Home / Devices

Back

Reading time: 3 min

0

1105

The trend of increasing popularity of affordable machines for inverter welding has been manifesting itself for 10 years. Main buyers: novice craftsmen, summer residents, welding students.

Craftsmen are willing to pay no more than $200 for their welding machine. The conclusion is that budget inverters have quickly and firmly become popular in the sales industry.

This is especially reflected in the reconciliations of stores concentrated on this target audience. Manufacturers promise us a fairly good level of performance for a budget inverter.

The Latvian brand “Resanta” is a leader in sales of inverters, which perform well in everyday life. The number of variations, reliable assembly, and availability of these devices do not leave welders indifferent.

This article focuses on the properties and capabilities of all models of this device for welding work.

- WELDING MACHINE RESANTA SAI-220 Model characteristics

Features of the welding machine Resanta SAI-220

The inverter unit has relatively small dimensions, which makes it easy to use. Thanks to the presence of a special handle, the equipment is easy to carry. The device is sold in a case, which makes it easy to transport and store.

The installation is characterized by the presence of a metal case, which protects the mechanism from various mechanical damage. The case has a paint coating, which limits the possibility of corrosion and negative environmental influences, and also increases the service life of the device.

Welding machine SAI-220PN

If you can call yourself a dacha enthusiast, Resanta SAI -220PN is something that may interest you.

You will certainly see the functionality when, while working outside the city, there is a power outage or a voltage drop (these are quite pressing problems for dacha cooperatives) - this inverter can easily cope with these troubles.

You will forget about what a voltage stabilizer is and will simply do the necessary work without worrying about the integrity of the device or your safety.

Your seams will be of good quality; all you need is a 220V socket and this welding device.

A device with an easy-to-use digital panel that remains readable even in bright sunlight. It’s not scary if your vision is less than 100%, because all the inscriptions are expressive and quite sharp.

With the help of general knowledge and intuition, you can figure out the device quickly enough. But don’t forget about the operating instructions - this is a reliable assistant at hand.

If you don’t know what to give your father or grandfather, this is what you were looking for. Get rid of these old bulky units from their summer cottages, move with the times, not forgetting about your loved ones.

Design of the welding machine Resanta SAI-220

The figure shows a diagram of the device, which allows you to determine its operating principle.

The diagram shows that the equipment has two fans at once, which ensures complete cooling during operation. The electronic circuits and the GP164 board are characterized by high resistance to overheating, which guarantees long-term operation of the device. The semi-automatic machine has a temperature sensor that turns it off when it overheats. The unit does not turn on until it has completely cooled down.

The device panel contains a current regulator, network and overheat indicators, which allows you to monitor its performance. There is an on/off button on the panel at the back of the device.

Pros and cons of purchasing

Resanta SAI-220, as well as all derivative models of this inverter, are a combination of price and quality.

Low performance and low power, which block the use of the device in the professional field, do not spoil the quality of seams or the ability to hone the skills of students and beginners in welding. Moreover, on the contrary, they make learning and work easier.

Nowadays the Latvians have a lot of competition from manufacturers from China, who position their inverters as more advanced for the same price. What should a welder choose for his work?

The Resanta brand has created a large service structure, a system of real guarantees for the functionality of devices. Of course this is important for such a dangerous industry. All these components will protect you when operating mechanical devices.

As for the inverters themselves, indeed, they do not differ in their work from Chinese ones. Same kit and specifications. Chinese devices, after all, will be a little more budget-friendly, although the purchase is made at your own peril and risk.

Still haven't found the answer? We think that service and warranty should be available, albeit at a slightly steep price. Safety and reliability are paramount.

Specifications

The installation is made using an inverter type. In order to ensure the operation of the equipment, an electrical network is needed to which it is connected. The mains voltage must be at least 220 W. The installation consumes 6.6 kilowatts of power.

The device is used for manual arc welding. The open-circuit voltage is 80 V. A direct current is generated at the output of the equipment, which makes it possible to perform electric arc welding. To do this, the coated electrodes are melted.

The device has a protection class of IP21, which ensures safe operation. The weight of the equipment is 4.9 kilograms. At peak load, the installation consumes a current of 30 amperes.

The equipment has excellent technical characteristics, which allows it to be fully used for welding various metals.

Advantages and disadvantages

The SAIPA installation is worth purchasing for home use, as it is characterized by a large number of advantages:

- Thanks to the presence of the Hot Start function, an automatic supply of increased current to the welding arc is provided, which speeds up the process of its ignition.

- The device is characterized by the presence of an automatic shutdown function when overheating, which ensures its long service life.

- The installation has an Anti-stick function, thanks to which the welding current is automatically switched off during the period of welding the tip of the electrodes to the metal.

- The Arc Force function automatically increases the welding current as the arc decreases, so the electrodes do not stick.

Thanks to the presence of all the above functions, the possibility of inverter malfunctions is eliminated and its long service life is ensured.

Despite having many advantages, the installation has certain disadvantages. Reviews from device owners indicate that there is a high percentage of defects. That is why, when purchasing a device, it is recommended to check its functionality. If you work with metal with a thickness of more than 10 millimeters, the efficiency of the device decreases.

Resanta SAI 220 is my favorite device!

Welding inverter "Resanta SAI 220"

Recently, the leading position in sales among the entire line of inverters has been occupied by a welding inverter...

Resanta SAI 220. This is evidenced by numerous positive user reviews about the functionality of the device and build quality.

BUY WELDING MACHINE RESANTA SAI 220 NOW!

Resanta SAI 220 is a high-tech welding inverter for manual arc welding. This is one of the latest developments, which boasts the latest technological innovations that contribute to high-quality and convenient work.

Why is this inverter model so popular? Perhaps the main mystery of this model is that its parameters cannot be classified into the class of both household and professional units and the users of these devices are both professionals and beginners. So what is its appeal to such opposing categories of buyers?

The characteristics of the Resanta SAI 220 welding inverter in terms of maximum welding current are an order of magnitude higher than similar analogues from the Resanta line, which gives professional welders more scope for creativity in their work and allows them to perform serious welding work using thick electrodes and with more stable performance.

Beginners without experience in working with a welding inverter are attracted by the ease of operation, because the SAI 220 welding inverter can be used immediately, without prior preparation, just read the instructions. The design features of the inverter help maintain a stable arc and ensure comfortable operation.

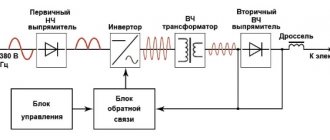

The operating principle of Resanta SAI 220 is a two-stage voltage conversion (AC to DC and conversion to high-frequency AC). The welding inverter circuit consists of the following main components:

1. power unit with a frequency of 50Hz

2. inverter unit that converts direct current into high-frequency alternating current

3. rectifier

4. transformer

5. throttle

Resanta SAI 220 belongs to the increased protection class IP21 and ensures safe operation for both beginners and professionals. All internal components of the inverter are motionless; all current-carrying mechanisms are insulated with high-quality varnish - this indicates mechanical security and the impossibility of objects getting inside.

The main advantages of Resanta SAI 220:

- The device has compact dimensions and light weight, which makes it easy to transport the unit and use it for mobile welding.

- Current adjustment range from 10-220A. This allows you to carry out specific work with electrodes of any thickness, at low current with thin electrodes, and at 220A you can carry out work with thick electrodes and massive surfaces.

- The powerful design of Resanta SAI 220 is very resistant to mechanical damage and allows for harsh use.

- The no-load voltage is 28V and the arc voltage is 80V. Such low values make the inverter safe to use.

- The design features of the device allow it to be used in harsh climatic conditions, down to -20°C. You just need to control the heating and cooling mode.

- A smooth regulator of the welding current allows operation without experience or special skills.

- The presence of two cooling fans improves airflow and cooling inside the case.

- Resanta SAI 220 is very resistant to overheating. Even if the fans fail, shutdown occurs only after two 5mm electrodes are used up.

- Additional functions “hot start” and “anti-sticking” will help beginners or people without experience master the welding process and facilitate easy and simple operation for a professional.

- Resanta SAI 220 has a high efficiency of current conversion and a welding control function during voltage surges, which significantly saves energy costs.

- Resanta SAI 220 ensures high stability of welding process parameters in conditions of unstable power grids. This advantage is especially relevant for residents of remote settlements with constant power surges and for places without central power supply with the presence of autonomous power sources (generators)

Here are comments and personal experience of using Resanta SAI 220 from customers of the online store

Mikhail, Sverdlovsk region, beginner

When we finally got around to electrifying the country house, the question of landscaping the area arose naturally. And any repair and restoration work is impossible without a welding machine. It was necessary to install a fence with a gate, and the material was available, only welding was missing. But you must admit that hiring a professional welder is a costly business, especially since there were financial restrictions. So I decided to purchase a welding machine, but I obviously limited the budget for the purchase. Since I’m not a welder by profession and it’s unclear whether the device will be needed in the future or not, I didn’t want to throw away a lot of money on equipment that might be collecting dust in the garage. But there was a desire to purchase a high-quality and reliable unit at a low cost, which would serve its purpose without repair. Of course, like most people who want to purchase welding, my first choice fell on the old proven classic - a welding transformer. I was almost ready to buy, but was stopped by the understanding of the inconvenience of its transportation. I couldn’t decide how to carry this huge and heavy box with me whenever I wanted to work. And then one evening, while studying information about welding machines, I came across a huge number of positive reviews in the direction of welding inverters. I took a closer look at this miracle of technology and was surprised; small and lightweight inverters promised technical characteristics no worse than those of transformers. The output currents of household models ranged from 120-240A, and they had a child’s weight, compared to the classics! The decision was obvious, and the scales tipped towards the purchase of a welding inverter. Now it was necessary to study the presented brands, models and prices. At one of the forums, during a conversation with old-timers, I was advised a specific model of the SAI 220 inverter from Resanta. Moreover, almost all the reviews towards this model were positive. Welding aces emphasized time-tested circuitry, functionality and ergonomics. The sellers claimed that this was the best-selling model of the entire Resanta line. After much thought, I decided to buy this particular model and found the cheapest price tag in the Resanta-Ural online store. This is my first purchase of a welding machine, but I was still impressed. I couldn’t even imagine that a welder could be so compact and light and still produce an operating current of up to 220A. I was also struck by the low energy consumption, which is approximately comparable to the operation of two electric kettles. After some period of operation, I was able to evaluate the breadth of current regulation, from 10-220A, which made it possible to confidently work with different electrode diameters. After two years of using the inverter, I can no longer call myself a beginner in the field of welding and quite reasonably say that I made the right choice. For a cottage, garage or workshop, this model is the most relevant and in demand. For these purposes, you can, of course, choose a less powerful inverter, for example 160-180A, but I believe that it is better to have a power reserve, and the voltage in our networks is often not normal.

Victor, Krasnoyarsk , 5th category welder

I have been using the Resanta SAI 220 device for four years now, and it has proven itself only from the best side. When purchasing, I was worried that it would be problematic to work with stainless steel without adding argon. But my fears were in vain, I cook with a 3mm stainless electrode and everything is fine. The only drawback of the inverter is the short wires, but we can solve the problem by carrying it.

Roma, Irkutsk, professional

Although I am a seasoned professional in this matter, I am impressed by the purchase of Resant SAI 220. Previously, I carried out work mainly on a transformer, which has problems with cooling and takes a lot of time to cool down. This is not the case with an inverter and this is its main advantage. The cooling system is at the highest level. An anti-sticking system has also been invented; even an inexperienced beginner can use it.

Andrey, Yekaterinburg , newbie with no work experience

I have a very interesting first experience using this device. I have never mastered welding technology and have never tried to weld, much less have my own welder. One day I came to a friend who was using Resanta SAI 220. Using this machine, a fence and a stove for a bathhouse were welded, so he persuaded me to try it, convincing me that there was nothing complicated about it. He handed me two 3mm angles and showed me how to weld. Surprisingly, everything worked out the first time, although it was a little crooked, but the fact is that everything held up. A week later I already had my Resanta SAI 220 and successfully practiced welding awnings to doors. Subsequently, he repaired the stainless steel tank and fence. There are plans to make a stove for a bathhouse. In general, I’m happy with the purchase, and I’m slowly gaining experience.

You can purchase the Resanta SAI 220 welding inverter on the website of the Resanta-Ural online store or in a specialized equipment store in Yekaterinburg, at st. Novostroya 1A, office 105.

Operating principle of the welding machine Resanta SAI-220

The installation has a simple operating principle and is also characterized by ease of use, which makes it possible for even inexperienced craftsmen to use it.

The device boards are located in a metal case, which is characterized by the presence of ventilation holes. The welding machine transforms the variable voltage to obtain a constant voltage - 400 V. After this, modulation and rectification of the constant voltage are carried out. Thanks to pulse width modulation, it is possible to regulate the current.

Recommendations for working with the device

The device is used for effective welding of carbon alloys, as well as stainless steel. If there is a need to weld small parts, you can connect the device to a household outlet.

It is not recommended to close the ventilation openings while working with the device, as this will lead to overheating.

To ensure full operation of the device, it is best to properly prepare it for welding. Before turning on the unit, you need to determine that the network switch is in shutdown mode. Grounded wires and an electrical holder are connected to the power connectors. At the next stage, the inverter is connected to the power grid.

Initially, the lowest welding current is set. To start the unit, you need to click on the Network toggle switch. After this, the current is adjusted. After welding, the current is reduced to a minimum. The switch turns off the device, and after that the welding cables and wires are disconnected from the power supply.

Reviews and technical characteristics of Resanta SAI 220

Topic of publication: welding machine Resanta SAI 220 - consumer reviews and price of equipment for a home workshop.

Specifications

SAI (inverter welding machine) Resanta is used for connecting metal structures with direct current using a consumable electrode. The low weight of the device allows a person to weld metal products in hard-to-reach places.

Welding machine Resanta SAI 220 - technical characteristics:

Design and principle of operation

The device's circuit boards are built into a metal case with ventilation holes. During operation, it is prohibited to close the forced ventilation system.

On the front panel there is (Fig. below):

- current regulator (2);

- indicators - network (3) and overheating (4);

- negative and positive cable connection connectors (5, 6).

There is a “Network” switch on the back panel of the device.

Operating principle: Resanta converts alternating voltage into direct voltage 400 V and then the direct voltage is converted into modulated voltage and rectified. Pulse width modulation is used to adjust the welding current.

When the overheating protection is triggered (signaled by a lamp on the front panel), the welder checks the serviceability of the cables and stops working.

The inverter is equipped with the following functions:

- hot start (Hot Start) - quality of welding at the beginning of work;

- Anti Stick - the electrode does not stick.

Watch an interesting video about how the device works:

Resanta SAI 220: instructions for use

Preparation for work and instructions for using the device:

- Connect a grounding cable and an electrode holder to the power connectors (+ and -). Polarity is selected depending on the brand of electrodes.

- The "Network" switch on the rear panel must be turned off.

- Connect Resanta SAI 220 to the power supply.

- Set the welding current regulator to the minimum value.

- Turn on the device on the rear panel with the “Network” toggle switch.

- Set the welding current regulator to the desired value.

- After work, set the current regulator to the minimum value.

- Turn off the device with the switch.

- Disconnect the power cord and welding cables.

Recommended current values depending on the electrode diameter:

Prohibited:

- use the inverter in a damp building and during bad weather;

- use cutting tools (which create metal dust) near the device;

- perform welding with faulty welding cables and power cord.

Storage rules:

- store the device in a box at a temperature of –10°С +50°С, humidity no more than 80%;

- storage is carried out without acid, alkali and dust vapors.

Possible causes of problems and solutions:

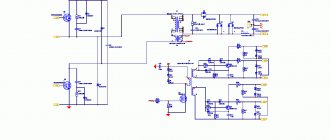

Electrical diagram of the welding machine Resanta SAI 220:

How much does the welding machine Resanta 220 cost?

This is a question that worries buyers! The price for a Chinese-assembled product is reasonable. As of May 12, 2016, Russian online stores sell the device for 8,660 rubles. You can find and buy a product a little cheaper.

Welding Resanta 220 - reviews from welders

Nikita, the device has been used for a year and 4 months:

Sergey, Rostov-on-Don:

Valera, production welder:

Video:

PS The Resanta SAI 220 welding machine receives mixed reviews. There are negative and good impressions from using the inverter. The choice is yours!

Device malfunctions

If the inverter is used incorrectly, malfunctions may appear in the form of:

- Overheating and failure of the power supply. If this breakdown occurs, you need to contact a service center, especially if the device is under warranty.

- Turn off the fan. It is recommended to stop the operation of the device, otherwise the unit will overheat.

- Long flashing of all indicators during initial startup of the unit.

- Equipment stops after a clicking sound. You can carry out repairs yourself. The adjustable linings and all relays are checked in accordance with the diagram. If one of the ends of the wiring is burnt, this may cause a problem.

- Punching through the mass when turned on. It is recommended to check the wiring, which may be damaged.

- Two indicators blink, the relay activates and the fan turns on. After one second, the unit turns off and the process repeats. To eliminate the problem, the resistance and output transistors are checked.

- Excessively weak material used to make the fan, causing it to break into pieces.

You can fix a large number of inverter malfunctions with your own hands. But, if you need to replace spare parts, then in the absence of appropriate experience and knowledge, it is recommended to seek help from a specialist.