In the immediate vicinity of my summer cottage there is a forest with a lot of dead wood. To save money on purchasing lumber for building a small bathhouse, I decided to prepare straight trunks myself and make construction timber from them. This task was complicated by the lack of the necessary tools. While it was possible to use a chainsaw to fell wood, turning round timber into timber using an ax was simply a hellish task. Having shared my problem with my neighbor at my summer cottage, I received very simple and practical advice from him on how to make a tire sawmill with my own hands from an ordinary chainsaw.

Source youtube.com

What is a tire sawmill used for?

The main purpose of a chain sawmill tire is to quickly and correctly saw a log to obtain lumber. Why is the design called that? The fact is that to create such a mechanism, a saw bar is used.

The cutting part is designed in the form of a chain bar with a sharp chain. The main advantage of this design is its simple design and the ability to use it in various fields.

Most craftsmen prefer to use a regular chainsaw as the cutting part.

The principle of operation is to pre-harvest logs of the required size, and then, when installing the saw in the frame, it is possible to cut the elements into blanks of different lengths and widths. Thanks to this, it is possible to achieve high cutting accuracy.

Tips and tricks for making a sawmill

A woodworking unit is an object with a high level of danger due to moving cutting elements. It is also quite large in size. Therefore, the location for assembling the structure should be chosen very carefully.

The site for installing the sawmill should be level and spacious, allowing access from any side. For these purposes, you can use a well-lit garage, barn or other utility rooms. You can install the machine outdoors, but in this case you should build a canopy.

If the unit is equipped with an electric motor, it is necessary to follow all electrical safety rules and monitor the condition of power and grounding cables.

The machine must be in a stable position, and the log must be firmly secured so that it does not fall off during cutting and injure the operator.

Before starting the assembled unit, you must make sure that all components and connections are reliable.

A sawmill is a woodworking system that has a not very complex design. It is easy to assemble it with your own hands. You just need to carefully follow all the recommendations, carefully read the drawings and rely on the provided videos and photos of the homemade sawmill.

Types of tire sawmills

A simple saw bar design can consist of any drive. That is why homemade models are divided into several types depending on the type of engine.

These include the following designs:

- Gasoline. In this case, a four-stroke engine operating on the principle of internal combustion is used;

- Electric. In this case, three-phase asynchronous operation of an electric motor with high power is observed.

The use of an electric motor is cost-effective if the equipment will be used as a stationary device. The sawmill will be used outside a closed space. In this case, it is better to choose a package consisting of an asynchronous motor.

- A sawmill with an electric motor requires high power consumption.

- Experts recommend choosing models with a power of at least 4 kW. A cable consisting of a large cross-section of wires will provide power.

- In the process of longitudinal sawing a log, it is important to take into account that such a mechanism is movable.

- It can deviate from its original position up to 5 m in length.

- In this case, it is necessary to consider isolating the cutting base from surrounding objects. The working part must be plastic and movable.

If you install a gasoline engine in a tire sawmill, you will not need an electrical cable. The design of a gasoline engine has significant disadvantages.

For example, if an engine running on medium-power gasoline is chosen for the mechanism, then a battery may be required to start it. If a chainsaw drive is used, a powerful cord-based starter will allow the mechanism to be prepared for operation.

Self-assembly of a disk unit

The work begins with the acquisition of the necessary parts, assemblies and components. Then you can begin assembling the frame. Metal pipes and high-strength guides are used, which are attached by welding. The next step is to assemble the carriage.

A powerful engine is required to rotate the metal disk, so in most cases a gasoline version is used. The working elements of the unit are connected to the engine through special holes.

This usually happens using a chain drive, but in this case the sawmill will not be able to operate continuously for a long time - the drive will constantly overheat.

A rapidly rotating saw blade is a source of increased danger, therefore, during installation, all risks should be taken into account and all safety conditions must be observed.

How to make a sawmill at home

Before starting the work process, it is important to correctly determine the type of launch and the supply of material. You can follow a technique in which the moving part is the material, or you can do the opposite.

When you have decided on the type of lumber supply, it is important to take into account one more fact that the location of this mechanism should take up enough space so that no additional inconvenience arises during operation.

The correct position of the runners requires special attention. The fact is that a wooden log will move along them.

The surface of the conveyors must be promptly cleaned of sawdust and small branches.

To create a tire sawmill at home, you will need the following components:

- Mechanism drawing;

- Metal corner size 50/50. We will use it to create a staging path;

- Rectangular pipe made of dense metal. The length of the elements must be at least 60/60. We will use it to construct the carriage;

- Round metal pipe. It is necessary to fix the power part of the unit;

- Metal sheet 1 sq.m. The thickness of the workpiece must be at least 4 mm;

- Metal wheels with axles – 4 pieces;

- Tire, drive sprocket and chain;

- Electric welding;

- Electric motor;

- Drill with a set of drills of different diameters;

- Bulgarian;

- Ruler;

- Building level;

- Chalk for making notches.

You can determine the length of the corner to create a staging path by following several recommendations.

They include:

- Length of the wooden piece + distance from the wheel to the edge of the tire. We multiply the result by 2. Allowances of 10 cm will help to avoid mistakes.

- You can determine the size of the pipes for the carriage by taking into account the type of tire. The design should be 30 cm larger than the cutting part.

Preparatory work

To make a homemade sawmill you will need the following tools and materials:

- Husqvarna chainsaw with 3 HP engine. With.

- Profile pipe 25x25 mm and 40x40 mm.

- Welding machine.

- Drill.

- Small furniture casters.

- Aluminum ladder.

Source youtube.com

To make a homemade tire sawmill with your own hands, you will also need a sufficient amount of hardware, as well as a ruler and a marker for marking.

How to assemble a sawing mechanism

It is necessary to weld a square from metal pipes. Externally, such a blank will look like an ordinary box. It should not have external walls, bottom and lid.

The bottom side should be short, and the top side should be about 20 cm longer. As a result, we have the appearance of a carriage. Wheels will be attached to the protruding elements.

After this, we move on to making a platform for the engine location. We make several holes on the metal sheet to fix the electric motor.

After that, we will weld another flat strip to the platform, which will hold the tire from the chainsaw.

- We will mount the axle on this site. From it we will fix the drive sprocket for the chain.

- It is necessary to attach the tire in such a way that it is possible to maintain the possibility of adjustments for the tension of the cutting part.

- If the chain is poorly tensioned, it may become deformed or break during the cutting process.

- If the cutting part is too tight, it will put additional stress on the sprocket axle.

- As a result, you can observe severe load on the electric motor and overheating of the circuit.

The final step will be to fix the power cable at one of the edges of the site. To start, simply connect the electrical cord to a power outlet. When the equipment is turned on, the carriage with the tire will begin to move slowly along the metal frame.

Installation of the structure on the base

After assembling the working unit, it needs to be secured to a metal frame , the manufacture of which with your own hands consists of simple steps.

- Two blanks are welded from durable steel tubes, shaped like the letter “P”. The upper parts of the resulting blanks are fixed to each other by electric welding or bolts.

- Four pipes placed vertically are welded in the center of the frame. On each element, several small recesses are made on the outer side at a distance of 20 mm relative to each other to a depth of up to half the diameter of the tube.

- Four tubes are also welded onto the working unit, the internal cross-section of which must correspond to the outer diameter of the pipes located on the base. The placement of elements must be done in such a way that the pipes on the working unit fit onto the tubes of the supporting base.

This design is necessary to ensure free movement of the sawing unit in a vertical position. Fixation of the working unit in the required vertical position is ensured using bolts.

Photo of a homemade tire sawmill

Types and features of homemade sawmills

Bent channels will be needed to assemble the sawmill.

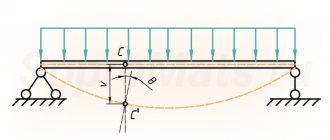

A do-it-yourself tire sawmill can be made in two versions:

- with movement of the working unit relative to the tree trunk;

- with longitudinal wood feed.

There is no point in saying that one of the options is better, since both of them have both advantages and disadvantages. For example, if the working unit is fed along the barrel, then it is easier for the operator to regulate his efforts to ensure uniform progress and sawing at high speed.

Feeding a log is more difficult in this regard: it is enough to feed the log a little more, and the load on the tire and chains will be too high. This may cause the chain to jam or burn out the motor. But such a sawmill does not require a large amount of electrical wiring, as is the case when using a work unit feed. It's up to you to think about what to prefer. But do not forget that the homemade sawmill and the log must be in a strictly horizontal position when sawing.

Make sure that these elements are on a solid basis that eliminates vibrations, “swings” and shocks.

Typically, a do-it-yourself tire sawmill is located either on channels or on rails.

Wheels are installed at the bottom of the sawmill frame to ensure easy movement (of sawmills or logs).

https://www.parnikiteplicy.ru/www.youtube.com/watch?v=5W7ipbs2NGY