Today, the population prefers life in the city, and suburban areas, as a rule, are purchased for recreation. Often, on the territory of such country houses, people build bathhouses or install stove heating in the house. This is where the issue of firewood procurement becomes relevant. In the modern world, this is not a very popular activity.

A huge number of different devices have been created that help chop firewood, both with and without human participation. Lighting a fireplace or sauna may still require manual labor, and you will have to chop the wood yourself using a wood splitter. How to choose the right cleaver for firewood, what to look for when purchasing? What is the difference between an ax and a cleaver and how to choose the right and correct tool suitable for a particular person? Today we will look for answers to these questions.

Many people mistakenly believe that an ax is the same as a cleaver. In fact, these are different things. More precisely, a firewood cleaver is a type of axe. Its main difference is that trees are cut down with an ax, and firewood is chopped with a cleaver . Thanks to it, even a huge tree trunk turns into small logs, which are very convenient to use.

In addition to functionality, it differs from an ax in appearance. The ax has a thin, very sharp blade with slight curves. The cleaver is a rather voluminous structure, the weight of which can be three kilograms, and the ax handle is quite long.

When talking about a cleaver or an axe, there is no need to explain the method of their use, since it is clear to everyone. When cutting down a tree, you need to repeatedly hit the trunk with an ax, while holding the tool at arm's length. Working with a cleaver is a little different: the log should split into pieces with one blow. It is not difficult to understand that the sharpness of its blade is important for an ax, and the striking force for a cleaver .

Structure and types of tools

There is nothing to say about the design of this tool - it consists of an ax and a “head”. Everything is very simple and clear.

As a rule, the ax handle is made of flexible and soft wood, which includes:

Some craftsmen make axes from oak, but such an ax or cleaver can only be used by an experienced woodcutter. Oak is a fairly hard wood and this is a significant disadvantage for an instrument. The handle will break very quickly due to the fact that there will be no vibration damping upon impact, and it will simply crack. This, unfortunately, happens quite often.

Externally, the tool is very similar to a sledgehammer with a sharpened side (blade), the other side is called the butt. The weight of such a “head” can be from three to five kilograms. The blade must be sharpened at an angle of 45 degrees, this is what causes the log to split into pieces.

The ax has many varieties:

- universal;

- blacksmith;

- for the lumberjack;

- carpentry;

- butcher;

- firefighter.

Cleavers are divided into only two types:

The first type is very similar to a sledgehammer, and the second is the same in weight, but the blade is sharper.

There is another classification of cleavers, according to which the tool can be:

There is no significant difference when using the tool; these factors do not have much influence on the quality of the result. The structure of the cleaver is much more important.

There are no universal recommendations for choosing a cleaver for chopping wood. You should choose a tool based on some individual factors:

- weight;

- ax material;

- length of the ax;

- blade shape.

The weight of the tool is the most ambiguous characteristic. On the one hand, a heavier cleaver will be easier to chop wood; when working with a lighter one, you will need to hit the wood several times.

It should be borne in mind that collecting firewood is not an easy and long process. Not every man can swing a cleaver for several hours in a row. That is why a tool for chopping wood must correspond to the physical capabilities of the particular person who will work with it.

Unfortunately, you may not find your ideal tool right away. If you are buying a tool for yourself, then you should not take the first one you come across. You need to hold the model in your hands, swing it and feel its work.

For a person with average physical fitness, the optimal weight of the instrument will be 2-2.5 kilograms. For larger and stronger people, a heavier cleaver is quite suitable. It is very convenient to work with a light tool; it splits small logs without any problems, but it may not be able to cope with larger logs.

Blade shape

A suitable cleaver can be selected according to the shape of the blade. They come in two versions:

The eared species appeared on the market relatively recently and reviews about it are contradictory. Experienced woodcutters say that it often does not split logs and gets stuck very firmly in them.

This suggests the conclusion that the wedge-shaped species has no competition, but in fact this is not the case. The instructions for the “eared” blade contain a disclaimer stating that only dry firewood can be split with this tool . It's no secret that very often people chop raw or freshly cut firewood, for which the wedge-shaped type is best suited. The main thing is to use the tool correctly and then everything will definitely work out!

Until recently, cleavers only had wooden handles. The handles of axes and cleavers have always been made of wood to dampen the vibrations of the blows. It is impossible not to say about the cost of such axes, since their low cost is a fundamental factor in purchases for many people.

There is only one drawback to such handles, and that is that they can crack if used improperly. The point is not in the strength of the handle, and not in its quality, but in the striking technique.

More recently, handles made from a composite material called fiberglass began to be produced. Despite the fact that it is very light, fiberglass is superior to wood in many ways, especially in its strength. Vibration damping from impact in this material is also at the proper level. This handle makes the tool very comfortable , dense and durable. A handle made of composite material can be of any length, and therefore this option is preferable to a model with a wooden ax.

The length of the handle directly affects the force of the blow - the longer the lever, the greater the force. To fully unlock the potential of such a cleaver, you need to use it correctly. In other words, using a long handle will only be effective in the hands of an experienced person. Beginner users will find it difficult to work with such a tool.

Choosing a cleaver

- First of all, you need to take into account the weight of the tool, since it must correspond to the physical development of the person who will use it.

- Before purchasing a tool, you need to consider what type of firewood will be split: dry or wet. In accordance with this, you need to buy either the “eared” or wedge-shaped type.

- The length of the ax and the material from which it is made are very important. Here user experience is a fundamental factor. You should also consider your financial capabilities. The wooden handle is not very practical, but its cost is very affordable. A handle made of composite material is much more practical, but much more expensive.

How to properly sharpen a carpenter's ax

There are two types of methods for sharpening an ax - manual and mechanized. Each of them, with a competent approach, is able to bring the instrument to perfection.

Bulgarian

The sparks emitted by the grinder are dangerous if the ax is sharpened by a person who is not protected by special clothing and glasses. This method, although fast, is not effective, since heating the metal worsens the performance characteristics of the ax.

On sandpaper

You can sharpen an ax on emery only after making sure that the grinding wheel is free of defects. Next, mark the corner to be cut with a marker. After this, fix the tool and turn the grinding wheel. Sharpening is completed when the surface marked with a marker on the blade is completely erased.

On the grinding machine

Ideal chamfer parameters and a neat edge can only be achieved on a sharpening machine. Doing this is easier than doing it manually. However, the continuity of this process leads to overheating of the metal part. High temperatures destroy structural bonds in metal molecules and lead to deterioration in strength characteristics.

File

To manually sharpen an ax with a file, you need to secure it in a vice and place the file at the desired angle to the top of the tooth. This operation must be done on both sides.

Terms of use

Even with the best model of a cleaver, an inexperienced person will not be able to work effectively. When chopping wood for the first time using a cleaver, we recommend using some tips that will make your work much easier.

First, you need to choose the widest deck and place it evenly on the ground. Chocks will be installed on it, like on a block. In addition to organizing the workplace, you need to pay attention to the logs themselves, since wet logs will split much harder , while dry ones will split in no time.

The split firewood must match the size of the firebox in which it will be used. Their length should be no more than three quarters of the oven space, and their diameter should not be more than 10 centimeters. Such firewood will burn for a long time and save fuel.

The number of parts from one chock completely depends on the size of the chock itself. From small logs you get 2-4 pieces, from large ones - about eight. When working with large logs, do not try to split them in half in one motion. It will be much easier to trim them around the edges and cut the rest in half. At first, this process seems very simple, although it is quite possible to improve this matter and spend less energy.

Before harvesting, be sure to dry the firewood or at least dry it a little. In winter, the logs should be allowed to freeze , then the wood will not be loose and will easily split. If there is a crack on the chock, then you need to try to get into it. If this fails, then you need to insert a blade into it and hit the butt with a sledgehammer. If you don’t have a sledgehammer, then you need to take a deck with a cleaver, swing it hard, turn it over in the air, and hit the block with the butt. These are radical measures in which the lump will definitely split.

If there are knots in the deck, then you need to hit between them. If there is a problem similar to the situation with a crack, then you need to do the same. Chopping wood with your own hands is not that difficult. The main thing is not to rush and quit at the first failure. You need to try again - and with experience this activity will bring pleasure.

Necessary equipment

To sharpen the angle of the blade at the desired angle, you need to have on hand:

- A sharpener for sharpening an axe. This could be a set of grinding stones with different grain fractions or a hand sharpener.

- Goniometer or protractor. You can use a block with a beveled angle equal to the required degree of sharpening of the blade.

- A coarse fiber cloth and a set of brushes with varying bristles.

It is worth taking care of personal protective clothing and glasses. And also prepare the workplace and set up the plumbing equipment.

The process of sharpening an ax

The working surface must be cleaned, removing dirt and rust. After this, measure the existing sharpening angle to avoid making an error when calculating the required new parameter.

To sharpen an ax, place it on a straight surface or secure it with a vice. Using tools for grinding with a coarse grain fraction, the required values for the inclination and chamfer width are obtained on both sides of the working blades.

The treatment is repeated, reducing the coarseness of the grain of the grinding devices. The finishing device is used to bring the blade to absolute smoothness.

Proper sharpening of the blade and correctly set chamfer width will allow you to perform even the roughest processing of timber with minimal expenditure of physical energy.

Precautionary measures

When preparing firewood, it is imperative to observe safety measures, regardless of how this work will be carried out: with a cleaver or an electric or mechanical wood splitter.

You must always be on guard, as during the work, chips fly in different directions, the trajectory of which is unpredictable. Therefore, the area for chopping wood must be suitable, that is, at a distance from people and animals.

A cleaver (like an ax) is a dangerous tool, and one wrong move can result in injury. The correctly selected tool and the rules for its use significantly affect human safety.

Particular attention should be paid to the deck on which the firewood will be split, as well as to the lump that will split. It should not be larger in diameter than the block, and its height should be slightly above the knee. If you install the block incorrectly, it will be quite problematic to deliver the right and strong blow that will split it.

Before starting work, you need to think about your protection and wear goggles and gloves. Safety glasses will help prevent splinters and wood dust from getting into your eyes, and gloves will give you a better grip on the handle. If you follow all safety rules, this activity will become easy and even fun. Firewood will split easily and correctly.

Ax chamfer width

The width of the chamfer corresponds to the distance from the axis of the blade to its side surface. This parameter determines both the sharpness of the tool and the service time until the next sharpening. Sharpening an ax with the correct bevel is quite quick and easy.

Correcting the dimensions of the chamfers is a more complex operation and will require a lot of time and effort. To change the width of the chamfers, it is necessary to remove excess metal.

Historically, axes damaged by long work or corrosion, which had lost part of the metal in the chamfer area, were restored by a blacksmith using the method of partial reforging. The weight and dimensions became smaller, but the geometric parameters and functionality of the instrument were restored; it was enough to sharpen it again.

Double beveled ax

Axes made from low quality metal wear out quickly and lose their bevel shape. In this case, you should sharpen the tool asymmetrically: - one chamfer is made at 15°, and the other at 25°.

How to choose a cleaver

The log should be installed on the far side of the block, then the cleaver, if hit incorrectly, will stick into the block itself, and not into the knee of the person chopping wood.

In general, to successfully harvest firewood you need not only to purchase a high-quality cleaver, but also try to follow all safety rules when working with this tool. Choosing the right tool is not at all difficult if you know some aspects that you should pay attention to. It is also recommended to purchase protective equipment along with the tool: first of all, you should protect your eyes, as you can unexpectedly get injured. The chips fly so hard and far that you simply don’t have time to react.

All comes with experience. You just have to try, and after a while you can become a real professional in chopping wood. Moreover, if there is a high-quality, correctly selected tool.

Source: tokar.guru

What weight should Cleaver have?

The average weight of a cleaver should be 2-2.5 kg - this is ideal. Then it has enough strength to split wood, but also moderate weight so that you can handle it. However, when purchasing a cleaver, it is best for you to hold the tool in your hands. You must understand that it is not too heavy for you.

Interesting materials:

Why toothpaste without fluoride? Why did Pechorin become evil? Why does tap water foam? Why do LED bulbs on cars burn out? Why did the toilet stop flushing? Why did they stop making the sign of the cross with two fingers? Why is the Permian period called this way? Why do roosters crow early? Why did Petunia stop growing? Why is it Friday in Robinson Crusoe?

How to chop/split wood correctly. How to sharpen a cleaver.

We brought a car of firewood, it was necessary to remove it from the parking lot and chop it into logs. Before this, the volume of firewood that I chopped was negligible; a couple of armfuls were enough for me to heat a barrel sauna. But from the moment the refining vat appeared on the site, the volume of fuel burned increased significantly. And now, having started chopping firewood in the old fashioned way, I quickly got tired - the firewood from the brought oak and elm was very hard to chop - my arms fell off after only 3 large round logs, and the chopped logs scattered and collecting them soon made my back hurt...

I decided to scour the Internet and read what was wrong, how to chop wood correctly, how to sharpen a cleaver and an axe, what tricks there are in chopping wood.

As a result, the process began. I started with a chopping block. I picked up a stump approximately knee-high - this way it’s convenient to remove chopped logs from it without bending over and the blow of the ax (cleaver) is obtained with maximum impact force.

I placed a car tire on the log stump so that half of it stuck up, while the short logs, when installed inside, did not fly apart after cutting. I put another tire on top of the stock placed on the stump if I need to chop longer logs (for a sauna barrel I need short logs, but under a sauna vat I can push logs up to a meter long).

subtleties in sharpening a splitting ax

Then with the tool I sharpened all the axes very well. As a life hack, I wiped an ax with old sunflower oil, I saw this advice on YouTube - I think a little really increases the efficiency of the ax, despite the fact that this oil, unlike machine oil, is quite environmentally friendly.

A separate topic is cleavers. The cleaver had to be sharpened correctly. Bought at the store, it was completely stupid. In addition, on the forum of Canadian lumberjacks I read about how a classic cleaver should be sharpened. There is one subtlety in sharpening a cleaver! The fact is that the lower corner of the ax of a classically shaped cleaver is sharpened only from the side of the blade, namely, it is the first to enter the log upon impact and it turns out that its penetrating ability is very insignificant - in fact, it crushes the wood while uselessly absorbing part of the energy put into hit. It is necessary to sharpen the cleaver on the underside of the ax handle as well. This little nuance really made the work of chopping wood a pleasure. The log that I hit with a freshly bought cleaver about 10 times before finishing it was to no avail; after finishing it, the cleaver was split at the first blow!!

Here is actually a short video from which it becomes clear how to prepare a store-bought cleaver for work.

Source: ruskemping.ru

Design and types of product

There are different designs of axes, which are divided into groups according to purpose:

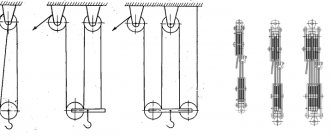

Figure 1 – Ax design

- Plotnitsky. The blade is straight or slightly rounded, medium size and weight.

- Building. It differs little from the carpenter's one, but usually has a slightly larger size for the convenience of driving nails or dismantling various structures.

- Meat. Used for chopping meat, it is large in size with an elongated blade that allows you to separate pieces of carcass with one blow.

- Cleaver. A compact and massive tool with a thick, chisel-like striker. Designed for splitting ridges, not used for other work.

- Lumberjack. Used for cutting off branches and separating the tops of canes. for greater amplitude and saving effort, it has a long handle (axe handle). It is not currently used for felling trees, although there are still some specialists in this field.

- Hunting. It has a compact shape, usually tapered just behind the blade to reduce weight.

- Tourist. reduced size, the ax handle is usually plastic. It is used on hikes, where you have to carry everything on yourself, so compactness and lightness are highly valued.

Cleavers - features of their design and operation

An ax is an indispensable assistant in the household, but not everyone knows how to choose the right type of this tool for a specific type of work. To split firewood, especially long logs, experienced workers use a special type of ax - a splitting ax. Working with it requires physical strength, but under the influence of the weight of the cleaver, the log can be split much faster than using a conventional tool. The dull blade of the cleaver acts as a wedge and does not get stuck in the log. Like the classic axe, the cleaver consists of two parts - the ax and the blade, but differs in geometric and physical characteristics.

Design and types of axes

The first tools of labor are the ancestors of the axe, which have a primitive structure. They were pointed stones tied to a stick. Later, fighting ragnars, arguns and axes appeared, which had metal plates as a blade. In general, the spectacular forms of these maneuverable weapons differed little from their predecessors. Therefore, the modern appearance of the instrument has practically not changed.

The ax consists of three main structural elements. Taken together, they represent a massive, chopping tool designed for primary or rough processing of wood.

- Ax handle - handle. For its manufacture, wood species with high impact strength characteristics are used. The impact strength of wood is the ability to absorb maximum mechanical forces (work) upon impact and resist impact bending, while maintaining the original strength characteristics. This indicator is higher for deciduous trees than for coniferous trees. Therefore, the handle is often made of hardwood oak, ash, maple and birch. It is known that wood, as an organic material, is susceptible to rotting and is prone to deformation under heavy loads. Therefore, some manufacturers prefer to make the ax handle from plastic or metal. However, these materials are significantly inferior to the classic wooden handle, since they strongly transmit vibration waves from impact. For this reason, the specifics of working with them are limited.

- The ax is a steel blade with a butt located on the opposite side. For the manufacture of the blade, steel grades with a carbon content limit above 0.7% are used. They are resistant to physical and mechanical stress and show high performance.

- Wedge - a system for attaching an ax to the handle. It is made of iron or wood in the form of a polyhedron or prism, which ensures reliable fixation of the working part to the handle. It is tightly installed in special grooves and secured with a metal fastener - an insert.

The technical parameters that each structural element must comply with are defined in GOST 18578-89.

GOST 18578-89 Construction axes

1 file 459.02 KB

The weight and appearance of the device depends on the need to perform specific tasks during operation. According to their purpose, axes are:

- Plotnitsky. They have universal overall dimensions and can be used both for chopping firewood, branches, cutting small trees, and for the primary processing of wooden products.

- Lumberjacks. Massive and strong samples are necessary in the process of harvesting and rough processing of timber in production.

- Tourist or hiking. These compact models are often made of stainless alloy. They have a wide range of functionality: from cutting pegs and trimming wood fibers to splitting small stones.

- Specialized. These include a fireman's belt and assault hatchet, an ice ax and an army axe. Their appearance is transformed for the tasks they perform. For example, the working parts of the tool are located on two blades at once.

- Cleaver. The working part has rounded shapes. The heavy, wide-shaped blade has an obtuse sharpening angle, and a strong blow is delivered thanks to the elongated handle. Suitable for splitting wood.

- Professional. Designed for general construction work. For example, a roofing ax is used to construct a roof covering. Their modifications are different: a butt in the form of a hammer head, a nail puller or a pick.

An ax, as a tool of labor, is used in many areas of human activity. It is convenient and multifunctional, and in operation it requires only physical strength and a little dexterity.

Design features of the splitting ax

The advisability of using a cleaver when splitting long logs is explained by the structure of the tree trunk, which consists of longitudinal fibers. At the center of the trunk and near the knots, the fiber density increases significantly. If there are no cracks in the core, then it is difficult to split such a log with an ordinary ax.

Attention! When working with coniferous wood, which has a high resin content, the blade of a traditional ax design may jam.

Let's look at the differences between a cleaver and a regular axe:

- Longer and more massive handle (axe handle). It is made from durable and flexible wood. The best option is ash, the use of which allows you to dampen the vibration that occurs when chopping wood. Less durable - maple, birch, beech. Sometimes oak and acacia are used to make axes, but it is better not to use these species for this purpose. This is explained by the fact that such wood is not capable of dampening vibrations in a plane located perpendicular to the surface of the palms. People say about such axes that they “dry your hands.”

- The blade of the cleaver is thicker, but narrower and shorter, compared to a regular axe, and has the shape of a wedge. The tool wedges two parts of the block along the direction of the grain.

Attention! The splitting of logs occurs due to the large amount of generated kinetic energy that occurs when swinging a cleaver, the mass of which is approximately one and a half times the mass of a conventional axe. The weight of an ax for chopping wood is approximately 2-5 kg.

- The blade is sharpened at an angle of 40-50°, that is, it is not too sharp. Some cleavers on the blade have two protrusions - “ears”, which make the splitting process easier.

A variation of this tool is a double-sided cleaver, which has a blade on one side and a sledgehammer on the other. A sledgehammer is used in particularly difficult cases - for driving steel or wooden wedges into a block of wood that widen a crack.

How to choose the right cleaver geometry:

- To work with thin and dry firewood, a splitting ax with a handle 40-60 cm long is recommended.

- For thick logs, use a massive splitting ax with a handle up to 90 cm.

Mechanical cleaver

Nowadays mechanical cleavers equipped with a spring mechanism are produced. The drive is manual, but the spring takes on part of the load, which greatly simplifies the process of chopping wood.

On the Internet you can find photos of homemade cleavers that craftsmen make with their own hands. This is quite possible if you want not only to get things working without serious effort, but also to save money. The operation of the device is that a person swings, aiming at a log, it splits, and the mechanism returns to its original position.

If the question arises of how to make a cleaver yourself, then it is not so difficult. You will need a drawing and a general understanding of the principle of operation. You will need to assemble a structure like a tripod from an iron angle or channel. Elements - spacers - are attached to it for additional stability.

The level at which it would be optimal to place a moving beam or monorail is determined, to which the wood splitter itself, weighing approximately 35 kilograms, will be attached on one side. A spring mechanism is attached under them as a counterweight, providing movements such as swinging up and down. It would be useful to equip the mechanism with wheels to make it easier to move.

You can completely optimize the process by using such a splitting ax with an installed electric drive. The main element will be a cone, which, rotating, enters the log, and its physical shape contributes to the rupture of wood fibers and the log splits. This is done without the use of force.

In order to make such cleavers with your own hands, you will need to turn a conical part using a lathe. The device is activated by pressure passing through the liquid, the piston is activated, giving a force directed to the log, which is fed vertically. Using multiple blades will ensure that the wood is separated in one go.

Since a cleaver is a working tool, it doesn’t matter whether you purchased an expensive option or you made it yourself. The main thing is that it really simplifies work and saves time for more pleasant moments.

Features of sharpening cleavers

In normal condition, the thickness of the blade of this tool should be at least 3-5 mm. There has long been a lot of controversy surrounding the issue of sharpening a cleaver. Some argue that this should be done, others that the cleaver should remain blunt. Experts consider the best ax for chopping wood to be a tool with a floating sharpness.

Definition! With a floating sharpness, the blade is sharpened in the center at a sharper angle, and its upper and lower edges are sharpened at a more obtuse angle.

For different types of wood, different sharpening angles are recommended. When working with damp and soft wood, a small sharpening angle leads to the fact that the cleaver gets stuck in the block without splitting it. To split dry or frozen wood, you cannot use a tool with a large sharpening angle. The cleaver will bounce off the surface of the block.

In most developed models, the sharpening angle ranges from 40-60°.

To sharpen the blade, you can use an electric sharpener at low speeds. Position the blade towards the rotation. To prevent overheating, the cutting part is periodically immersed in cold water.

Hand cleaver

If you look at a photo of a cleaver, you can’t immediately distinguish it from an ordinary carpenter’s axe. The work with these tools is fundamentally different, so they are usually separated.

If a standard ax is needed for rough processing of a log in the form of a blank, a cleaver is required specifically for dividing large pieces of wood into smaller ones. They usually differ in the length of the handle, because... carpentry tools have a shorter handle, which is more convenient for small work.

The cleaver is designed to maximize the force of impact on wood. For this purpose, the ax handle of the cleavers is specially lengthened and another sharpening is done. The cleaver is specially made to be blunter in order to split wood rather than pierce into it.

Rules for working with a cleaver

When working with a cleaver, you should follow simple rules:

- When chopping wood, you need to place your feet as wide as possible so that if you miss, you don’t hurt yourself.

- To ensure strong contact between the blade and the ax handle, it is recommended to immerse the handle in water before use.

- When splitting, you should not hold the stumps with your hand, but fix them on a flat surface. For work, it is recommended to use a block or block - a stump of large diameter. The deck is installed on a flat, hard, inelastic base, which should not absorb shock.

- It is advisable to hit the existing cracks in the log with a cleaver; if there are none, hit along the knots or between them.

- When chopping thick logs, it is recommended to point the blade not towards the middle of the block, but closer to its edge. When lowering the cleaver onto the block, you do not need to apply too much force, since the weight of the tool itself is sufficient.

- If the wood misses, the cleaver hits the block with the handle, which leads to rapid wear at the point of attachment. To protect the tool from breakage, it is recommended to nail a piece of steel in this area or wrap it with several turns of aluminum wire.

Advice! For the most efficient organization of firewood procurement in significant volumes, three tools are needed. The first is a cleaver. The second is a medium-sized ax used for chopping the resulting logs. The third is a small sharpened axe. With its help you can get small wood chips used to light a stove or fireplace.

Source: kotel-otoplenija.ru

Sharpening methods

There are two main ways to sharpen an ax:

- manual method;

- electrically driven devices.

When choosing parameters, consider the following:

- wood hardness;

- humidity level;

- purpose of processing;

- the quality of the steel from which the ax is made.

Bulgarian

To sharpen with a grinder you should:

- Buy a special disc for sharpening. In this case, it is prohibited to use a cutting wheel.

- To secure the grinding wheel, it is necessary to remove the casing and use special nuts for tightening.

- Place the grinder in a vice and securely fasten it.

- Carry out work using personal protective equipment.

This tool can process the working surfaces of axes made of high quality steel. The disadvantage is the lack of adjustment of the speed of rotation of the circle, as a result of which the edge overheats and changes in the characteristics of the metal.

Sharpening an ax with a grinder

Bruskom

You can sharpen an ax using emery if you have the following materials and equipment:

- metal brushes;

- sandpaper with different abrasives;

- personal protective equipment;

- felt cloth and polishing paste;

- a workbench with a bench vice;

- a file with a large notch;

- emery stone;

- devices for measuring angle and flatness;

- lubricants and wax.

When sharpening, observe the following order:

- Using a wire brush, remove traces of rust and dirt from the working part of the ax.

- Use sandpaper to sand the blade on both sides.

- Using polish and felt cloth, polish the tool blade on both sides.

- Secure the back of the ax in a vice. In this case, the cutting edge must be free.

- Using a file with a large notch, process the edge on both sides, performing reverse movements with the master from the shoulder.

- Use a brush to clean off any metal shavings.

- Using an abrasive stone treated with wax and water, straighten the blade.

- Upon completion of work, apply rust protection to the metal surface.

On the grinding machine

To properly sharpen an ax, you need to prepare the following tool:

- a machine with two sanding wheels with abrasives of different sizes;

- finishing paste;

- marker;

- Remedies;

- angle measuring tool.

The work is performed in the following sequence:

- Place the machine on a flat surface.

- Visually check the grinding wheels for defects. If necessary, correct the surface.

- Secure the blade, while the rotation of the circle should be towards the ax.

- Lowering the working edge to the emery stone, set the sharpening angle.

- Processing is carried out until the burrs and nicks on the edge of the ax are completely removed.

- Precise editing is carried out using a wheel with fine abrasive. In this case, ideal smoothness of the cutting part is achieved.

- After removing the tool from the mount, polish the blade with finishing paste.

- Upon completion of work, carry out anti-rust treatment.

Sharpening an ax on a grinding machine

File

To sharpen an ax you must do the following:

- Protect your hands with gloves.

- Secure the metal part in a vice or other device.

- Perform the first processing using a file with a large notch.

- For precise sharpening, use a finely cut tool until a burr appears on the back side.

- Turning the blade over, repeat the manipulations on the other side of the working edge.

Do I need to sharpen the cleaver?

Sorry for what may be a stupid question, but I recently moved to the village. Share your experience. I want to know everything about chopping wood and the tools associated with this procedure.

The cleaver is a wonderful thing. As for sharpening, we have never sharpened a cleaver in the same way as they do with other tools. But my father always tried to keep the edge (this is about one and a half to two centimeters from the cutting edge). That is, in cross-section you get a triangle at the top (about 30-40 degrees), which sits on a kind of trapezoid with slightly curved walls, where the widest base of the trapezoid is the butt of the cleaver). In general, in ancient times, the ax will not replace the cleaver, but the cleaver will not replace an axe, both are needed.

I grew up in a small village in Polesie, which is why I had to chop wood with a cleaver many times, and I want to note that this device does not need sharpening. Due to the fact that the iron part of the cleaver is quite massive, the force with which it hits the wood makes it easy to split it due to weight and acceleration. Of course, if the cleaver is excessively dull, you will have to give it a sharper shape, since otherwise it will be more difficult to chop wood and more effort will be needed. In principle, it will not be possible to make it as sharp as an ax due to the thickness of the cleaver itself.

There is no need to sharpen regularly, but sometimes sharpening is definitely necessary, since with constant work, notches are formed, and the cleaver itself gradually becomes dull. A properly sharpened cleaver will penetrate the stump more easily and you will need to spend less effort.

Nowadays, when gas has become much more expensive (Ukraine), more and more people began to switch to solid fuel, namely firewood.

Those who sell cut trees, and these are foresters and those who share with them, cut everything. If you want fresh oak - please, acacia - this minute, hornbeam - there is nothing simpler. Soon we will live in the desert.

How is an ax sharpened?

Sharpener Fiskars xsharp! With the advent of my X7, X5 ax and K40 knife, this sharpener became an excellent and very important addition!

sharpener in position for sharpening an ax

Characteristics:

- Size – 16.5 cm

- Weight – 90 grams

The Fiskars sharpener is very simple. It can handle both an ax and a saw. It has two “modes”. By smoothly pressing the yellow “button” the sharpener switches to the desired position. For clarity, there are icons below that tell you where to switch and what to focus on.

sharpener in knife sharpening position

For a knife, the guides are narrower, and for an axe, on the contrary, they are wider.

The sharpening mechanism is located on one edge of the sharpener. This is done so that you can hold most of the Fiskars xsharp with your hand. Convenient and thoughtfully made.

If most of the body is made of plastic, then the bottom of the sharpener is rubberized. This is so that while sharpening it does not slip on the surface.

rubberized insert and button for disassembling the sharpener

On the back there is a small button, by pressing which you can disassemble this structure.

This is done so that you have access to sharpening stones. During operation, they can be removed and cleaned of accumulated chips.

disassembled

Ceramic sharpening stones are located at an angle. This is done for better sharpening of the tool. They leave small transverse stripes on the blade.

Here you no longer need to figure out at what angle you need to sharpen your ax/knife; the guides did it for you. Simply insert the tool and make about 15 movements back and forth. Ceramic stones can be scrolled, which ensures good sharpening! Everything is simple and high quality.

A nice thing is that this sharpener weighs very little and can be taken on a hike without any problems. And sharpen the tool along the route. If your trip is short, then there is no point in taking it, but if you are going for a couple of weeks, then you can take it. You can sharpen any saw axes on it, not just Fiskars.

Before going to the Carpathians, I sharpened 3 different knives and they cut perfectly throughout the trip. I also actively use the sharpener to sharpen kitchen knives. 15 simple movements and the knife is like new. You can buy a Fiskars sharpener for 190 UAH! The cost is taken from the website of the official representative in Ukraine. I think it's a good sharpener. Simple and lightweight, it does its job perfectly!

What types of axes are there and how should they be sharpened?

Axes are needed for working with wood, no matter what it is. It could be a banal chopping of wood, or it could be the jewelry work of a real carpenter. All axes can be divided into several types, depending on their purpose:

- Business models. The most popular axes in Russia and the CIS. Initially they were used by carpenters and simply craftsmen. Now many men, especially older men, have such models in their households. Using this tool you can carry out a wide range of household work;

- Carpentry models. A more specific tool designed for working with wood;

- Cleavers – have a wedge shape and are mainly intended for splitting firewood;

- Hunting and tourist models. Small and lightweight models designed for cutting bushes, branches and cutting prey;

- Axes for lumberjacks are heavy two-handed models with a large sharpening angle.

It turns out that before you begin the sharpening process, you need to decide what type of ax your ax is, otherwise you may sharpen it incorrectly. Many people simply forget about this, sharpening their axes on an electric sharpener, without delving into the nuances, but we will do everything according to science.

In addition to determining the type of working tool, it is important to decide what kind of work will be done with a specific ax. If they plan to cut branches or trees, then the sharpening should be at a large angle, and if cutting meat, then at a smaller one. For universal axes, the average angle value is selected. Types of sharpening can be of several types:

- Lens with a small angle of approach for lumberjacks and splitting axes;

- A lens with a steep convergence works well when felling wood;

- Straight bevels are ideal for carpenter's axes.

Based on what work is supposed to be done with the ax, the type of sharpening is selected.

Sharpening tools with water stone

To work, you must have at your disposal abrasives with a grain size of 1000, 4000, 8000 grit. The technology involves processing the cutting edge using three stones.

Tip: You can reduce costs by purchasing combined stones, the sides of which have different grain sizes.

Features of the method are as follows:

-before sharpening the tool, the abrasive must be soaked (immerse in water for 15-20 minutes);

-during the work process, the stone should be periodically moistened;

-finishing begins by treating the blade with a 1000 grit stone, after which they move on to 4000 grit, and then 8000 grit.

It is important to know: 1000 and 4000 grit abrasives can be kept in water for a long time, but smaller ones may become unusable. What is bad and what is good about the method

What is bad and what is good about the method.

1.The service life of water stones is short. The surface of the abrasive must be periodically leveled to eliminate grooves.

2.It takes a lot of time to polish the tool on a water stone.

3.The water for wetting the stones must be changed periodically to avoid contamination of the workbench.

4.Wet stones should be dried thoroughly in a warm room after work. In the cold they can collapse.

You can learn more about the process of sharpening a tool on a water stone by watching the video.

How to decide on the sharpening angle?

Based on the purpose for which you need the ax, the sharpening angle is selected. For splitting axes and logging axes, the correct sharpening angle is 40-60 degrees. A household ax that is used for various household needs should preferably be sharpened at an angle of 30 degrees. It is advisable to sharpen hunting and hiking hatchets at the same angle. But for the most delicate work with an ax, you can try sharpening it at an angle of 20 degrees. You can shave with this axe.

Why did I say try? The fact is that theory often diverges from practice. Try now to buy an ax that can be sharpened at an angle of 20 degrees. Nowadays you can’t find such tourist knives. Hardware stores are full of Chinese axes, the sharpening angle of which is about 60-90 degrees.

If you sharpen them at an angle of 30 degrees, they will simply become dull after several hits on the wood. It is impossible to work with such axes, so it is better to leave the sharpening angle provided by the manufacturer.

Let's take a better quality ax, the same Fiskars. Its sharpening from the factory is approximately 30 degrees. Already in this case, problems with the chopping edge often arise. If you come across a knot while cutting, chips will appear. Special branded sharpeners from Fiskars are sold; they sharpen axes at an angle of 40-45 degrees. Such an ax will be great at cutting knots.

So, it turns out that the ideal sharpening angle for an ax is approximately 35 degrees. I don’t know which axes can be sharpened at 15-20 degrees; it will simply be impossible to work with them.

How to sharpen axes with your own hands?

Large selection of tools on the website https://www.geom.ru.com. Your cleaver is not sharpened correctly. Read here Please - theory: 1. If a block of wood (a block of wood, a block of wood, a block of wood, a block of wood, a block of wood, a short stump of a log, a pole, a round tree) is for logs, then chop it. 2. They prick, not prick. 3. As a rule, with a special tool called a cleaver. 4. Other operations with firewood (with the exception of 1) are usually performed with a saw and an ax - then, respectively, sawing and chopping. 5. A chock of small diameter can be split with an axe. A large diameter is also possible, in the absence of a cleaver, a lot of free time and unused health. 6. The cleaver, unlike the axe, is much heavier (3-4 kg), and has a less acute angle between the planes of the blade, and a longer ax handle (handle). 7. The effectiveness of the cleaver is explained by: firstly, the increased mass and, consequently, the impulse and force of the blow; secondly, by the shape of the blade, which directs a significant part of this force to separate the wood fibers from each other. An ax, first of all, cuts. 8. The sharpening angle of the cleaver is 40-60 degrees. The blade is narrow (70-80 mm). 9. The best ax handle made of ash. Oak, birch, and acacia are used. True, they are less durable. In addition, the handle made of oak or acacia “dries out your hands” and does not dampen the recoil upon impact. The ax handle is straight - without the frills typical of axes. Length - 700-800 mm. 10. The steel part of the cleaver is secured to the ax handle using a wooden or metal wedge (using a clumsy one). A more successful, and now rare, fastening option is similar to fastening a pickaxe - the handle, expanding upward, is pulled along the entire length through an oval hole (embedded) and self-fixes, thanks to the taper of the latter. 11. They chop wood on a block, or block - a wooden stump, larger in diameter than the block being split. 12. Even on a log that is not very dry, a crack running close to the middle is almost always noticeable. Orienting the cleaver blade upon impact parallel to this crack significantly improves the result. 13. If the diameter of the log is too large, then it is easier to split off the first logs along the perimeter. 14. Firewood splits more easily in the cold - the fibers with frozen moisture do not stretch, but break. 15. It is preferable (due to labor costs) to chop any firewood before it dries completely. 15. The trick of turning over a block of wood with a stuck blade and hitting the butt on the block is good for an ax, but difficult to perform with a cleaver. 16. It is very difficult and unsafe to split twisted and knotty firewood. Of course, it is better to do this in smaller chips, and not across the knots. 17. Previously, in especially difficult cases, in addition to the cleaver, wedges were used - wooden or steel, driven into the crack with a sledgehammer or the butt of the cleaver. 18. In field conditions, sometimes they use something intermediate between a cleaver and an ax, in terms of weight, sharpening angle, and handle length. Or a standard axe, at the expense of efficiency, but with a gain in equipment weight. As a rule, there are small branches and dead wood, for which an ax is quite enough to work with.

The sharper the sharpening angle of the blade B (Fig. a) and the smaller the width of the chamfer A, the more productive the ax. On the way to reducing the angle B, the possibilities for increasing the productivity of the ax are usually fully used - the optimal angle, depending on the strength of the steel and the nature of the work, is dictated by practice itself: if the angle B is too small, the ax quickly becomes dull.

Typically, the sharpening angle of an ax for cutting dry wood lies within 25...30° (an ax intended for cutting freshly cut raw wood can be sharpened at a sharper angle - up to 20°). The second way - reducing the width of chamfer A - is not always used. In earlier times, to reduce the width of the chamfer, the ax was periodically removed from the ax handle and the worn blade was pulled back in the forge. Despite the fact that the wedge angle of the blade a was usually made larger than that of modern axes, the thickness of the blade at the edge was smaller, only 1...2 mm, and therefore chamfer A had a small width.

Nowadays, factories do not bother themselves with carefully forging and tightening the edge of the blade. Near the chamfer, its thickness is 3...4 mm, so the blade is sharpened. Even with a new axe, the chamfer turns out to be unreasonably wide and the ax cuts poorly. Unable to pull back the ax blade in the forge, modern craftsmen get out of the situation by sharpening such axes “on two cuts” (Fig.b)

Blade sharpening

An electric sharpener is usually used to sharpen axes, although this is far from the best option. The grinding wheel of an electric sharpener rotates at high speed, and the heat generated in the contact zone of the wheel with the metal does not have time to be removed into the depth of the metal. This causes strong local heating and burning of the treated surface.

Direct sharpening process

Sharpening an ax is, in principle, no different from sharpening a knife. It also requires several sharpening stones of different grain sizes and a piece of leather attached to the block for final finishing. First, we determine the sharpening angle, then use the coarsest stone to remove excess metal from both sides of the blade. Do not press too hard on the whetstone; this will not speed up the procedure and will only damage the whetstone. Many people remove excess metal using an electric sharpener, but this procedure requires a certain skill, since the metal can be overheated and an unplanned release of the metal will occur.

To speed up the procedure for forming a sharpening angle, you can use a file. At the same time, this will help to understand the real hardness of the ax blade. If the file grinds metal easily, then making the sharpening angle less than 45 degrees is pointless; it will become dull in half an hour.

After the angle you need is formed, you need to move on to finer-grain stones. At the end, the blade can be polished on the skin with GOI paste, but this procedure is for aesthetes. An ordinary work ax does not need such careful sharpening. It is enough to form the desired sharpening angle and then use a couple of stones of different grain sizes. Three stones are enough for the eyes - coarse, medium and fine.

Features of the process taking into account the chosen method

It is not enough to know how to sharpen an ax at home; it is also extremely important to follow safety precautions during the process. You should prepare protective equipment, such as glasses or a shield, a respirator (if working with an electric sharpener), and gloves. It is imperative to free the work area from all unnecessary things and limit the entry of strangers, especially children, into the room where manipulations will be carried out

Electric sharpener

The device is a machine with an electric drive and an abrasive wheel. To sharpen an ax you will need:

- double-sided hand sharpener;

- polishing paste;

- personal protective equipment;

- marker;

- goniometer.

Before you start working on a sharpening machine, you need to use protective equipment, such as gloves and goggles, and then follow the established procedure:

- Finish the chamfer with a marker.

- Secure the chopping tool with special fasteners.

- Bring the tip to the grinding wheel, first select the required sharpening angle using the protractor.

- Turn on the equipment and work with the chamfer until the cracks completely disappear.

- Level the work surface using a hand sharpener.

- Finish and polish the tool.

- Remove the ax from the mount, coat the machine circles and the bevel of the tip with polishing paste.

- Apply anti-corrosion liquid to the blade.

If you just need to change the sharpening angle, start work from the 4th point.

Correct placement of the ax

We begin to sharpen

If necessary, the abrasive wheel should be brought to a smooth surface using a sharpening stone

We continue to work without overheating the ax

Manually

You can achieve excellent tool sharpness without expensive equipment by sharpening it manually. The easiest way is to fix the ax in any convenient way, set the abrasive wheel at the right angle, and run the blade horizontally along the sharpener the required number of times. You can use the second method; you will need the following tools and accessories for sharpening:

- directly the sharpening stone;

- a wire brush to remove fine dust;

- rust remover;

- polishing paste;

- wax;

- felt fabric;

- clamp or vice;

- a file with a large notch;

- ruler;

- machine oil.

Work algorithm:

- Remove rust from the blade, if any.

- Sand it with sandpaper, sticking to one direction.

- Repeat step 2 with less hard sandpaper.

- Apply polishing paste.

- Fix the ax; the handle should be on the working surface.

- Sharpen the blade with a file at an angle of 25° using translational movements.

- Get rid of metal dust.

- Treat the whetstone with liquid and walk along the blade until it reaches the desired sharpness.

Upon completion of all work, the ax sharpened with a bar must be processed: lubricate the metal part with oil to prevent corrosion.

Clean the ax

Sand it down

Using a hog file, process the blade

Measure the chamfer

Place the ax on its side on the workbench and press it against the table surface

Work the blade evenly on one side until a metal burr appears on the other. Now the ax can be turned over to the other side and continue working

Apply a protective coating