And again I am glad to welcome you to the pages of Andrey Noak’s blog. Today I want to talk about which sawmill is better, belt or disk. After all, sawmill equipment is the basis for organizing both large-scale wood processing production (for example, for organizing the production of radial materials), and for small sawmills or even home use. And the profitability of the enterprise and user comfort largely depend on the quality and operational characteristics of the sawmill.

Introduction

I won’t delay and I want to immediately offer you my new book “HOW TO MAKE THE MOST OUT OF A BAND SAW MACHINE.” The book provides simply unique information based on my personal experience working on band sawmills.

It tells you how to work to get everything from a band saw. What kind of wood to cut and what needs to be done to reduce the number of downtimes. The main advantages of the ribbon are described, which you simply need to use. More details about the book in the “BOOKS” section. I’ll say right away that you definitely won’t find such information on a regular forum!

"Sever 550 AVT-M"

The Sever-550 AVT-M mobile miter sawmill is a universal tool for the production of various lumber in the immediate vicinity of the place where the lumber is harvested.

The maximum log diameter in the basic configuration (in the butt) is up to 500 mm. Optionally, this parameter can be increased to 600 or 700 mm.

The sawmill produces edged, semi-edged boards and timber with a maximum width of up to 200 mm.

Sever-550 AVT-M corner disc sawmill is equipped with a reliable Lifan or Honda gasoline engine (at the customer’s choice), is installed on a trailer and can be transported from place to place by a vehicle with a curb weight of 1.5 tons and above (UAZ “loaf”, jeep , "Gazelle").

Independence from power supply (you can work remotely from populated areas and power lines).

Easy to transport: the sawmill can be folded into transport position or deployed into working position within an hour. Thus, moving to a new location can be accomplished within a few hours.

The ability to produce a wide range of products using a single machine - a circular sawmill.

High percentage of lumber yield due to the ability to flexibly change the cutting pattern.

High cutting precision, typical for circular sawmills.

Long service life of the circular saw.

Safety of the operator’s work (the work area and the operator’s location are separated as much as possible in space and separated structurally).

the Sever 550 AVT-M disk sawmill over similar single-disc sawmills with a rotating mechanism is the well-thought-out ergonomics of the machine, which entails an incomparably higher level of ease of use on the sawmill, which in turn, naturally, directly affects the productivity of the machine.

The operator working on the Sever 550 AVT-M walks inside the frame on a special flooring, which ensures comfortable and free movement even in winter.

The rotating mechanism of the sawmill is designed in such a way that the saw is rotated with one movement of the operator’s hand, unlike models of single-disc rotary sawmills from other manufacturers, in which, in order to rotate the saw, the operator needs to approach the saw unit from the side (which is very difficult when sawing directly on the trailer), unscrew the latch, turn the knot, tighten the latch (all this happens in a dangerous inclined position above the saw) and only after all these by no means instantaneous manipulations is the carriage ready for the next cut. The operation of turning the disk on such sawmills takes from 10 to 15 seconds, while on the Sever 550 AVT-M sawmill, moving the disk from a horizontal to a vertical position (or vice versa) takes no more than 2 seconds!

Sever 550 AVT-M circular sawmill is equipped with a special adjustable movable limiter for the lateral movement of the saw unit, which allows you to literally move the saw unit to the side with your eyes closed, setting the next thickness or width of the board, while guaranteeing absolute stability and identity of these dimensions. Operating principle: the limiter is adjusted to the appropriate size (taking into account the thickness of the cut) of the board, for example, a thickness of 50mm, and when subsequently moving the saw unit, simply move it all the way and you can cut the next board. While the cut is being made, the limiter moves further to the side until it stops and is fixed. The saw unit can again be moved until it hits the stop to get a board exactly the same size as the previous ones. This device allows you to significantly reduce the likelihood of operator error and always obtain products of accurate and stable dimensions.

Relevance of sawmills

One of the most important decisions that a sawmill owner needs to make is the choice of specialized equipment for cutting logs, and the efficiency of future production largely depends on this decision.

The user needs to understand what manufacturers offer today from different types of equipment, what advantages and disadvantages certain units have, and also which of them are not worth the buyer’s attention due to low quality and frequent breakdowns.

I would like to note that today only band and disc sawmills are used both in large enterprises and in small workshops.

Disc machines

They are often used for large and small woodworking industries. They are mobile and compact in size, so they can easily be brought to a remote logging site. Their advantages include:

- Mobility and ease of installation and dismantling of equipment, although the ribbon is even simpler in this regard;

- Unpretentiousness when processing wood;

- Simply indispensable in woodworking production for producing radial boards;

- Excellent for processing substandard timber;

- The quality of lumber will delight specialists and clients;

The disadvantages include:

- Expensive cutting tool;

- It is not possible to process timber diameters that are too large, and even if this is possible, the costs are greater than on a strip;

- The need to install an additional multi-rip machine.

Band machines

They are intended for small volumes of work on farms and small industries; in some cases, several sawmills installed are also used in large enterprises.

Band saws for sharpening…

If you decide to purchase a unit for your home, then a tape unit will be quite enough. Such machines have the following advantages over disk machines:

- Inexpensive in cost;

- Consume little electrical energy;

- A thinner cut and, accordingly, on a thin board, the yield of lumber is 5 - 7% higher than that of a circular sawmill;

- They allow the operator to visually assess the condition of the logs after each specific cut, and, if necessary, make adjustments to the work of the models, in other words, you can make individual cutting of the log, although the disk one does it better, but we will also write down the ribbon as a plus;

- Possibility of using mobile sawmills with gasoline engines or electric ones;

- In addition, when using this type of installation, the logs rotate, which will allow a person to choose for cutting the side where there are the least defects. For example, if the main wood used for processing is birch or aspen, then a band saw is better than another option, since you can easily cut out high-quality material, leaving the core.

Flaws:

- Problem with saw repairs and constant frequent replacement of band saws;

- Poor ability to process dirty, dry or burnt wood due to the fast output of the band saw.

DIY sawmill with a gasoline engine

In the process of choosing equipment intended for wood processing, it is also necessary to take into account the high cost of the tool itself. It is for this reason that few consumers can afford to buy a sawmill. But as we said earlier, anyone can make this kind of tool themselves.

Homemade sawmill with a gasoline engine

At this point you can learn how to make homemade circular sawmills with your own hands with a gasoline engine. We will also take a look at a homemade circular sawmill driven by a PTO. So, let's begin to consider this issue.

First of all, what you should stock up on is patience and a great desire to acquire this kind of device.

In order to actually begin this process, first prepare drawings for a homemade circular sawmill (can be obtained on the Internet), and also prepare construction sawhorses, metal plates, boards, screws, screws, nuts, a special tool with the use of which you can work with wood and metal, as well as the gasoline engine itself. So, let's get started.

Does the chainsaw not start when starting? Read the reasons and what to do in this situation here.

Check that you are starting the chainsaw correctly. Read our instructions.

You can buy many different chainsaw attachments that will even turn your chainsaw into a boat motor.

- First you need to get all the necessary information regarding the device itself this tool in order to have the opportunity and understanding of what and how you should produce.

It is worth noting that the analogue of the working element for you will be the toothed circular saw, which is actually installed on the machine spindle.

- In addition, there is another option, which has the saw itself mounted on the motor shaft. On the very surface of the sawmill, processing of the so-called sawlog begins, which actually divides the unedged board. You also need to cut special blanks, each of which must meet the required size.

- It is worth noting that the simplest design of this process is the table . It is under its lower part that you must actually place the shaft itself with the saw mounted on it. The cutting part with which it is equipped should rise, so to speak, on the table surface itself. the movement of the saw shaft is produced by the action of a gasoline engine on it, which transmits peculiar impulses to the belt itself.

- Actually, the discs themselves for this kind of sawmill will serve best if they are made of duralumin or steel sheets. And its actual size should correspond to three millimeters. And the actual diameter should be 500 mm. It is important that if you are making a device in order to subsequently cut wood, then in this case you will need a disc with two or three teeth. Since this is the best option for this type of work.

- It is worth noting that the basis for the high level of sawmill production is the very manufacture of these teeth. In addition, the most important thing is that you carefully carry out the balancing and determine the correct cutting angle.

In the video you can watch how to do this:

Comparative characteristics

Which machine to choose for your own sawmill? How to understand whether “Taiga” or “Kara Master” or a model from another manufacturer is worth the attention of buyers?

To answer this question, I also visited a forum of experienced sawmill owners and asked their opinion on this matter, and now I invite you to read a comparative description made by me from my own experience and the experience of sawmill owners.

The choice of a specific type of sawmill equipment largely depends on factors such as the size of the sawmill, the nature of the logs used, the experience of the sawmill owner, etc. No less important are such characteristics of equipment for cutting logs as productivity, efficiency, and the presence of shortcomings in work. Of all these parameters, I highlighted the following points as the most important:

- The quality of the resulting board wins over the disk board;

- A radial or regular cut is required, if radial is also a plus for the disc;

- Speed of installation, plus the ribbon;

- Cost-effectiveness in electricity costs is a plus for the ribbon;

- Economical use of wood or a useful solution - a ribbon;

- Productivity is approximately the same.

More about efficiency

It is important to compare the cost-effectiveness of both options. This makes belt units more economical to operate. The price of the issue sometimes reaches decent amounts. Let me give you a specific example. The cut made by a band saw is 1.5-3 mm thick.

As a result, from a log with a diameter of 26 cm, 9 boards can be obtained using such equipment. Their thickness will be 27 mm. At the same time, the cutting thickness of the disk machine is 6-9 mm. From the same log, using such a unit, you can get 8 boards with the same thickness (27 mm). Thus, belt equipment produces almost half the amount of waste.

And if you multiply these results by the scale within a work shift, you get some pretty impressive savings. In approximately a certain period of time, you can save even a carload of boards using a belt unit for cutting wood.

Understanding how much such a carriage costs, which is approximately 90 cubic meters for 6,000 rubles, totaling 540 thousand rubles, the user will appreciate the advantages of band saws for cutting trees.

Another plus for the ribbon

When choosing a specific type of sawmill equipment, the diameter of the logs used when cutting is of great importance. The productivity of disk equipment with large-diameter material is practically zero. That is, a disc machine cannot handle huge logs. You can't cut large cedar with it.

But the tape installation in this regard is the most productive and expedient. In other words, the advantage of this type of sawmill model is the good quality of the boards, even if the logs had an impressive diameter.

One of the successful models of a band sawmill, in my opinion, can be seen in the video below:

Features of operation

Band cutting equipment for logs requires some experience in managing the entire process. Only if this condition is met, the output material will be sawn into boards with high quality, and there will be no defects on it. This mainly concerns such a defect on the ribbon as “WAVE”. From time to time, when a saw fails and needs to be sharpened, this defect appears, and only the experience of the operator will help identify it at an early stage, preventing it from becoming defective.

But disc sawmills work much easier; it is enough to change the cutting tool once a shift. An inexperienced sawmill owner can follow this principle and get quality boards by gaining experience without producing defects.

Disadvantages of sawmill equipment

Band machines, like any other technology, are not perfect. Problematic issues that may accompany the operation of a sawmill must be taken into account when choosing a specific type of saw.

Such units may have the following disadvantages: low productivity and frequent need for sharpening and spreading blades (every 3 hours subject to continuous use). And only an experienced specialist can perform this operation efficiently and without negative consequences. A beginner in such matters cannot undertake such a task.

At the same time, circular saws do not require regular sharpening. They are sharpened a little once every 8 hours, and full sharpening is required for such equipment only once every couple of days.

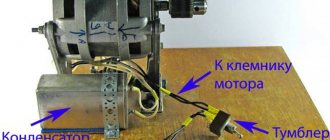

How to make an electric motor at home

As we said earlier, sawmills are extremely popular precisely because of their versatility and, of course, due to the simplicity of their design. That is why anyone who wants to have such a tool at home, but does not have the financial ability to purchase it, can make such a device with their own hands.

Also, to save money on repairs, the chainsaw owner can independently adjust the carburetor.

Homemade circular sawmill with electric motor

So, let's actually understand this issue: how to make a circular sawmill with your own hands at home? Let's begin. So, first you need a circular saw, the size of which must exceed 500 mm.

In general, the larger diameter you find, the better it is for you. In this sawmill, a kind of propulsion device will be the electric motor itself, by means of a pulley that increases the speed

So, you must weld the required frame , after which you need to place a plate on this frame; mostly metal is used; wood is used much less often. In the middle, which actually should be a slot intended for the disk itself. But remember that the gaps between the plate and the disk must be of minimal dimensions.

The next thing you should do is install the pulley and bearings in the lower part of the plate itself. After that, connect the electric motor pulley and the saw with special belts. This kind of manipulation will serve as a kind of insurance when the saw itself jams.

Do not forget that in order to produce high-quality tension of special belts, it is necessary to take into account the weight category of the propulsion mechanism itself with the addition of weighting agents . The supporting platform must be made with the ability to move, relative to the shaft itself, with a certain kind of deviation through gravity in the opposite direction.

Video on topic

Each user must decide for himself which characteristics of sawmill equipment are most important to him in the process of work. As a result of the above, I note that band sawmills are still characterized by wider application in comparison with disk models. They can produce boards of good quality, and have a greater useful yield, and, accordingly, greater profitability.

I hope my article was useful to you and you can make the right choice. Read my articles, subscribe to updates and recommend my blog on social networks. Until we meet again, Andrey Noak was with you.