance, making it convenient at first to get acquainted with the control panel.

Full list of advantages:

- The model operates from a household power supply and is easy to connect.

- The inverter system involves the use of small transformers. In combination with IGBT transistors, this ensures low weight and modest dimensions of the device.

- There is a built-in overheat warning indication. This makes work more comfortable and safe.

- Anti-stick and hot start functions simplify the use of the unit.

- The switching duration is 70%.

- The durable case reliably protects the interior from damage.

- Wide range of power regulation and the ability to convert high-frequency current.

- The use of alternating and direct current electrodes is allowed.

- No prior specialist training is required. A little practice and basic knowledge about welding is enough.

Now about the disadvantages. The Resanta trademark is registered in Latvia, but production is located in China. This fact is due to two features. First, production located in China makes it possible to create an affordable price for consumers. Secondly, not every buyer can trust the quality of manufacturers from the Middle Kingdom. Everyone will have to make a decision after weighing these factors.

The second important disadvantage lies in the technical characteristics. For the same price, many other Chinese manufacturers offer equipment with much more impressive parameters. Here, buyers have to pay extra for the brand and service. Over time, the functionality of the equipment ceases to be sufficient and to perform more complex tasks you will have to buy another inverter.

Advantages

The special coating of the rods provides a large number of advantages of using this type of electrodes.

- Possibility of overlapping seams regardless of their size.

- Easy separation of slag crust.

- Easy to re-ignite the arc.

- Ability to weld with a long arc.

- The ability to weld on wet edges, as well as with traces of rust, without first cleaning them.

- Possibility of connecting parts with galvanic coating.

- No release of harmful substances during the welding process.

- High deposition coefficient.

- Possibility of welding thick products.

- A small number of pores in the resulting seam.

- Economical consumption of electrodes.

- Possibility of making short seams - tacks.

- Slight spattering of metal during welding.

- High efficiency of work with electrodes of this type.

- Good appearance of the resulting seam.

A minor drawback is that due to the presence of silicon in the coating, the seam is not sufficiently plastic. Its impact strength is also low.

These advantages expand the scope of application of this type of electrodes. They can be used to connect conventional types of structures. No special preliminary training is required, so such electrodes can be used by novice welders.

Preparation for work and safety measures

Structurally, the Resanta 190 inverter welding machine is not a complex device. Almost anyone can prepare it for use. It is important to initially provide basic security measures and take some points into account. This is necessary to prevent the possibility of electric shock, as well as to eliminate a number of other unpleasant situations.

The equipment is grounded through the power cord. Therefore, it is necessary to use sockets of the appropriate configuration connected to the ground circuit. The power cord is connected to the power supply after the power welding cables have been connected. The “network” toggle switch is turned on, and the current regulator is moved to the lowest position. After completing the work, the device turns off in the reverse order.

Carrying out welding work indoors requires additional training. It is necessary to take care of ventilation of the internal space. It is imperative to get rid of flammable materials and liquids. You can start work only in personal protective equipment: mask, gloves, headgear, suit made of fire-resistant material, durable closed shoes.

How to use the Resanta 190 welding machine

Before you start working, you should carefully read the safety requirements. Work order:

- The surface of the parts to be welded is cleaned. At a distance of 1-2 cm from the welding seam, the material must be cleaned of paint, oil, dust and other contaminants;

- Hold the welding helmet in front of your face and light the arc. The most effective method is considered to be “striking” - on the principle of lighting an ordinary match;

- After activating the welding arc, you need to hold it. To do this, it is necessary to maintain a distance from the electrode to the metal surface, which is equal to the consumable. It is advisable to maintain the vertical tilt angle in the range of 20-30 degrees;

- upon completion of the formation of the welding seam, the electrode should be pulled back a little, and then sharply returned to its original position so that the bath is filled with melt;

- the slag is cleaned using a special welding hammer or a stiff metal brush;

- It is safer to replace the electrode and move the elements being welded using dielectric pliers;

- When changing the electrode, you need to turn off the welding machine, first reducing the current to the minimum value.

For safety reasons, it is prohibited:

- operate the equipment indoors with high humidity or in an open area during rain;

- use abrasive and cutting metalworking tools in close proximity to the inverter. This will lead to small metal particles getting inside, which will ultimately lead to equipment failure;

- work if the insulation on the supply or welding cable is damaged;

- turn on the device brought from the cold to a warm room. It is necessary to allow the equipment to gradually warm up (adapt) to avoid the formation of condensation.

Which electrodes to choose

If you, too, were among those who wondered about which electrodes are best for an inverter, then you should read the information presented below. Consumable-type electrodes used in inverter and in general arc welding are made from welding wire, in the process of which state standards of 1970 are used.

According to GOST 2246, electrodes for inverter welding are classified into:

- alloyed;

- carbon;

- highly alloyed.

The first ones are made from the following types of wire:

- Sv-08Х3Г2СМ.

- Sv-08HN2GMTA.

- SV-08KhGSMFA.

When deciding which electrodes are best for inverter welding, you should become more familiar with carbon rods, which are made from wire Sv-08 and Sv-08AA, etc. High-alloy electrodes are based on wire Sv-30Х25Н16Г7 and Sv-01Х23Н28М3Д3Т. However, none of these lists can be called complete. The rod is coated by pressing. It protects the weld pool from atmospheric influences and allows the arc to burn more steadily.

Beginners should know that electrodes can be classified into two subgroups. The first provides products intended for making seams when connecting critical metal structures. The second subgroup is intended for work with conventional connections.

For critical products, it is best to prefer UONI or ANO electrodes. If you are faced with the question of which electrodes are best for an inverter, then you should also pay attention to products marked MP-3, which are intended for conventional welded joints. The SSSI brand of electrodes is quite capricious. This is due to the fact that not every novice master will be able to work with such rods. If you do not have experience in such activities, then it is better to avoid such electrodes.

Circuits and faults

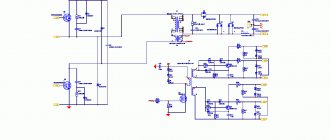

Below are several diagrams that will help specialists understand the principles of the design and operation of the equipment.

Sometimes malfunctions occur that the user can fix on his own. These are, as a rule, minor defects that do not require special knowledge or skills to correct. Serious breakdowns force owners to contact service centers or specialized repair shops. So, now in more detail:

- Equipment overheating or power supply failure . In this case, you need to seek the help of specialists and contact a workshop.

- The network indicator does not light up . First of all, you need to check whether the plug is plugged into the socket and the position of the toggle switch on the control panel. If everything is in order here, then you need to connect an electrician to the solution.

- The equipment is not operating at full capacity . The reason for this may be a wet electrode surface or too low voltage in the power supply network.

- The overheat indicator lights up . You need to remove the housing and check for clogging of the cooling system and clean it if necessary. If manipulations do not help improve the situation, you should contact the workshop.

- Fan switches off when there is no overheat signal . Contact the service center.

- The indicators flash for a long time when turned on for the first time . Working in argon welding mode is characterized by arc instability. The device needs to be repaired by specialists.

- The inverter stops working and makes a loud clicking noise . The cause may be a burnt contact or wiring. Adjustable pads and relays need to be checked.

- When turned on, it breaks ground . Indicates a violation of the wiring insulation. You need to check it carefully.

- Two diodes blink on the front panel, and the fan turns on and off synchronously with them . This behavior of equipment components indicates a malfunction of the cooling system. Most likely the control chip has failed. In cases where the cooler power supply is interrupted by the relay, it should be replaced with a new one.

- The lights flash, the relay activates, and the fan turns on . After one second, everything turns off and the process repeats again. It is necessary to check the resistance R43 (indicated in the diagram - 51 Ohm, 12 V), diode D14 and output transistors.

- The current adjustment knob turns too easily . Over time, the fastening weakens and becomes loose. The worn part needs to be checked and replaced.

- The fan has collapsed . The material from which it is made is very fragile. The entry of a foreign object or branch inevitably leads to destruction. The part needs to be replaced.

- The braid on the wire cracks when working in the cold . Not all wiring is designed to operate in sub-zero temperatures. You need to stop working or purchase the appropriate cable.

For reference

An inverter is modern equipment with which you can weld different surfaces using almost all existing types of electrodes. This is the popularity of the device. However, when choosing the best welding electrodes, you must remember that not all rods provide high-quality results and excellent presentation of the seam.

In addition, safety issues will be compromised when using rods that are not recommended for this type of welding. This suggests that when choosing rods it is necessary to follow the recommendations of specialists.