Welding technologies are very important for modern metallurgy, especially when it is necessary to create high-strength and heavy metal structures. Moreover, the welding operation speeds up the work process, and also not much equipment is needed to carry out welding, so it can be considered very economical. It is for these reasons that the production of welded beams has recently increased several times.

§ 116. Beam structures

Beams are widely used in the structures of civil and industrial buildings, in bridges, overpasses, hydraulic engineering and other structures.

Beams with a solid wall section are made of sheet metal. Mostly I-beams are used, less often - box-shaped ones.

In single production conditions, beams are assembled according to markings and welded manually with coated electrodes or semi-automatic machines. In mass and serial production, assembly is carried out in jigs, and welding is carried out using automatic submerged arcs or for seams with a leg of 4 - 6 mm - in shielding gas.

Manual or semi-automatic arc welding is used in beams and when installing stiffeners. Inconveniences during this operation do not allow the use of automatic welding.

Extension of beams by butt joining of short sections is carried out by manual arc welding with coated electrodes. In mass production, automatic arc welding is also possible in this operation.

When installing beams, the butt welds are welded first, and then the fillet welds. The procedure for welding assembly joints of rolled beams is shown in Fig. 150, a

. First, butt welds are performed on thick metal, and then on thin metal. Typically, the flanges of I-beams are thicker than the web. Therefore, to ensure minimal stresses in the joint metal, the butt welds in the flanges should be laid first and, lastly, the butt weld in the wall.

During installation, welded beams are connected to the combined one (Fig. 150, b

) or with a displaced (Fig. 150,

c

) joint.

Rice.

150. The procedure for welding assembly joints of beams: a - rolled, b and c - welded; 1 - 4 - welding sequence The welding sequence in these cases is similar to the sequence of butt welding of rolled beams; first of all, the butt seam of the flange is made with increased thickness (if the I-beam has different thicknesses of the flanges), then the second butt seam of the second flange is applied, the wall joint is welded with the third seam (the thinnest in the I-beam) and the fourth is the corner waist seams (Fig. 150). Longitudinal welds usually do not extend to the ends of the beam by an amount equal to one flange width (mild steel) or two (alloy steel). In these cases, the deformation and stress of the metal in the butt joints of the flanges and the entire butt joint of the beam will be uniform and minimal. Fillet welds in the assembly joint are made last. In this case, it is desirable that fillet welds are applied simultaneously by two welders - from the ends to the middle of the seam.

Stiffeners can be welded both to the wall and to the flange of the beam in any sequence after preliminary tacking. Tacks are placed at the locations of the welds. The height of the tacks should be no more than 2/3 of the height of the seam, so that during subsequent welding they will be covered by the seam, and not less than 4 - 6 mm for tacked stiffeners with a thickness of 6 mm or more. The length of each tack should be equal to 4 - 5 times the thickness of the elements being tacked, but not less than 30 mm and not more than 100 mm, and the distance between the tacks should be 30 - 40 times the thickness of the metal being welded.

Calculation and production of welded I-beam

High-quality welding of I-beams for floors will require a lot of attention and responsibility from you. You will need to calculate all the upcoming loads on the structure in general and on the joints of the beams themselves.

The modern market offers a fairly large variety of sizes of finished I-beams with their own designations and types. The dimensions of the beam are determined by the number, which indicates the distance between the outer edges parallel to each other.

For example, the marking K denotes columns and beams that must withstand enormous loads. Keep in mind that there is also a certain type of beams that are not used for floors, but only for creating heavy equipment and machinery. Such beams have their own manufacturing standards and properties.

Wide-flange designs are suitable for lighter loads. And the strength of such beams will directly depend on the length, the formula of the transverse profile, the use of raw materials and manufacturing methods, i.e. metal rolling technologies. Here is a standard welded beam for private housing construction:

Here are the parameters of welded steel I-beams for the manufacture of such beams:

How to weld a beam yourself?

If you already have some experience working with this material and you want to make welded beams for building your house yourself, you will need an alloy steel sheet as a base. The hot-rolled method of manufacturing at home is quite complicated, so welding is really better for you. This is a responsible task, so if you have the opportunity, it is more rational to immediately invite an experienced welder.

After the individual elements are ready, assemble the structure using the selected welding method. First you will need to install a vertical wall and secure the stiffeners and press everything down with clamps. The finished beam must be protected with a special coating so that it does not corrode in an aggressive environment.

How to avoid deformation?

If you make mistakes during the manufacturing process, you may encounter such unpleasant deformations of the beam, which in the future will significantly complicate the installation process:

Let us explain in more detail. Your main task when making welded beams is to then join the parts so that the seam does not work in tension.

You also take into account this important fact that the welding itself puts some stress in the beam, and this is not always noticeable to the eye. Therefore, it is advisable not to immediately weld the next part to it. Just push the seam back slightly and the beam will be level.

Comparisons: in order to avoid any deformation of the beam, especially for arranging an interfloor floor, it is subjected to special processing in the factory:

If you undertake making such a beam yourself, the following steps will help you figure it out:

This is interesting: Electrodes for welding stainless steel: welding stainless steel correctly

Welding I-beams

Beam I-beams of standard sizes are produced in industrial quantities; small batches are made according to individual drawings. The welded beam consists of three elements: two walls and an intermediate belt. It is made from branded sheet metal and is used in high-strength metal structures. With little metal input, reliable structures are obtained that can withstand multidirectional loads due to stiffening ribs.

What it is

The most often used in construction is an I-beam - this is a metal connection consisting of a wall and an upper and lower shelf, roughly speaking, its profile is similar to the Russian letter “N”, that is, there is a wall and there are two shelves on both sides. This type of metal structure can be welded or rolled, it all depends on the manufacturing method.

A rolled beam is made on rolling mills from a single ingot. During the process of passing through the rolling strands, the metal changes shape and the output is a solid metal I-beam.

A welded beam is made by welding three elements - a belt and two walls - into a single metal structure. Welded beams are most often made of steel of various grades.

Application area

Prefabricated buildings and structures are created with supporting and load-bearing metal frames; floors and trusses are made from them. When using welded I-beams, the weight of buildings is reduced and they do not require a powerful foundation.

The welded I-beam is characterized by high strength, durability, and is not subject to fatigue failure. It is used in heavy engineering; it is used to make elements that experience high pressure and are subject to rupture.

Unlike I-beam wire rods, welded wire rods are not limited in size. By welding strips, beams of any section and length are obtained. Architects are not limited in their flights of fancy.

The manufacturing process for I-sections produces little waste. They can be made with shelves and walls made of different grades of steel: in places of minimal stress, carbon steel or perforated steel sheets are used, loaded parts are made of alloy rolled steel.

Types of metal welded beams

Continuous production of I-beams for various purposes has been established. According to the standard, there are several types of I-beams:

- with a short shelf length in relation to the partition, they are used for overhead tracks, floors, and strengthening of mine workings;

- with the proportional size of the partition and shelves, they are used in the construction of support frames and reinforcement of decorative columns.

According to manufacturing accuracy, there are two types of I-beam profiles: regular and high-precision.

Production technology of welded I-beams

Small batches are made using electric arc or argon welding, depending on the grade of metal and its ability to be welded.

To produce welded beams industrially, special welding lines are used. Fluxes are used to protect the melt pool from oxidation.

Welding a beam in automatic mode is similar to manually making an I-beam. Main technological stages:

- cutting rolled sheets into strips of the required width using a thermal cutting machine with program control, average cutting speed 1 m/min.

- end milling on end milling machines reduces the joint gap between the wall and the shelf and improves the quality of welding;

- the process of assembling an I-beam is carried out at high speed on a special machine; metal strips are fixed by clamping devices with hydraulic amplifiers; first a T-shaped joint is made, then the second wall is added; this design is convenient to weld;

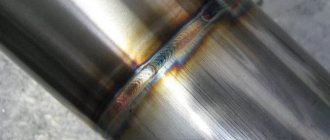

- welding work is carried out using portal-type machines of two types: a) two seams are shallowly welded at once using inclined electrodes; b) the boat seam is created in stages: first on one side of the I-beam, then on the other; the metal is boiled to a great depth;

- the final stage is straightening the I-beam on special rollers; minor distortions that arose during assembly and welding of the profile are eliminated.

Beam and lattice structures

WELDED STRUCTURES MANUFACTURING TECHNOLOGY

Frames are a three-dimensional spatial structure designed to combine individual parts and mechanisms into a single unit. One of the main requirements for frames is structural rigidity. Therefore, enter

IJ

The beam blanks that make up the welded frame are connected to each other either directly or with the help of auxiliary stiffeners. The sizes of frames and their design are very diverse, and the methods for obtaining beam blanks are also different. Thus, stand frames of powerful rolling mills are assembled and welded from beam blanks in the form of massive steel castings (Fig. 12.5). In the frames of railway rolling stock bogies, the most complex elements are often made in the form of steel castings with relatively thin walls. An example of this is the frame of the electric locomotive V L-80 (Fig. 12.6), consisting of sidewalls I,

that pivot beam 2 and two end beams 3, where the sidewalls and end beams are welded box-section beams. Larger frames are usually assembled from profile and sheet elements, reinforced in many places with stiffeners.

What is common to lattice structures is the presence of several separate rods of one or another section at the joints.

| -WITH. - ……………. »———— |

| t |

| / 2 Fig. 12.6. Frame of a two-axle electric locomotive bogie |

Trusses, like beams, work in transverse bending. The structural forms of beams are simpler, but for sufficiently large spans the use of trusses turns out to be more economical. Typical truss lattice designs are shown in Fig. 12.7. Triangular (a) and diagonal (b) patterns are the main ones. Trusses that take loads along the upper or lower chord, in order to reduce the length of the panel, are manufactured according to the diagrams shown in Fig. 12.7, c, d. Sometimes braceless trusses with rigid nodes are used (Fig. 12.7, d). According to the outline of the belts, trusses can have parallel belts or belts formed by a broken line (Fig. 12.7, e). According to their purpose, trusses are divided into trusses and bridges.

Rafter trusses operate under static load. The rods used are mainly rolled ones and much less often bent closed welded profiles and pipes.

In the total production volume, trusses made from paired rolled angles account for about 90%. The rods in the nodes are connected either directly or with the help of auxiliary elements, mainly by arc welding. The use of spot resistance welding is promising. Due to the static nature of the loading of trusses, the sensitivity to stress concentration in point connections is low; at the same time, resistance welding provides a significant increase in the productivity of assembly and welding work.

| Rice. 12.7. Truss lattice diagrams |

Bridge trusses operate under variable loads and often at low climatic temperatures, which determines the high sensitivity of their welded joints to stress concentrations. Therefore, in the process of designing and manufacturing welded bridge spans, special attention is paid to preventing and eliminating stress concentration in welded joints and assemblies.

Lattice superstructures with running underneath are used mainly for railway bridges. For road bridges, it is more typical to use steel and steel-reinforced concrete solid-wall span structures with a ride on top.

Spatial lattice tower-type structures (radio masts, radio towers, drilling rigs, etc.) due to their high height are subject to significant wind loads, so they are made mainly from tubular elements. Since the dimensions of these structures exceed the dimensions of railway rolling stock, they are assembled from sections welded at the factory. The main pillars of the tower are located at the corners of the sections' faces and are the belts of flat trusses. The racks are made up of separate pipes of standard length and are connected to each other with bolts through flanges welded to their ends.

Drilling rigs operate in particularly difficult conditions for oil and gas production in the open sea at depths of about 150-200 m. In addition to wind, they experience significant loads from wave impacts. Therefore, in these designs they use

A)

Rice. 12.8. Types of welded mesh

large diameter pipes. Thus, the supports of drilling rigs for oil production in the North Sea at depths of more than 150 m are constructed from pipes with a diameter of up to 4270 mm and a wall thickness of up to 64 mm.

| Rice. 12.9. Reinforcement of beams with flat* welded frames |

Power transmission line masts are also spatial lattice structures, but for their manufacture they use rolled steel in the form of angles.

Lattice structures also include welded elements of reinforced concrete reinforcement: meshes, flat and spatial frames. Meshes of mutually perpendicular rods of round or periodic profile, connected by contact welding, can be rolled (Fig.

12.8,a) and flat (Fig. 12.8,6).

Their purpose is to reinforce floor slabs, partitions, road surfaces, airfields, canals and other structural elements and structures.

The types of welded frames are varied. Flat frames are used in beam floors (Fig. 12.9); they consist of longitudinal reinforcement (belts) and a connecting lattice in the form of individual rods or a continuous snake. Flat frames, like meshes, are welded on point contact

| Rice. 12.10. Oversized containers: a - vertical cylindrical tank; b - wet gas tank; c - dry gas tank; g - spherical tank; |

cars. Space frames usually have belt longitudinal rods and a connecting lattice, either in the form of separate rods located along each of the faces, or in the form of a continuous wire wound in a spiral.

The face of every home or office building is the door. It should not only look good aesthetically, but also perform a protective function, preventing intruders from entering premises or living rooms.

The main elements of CAD are a team of designers, as well as technical, software and information systems. Communication between designers and computers, programs and information is carried out through means of input, output, accumulation and transmission of alphanumeric and...

Computer-aided design of metal structures refers to the automated and automated execution, using a computer and other technical means, of the basic procedures for the step-by-step design of a product. Computer-based design allows you to automate a number of...

msd.com.ua

Possible defects

During welding of an I-beam, due to non-compliance with the technology, crystallization of the steel occurs due to high temperature. Due to phase discrepancies, internal stresses arise in the metal. Strength and rigidity decrease, and the risk of corrosion increases.

When welding steel sheets, other defects are possible:

- violation of the shape of the seam; deviation from the shape of the outer surfaces or the geometry of the joint;

- burns, when the melt flows out of the bath, holes form in the seam;

- undercuts – grooves along the joint boundary;

- cracks forming in places where the seam breaks;

- slag or tungsten inclusions in the diffusion layer; at high welding speeds, refractory oxides are formed.

Metal products with defects are unreliable; they will not withstand heavy bending or torsion loads. They are discarded and boiled again if possible.

Welding I-beams together

Installation of beam metal structures involves connecting I-beams end-to-end or at an angle. To strengthen the connections, metal plates are used - rectangles cut from sheet metal.

Butt welding of beams is carried out after processing the ends. Angular bevels are made on them so that the seam is well welded. Additionally, pads must be attached to each side of the walls and both shelves; they are welded to strengthen and protect the connecting seam. With this connection, the supporting structure of I-beams does not decrease after welding.

The I-beams are connected at an angle so that the secondary one rests on the main one. An isosceles triangle with an apex of 90° is cut out in the top shelf of the main one. Its place will be taken by a similar insert of a secondary I-beam; the sections should fit tightly to each other. The bottom flange is cut ½ of the width so that the cut rests against the flange of the main I-beam. Welding is flush. The connection is strengthened by the bottom pad.

The secondary channel is welded to the supporting I-beam at an angle of 90°. First, the upper flange of the channel is joined to the beam flange, cutting them at an angle of 45°. The lower flanges are connected so that the channel rests against the wall of the I-beam, and the excess is cut off. Then the lower reinforcing pad is welded on.

It is easier to weld in a horizontal position. The longitudinal axis is bent minimally. During vertical welding, deflection of the cross members is possible, so all stiffeners are marked.

The pads for welding I-beams are cut out in the shape of a rhombus and placed symmetrically to the longitudinal axis. They are scalded with oblique seams along the entire perimeter. The overlays concentrate stress at the seams, compensating for the section shape that has changed after welding.

I-beams are designed for heavy loads. When working with them, you must adhere to the developed technology. It takes into account the distribution of forces along the guides. High-quality connections are the key to long-term operation of metal structures.

Welding an I-beam at the enterprise. Let's reveal the secret of production

Welding an I-beam at the enterprise. Let's reveal the secret of production

We reveal the secrets of the manufacturing process of welded I-beams. Manual, semi-automatic and automatic welding of I-beams.

I-beam welding is a technology that has replaced old-fashioned rivets and pins in the manufacture of I-beams.

Even 20 - 30 years ago, the construction industry used beams held together by rivets, bolts and pins. This fastening technology had many disadvantages. Starting with a significant complication of the construction and installation process and an increase in the number of components, which in turn led to a significant increase in the cost of construction. And ending with a serious increase in the weight of the beam structure, which increased the load on the load-bearing elements of the building and, as a result, reduced the freedom of action of designers when creating multi-story structures. However, modern construction technologies and designs are constantly developing and improving. The result of this development was the emergence of welded metal structures.

Beam production

An article about the production of beams, equipment and manufacturing technology. Briefly and in detail about the most important thing in this business

Beam - is a special structural element, which is an inclined or horizontal beam, which mainly works in bending.

Most often, as a rule, it is the horizontally located beam that perceives a separately located vertical transverse weight load. But in some cases it is also necessary to take into account the influence of probable horizontal lateral forces, for example, wind load or a possible earthquake. A very overloaded beam, in turn, directly affects these supports, which can be objects such as columns, suspensions, walls or other beams, crossbars. Afterwards, the load is transmitted further along the overload line, and as a result, in most all cases, it is perceived by all these structural elements. Separately, we can also highlight the case of a specific truss structure, in which all existing rods rest directly on a horizontal beam.

Equipment for the production of beams

A specific production process always requires the same specific or individual equipment. A special line is used for the production of welded beams.

There are only two options for such equipment. This is equipment such as:

- Automatic mill for the production of welded I-beams. This device makes it possible to carry out all beam manufacturing processes on one complete machine.

- Line for the production of welded I-beams. The composition and components of this line of equipment may directly include: a machine for assembling I-beams;

- installation for beam welding;

- machine for straightening I-beam flanges;

- thermal cutting machine for cutting sheets.

This equipment can always not only cover the entire technological process of producing steel I-beams, but also significantly reduce the cost of resources for the production of beams. Such equipment can be purchased in parts, as individual devices, or as a whole continuous line.

Beam production technology

There are several characteristics and principles on which the strength of a beam depends and is determined:

- cross-sectional area and shape;

- length;

- material of manufacture;

- the way it was attached.

There are several main materials for the production of beams, and most often these are: steel, reinforced concrete, wooden beams. In construction, it is mainly the steel I-beam that is used, since it is considered the most durable and the strongest, withstanding very heavy loads.

I-beams are most used in the construction and construction of various frames of buildings and bridges. Also, such steel beams use T-beams, channels, or beams with a hollow profile, and possibly beams with an angular section profile.

Each production process has its own principles and standards, which are often established by laws or regulations of the state government, since most production, whether industrial or non-industrial, is associated either with people who work in production, or with people who consume or exploit the resulting product .

Such standards did not bypass the process, or rather the technology of beam production. This technology also has its own specific steps, stages and processes. The beam production process has only five main stages:

- Cut sheet metal into strips. A strip of the required length and width is manufactured on a CNC thermal cutting installation specific to this production, which also allows the sheet to be cut into pieces simultaneously using several cutters. The speed of the cutting process, depending on the thickness and density of the metal, reaches one meter per minute, which is quite fast nowadays.

- Edge milling. This process is aimed at improving the penetration of the seam between the shelf itself and, of course, the wall. To do this, milling adjustment and processing of all edges is carried out on a special edge milling machine.

- Beam assembly. The assembly process must be correct. The entire assembly of the I-beam must be quite clear and precise, and most importantly, special attention is paid to the symmetry of the territorial location and the mutual perpendicularity of the flange and the I-beam wall.

- Beam welding. The entire process is regulated by automated production lines. But at the same time, the sequence in which seams are taken and applied may be different depending on the welding process itself. Welding, which is performed with an inclined electrode, allows not only to simultaneously weld two seams, but also to perform a “boat” seam, which provides only the best conditions for the formation of the entire perimeter of the seam and the depth of wall penetration, and at the same time, the product has to be completely rotated after welding each seam directly.

- Editing the flanges of an I-beam. During the production process of a welded I-beam, a violation of its “geometry” of flanges and walls always inevitably occurs.

Visual video of the process:

As you can see, the process itself is quite simple.

The main advantages of using welded I-beam structures

A design such as an I-beam has a number of advantages that distinguish it from other metal structures used in construction:

- Welded I-beam metal structures are able to withstand enormous static and dynamic loads without losing their performance characteristics. Due to these characteristics, in most cases, reinforcement of the I-beam is not required.

- Ease of transportation and relative ease of installation make I-beam elements indispensable in the construction of prefabricated structures.

- Such beams are extremely popular and are widely used for the construction of buildings and structures for a wide variety of purposes, so their prices are quite affordable. To purchase such metal structures, just go to the website of the nearest manufacturer and go to the section - selling I-beams. Most companies offer a wide range of I-beam metal structures available in stock, and also manufacture them to order. Also, by calling the marketing department, it is easy to find out how much a beam of the brand you are interested in costs, depending on the tonnage.

Possibilities

In addition to the advantages, the use of welded steel beams will allow each buyer to:

- Increase the width of the building span, as they are longer;

- Order different parameters and sizes, there are a huge number of GOST standards for I-beams, so that every customer can find suitable parameters;

- The architecture of the structure, as mentioned above, can be completely diverse.

Thus, the welded beam has a huge number of advantages, which is why it is widely used in all areas of construction. The use of welded beams has helped people improve the quality of structures of buildings and various structures, increase their safety, and therefore safety for people.

Manufacturing of I-beam metal structures

The process of manufacturing metal beams with an H-shaped (or I-beam) section is quite complicated. To obtain a high-quality design, it is necessary to use proven high-quality raw materials, modern high-tech production mechanisms, as well as the presence of highly qualified personnel. At the same time, high-quality incoming control, comprehensive control of all stages of manufacturing and processing of elements, as well as control of products at the output are required. Only this approach to production can guarantee the highest quality and performance characteristics of the finished product.

Welding work in the manufacture of I-beam metal structures

Welding of I-beams at large metalworking enterprises takes place on a modern automated line. The beam enters a special conductor, inside of which the waist seams of the future metal structure are welded under a layer of flux, in a fully automatic mode.

This welding of I-beams ensures maximum quality of seam connections due to the use of a protective layer of flux. During welding work, a layer of flux protects the weld, which allows minimizing the splashing of hot drops of metal, without compromising the welding speed and quality of the connection. Also, thanks to the flux layer, the cooling of the welded joint occurs much more smoothly and evenly. With this method of welding, reinforcement of the I-beam is not required, due to the maximum strength and reliability of the manufactured structure.

- Low speed of welding work.

- Quite mediocre quality of welds, in comparison with automatic submerged arc welding.

- Insufficient geometric accuracy of the finished product due to manual assembly, overheating and, as a consequence, large deformations, in contrast to the automated welding process.

- Serious losses (up to 30 percent) of metal due to strong splashing of hot metal drops during welding.

Bottom line

As can be seen from the above, welded I-beam metal structures have a number of advantages in comparison with other types of beams. Welded I-beams have found their niche in the modern construction market and are used according to their strengths and weaknesses. The production of such metal structures has been launched in most regions of our country, which makes the I-beam an accessible and relatively inexpensive building material. Therefore, due to the high competition in this niche, any seller, when asked “I will sell an I-beam,” will provide good discounts and advantageous offers.

Manufacturing process

The technology for manufacturing welded I-beams is not too complicated, but its requirements must be strictly observed at each stage of processing. Errors inevitably lead to a decrease in the rigidity of the structure. Usually they are produced according to GOST requirements. It is also possible to produce them according to the technical conditions of the enterprise . Specifications for the production of steel welded I-beams provide for dividing the process into the following stages:

- Design and calculation . At this stage, the loads that the structure must withstand should be calculated. Using the formulas of applied mechanics (strength materials so beloved by students), the strength and rigidity of the structure is calculated, its geometric dimensions and material requirements are determined. Working drawings are being built.

- Cut out the blanks . They are cut from sheet metal using a gas, plasma or laser cutting machine. Metal samples are necessarily taken and sent to the laboratory to confirm the chemical composition and physical and mechanical properties.

- Milling of blanks . The longitudinal ends are chamfered and the edges of the welds are cut.

- Assembly operations . The parts are placed in special equipment that precisely fixes the workpieces in the correct position relative to each other and eliminates thermal deformation of the product. Products with a unique design and small series are welded manually; in mass production, automatic welding machines are used. Typically, assembly is carried out in two stages: in the first, the T-shaped profile is assembled, in the second, the second strip is welded to it. The method of guiding the electrode is chosen depending on the thickness of the sheet to ensure complete penetration and high-quality seam geometry. Particularly thick products must be welded in several passes.

- Editing operations . After completing all the seams, it is necessary to check and correct, if necessary, all deviations of the resulting product from the specified geometric shapes. For this purpose, hot or cold straightening mills with massive rolls are used, which correct all deformations that arise during beam welding.

Shot blasting can be added to the technology as an additional finishing touch. It knocks down scale and slag and compacts the surface layer of the metal, increasing the strength of the product.

How to cook it yourself?

Taking on this difficult operation for a home workshop makes sense for those craftsmen who already have sufficient experience in welding. Or there is an opportunity to hire an experienced welder. As blanks you will need a steel sheet made of high-alloy durable alloys . It is better if the cutting is carried out at a metal warehouse using a stationary installation. When cutting with a gas cutter, the loss of expensive metal will be noticeable.

You will also need equipment for welding I-beams under submerged arc or in an atmosphere of shielding gases.

After assembly and straightening, the product will need to be completely cleaned and painted to protect against corrosion..

How to avoid deformation?

If you simply weld the seams of a beam, then thermal deformations are almost inevitable. The product will move, bend or tighten with a screw. To minimize the risk of distortion, the following description of the technology should be observed:

- assembly is carried out on a special slipway inclined at an angle of 45°, this allows you to form an even seam with the correct leg;

- weld two strips into a T-shaped tee;

- first, the workpieces are grabbed by spot welding every 10-15 cm;

- Next, the seam is welded on both sides with obligatory edging, so that the hypotenuse of the seam is horizontal;

- straightening is carried out using manual or mechanized rollers;

- repeat the operations for the third strip.

The method of welding the seams starting from the ends towards each other is also used.

Advantages of welded I-beams

Nowadays, it is very difficult to find a construction project that was erected without the use of welded I-beams. Beams with this cross-section are widely used because they can significantly reduce the costs of constructing structures for various purposes, while ensuring high reliability of the structures being built.

A welded beam, the cross-section of which has the shape of an I-beam, is capable of withstanding significant static and dynamic loads without losing its performance characteristics. An important factor is that the use of such welded beams makes it possible to reduce the weight of building structures, which ultimately reduces the load on the foundation of the building and on its supporting structures.

The use of I-beams in the manufacture of a building frame

A welded I-beam is especially indispensable in those elements of building structures where strength and the ability to successfully withstand mechanical loads of various directions are especially important. Such elements, in particular, include frames for various structures, columns, interfloor ceilings, overpasses, work platforms, etc.

Welded beams are in great demand in various branches of mechanical engineering and in the construction of prefabricated structures, since the technology for its production is very economical.

Despite the fact that it is quite simple to organize the production of welded I-beams, it is more economically profitable to produce them using automated equipment. Automated lines on which the production of such welded beams is put on stream allow not only to significantly reduce the cost of production, but also to strictly adhere to the technology of its production.

Floors on metal I-beams

What does it represent?

According to the production method, I-beams are divided into welded and hot-rolled.

The welded I-beam is assembled from three strips of durable high-carbon steel using electric arc welding.

The advantages of this design over hot-rolled ones are:

- the ability to carry high loads, this makes the element suitable for covering large spans;

- a special profile increases rigidity and resistance to bending, since the upper strip works in compression, and the lower one in tension;

- ability to work in difficult conditions, with changes in temperature and humidity, in aggressive environments;

- after strength calculations, reduce the linear weight of rolled products and the total weight of structures;

- possibility of manufacturing beams with asymmetrical and variable cross-section length.

I-beams are perfect for the construction of prefabricated structures . They are widely used in commercial and industrial, as well as in public and private construction.

Despite the high weight of steel beams, their increased load-bearing capacity can significantly reduce the overall weight of the building.

This is interesting: Rhombic corrugated sheet: characteristics, production, GOST

How to weld I-beams

The design of the assembly equipment used to manufacture welded beams having an I-section is determined by the welding method used to form the waist seams. The choice of such equipment also depends on what devices are planned to be used in the production process. At modern enterprises, automatic submerged arc welding is most often used to form long belt seams of I-beams. This method allows us to obtain welds of high quality and reliability along their entire length.

Beam welding as a stage of its manufacture

The use of automated equipment for welding under a layer of liquid flux to produce I-beams allows not only to reduce the cost of the finished product, but also to ensure its high quality and reliability. The operating principle of such equipment provides that the unmelted flux protecting the welding zone is under pressure. Thanks to this, the splashing of liquid metal from the welding zone is minimized, which allows this operation to be performed efficiently even at high current values (up to 4 thousand Amperes). In addition, the flux protects the molten metal from rapid cooling, which facilitates more efficient removal of gas from it.

Meanwhile, the welded beam can be produced using manual arc and semi-automatic welding. In such cases, special conductors with clamping elements, or ordinary tacks and clamps are used to assemble them. However, it should be borne in mind that in this case you will have to deal with large losses of molten metal, which will occur due to its splashing and waste. Such losses can reach up to 30%.

Features and Benefits

A welded I-beam is made from sheet steel, which is cut into individual plates. To fasten the plates, the following operations are performed: edge cleaning, milling and metal welding. The main advantage of welded beams is their low metal consumption and simplicity. No equipment is needed to produce an individual spare part, and the cost of sheet steel will be minimal. The welded beam has high strength and reliability, does not deform under high loads, and withstands the effects of chemical reagents and high temperatures.

The main area of application of I-beams is the construction of various objects - houses, warehouses, factory premises, frame structures. I-beams are suitable for creating long spans, overpasses, bridges, floors, platforms, and crane structures. Depending on the type of structure, there are several types of I-beams - normal, wide-flange, column, sloped, reinforced. The use of welded beams in construction has many advantages:

- Reduction in the total weight of the structure by 10-20%. This is achieved due to the fact that welded I-beams are produced in different sections. This allows you to select a part to create any design.

- Universal composition. The metal welding method allows you to connect almost any type of steel, so an I-beam can be made even from dissimilar materials. This simplifies the selection of steel and reduces the cost of producing spare parts.

- Possibility of creating asymmetrical walls. Welding can be used to connect any metal surface. Therefore, it can be used to connect even metal walls that are asymmetrically located relative to each other.

- Minimum scraps and debris. A welded I-beam is made from flat blanks, which are created by cutting metal sheets. During welding, a minimum of debris is generated. Therefore, this production technology is economical, and cuttings are generated to a minimum during operation.