If you look from the outside, it may seem that welding is very simple. Indeed, after several unsuccessful attempts, the person who picks up the holder for the first time will connect the two workpieces. However, the quality of the seam will be so low that even with a slight load the parts will fall apart. Therefore, only those who have the ranks of welders, confirmed by documents of the established form, are hired.

Welder 5th category

To become a 5th category welder, you must have a special education for this profile and work as a 4th category welder for at least one year.

It is impossible to immediately obtain this rank, but after working for at least a year, a specialist has every chance of obtaining the status of a 5th rank welder.

What should a 5th grade welder be able to do?

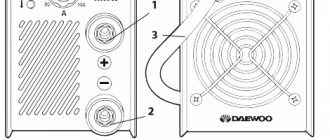

A 5th category welder must be able to understand the internal mechanisms of various welding machines with semi-automatic and automatic operating methods, as well as the features and properties of various metals being welded, including high-tech steel. He must know the mechanism of the correct sequence of work to establish a weld and the rules for cutting metal under water.

A 5th category welder must be able to perform manual electrode and plasma welding on critical, complex construction and technical metal structures, working in difficult conditions.

A worker in this category must be able to cut complex products from different types of steel and their alloys in any position using oxygen and plasma equipment, using special fluxes.

A welding professional of the 5th level must perform his work efficiently using automatic welding under dynamic and vibration loads.

In addition, a 5th category welder must be able to weld critical complex metal structures for construction and technological purposes, using mechanized welding and working in difficult conditions. Also, an electric gas welder of the 5th category is required to weld important block systems in any position of the seam in space.

In addition, the welder’s responsibilities include welding and surfacing of cracks and shells of thin parts in hard-to-reach places and performs heat treatment of joints after welding with a gas flame. The welder is also required to understand and freely read drawings that depict particularly complex metal products and systems located in space.

You need to understand that a welder is not just a working specialty in welding metals.

He performs gas or arc welding of products and metal systems, strictly adhering to technical welding methods, volumes of material consumption, instructions for the technical use of special equipment and safety precautions.

This is a professional who can use methods to prevent defects from appearing in the weld area and check their stages throughout the welding process. And this is the meaning of his work as a welder, which is very similar to the work of an engineer.

A well-made welded joint is not inferior in reliability and strength to the node metal. Many characteristics of a particular product depend on the quality work of a welding master: the reliability and strength of weapons, tools, oil and gas pipeline pipes and building metal structures.

5th grade welder salary

What is the salary of a 5th grade welder? It is impossible to answer this question unequivocally, because the wages of a welder depend on what production, what welding equipment and in what region a welding master of this category works or will work.

It is known that the highest salary is for a 5th category welder in the oil and gas and defense industries, and the lowest in housing and communal services enterprises and some private owners. Also, arc and plasma welders are better valued than gas welders. And of course, a lot depends on the region of work; each region and city has its own prices and needs for welders.

For example, in Moscow and the Moscow region, a welder of any category receives a salary of 10-15 thousand rubles more than, say, in Kazan or Yaroslavl, but, on the other hand, it is more difficult for a welder to get a job in the capital, because the competition and requirements are great. However, there are exceptions, for example, welders of the 5th category, according to statistics for 2014, in some regions of Russia received no less than their Moscow colleagues.

So, many parameters influence a welder’s salary.

On average in Russia, a 5th category welder receives a salary of 45-65 thousand rubles. Although this is not the limit. You cannot stop at the achieved result and you need to constantly strive further, because there are also higher categories, whose specialists not only receive even more, but the demand for them is much higher.

To do this, it is necessary to constantly practice mastery of welding equipment, neatness and thoroughness in the execution of welding work, and improve your professional skills. Then, after a year, you can try to take advanced training courses and, after successfully passing the exam, achieve the next level - 6 with more serious responsibilities and a larger workload.

Source: https://medcollege5.ru/professii/svarshchik-5-razryada.html

Various welding categories

Before we move on to describing the categories of welders, it makes sense to focus on the categories.

Welding has its own classification. Belonging to one group or another directly depends on what technology is used in the work:

- Press room

. The specialist's job is to use a pressing machine. The connection occurs due to a combination of extremely high temperature and high pressure on the elements. This category allows you to weld all types of metals. - Diffuse welding

. This category is characterized by the presence of piece orders. As a rule, with this type of work, specialists use only experimental materials. In order to connect the elements, honeycomb furnaces are used. To make the material as strong as possible, nitrogen is used in the welding process. - Electron beam

. Here, a vacuum chamber is used to join metals. The equipment can be configured for both piece production and batch production. Welding jewelry occurs in this way. Electron beam welding is also suitable for products with thin walls that cannot be heated too much. In order to end up with high-quality products, it is necessary to correctly configure the system, and this can only be done by an experienced welder.

- Termite

. A special welding press is used for the work. The parts are heated by burning the thermite mixture. An employee in this category must know how to correctly install a welding press, be able to prepare the surfaces of working elements for welding, understand how the thermite mixture is prepared and its required amount is calculated. - Gas welding

. This category is characterized by the assembly of the most complex models and pipes, regardless of their position. A gas welder can work with any metal and has the skills to work with a gas cutter. - Electric gas welding

. The broadest category of welders. Such a specialist is fluent in gas, arc, argon-arc and plasma welding techniques. Specialists bear great responsibility, since quite high demands are placed on their work.

Improvement of welder qualification to 5th grade. Welder's certificate

Any industrial production requires the connection of metal parts. Often parts are joined by fusion. Therefore, workers involved in this process are in great demand. But to become a real professional, you must first undergo high-quality training and then gain good work experience.

Where can I learn to be a welder? On the one hand, the question is simple, because... training for electric and gas welders is carried out in many educational institutions, but on the other hand, making the right choice is not so easy. You must take your choice very seriously, because how you master your specialty depends on your initial training.

general description

Workers in this specialty are graded based on knowledge and experience working with equipment. Improve the qualifications of a welder - receive a higher rank, respect, honor, increase in salary, and the ability to perform complex tasks.

Disadvantages of the profession:

- work in difficult conditions;

- high eye strain;

- industrial dust that causes asthma and silicosis.

A master of any qualification must have knowledge of:

- in the field of chemistry and physics;

- safety precautions;

- operating principle of the equipment;

- basics of electrical engineering.

Responsibilities include:

- work with proper preparation of the place and materials;

- produce quality products;

- comply with deadlines for completing assignments;

- comply with labor protection rules;

- increase productivity and efficiency of processes;

- place orders for necessary consumables for welding.

People cannot work in this position:

- too irritable;

- having heart disease and allergies;

- with visual and hearing defects;

- with mental disorders;

- with respiratory diseases;

- with impaired motor functions.

We recommend reading

How much a welder earns is of interest to everyone, but the choice of profession should be approached thoughtfully, assessing the state of health.

Qualification characteristics for the profession of electric and gas welder

On this page you will find qualification characteristics for the profession of electric and gas welder in accordance with the categories - what welders of different categories should know and what skills they should have.

First of all, you should know that persons at least 18 years of age who have undergone preliminary training and have the appropriate certificates are allowed to work independently in this profession. The electric gas welder should not have medical restrictions on fulfilling his obligations.

Electric and gas welder 2nd category

Perform manual oxygen cutting and cutting with liquid fuel (kerosene cutter and gas cutter) and gas equipment of light and heavy steel scrap metal.

Perform manual oxygen cutting according to markings in the lower and vertical spatial position of parts of simple and medium complexity from carbon steels.

Tack parts in all spatial positions.

Clean, prepare and assemble parts for welding.

Clean seams from slag, splashes and other contaminants after welding.

Perform surfacing of simple and non-critical parts.

Eliminate casting defects, cracks, cavities in simple parts, assemblies and castings.

Preheat the metal before straightening it.

Also, a 2nd category electric gas welder must be able to read simple drawings, prepare gas cylinders and equipment for work, and service portable gas generators.

Electric and gas welder 3rd category

An electric gas welder of the 3rd category performs manual arc, gas, automatic and semi-automatic welding of simple parts and structures from structural steels, non-ferrous metals and alloys. Welding of medium-complexity parts, parts, structures, assemblies and pipelines made of carbon steel in all spatial positions, except for the ceiling.

Performs oxygen separation cutting in all spatial positions of parts of simple and medium complexity according to manual markings.

Performs manual cutting with gas-cutting and gas-cutting equipment to specified sizes, separating waste non-ferrous metals and preserving or removing parts of machine components.

Must be able to perform manual gouging of simple and medium level of complexity parts made of steel, cast iron, non-ferrous metals and alloys in different spatial positions.

Must have skills in surfacing cracks, pits and other casting defects in moderately complex castings.

Performs preliminary and accompanying heating of parts during welding while maintaining the required thermal conditions.

Reads drawings of structures and assemblies of average complexity.

Performs rigging work when moving cargo using simple lifting equipment and mechanisms controlled from the floor.

Electric and gas welder of the 4th category

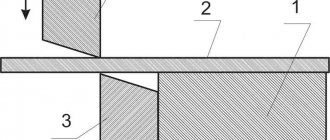

A 4th category welder performs welding of simple components, pipelines and structures made of steel, cast iron, non-ferrous metals and alloys, as well as complex parts made of carbon steel in all spatial positions.

Performs manual gas straight and shaped cutting, cutting with a gas cutter and gas cutting equipment in different positions of complex parts made of different metals and steels.

Performs semi-automatic and automatic welding of medium and complex structures and pipelines made of steel, cast iron, non-ferrous metals and alloys.

Performs automatic welding of complex building and technological structures that operate in difficult conditions.

Performs manual air arc gouging of parts and critical structures made of different steels and metals in all spatial positions.

Welds structures from cast iron.

Performs surfacing of complex machine parts, mechanisms and structures and castings for mechanical equipment and test pressure.

Performs hot straightening of parts of complex and critical structures.

Reads drawings of complex welding structures.

Performs rigging work using special lifting mechanisms and special devices.

Electric and gas welder of the 5th category

A welder with such qualifications must perform manual gas welding of complex and critical structures, apparatus, parts of units, pipelines made of different types of steels, cast iron, non-ferrous metals and alloys. Gas welding of structures designed to operate under dynamic and vibration loads, as well as under pressure.

Must be able to perform manual arc welding of critical building and technological structures that are designed to work in difficult conditions.

Perform oxygen straight, horizontal and figured cutting of especially complex parts from various steels, non-ferrous metals and alloys.

Source: https://osvarke.net/drugoe/kvalifikacionnye-harakteristiki-elektrogazosvarshhik/