Generator for welding: choosing an alternator and calculating power

Not every generator is suitable for welding, and this is important to understand when choosing. Essentially, electric welding is a short circuit, so not every generator will respond adequately to it.

In addition to power, it is important to know that there are different generators: asynchronous, synchronous, and also inverter. Synchronous generators are not suitable for welding work, and inverter generators are not designed for this purpose.

Therefore, before choosing a generator for welding, it is important to understand what to look for first.

How much power does a generator need for inverter welding?

The selected generator for welding must have a power no lower than that of the inverter, but on the contrary, slightly higher, taking into account the required margin of 25%. Typically, the power of the generator and welding inverter can be found in the technical data sheet. At the same time, you should not make mistakes in the units of measurement, since very often the power of electrical appliances is indicated not in kW, but in kVA.

kW is active power, and kVA is the apparent power of an electrical appliance. If the power of the welding inverter is indicated in kVA, and you need to convert it to kW, then it is enough to use the following formula for calculation: where 10 kVA * 0.8 = 8 kW. At the same time, you need to understand that the welding inverter will not always operate at full power, and here everything largely depends on the required current strength. And since the efficiency of the inverter for welding and the arc voltage always have a constant value, then calculating the power of the generator for welding is not so difficult. The efficiency of the welding inverter is 85%, and the arc voltage is 25V.

Knowing these parameters, you can independently calculate how much power a generator is needed for inverter welding, based on the strength of the welding current. If the inverter for welding has a maximum current of 160 Amperes, and you need exactly this current for welding, then the power of the inverter will be equal to: 160A * 25V / 0.85 = 4705 W. Considering the required power reserve for the generator, which is at least 25%, you can easily calculate its optimal power: 4705 W + 25% = 5881 W, which is almost exactly 6 kW.

From all of the above, it becomes clear how exactly the current strength of the welding inverter affects the required power of the generator. Consequently, by reducing the current on the inverter, it will be possible to use a generator of much lower power, for example, 2.5 or 3 kW. Here everything depends on the diameter of the welding electrodes and the thickness of the metal being welded. For example, using electrodes up to 2 mm, you can weld from a 2.5 kW generator, the power of which will be quite enough for the welding inverter to produce the required current for welding.

How to choose a generator (power station) for a welding inverter (WID)

“Which generator is suitable for welding” is a question that often arises among people who have decided to seriously engage in welding on their own and at the same time do not have the opportunity to connect the welding machine to the network. It’s easy to get confused, especially after we see a huge list of available models on the online store page.

It would seem that it is very difficult to understand this diversity, especially if you have a liberal arts education behind you. In fact, any of us can choose the right generator for a welding inverter; to do this, you just need to know a few small but very important nuances. They will be discussed in this article.

What points must be taken into account when choosing a generator?

As befits a serious unit, each generator for inverter welding has a huge number of different technical characteristics, among which it is very easy for a beginner to get confused. But for the right choice, only five of them are most important:

- power consumption;

- welding current;

- diameter of the electrodes used;

- compatibility of the generator with inverter equipment;

- the generator must be synchronous or with Duplex technology, generator manufacturer Endress (or equivalent).

It is these parameters that you should pay special attention to in order to use the generator for a long time and safely.

Generators differ by type into synchronous, inverter and asynchronous, as well as a symbiosis of asynchronous and synchronous Duplex series (manufactured by Endress); synchronous or Duplex series generators are suitable for welding . Inverter engines, as a rule, have insufficient power and are not designed for high starting loads. You can find out more about the types of generators in a separate article here.

Generator power for welding - what is the reserve for?

In most cases, the power of the welding inverter and generator is indicated by the manufacturer in the technical data sheet. Therefore, even a child can easily find these values and compare them. The main thing is not to confuse the power units kVA and kW, as well as the declared rated and maximum power of the generator.

It should be remembered that when buying a generator, you need to choose a model that has 25-50% more power than the inverter you have. This is explained quite simply - constant operation of the generator at the limit of its capabilities will very quickly disable it and will not make it possible to use the full potential of the welding machine.

If for some reason you do not have information about the power of your welding inverter, you can calculate it yourself using a simple formula:

Maximum current * arc voltage / efficiency of the welding inverter - maximum power.

In this case, you only need to know the value of the maximum current, since the other two components are almost always constant (the arc voltage is 25V, and the inverter efficiency is 0.85).

For example, if your welding machine has a maximum current of 180 Amps, then approximately its power is:

180A*25V/0.85=5294 W, which means that in this case, the optimal value for the generator will be a power of 5294 W + 25% reserve = 6617.5 W, or if converted to kW - 6.6 kW. In this case, the Huter DY8000LX gasoline generator model will be one of the best options.

Welding current - it must be taken into account

Another good news is that you can very well use a generator for inverter welding, which has less power than your inverter. However, in this case, you will have to use it with some restrictions, namely, reduce the current strength to an acceptable value.

Take, for example, the case if you decide to purchase a 4 kW generator model.

We use the same formula as when determining power, but in reverse order:

Power*Efficiency/Arc Voltage = Current or 4000*0.85/25 = 136 A

Thus, on a 4 kW generator you will be able to weld on your welding inverter without any noticeable loss of quality with a current of up to 130A.

Electrode diameter - a label that is easy to remember

Another important nuance that should be taken into account is the correspondence of the electrode diameter to the minimum power of the generator. These data are approximate and fit into a simple table:

| Electrode diameter (mm) | Minimum generator power (kW) |

| 2 | 2,5 |

| 3 | 3,5 |

| 4 | 4,5 |

That is, if you plan to carry out welding work with a 4 mm electrode, then the minimum power of the generator for welding should be at least 4.5 kW and higher.

Which generators are suitable for working with a specific welding machine?

You have read the main rules for choosing a generator for welding in the previous sections. Using them, you can safely start purchasing a power plant. But to make it easier for you to navigate the assortment, let’s take a closer look at the most popular inverters for household tasks and determine which generators are most suitable for them.

For inverters Svarog

Unpretentious and inexpensive Svarog inverters stand out among other brands with a long five-year warranty. Buyers also often prefer them due to their low price, so purchasing budget options for Huter and Fubag generators seems like a completely reasonable decision.

The welding inverter Svarog REAL ARC 200 (Z238N) will work perfectly in tandem with the Huter DY6500L generator. This high-quality and useful unit can successfully operate on natural gas, which significantly increases the efficiency of the generator.

For Resanta inverters

The popular inverter manufacturer Resanta also produces products intended for the mass consumer. A distinctive feature of this brand is the compact size and light weight of welding machines.

For the household welding inverter Resanta SAI-190, you can use the BRIMA LT 8000 B gasoline generator, which, in addition to this purpose, will, if necessary, serve you as a backup power source at the dacha or in a country house.

For Kemppi inverters

Finnish Kemppi inverters have proven themselves worthy when working in harsh natural conditions and in production. They are rightfully the leader in sales among imported premium models. They are bought by people who know how to value real quality and reliability.

In addition to the popular model of the Kemppi Minarc 150 welding inverter, you can safely purchase the Fubag BS 5500 generator, which is characterized by very low fuel consumption, a durable frame and reliable overload protection.

For EWM inverters

Products of the famous German brand EWM appeared on our market back in Soviet times. From then until now, EWM inverters have brought real pleasure to the people who work with them. Such a device needs an excellent generator.

Therefore, for the EWM Pico 160 welding inverter, the Fubag BS 7500 A ES generator seems to be a worthy partner, which is equipped with a powerful engine, an AVR unit and is equipped with a spacious fuel tank for long-term operation without refueling.

Useful tips for choosing a generator

There are several other useful tips based on the recommendations of welding professionals that will be useful to you when purchasing a generator for an inverter welding machine.

- generators with a power of up to 10 kW on a gasoline basis . They are most widely represented in this segment. And more powerful power plants run on diesel fuel.

- The power reserve of a gasoline generator, at least 15-25%, greatly facilitates ignition of the arc. For power plants running on diesel fuel, it is desirable to have a larger reserve - up to 50%.

- The most functional are power plants equipped with cast iron sleeves. Their minimum service life is 1500 hours . Aluminum blocks can withstand significantly less load - up to 500 operating hours.

- Inverters with the abbreviation PFC in the name have a built-in power factor corrector in their circuit design, so they can operate at reduced voltage and are excellent for operation from a generator, for example the Svarog ARC 160 PFC model.

The information provided in the article is intended for conventional welding inverters, which are often used in domestic conditions.

For professional equipment (semiautomatic welding machines and inverters designed for argon-arc welding), certain problems may arise when operating from a generator. Many manufacturers explicitly state this in the user manual. Therefore, it is highly advisable to consult with specialists before purchasing in order to avoid serious consequences.

It is quite possible to select a generator for a welding inverter yourself, using common sense and our advice. And for complete confidence, contact the consultants and managers of our welding hypermarket, who will tell you which generator is suitable for welding in each specific case. Our specialists have the right answers to the most tricky and difficult customer questions!

Principle of operation

All electric generators are designed approximately the same. A compact internal combustion engine drives an electric generator. Today, the most widely used are electric generators that produce alternating electric current. Such devices are simpler, more reliable and cheaper than DC generators. Household consumers, which also include welding machines, are designed for power supply with an alternating voltage of 220 V with a frequency of 50 Hz. To maintain these parameters within acceptable limits, mobile gas generators must contain an engine speed regulator when the load changes.

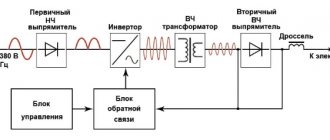

Modern autonomous generators (in order to obtain high-quality power at the output) are built according to a two-stage scheme. First, the voltage from the generator is rectified. This eliminates the influence of gasoline engine speed on the frequency and voltage at the output of the unit.

Inverter gas generators provide high-quality power supply to any household appliances. But if the unit is intended exclusively for welding, its circuit is somewhat simplified - such an inverter is initially built according to the circuit of a welding machine. A gas generator with a welding function does not require intermediate conversion of electricity to the “220 V 50 Hz” standard. This makes the design easier and simpler, but narrows the scope of application of the unit.

How to choose the right generators for welding inverters: power and current

A large share of welding work takes place in places remote from electrical networks.

Even when building a house in a village, permission to connect to a power line is issued after the construction of the building, when there is somewhere to connect the cable.

The generator for the inverter is used for welding work. In the remaining time, it can serve as a source of current in the country and for working with power tools.

Structure

Generators convert the energy of mechanical movement into electrical energy. The simplest example is a car generator, which uses the torque of the wheels to charge the battery.

The gas generator for the welding inverter is driven by an internal combustion engine, which rotates the shaft and the current collector and frame . When the rotor rotates, an electromagnetic current with alternating polarity is alternately excited on the magnet coils and supplied to the output cable.

Operating principle of the inverter

The welding inverter converts 220 V current with a frequency of 50 Hz into high-frequency alternating current with low voltage.

- The current from the network is supplied to a rectifier - a diode bridge.

- The filter smooths out peak values, leveling the current to a straight-line value.

- The transistor unit turns it into an alternating, but high-frequency one.

- The voltage in the transformer is reduced. The current increases.

Additional current regulator and stabilization units ensure a uniform high-frequency output flow. As a result, in case of any voltage drops in the network, the inverter produces a stable current . This makes it easier to choose which generators are needed for the welding inverter.

To excite current in the windings, pull the starting cord. The hand makes a sharp movement towards itself. If you have a battery, just press the button.

Selecting a Power Source

Inverters are capable of operating not only from a 220 V network, but at a strong voltage drop to 0.165 kV. The minimum current drop data is indicated in the technical data sheet . This feature of the equipment allows you to cook not only from a stationary power source. You can connect a generator for welding with an inverter. The choice is made according to the following parameters:

- inverter power;

- electrode diameter;

- current strength;

- compatibility of the generator with the welding machine.

According to the principle of generated current, generators are divided into: synchronous, asynchronous and Duplex type. You should choose only synchronous models , they are suitable for electric arc welding as a power source.

Power calculation

The power of a generator for an inverter-type welding machine is determined according to technical characteristics, or is calculated using the formula:

PG = (AC · 25V ÷ 0.85) · 1.25;

where: PG – power;

AC – rated current;

0.85 – efficiency;

1.25 – the minimum power reserve is 25%;

25V – arc voltage.

For example, with a current of 180 A, indicated within the regulation limits as a large value, a generator with a capacity of 6.7 kW should be connected.

Maximum value

The maximum power of the power plant must exceed the rated power of the inverter by 25 - 50% . Otherwise, the equipment will operate for a long time at maximum power, and the generator will quickly fail - it will burn out.

When the arc is ignited, a short-term voltage surge occurs. It significantly exceeds the rated voltage specified in the technical specifications of the device. The energy reserve protects against overloads.

Effective and reactive power

On the bodies of the devices you can see the value of the active power and the sine of the angle ϕ. From these values, reactive power is calculated - the value of the current that the oscillating circuit releases back into the system . Reactive power does not perform any work.

Active power is used for useful work and heating - consumed by the resistance of the internal components of the equipment. It is the amount of active power that should be known to select equipment. The value of the angle ϕ determines the magnitude of the phase shift.

Sockets

When connecting the welding machine to the generator, a cable is used, at one end of which there is a grounded socket, at the other end there is a special plug, which is inserted into the output socket of the power source. Such a cable is usually found among the components of the generator and inverter.

Fuel type

A generator is a power plant with an internal combustion engine . Diesel fuel or gasoline generator for welding, which one is better to choose and how they differ. From the point of view of weld quality and the ability to weld alloy steels and aluminum, a gasoline engine is better.

The diesel generator is designed for long-term or continuous operation. It can be used in the country as a power source for home electricity, and at the same time for welding and operating various power tools. It must be selected according to the maximum simultaneous load.

The disadvantage of diesel engines is their large size and weight. You can’t take such a generator from the garage to the dacha or to the construction site to weld the structure.

The gasoline engine is not suitable for long-term use with heavy loads. At the same time, it ensures stable operation of the inverter. It can be used in the welder operating mode of 40%.

How to choose a gas generator for inverter welding, taking into account long-term use.

To connect to your home and dacha, you should choose a power plant with a power reserve of 25% of the peak network load .

It is rational to install a gas generator for welding with an inverter under the condition of short-term operation or with a power reserve of 50 - 75%. You should follow the recommended operating mode for the inverter and the generator, alternating load with rest.

Frame

For better cooling, generator components can be mounted on a rigid frame and partially covered with a housing . This unit heats up less and requires special conditions. It can be used in indoor conditions with clean, dust-free air. Light weight allows the generator to be moved freely.

Solid-body equipment has a fan installed and slots for air circulation. It is less demanding on dust and moisture, but requires daily maintenance.

The housing contains a control unit, a start button, a grounding bolt and cable connectors.

Types of generators

Only synchronous generators are suitable for welding. The best way to rotate an armature is with a 2 or 4 stroke engine .

The 2 stroke diesel engine can run continuously. The voltage is not stable, which negatively affects the quality of the seam.

The four-stroke gasoline engine has smoother current output characteristics, provides a stable arc and smooth adjustment of modes.

Gasoline generators with welding function

Welding gas generators provide a full guarantee of identical characteristics . In one housing are connected: an inverter-type welder and a generator with a gasoline engine.

Amateur models produce current up to 170 A, professional 220 A and higher.

Models

Popular types of welding gas generators are suitable as a power source in the country. It can power the tool during periods when welding is not working.

The most popular models in stores are from Germany:

- RID RH5221 S – gasoline power station has a built-in welding machine;

- RID RH7220 S – constant welding current up to 220 Amps.

RF equipment from Svarog is popular among professionals and amateurs..

Operating rules

The generator must always be clean. Dust and dirt settling on electrical terminals and windings lead to overheating and malfunction.

To excite the current in the winding of gasoline generators, a battery is installed. It should be charged periodically. In addition, there is an oil level indicator on the panel. A red light means that the coolant and lubricant level is low and needs to be topped up.

Like all electrical equipment, the generator should be periodically checked for insulation integrity, the terminals should be cleaned of oxides and the contacts should be tightened.

Specifications for selection

In addition to general parameters and characteristics, there are specific indicators that must be taken into account when solving the problem of which generator is needed for a welding inverter.

Particular attention should be paid to the following:

- Gasoline generator power reserve. This data is displayed in the technical documentation of the device. When purchasing, this figure should be 25-50% higher than the power of the inverter. If the generator is constantly working at the limit, it will quickly become unusable and will not allow the welding equipment to be used at full capacity. The stock made will make it possible to fully unlock the potential of the inverter, and all units will significantly increase their service life.

- Welding current. Adjustments and limitations of this indicator to certain acceptable values allow the use of a gas generator with less power than that of an inverter. For example, a 4 kW unit provides welding with a current of 136 A, without any noticeable loss of quality. But, naturally, the capabilities of such a device as a whole will be significantly limited.

- Diameter of electrodes. This parameter must be in full compliance with the minimum generator power. For example, a 2 mm electrode can work normally with a minimum power of 2.5 kW, 3 mm corresponds to 3.5 kW, 4 mm corresponds to 4.5 kW, etc. Thus, if you plan to weld with a 4 mm electrode, you will need a generator with a power of 4.5 kW or more.

Synchronous, asynchronous or inverter?

For welding, the best option is a generator with an asynchronous alternator. It is this type of alternator that is least susceptible to short circuits, which is what electric welding actually represents.

Plus, these alternators are brushless, so you won’t need to constantly change brushes. They also have good protection from dirt and dust, light weight and small dimensions.

In inverter generators, due to their design and low power, it is often not possible to connect electric welding. As for generators with a synchronous alternator, they are not at all designed for working with a welding machine.

So, three important components when choosing a gasoline generator for welding are:

- Suitable power, but not less than that of a welding inverter, plus 30% on top. If you need to calculate the generator power according to the welding current, then we use the formula above;

- If possible, copper winding in the generator;

- Asynchronous alternator only.

Review of popular models

Model Hammer GNR2000i

Hammer GNR2000i

- Type - power plant;

- Engine - petrol;

- Phases - single-phase;

- Generator type: synchronous;

- Power - 2 kW.

The Hammer GNR2000i gasoline inverter generator with a manual drive and a 5.7-liter tank capacity provides uninterrupted power for 4.5 hours. This device can be installed at the dacha or in country cottages.

In case of unplanned power outages, the portable station will heat the room, provide lighting and provide consumers with the necessary amount of energy for domestic needs. The price of the Hammer GNR2000i petrol inverter generator is 23,596 rubles.

DDE device DPG1101i

DDE device DPG1101i

- Type - power plant;

- Engine - petrol;

- Phases - single-phase;

- Generator type: synchronous;

- Power - 0.8 kW.

This manually operated station with a 2.6-liter tank capacity provides electricity for five hours. The model is perfect for installation in country cottages and providing summer residents with autonomous electricity during unexpected power outages.

The disadvantage of the DDE DPG1101i gasoline inverter generator is the lack of a noise-insulating casing, which does not allow it to be installed directly in living rooms. The price of the device is 8,150 rubles.

Model Hyundai HY 2000 SI

Hyundai HY 2000SI

- Type - power plant;

- Engine - petrol;

- Phases - single-phase;

- Generator type: synchronous;

- Power - 2 kW.

This model of inverter gas generator for gas boilers with manual drive and a tank volume of 4.5 liters provides the circulation pump with power for up to 5.5 hours. A stable supply of high-quality current maintains the functionality of the boiler for a long time and ensures uninterrupted operation of the heating system in the house.

In addition, the power of this inverter gas generator is enough to provide lighting and power to household electrical appliances (TV, hair dryer). To connect large household appliances (refrigerator, washing machine), a device with higher power ratings is required - for example, an inverter gas generator up to 3 kilowatts.

What to look for when choosing

Power

What characteristics should you use to choose a quality device? First of all, you need to determine the purpose of the device: what it will be used for. If you need to connect only a couple of household appliances and a few light bulbs, you need to choose a gas generator of appropriate power: no more than 2 kW. Such devices do not weigh much, and they can be taken on a hike or installed in the countryside.

, medical equipment or pump are chosen with high power characteristics: from 5 kW. Such devices are heavy and are often equipped with wheels for ease of movement. They are capable of providing energy to a large number of current consumers.

Type of current

Power consumers differ in the quality of the current consumed: single- or three-phase. Low (single-phase) power consumption devices include household appliances. Three-phase power is required for such devices as a concrete mixer, compressor, electric boiler and others.

Control type

The type of control of a gasoline inverter generator is of no small importance. What is better - automatic or manual drive? Manufacturers offer several options for controlling power plants: manual, semi-automatic, automatic

In addition, combinations such as manual control from a remote control have been developed. The choice will be up to the consumer. The cheapest option is manual.

Synchronous or asynchronous

Synchronous inverter gas generators produce current with better characteristics and are resistant to short-term network overloads. It is recommended to buy such devices when connecting equipment with high starting current values, as well as household appliances, microwave ovens, etc.

Asynchronous devices cannot cope with high loads, but they can withstand short circuits. It is recommended to buy this equipment for all types of heating appliances: electric stoves, lamps, etc.

Top 5. CHAMPION GW200AE

Rating (2021): 4.49

- Characteristics

Average price: 74,800 rub.

- Country: Russia (manufactured in China)

- Engine capacity (cm3): 420

- Engine power (hp): 13

- Generator power (kW): 5.5

- Maximum current (A): 200

- Noise level (dB): 94

A universal-purpose gasoline device from a popular Russian manufacturer. A model that produces 5.5 kilowatts of power at peak is an excellent value, but the current is only 200 amperes, with the lower value being 80 A. Welding with very thick or, conversely, thin electrodes with such a device will be impossible. But it should be noted that in most situations they are not used. The purpose of the tool is household and semi-professional, that is, the parameters will be quite sufficient. The characteristics of the current generator itself also speak in favor of domestic use. There are two 220-volt outlets and separate low-voltage connectors. An excellent option for powering a residential building.

Advantages and disadvantages

- Lots of output connectors

- Greater autonomy

- Few degrees of current adjustment

- Loud operation

- Inconvenient transportation

Review of inexpensive household generators

Not every generator is suitable for working with a welding inverter. The selection criteria were discussed above, and now it is proposed to visually imagine the most suitable models. All of them have been tested in practice and have proven themselves in a wide variety of operating conditions.

Huter DY6500L

The Huter DY6500L household generator device (Fig. 1) has proven itself to be literally indispensable for the household. The power of the unit is within 5 kW, which is enough to power an inverter with a welding current of 150 A. To operate this synchronous generator, gasoline with a recommended grade of at least AI-92 is used. The fuel tank capacity is 22 liters. If necessary, propane gas can be used.

The device is started by a manual starter. A built-in air system is used for cooling. The total weight is 80 kg, but 2-3 people can easily carry it from place to place.

BRIMA LT 8000 B

A more powerful gas generator for a welding inverter, suitable for connecting such loads, is the German model BRIMA LT 8000 B (Fig. 2). Its rated power is 6 kW, maximum – 6.5 kW. This device is suitable for equipment with a welding current of 180 A. The unit runs on gasoline, the fuel tank holds 25 liters. The generator is driven by a four-stroke gasoline engine, which is highly reliable and equipped with forced air cooling. A built-in electronic device is used to start. The continuous operation time is 8 hours, after which a technical break is required to avoid overheating of the unit.

The dimensions of the device are usual for models of this class, and the weight is significant - 83 kg. Therefore, if necessary, the generator is equipped with wheels to facilitate its movement.

Rating of welding inverters

Connecting a welding inverter

Operating principle of a welding inverter

Which welding inverter is better to choose for home and garden?

Which gas generator to choose for your home

How to make a welding inverter with your own hands

Types and features of generators

Generators running on gasoline are mainly used as a backup source to supply electricity to any objects or, if necessary, to carry out field work with power tools that cannot be connected.

Gasoline generators for welding are designed for temporary operation (for several minutes or hours). If you need to work for a long time without breaks, it is better to get a diesel generator.

Gasoline generators for summer cottages and recreation - this type of generators is the most popular among buyers. The stations can produce power from 0.7 to 5 kilowatts, and are quite easy to transport.

Gasoline generators for welding machines - a variety with a power of 5 to 10 kilowatts. They are well suited for intensive work for 8 hours. It is very important to know the engine manufacturer so as not to end up with an option that will make its shortcomings known within a month. An important parameter is the size of the fuel tank and the presence of a sound insulation casing and the ability to start the generator with an electric starter.

Scheme and structure of the device

Modern overhead valve generators can be compared with diesel ones in terms of the quality of the energy released. The units can provide very high performance while minimizing noise, and are compact and durable. It is advisable to buy this generator for welding if you plan to carry out work on a construction site or power a welding machine that periodically requires a powerful flow of energy.

A gas generator with a welding function for a cottage or enterprise produces power from 10 to 20 kilowatts. They are equipped with automatic start and are used as a stationary installation.

Generator power calculation

Maximum value

Before you begin calculating the parameters associated with the electric generator, you should carefully study the operating characteristics of the welding inverter itself, given in its passport (photo of the appearance of the unit below in the text).

Inverter welding unit

If it states that this device produces an output of 160 Amperes, then based on this parameter the maximum power consumption can be determined. Its indicator (P max) is calculated as the product of the arc voltage (it is usually equal to 20-25 Volts) and the output current.

For our case, we choose the maximum efficiency = 0.9 and as a result we get:

P max = 160 x 20 x 0.9 = 2880 watts.

Rounding the result obtained, we can say that the power consumed by the inverter will be approximately 3 kW. Based on the results of this calculation, the generator for an inverter welding machine P max should not be lower than the specified one (it is better if it is a little higher, that is, with a small margin).

Effective and reactive power

When assessing this indicator, it should be borne in mind that during the welding process the operator never works in the maximum current mode, but always leaves a small margin for the work he performs. This circumstance is also taken into account before choosing a generator for inverter welding that is suitable for current and output power.

It is believed that the so-called temporary correction of its use, denoted as VP, should be taken as a real indicator of the energy spent on welding. Usually it is given in the passport for this device and is about 40%. Taking this correction into account, the power selected in the example above should be only 1.2 kilowatts.

In addition, the difference between the active component of power (consumed in the form of heat) and its reactive component should be taken into account.

Necessary clarification. This component is understood as that part of the total energy that is associated with the processes occurring in the reactive elements of the load (in capacitances and inductances, in particular).

Since the gasoline generator is loaded onto a standard welding inverter, the design of which contains a sufficient number of reactive elements, taking this component into account will affect the final result of the assessment. The correction made to the calculation formulas is introduced in the form of the so-called “power factor” (it is denoted in the formulas as the cosine of the phase shift angle between the reactive and active components).

Power factor (PF), depending on the device used, can range from 0.75 to unity. For those who want to know how much power is required for the purchased device, let us remind you that for industrial inverter units this figure is indicated in the passport and is approximately 0.8.

What is a welding generator

Electric generators capable of working with welding equipment come in two types: welding and synchronous.

A welding generator is a power plant that combines 2 units: a welding machine and a conventional electricity generator.

To prepare such a device for operation, it is enough to connect cables to it, one of which has a holder for electrodes, and start the engine. No additional equipment is required for welding work. Due to their ease of setup and use, welding generators are widely used by construction organizations and utilities. Also, these units are used when performing a large volume of welding work and for laying pipelines in places remote from the power grid.

Synchronous generators are a voltage source for both transformer and inverter welding machines.

Synchronous generator OS-71-U2

It is important to know that an ordinary standard power station is most often not suitable for connecting a welding machine to it, since it requires certain power parameters. Although short-term use of a standard station is possible, in most cases this leads to its failure.

Electric power stations are classified according to engine type. These units can run on both gasoline and diesel fuel.

Gasoline generator

This type of electric generator is the most popular among professionals and home craftsmen. It can have a gasoline two-stroke or four-stroke engine. The device has low power and is used for work with light loads. In addition, the welding gas generator has improved current indicators, which have a positive effect on the quality of welding work.

The power of petrol models ranges from 2.5 kW to 14 kW. The tank volume of gasoline units is also small - about 4-25 liters. This type of generator is capable of delivering a maximum current in the range from 160 to 300 A and can work with electrodes up to 5 mm in diameter.

Gasoline generator GE 4000

Advantages of gasoline units:

- reasonable cost;

- small weight (from 50 to 100 kg);

- ease of use;

- ability to start and operate at low temperatures.

Disadvantages of gasoline units:

- short service life, from 500 to 3000 hours;

- high fuel consumption, for example, a 4 kW unit will consume on average from 1.7 to 2.4 liters of gasoline per hour;

- the generator must be given a rest after a certain time (indicated in the instructions for the device).

Diesel generator

Diesel generators allow welding work to be carried out under heavy loads and have a long working life. Diesel units are not suitable for domestic purposes, since they have a power of 6 to 16 kW and are high in cost. Stationary units can have a power of up to 80 kW.

Diesel generator TSS SDG 5000 E

Diesel power plants have fuel tanks with a volume of 12 to 65 liters, a current strength of 160-520 A and can work with electrodes up to 8 mm in diameter.

Advantages of diesel units:

- service life about 40,000 hours;

- stability of work;

- welding of metals under heavy loads;

- high efficiency;

- lower fuel consumption compared to a gasoline type generator, about 1.6 l/h with a power of 4 kW;

- a diesel unit can operate without interruption, almost around the clock.

Disadvantages of diesel units:

- the engine is difficult to start at low ambient temperatures;

- heavy weight (from 100 kg and above);

- high cost (more than 100 thousand rubles).

Generator classification

Many people, when choosing which generator will power an inverter welding machine, pay attention only to its power, but there are other important characteristics. Among them:

- Engine's type;

- Type of welding current;

- The magnitude of the current on the generator;

- Availability of additional functions and characteristics.

The most popular are the two types of internal combustion engines that are used here. The first is a gasoline generator, which is very easy to maintain and is not difficult to repair. It can be used over a wide temperature range

One very important practical benefit of this product is its unpretentiousness to fuel quality

Gasoline generator for welding

The second type of engine is diesel. It is more designed for intensive and long-term work. Gas generators can also be used, but they have not gained widespread popularity due to the complexity of operation and problems with fuel supplies.

Diesel generator for welding

Generator winding - copper or aluminum?

There is no fundamental difference whether the generator winding for welding will be copper or aluminum. It will be possible to weld metal in both cases.

However, it is worth considering the fact that the copper winding of the generator has greater reliability, resistance to overloads and durability. Therefore, if you are choosing a gasoline generator for constant welding work, then it is better to give preference to one that has a copper alternator (winding).

Basic parameters of the generator

Most users who have chosen unsuccessful equipment made a mistake in selecting the correct rated power

This can lead to unstable operation, but this parameter is not the only one you should pay attention to when choosing which generator is needed for welding. The following data is important for the device:

- Rated power;

- Number of power phases;

- Reserve short-term power;

- Voltage.

All this must match the parameters of the generator used. Thus, it is impossible to do without preliminary calculations for compatibility.

Generator selection

If you don’t know how to choose a generator for a welding inverter, then you should start with the type of engine it contains. This is the main difference from which to start the selection. Convenience of gasoline engines. And also the availability of fuel for them is undeniable. The ability to operate at different temperatures as well as versatility makes them the most popular option. But if you have to carry out long-term work, then diesel generators will be more suitable.

The next parameter is power, current, voltage and other electrical characteristics. When a buyer asks the question of how much power a generator is needed for inverter welding, he needs to start from the power of the inverter itself. The fact is that very weak generator power will lead to failures during welding, and too much power will result in excessive energy consumption.

Dimensions are actually a very important parameter. The ease of use of the generator in practice very significantly affects the frequency of its use. Modern inverter models are compact and economical. This leads to weight loss, so you can manage it alone or together. There are also no problems during transportation. Naturally, powerful devices that have a wide range of parameters, as well as a capacious tank, cannot take up little space, so when choosing dimensions, you need to take this factor into account.

When people are interested in how to choose a generator for a welding machine, they forget about one very important point. Indeed, in addition to the welding machine, it can power household appliances at home in the absence of electricity or other work tools

This implies that the technique must be universal and suitable for all types of work.

In addition to the fact that engines can differ in the type of fuel used, it is also worth dividing them by the number of strokes. Two-stroke ones are used in budget models. This is an excellent inexpensive solution that is suitable for those who do not need to use the generator very often. Two-stroke engines cannot cope with long-term loads. But for a home there is little point in overpaying, so such motors are quite appropriate for simple generators. The four-stroke engine is more expensive, but for professional use its price is quite justified. It easily withstands long-term loads and is found in more serious generators.

Popular models

When choosing which gas generator is needed for a welding inverter, you can focus on popular proven models:

- HUTER DY6500L;

- BRIMA LT 8000 B;

- ERGOMAX ER 5400;

- Fogo FH 7220 SE.

Synchronous, asynchronous or inverter?

For welding, the best option is a generator with an asynchronous alternator. It is this type of alternator that is least susceptible to short circuits, which is what electric welding actually represents.

Plus, these alternators are brushless, so you won’t need to constantly change brushes. They also have good protection from dirt and dust, light weight and small dimensions.

In inverter generators, due to their design and low power, it is often not possible to connect electric welding. As for generators with a synchronous alternator, they are not at all designed for working with a welding machine.

So, three important components when choosing a gasoline generator for welding are:

- Suitable power, but not less than that of a welding inverter, plus 30% on top. If you need to calculate the generator power according to the welding current, then we use the formula above;

- If possible, copper winding in the generator;

- Asynchronous alternator only.

Choosing a specific manufacturer and model of generator is the next question. You can definitely get answers to them in the next review. It will be dedicated to the rating of manufacturers of gasoline generators.

Source

Rules of care

The most popular models of gas generators - with two-stroke air-cooled engines - require virtually no maintenance. You just need to carefully monitor the cleanliness of all exposed parts (especially the radiator fins). Before each start-up of a generator of any design, it is imperative to check the serviceability of the fencing device (shields and boots). Check the presence of all fastening elements and the tightening force of the screws (nuts)

Pay attention to the condition of the insulation of wires and electrical terminals

It is necessary to regularly check the oil level in the engine crankcase. To top up, you need to use oil strictly of the brands recommended by the manufacturer of the gasoline engine. Cheap and compact generators are usually started manually.

To start the motor of heavy and powerful welding generators, an electric starter motor is used. For such units, you need to monitor the battery charge level. In addition, the starting battery gradually becomes unusable and, as capacity is lost, requires replacement. In any case, since the exhaust gases of a gasoline engine are harmful to human breathing, it is best to use welding generators outdoors. In this case, it is necessary to provide protection from rain and snow. If you have to operate the gas generator indoors, you need to provide good ventilation.

Remember that 220 V electricity is dangerous to life! Always check the quality of the insulation of the welding inverter and the serviceability of electrical appliances (sockets, extension cords). Working in the rain or in rooms with high humidity is completely unacceptable.

In the next video you will find a brief overview of the FORTE FG6500EW gasoline welding generator.

What else needs to be taken into account?

Once you know the required power, you should consider other criteria for choosing equipment. These include:

- Fuel type. As we have already noted, either gasoline or diesel power plants are used in combination with welding machines. The former are cheaper, but more expensive to operate. With the latter, the opposite is true - their price is several times higher, but they are more economical in operation. In addition, diesel units are safer to use. Moreover, both from an environmental point of view (their exhaust is cleaner) and in terms of fire safety.

- Number of phases. Both single-phase and three-phase units are widely represented on the modern market. In addition, if necessary, you can purchase a universal model. The latter option is justified when it is planned to use a generator to power several welding machines of various types.

- Manufacturer. As for this parameter, a reasonable compromise should be sought between the company’s fame and the price of the device. Units produced by trusted manufacturers are more expensive, but their service life is usually longer. In addition, if any breakdown occurs, there are usually no problems with replacement or repair. If you need a cheaper option, you should pay attention to domestic equipment. It is traditionally cheaper, but in many cases it is not inferior to imported units in terms of technical characteristics, service life and other parameters.

By calculating the power of the welding machine, as well as deciding on the type of fuel, number of phases and manufacturer, you can select a generator that will best suit the needs of a particular user. However, there is an easier way to select a device - just turn to professionals. Specialists will clarify the details and offer a model that is optimal for your case.

Selection of generator for welding

When the design of a gas-welding generator is equipped with cast iron sleeves, its service life increases dramatically.

These devices can be used for approximately 1500 operating hours. Aluminum analogues have a shorter service life. Today you can purchase inverter units that have power factor adjustment. These systems can work with a variety of generator models as they can be set to low voltage.

Diesel models are suitable for daily, long hours of work. A device with a power of 0.7-5 kW is suitable for working on a personal plot. These products do not have much weight. Therefore, they are easy to transport from place to place. A power of 10 kW allows you to perform daily work for 8 hours.

The most important parts, especially their dimensions, in a gasoline welding generator are:

- Fuel tank.

- Sound insulation casing.

For construction sites, it will be better to use equipment with valves on the top. The advantage of such devices is:

- High performance.

- Silence.

- Durability.

- Compactness.

Most popular models

Depending on the operating principle of the engine, almost all gasoline welding machines are divided into several types:

- Two-stroke.

- Four-stroke.

To work in domestic conditions, the HUTER DY6500L model is considered the most efficient and productive. The device is not designed for long-term use, but it differs from other products in its good characteristics. Such a compact station works perfectly together with a Svarog-type inverter.

The target system Brima LT 8000B shows excellent performance with most inverters manufactured by Resanta. Sometimes Brima can become a backup power supply for a country house.

The Endress ESE 606 system has a very large fuel tank. The model is highly expensive. However, it lasts much longer than a conventional generator. The product is equipped with a Honda engine, which significantly reduces fuel consumption. The device shows excellent results when working in conjunction with an EWM type inverter.

How to care for your generator

Servicing a gasoline generator does not involve serious technological operations. It is enough to monitor the oil level. Top it up if necessary. Sometimes you will need to recharge the battery.

https://youtube.com/watch?v=MXDzKmpZEO4

What is better, select welding and generator separately or buy a welding generator?

A welding generator is a structure consisting of a gas generator and a welding machine paired with it. The power plant is designed in such a way as to serve welding, so it has a longer service life. Other advantages :

- Short circuit protection installed;

- It is possible to work in areas remote from the central power supply (city outskirts, field, road);

- The design is more compact than if you connect welding separately;

- The cost is lower than a diesel generator of similar power.

Flaws:

- Such an electric generator can only be used for welding;

- Gasoline has better fuel consumption and is more expensive than diesel;

- Cannot be powered from the central network;

- Low motor life.

The most significant limitation is that it cannot be used as a backup power source for other consumers. It is intended for welding only .

If you select separate power for welding, it is better not to use it for other purposes, and vice versa, if you have a power station at home for backup power, try not to connect welding to it. This can result in breakdowns and costly repairs.

A welding generator is the best option if you are professionally engaged in repair work, constantly traveling to open areas without access to electricity. You don't have to connect or configure anything - just start the engine and adjust the current to the diameter of the electrode. Fewer wires and easier to manage.

But, on the other hand, this way you will not be able to connect the structure to the central network. The average gasoline consumption is 0.5-0.6 l/kWh, and this will cost 10 times more than when connecting the device to the central network. In addition, with such a consumption, electric generators have limited autonomy. On average it is only 3-5 hours.

If you carry out most of your welding work with access to a central power grid, it is cheaper and more profitable to buy a generator separately . But, no matter what design you choose, it still requires proper care and maintenance. This is the only way you can increase the service life. Better yet, ask all your questions to a good specialist (by following the link you will find a special feedback form https://axiomplus.com.ua/elektrogeneratory/).

Features of choosing a generator

Before choosing a gasoline generator for a welding machine, it is very important to pay attention to its power. With its large value, the gasoline welding generator operates in normal mode. He will always have a reserve of power

He will always have a reserve of power.

The following selection criteria should be adhered to:

- To select a generator for inverter welding, you need to know the maximum current value. It is indicated on the body of the device. Designated Imax.

- Power calculation is determined by the formula of Ohm's law. Let's take Imax 23A. We multiply 23 by 220, we get 5060 W. Add 30% to the result obtained. The final power value of the device will be 6600 W.

- Which gas generator is needed for a welding inverter depends on the diameter of the electrodes used. This size must be suitable for the power of the device. For example, the operation of electrodes with a diameter of less than 2 mm requires a power of 2.5 kW. When the diameter increases to 3 mm, the power value also becomes greater - 3.5 kW.

- When determining how much power a generator is needed for inverter welding, it is necessary to take into account the voltage of the outlets. The inverter model must match this value. For a household system, an ordinary 220 V outlet is sufficient.

- Very powerful inverters with a three-phase connection must be plugged into sockets that can withstand 380 V.

- Professionals advise taking into account the weight of the device. The compact wheeled system is suitable for frequent transport.

Which generator will power a 160-250 Ampere welding inverter?

If you often have to cook in conditions without electricity, then buying a generator is the right decision. At the same time, in order for the generator to carry out welding and not turn off due to overloads, it is necessary to pay attention to a number of important points when choosing it.

With all this, it is important to understand that to operate from a generator, it is best to use inverter sources of the welding arc. Otherwise, you can damage the generator or achieve nothing from using it.

Coordination of gas generator and inverter

To ensure operation with optimal welding modes, it is necessary, first of all, to match the parameters of the gas generator and welding inverter. This is achieved in several ways, and one of them is to simply add the inverter power and 30%-40% reserve. This method allows for uninterrupted welding, but is an expensive solution because in this case you will have to buy an obviously expensive and heavy gas-powered unit. In order not to overpay and ensure greater mobility, several factors should be taken into account, namely:

the length of the cable connecting the inverter and the generator should not exceed 10-15 meters, which will avoid losses; to select a generator, the average power consumption of the inverter should be taken into account; modern inverters have hot start functions and current regulation, so in calculations it is necessary to correlate the current consumption at the time of peak load and the maximum power of the gas generator.

For example, we considered a generator with a power of 4 kVA, multiply this value by the efficiency of the welding machine, for inverters it is 0.8 and divide by the arc voltage, let’s say 25 V. We get a current of 128 A, which allows reliable welding with a 3 mm electrode. There is a simplified method for coordinating the maximum load on the generator and the thickness of the electrodes, and therefore the workpieces being welded. It consists of the following:

- electrode diameter up to 2 mm, requires maximum generator power of 3 kVA;

- with a diameter of 3 mm, a generator with a power of 4.5 kVA is required;

- for a 4 mm electrode you need a gas unit with a maximum rating of 5.6 kVA;

- using a 5mm electrode implies a power of 6.9 kVA.

These data are overestimated, since they are calculated for peak loads on the generator at maximum inverter consumption.

Description

Currently, stores offer two types of generators, which are designed to work in conjunction with welding machines . It is customary to highlight:

- synchronous;

- welding

The first type is conventional voltage sources that support operation with household appliances and welding inverters.

If we talk about welding generators, then these are small devices, additionally equipped with a built-in welding machine. Due to the fact that they require very little space, they are very convenient to take with you . It is important to take into account that gas generators with a welding machine differ in power indicators. Therefore, consumers need to choose a suitable model with an emphasis on this characteristic.

Gasoline generators with welding function

Gasoline generators with a welding function are multifunctional devices characterized by their ability to withstand heavy loads. The design of this device is an anchor that rotates due to an external drive.

A welding generator is also a power plant, but with a wider range of loads to bear. It is primarily used to start arc type welding. However, the above-mentioned versatility of such an installation is manifested precisely in the fact that in addition to power for welding, it can also be used to electrify ordinary household objects.

Among the professional areas of operation of such installations, the following stand out:

- Pipe welding;

- Installation of metal structures;

- Connecting autonomous objects to power supply, etc.

Portable welding generators are distinguished by their compactness, mobility, optimal weight and relative “silence” during operation. These qualities make it possible to use such installations in field conditions (welding, metal cutting).

Various models of such devices are distinguished by certain physical and technical characteristics and operational features:

- Manual or electric starting drive;

- Wide range of battery life;

- Certain fuel consumption;

- Noise level and other parameters.

Welding generators dominate over simple power plants, since their performance under load is many times higher, and they perform better under instantaneous overload conditions. In general, the functionality of these installations is more flexible compared to simple “household” analogues.

Top 5. GMGen Power Systems GMSD200YTE

Rating (2021): 4.41

- Characteristics

Average price: 373,000 rub.

- Country: Italy

- Voltage (V): 220/380

- Start: electric starter

- Generator power (kW): 5

- Maximum current (A): 190

- Alternator: synchronous

Diesel generator for professional use with average performance and long service life. Peak power is 5 kilowatts at a current of 190 amperes. Not the highest values, but acceptable for most types of welding, unless we are talking about joining thick metals. The generator is three-phase, capable of delivering 380 volts. It has smooth adjustment of current and other parameters, as well as multiple protective functions. The layout of the parts deserves special attention. Thanks to it, the noise level of the tool is only 89 decibels, which is very low for diesel engines. But finding the product in retail will not be easy. GMGen Power Systems is not the most popular brand in Russia and the CIS.

Advantages and disadvantages

- Low noise level

- Reinforced frame

- Convenient location of sensors and sockets

- A rare guest on store shelves

- Inconvenient transportation